by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- Steel dreams

- Steel dreams become real things!

- Let’s look at this rifle

- Back to today

- Postscript

This report is inspired by reader RobertA from New Zealand. He has been modifying a Gamo CF-S springer and sharing the experience with us in the comments. He is now struggling with a mainspring made from 3mm wire, which is 0.118-inches in diameter. He replaced the stock spring that was 2.3mm (0.091-inches) in diameter. Now his rifle is rough and recoils more than it did before. Here is what he said.

“Hello! Another update on my Gamo CF-S monster…

Changing up from the 2.3 mm wire spring to the 3mm wire spring has been a bit of a shock. Kept getting my nose hit with the dioptre sight. It was not fun after a while! Pellets definitly fly much faster but the TWANG and rifle kick/wobble is remarkable. The 2.3 mm spring is really quite nice, but slow. The .177 pellets are going through 1/3 inch pine plywood with no concern at 20m. For a giggle I swapped out the dioptre for the 4×32 scope, eye relief means I don’t get hit in the nose. ouch. A relaxed shoot with a friend and we were having a laugh. Lots of banter and very little serious shooting. Fun! But we got a few 10’s!

Here is a pic of the rifle with the scope ( still no cheek rest yet… I know I need to make one…) and the best looking target. I was shooting sitting in camp chair ( best way I reckon…) and trying not to laugh at my mates balderdash. ( he kept claiming all my good shots as his own… the cad. ) Hope you are all good and things are fine!” Robert.

This reminded me SO MUCH of the Steel Dreams report that I’m reposting the ENTIRE report for you today. I believe there are a lot of folks who haven’t seen it yet. I’m editing it to make it a single report. Here we go.

Steel Dreams

More than a decade ago (this was published in 2008, so I’m referring to the late 1990s), I saw a curious rifle at the Little Rock Airgun Expo. It looked something like a Beeman R1 but was quite a bit larger. When the seller told me that it was a handmade, one-of-a-kind rifle that was designed to be a more powerful R1, I couldn’t resist buying it. I had just published the R1 book, and here was a great follow-on story that needed to be told.

This curious Springer is a monster.

Steel dreams

The inventor of this rifle, Steve Vissage, had seen the Beeman R1 and wanted a rifle that would put a .22 pellet into the supersonic realm. That was quite a goal for a spring-piston gun of the early 1980s, and it still hasn’t been reached today by any except a few PCPs (remember — this was written originally in 2008). Steve thought the best approach was to increase the diameter of the piston and to increase the length of the stroke — some of the same topics we frequently discuss on this blog.

Now I’ll tell you why I am making this report. A number of our new readers are asking the same questions that Steve Vissage asked back in 1981. What does it take to get more power from a spring-piston air rifle? Back in 1982, the R1 was the most powerful spring-piston gun in the world. At 940 f.p.s. in .177, it offered velocity undreamed of 5 years earlier.

When the R1 came out, Robert Beeman wrote in his catalog that it took more than just a powerful mainspring to boost power in a springer. But, because those catalogs are now collector’s items, a lot of newer airgunners haven’t had the opportunity to read them. Many who might have read them don’t believe what Beeman said. What Steve Vissage did is what many of you think should be possible today, and I want to share my observations on that topic.

Steel dreams become real things!

Vissage built three rifles, of which mine was the first. Let me explain what’s so different about talking about airguns and actually building them. When guys start discussing airguns, anything seems possible; but, whenever Vissage made a decision, it got locked into steel…not easily changed. Even if he did make some changes, there was still a cost involved for the original decision that was not followed. Steel dreams cost more and take longer than daydreams. If you don’t understand what I’m driving at, you will by the time this report is finished.

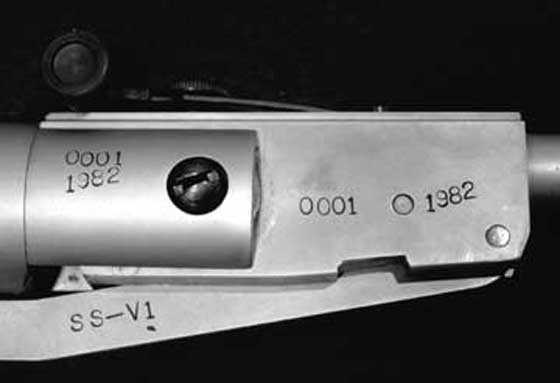

The date of manufacture and serial number are stamped on many exterior parts. SS stands for supersonic and V1 stands for Vissage model 1.

Both sides of the baseblock and spring tube are marked similarly.

Let’s look at this rifle

A stock R1 (The Beeman R1 was discontinued but the HW 80 that was its foundation still exists) weighs 8.9 lbs., give or take. Many new airgunners feel it’s far too heavy, and they’re also impressed by it’s sheer size. The Vissage rifle weighs 11 lbs. It’s also longer than the R1, but I don’t seem to have recorded the length. (I was told by the seller that) The barrel came from an Anschutz target rifle; and, since Anschutz doesn’t make target air rifles in .22 caliber, I think that means it’s a .22 rimfire barrel. So, accuracy was out the window, because .22 rimfire bores are several thousandths larger than air rifle bores, and don’t fit pellets very well. (After speaking with Vissage I sorted this confusion out.)

The spring tube, end cap, baseblock and cocking link are all custom-made parts.I spoke to Steve and he told me he reckoned he put $600-700 1980’s dollars into making this one rifle. The wood stock came from an HW80. It was opened up to receive the 40-thousandths-larger spring tube. The forward stock screws are very close to the end of the forearm. Look closely at the first photo, and you’ll see they had to be moved forward almost an inch.

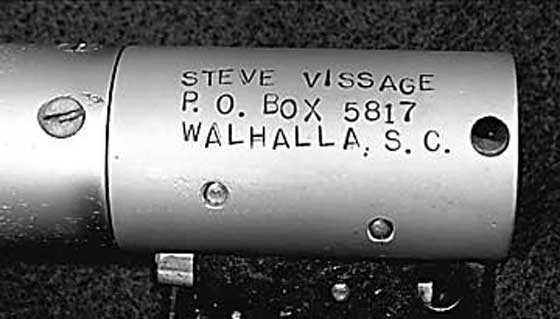

Just so there is no doubt who made the gun, Steve put his address on the end cap. He later moved from that address. See that flathead screw ahead of the end cap? That’s how the end cap is held to the spring tube.

The sights are stock Weihrauch items, the same as come on an R1. There is no provision for mounting a scope. The entire rifle is plated with Armaloy, a tough material used on tactical handguns. It is said to resist wear and to be self-lubricating.

The trigger is a Rekord, which was very popular back in the 1980s. Vissage would have been able to get one easily, since they had been on the HW35 for at least 20 years at that time. This is a good place to reflect that he used the factory trigger and sights instead of inventing his own. By this point in the project, he’d sunk a lot of money into this rifle, and inventing a whole new trigger would have cost him more than all he had spent to this point. Don’t forget that all the internal parts – the piston and mainspring, for instance, have to be made from scratch, because the entire rifle has different dimensions than a standard R1.

Speaking of different dimensions, how does Vissage get a stock Rekord trigger to line up with the piston hook if all the internal dimensions are different? Details like that are always overlooked when guys talk about airguns; but, when you actually build one, you want to cock it!

Here is what happens when dimensions change. The Rekord trigger had to be suspended at a different point inside the end cap in order to align with the piston hook. See the empty hole at the top left? That’s where the safety button is supposed to go if this were an R1, but ooops – it doesn’t contact the trigger because the end cap is larger than an R1 cap. Look at the picture before this and see the other side of the cap. No safety!

Naturally, as a red-blooded airgunner, I put it through the chronograph first thing. The cocking effort was 53 lbs., compared to a Beeman R1 that cocks with 36-41 lbs. of force. So, while the rifle isn’t the heaviest-cocking springer I’ve ever tested (that distinction belongs to a Hatsan 135 that took 75 lbs. to cock), it certainly wasn’t built for casual plinking.

The firing behavior was harsh. There was a huge lunge forward plus lots of vibration. The big lunge means a heavy piston, and the vibration usually means a canted mainspring. I said that the barrel was an Anschutz, but I found in my notes that Steve Vissage told me he thought he remembered putting a Webley Osprey barrel on the gun.That would have had the proper dimensions for a .22 caliber pellet.

The velocity I got with 14.5-grain Eley Wasp pellets was 755 f.p.s. I checked with the two .22 caliber R1 rifles I used in the R1 book, and they averaged 725 f.p.s. and 751 f.p.s. after 1,000-round break-ins. Steve Vissage remembered a velocity of around 800 f.p.s. with this gun, but that could have been with a different pellet.

Then, I disassembled the rifle. I was all set to use a mainspring compressor, but Steve told me the mainspring was under about a half-inch of preload. So, I removed those three machine screws and the one triggerguard screw, and the end cap popped up by less than a quarter-inch. I guess over time the spring had scragged (taken a set length from which it will never diminish until it wears out).

Not a lot of spring preload. Vissage saved some money by not threading the end cap like a Weihrauch.

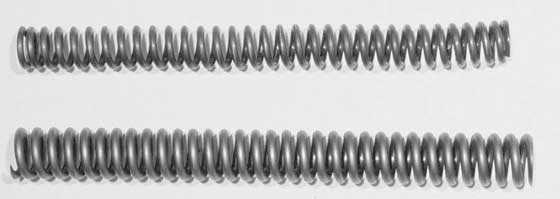

With the end cap off, the mainspring came out, and it’s a monster! Its 32.5 coils are made from 0.190″ ASTMA 410 silicone chrome wire. The compressed length is 6.175″, which must be a record for spring rifles. The mainspring weighs 12.2 oz. (RobertA — this is for you).

An R1 mainspring weighs 6.3 ounces, in comparison, or just over half what this one weighs. Look at the photo for a comparison.

Guess which spring goes in the Vissage rifle? The R1 spring on top is worn-out and canted. The Vissage spring is also canted, although this picture doesn’t show it.

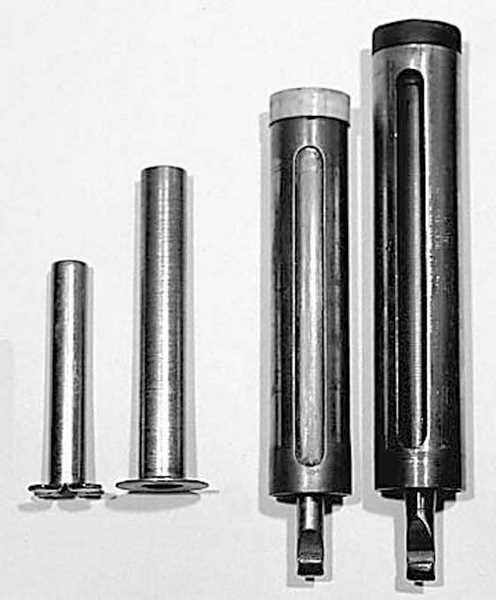

The piston came out next. It weighs 18.2 oz. and is 1.30″ in diameter, while an R1 piston weighs 12.6 oz. and is 1.147″ in diameter. Vissage had the piston tempered and shot-peened to relieve stress. The piston rod was hardened and drawn to a dark straw color. That should make it file-hard. The spring guide is also proportionately larger than the R1 guide.

Vissage’s piston weighs over a pound and dwarfs the R1 piston beside it. Those two things on the left are the respective spring guides.

A close examination of the piston seal revealed several flat spots, which are burn marks from excessive friction. Vissage told me he put a lot of effort into the selection of material for the piston seal. He was looking for high-lubricity and tolerance for high-temperatures from the heat of compression. Those flat spots told me the seal was too dry and was wearing from the friction with the chamber.

See the flat spot that’s facing you? That’s a burn due to friction.

After seeing the massiveness of these parts, I felt that some velocity was lost by a slowdown in acceleration of the piston. The weight of the piston told me where the rifle’s powerful forward lunge was coming from. However, before you start criticizing Vissage, let me tell you that Jim Maccari once made a plastic piston for a TX200 to accomplish just the opposite – faster acceleration from lighter weight. That gun vibrated like a jar full of mad hornets, so you can go too far either way. And if people hadn’t experimented in this way, none of us would ever know!

The piston seal is not a parachute design. Perhaps there’s some loss of pressure around the sides, where the high-pressure air has nothing to confine it. A parachute seal would inflate and push its sealing edges against the cylinder walls, but this seal can’t do that.

I lubricated the piston seal with Beeman M-2-M moly grease before installing it again. The mainspring received a coat of Maccari’s black tar to cut the vibration (Today I’d use Tune in a Tube). All friction points received a coat of M-2-M grease. The thin washers at the pivot point had never been lubricated. Steve counted on the Armaloy plating to self-lubricate, but I found it mostly scraped away when I disassembled the rifle. So, I used moly paste on the washers, and the cocking got smoother.

When the gun was back together, it felt like the cocking effort had diminished, when in fact it had actually increased by 2 lbs.! It was smoother but also a little harder to cock. The velocity with Wasps averaged 776 f.p.s., but that dropped to 767 pretty fast. I imagine the rifle will sink back to 755 in time. It vibrated much less this time, though there was still some present.

Sorry to say that I never shot the Vissage rifle for accuracy. I was more interested in how the powerplant performed; and, as we saw, it was about like a factory R1.

When I tuned a standard Beeman R1 with a Venom Mag 80 Laza kit, the average velocity with Eley Wasps jumped to 840.8 f.p.s., and the firing behavior was as smooth as glass. The Venom kit was the first to offer Delrin button bearings ( read my 10-part report on the Diana 45 to learn about them) to float the piston in the spring tube. It took 50 lbs. of effort to cock, but the return was a much more powerful air rifle.

That’s the tale of a man and his quest for speed. The other two rifles he built were a .177 and a rifle with both .177 and .22 barrels, which he kept for himself. Vissage never went supersonic in .22 caliber, but I bet he knew a lot more about what goes into a powerful spring rifle after this project was over! And, now, we all know a little more.

Back to today

Okay, there is a LOT more to talk about. I have reader Michael’s Walther LGV on hand to tune right now. It’s the gun that Michael said squeaked when cocked. He sent it into Umarex USA but wasn’t satisfied with it when he goit it back. I told him I would take a look at it and attempt to fix whatever is wrong.

Well, this rifle doesn’t squeak now; it’s dead quiet when cocked. To me that means that the technicians at Umarex USA lubricated the piston seal corerectly. But it has the worst vibration I have ever felt in an air rifle when shot. How Umarex could have returned it this way and say that it’s fixed is beyond me!

Postscript

That’s what this series will be about — getting a spring rifle to fire smoothly so it is a delight to shoot. I probably should have made this a Friday blog because I expect a lot of comments. And though we start with a lot of history, this isn’t an historical blog, either. I hope that this is a common-sense report about how a spring rifle ought to be set up. That’s my goal, anyway.

And, as a second postscript, Steve Vissage passed away years ago.

B.B.,

Wow! This is the project that made me say NEVER a serious Spring Piston in this man’s life.

That said, in This Report Covers: “He replaced the stock spring that was 2.3mm (0.91-inches) in diameter.” Wow! did he (RobertA) really use almost an inch in diameter spring wire! Decimal difficulties me thinks; 2.3 Centimeters is close to 0.91 inches.

Back to the project: the Physics of MASS is a difficult thing to overcome! Even in PCPs it shows up and slows things down in the most unexpected places!

shootski

shootski,

Ha, ha. Okay, I fixed it.

BB

I think it’s probably a typo. It should be 2.3 cm instead of 2.3 mm. That would be .91 inches.

Brent

B.B.,

A blast from the past. This one also lines up with your challenges for the armchair engineers on how they would design an air rifle. Is there a formula out there that can give a ball park figure on how heavy a piston should be?

Siraniko

PS Section Let’s look at this rifle 7th paragraph 4th sentence: “I said that the barrel was an Anschutz, but I found in my notes that Steve Vissage told me he thought he remembered putting a Webley Ospry (Osprey) barrel on the gun.”

Siraniko,

Fixed it. Thanks,

BB

B.B.,

First paragraph correction:

He replaced the stock spring that was 2.3mm (0.91-inches) in diameter.

2.3mm (0.91-inches) should be 2.3mm (0.091-inches)

John Carlisle

John,

Thanks. I fixed it.

BB

Bigger, faster, stronger……..humans will never learn.

On other forums, I read about .25 caliber guys who want 30fpe from their rifles and I shake my head….

Why don’t they put an ether port in the compression tube? lol.

-Y

BB,

Nice report/recap. It drives home the point to learn from those that have gone before. I like to tweak and mod as much as anyone,… but if you look around a bit,… ‘never been done’ has probably been tried many times already.

Chris

I for one have always shaken my head. I guess that comes from my powder burner days. When reloading, my Dad and I were always concerned with precision and accuracy, not with velocity and power. Quite often the “accuracy” load for a certain projectile from a certain rifle was not anywhere near the “maximum velocity/power” load. If you cannot hit what you are shooting at…

I myself am guilty of “armchair engineering” occasionally. We are fortunate though, that we have such a place as this where we can read and learn, not just from the writings of our experienced host, but also from bantering ideas back and forth. We may have an idea and the much experienced group we have here can usually “speak up and say” “Been there, done that, it does not work.” or sometimes we even “hear” “Been there, done that, it works.” or on some occasions “Give it a try and let us know.”

I remember a conversation I had with Mr. John McCaslin many years ago. Part of that conversation dealt with a certain web forum that dealt almost exclusively with AirForce airguns. Though he and I agreed that many on that forum were vulgar and crude, I pointed out to him that apparently someone within his company was paying real close attention to what was going on there, because there were also those on that forum that took his creations and built upon them and shared their knowledge and experience. He did not seem too happy about my observation.

To put a date on this conversation, it took place a few months before Ton’s revelations led to the introduction of the Escape series, all of which I had seen before. The TalonP was an old idea before it was new. Big bore AirForce air rifles already were in existence several years before the Texan was.

After utilizing this free R&D, I would see AirForce come out with the same ideas a couple of years later. Ever since the creation of the Talon, every AirForce airgun has been built before with the exception of one, the Edge.

Here was an AirForce air rifle that went in the opposite direction than all the others. It was not concerned with velocity and power. It was after accuracy and precision. Maybe that is why I just have to get my hands on another.

What does this all have to do with sproingers? Not much, except to make people think that maybe there is not too much left to do in that direction except to think about accuracy and precision. Speed and power is not where sproingers need to go.

I do hope there is someone out there who can make sense of my incoherent babblings.

“…my Dad and I were always concerned with precision and accuracy, not with velocity and power.”

Amen to that, RidgeRunner!

Back in my muzzle loader match days, I was checking my rifle before a match; I was using my accuracy load of 70 grains of Pyrodex P (FFFG equivalent) under my patched round ball. My “target” was an “X” made out of two pieces of electrical tape. From a seated resting position, I put the ball right through the middle of the x (easy to do from a rest, not quite so easy standing offhand in a match =>).

There was a kid, maybe 14, standing behind me; after my shot (which he looked at through a hand held scope), he ran over and told his Dad (the only other guy on the range), “Dad that guy just put a bullet through the middle of an X at 50 yards, and he doesn’t even have a scope!” (yep; open sights only at those matches).

So the Dad, who had a brand new in-line muzzle loader, complete with scope, asked if I might give him some advice on getting his rifle sighted in. He was about to load in THREE of the 50-grain pre-formed pellets of powder he’d brought along, as that’s what the manual said would give a good high velocity.

I advised him to use ONE 50-grain pellet to get on paper at 25 yards; and then we’d sight in a tad high at 50 yards with 100 grains of powder, which would be more than enough for the largest of deer.

When he asked if I was sure, I said that accuracy is more important than horsepower; I added that my target load of 70 grains of powder was also my hunting load, and that I had brought down some 250-pound wild boar with that load.

I think the only reason he heeded my advice was that I hit the mark with my rifle; had I not, he’d likely have gone off on his own, and maybe put a hurtin’ on his shoulder. =>

Dave,

Many do have to see to believe.

LOL! Sadly true! =)~

Found accuracy improved with my 1863 Zouave replica after dropping the charge from 70 gr FFFG to 60 gr, using Hogdon’s black powder. FM agrees – it is not all about velocity and generating gobs of energy for the helluvit.

RidgeRunner,

Perfectly!

shootski

BB,

I expect that I was at the Little Rock Airgun Show you mentioned but I don’t remember the rifle.

The gun I always dreamed about was an R7 power springer that weighted 3 pounds and had a folding stock.

I think it might be possible but not worth the engineering. Stocking one of springer pistols such as the butt stock for the P1 will get you close but not quite there.

I am interested in reading about others airgun dreams.

David Enoch

“That’s what this series will be about — getting a spring rifle to fire smoothly so it is a delight to shoot.”

Thanks, B.B.; I’m all about that.

I used to read those old Beeman catalogues from cover to cover…

…and the Air Rifle Headquarters ones before that. =>

Looking forward to the rest of this series,

dave

Mr. Vissage was talented machinist, whose skills I admire. There’s a heck of allot to know first, to do what he did.

Butchering old guns is the way I prototype too, RoberA, I don’t have all the skills of others, but I do have that curiosity. It’s wise to ask the ones who know the what and why first, but not required. could save a little work. If you try to reinvent the wheel, dont be surprised if there are some crucial details you didn’t consider first.

My R10 cocks with 29 lbs of force with a carbine barrel and no articulated cocking link. I think I get 830fps, but it may only be 810, with 10.3 AA, I’ll need to check today, but I wont be a butchering that one any time soon.

R

B.B. and Readership,

I remember a very animated discussion in the late ’80s with a German Social group’s shooters where the discussion revolved around 10M airgun target shooting and the future of the spring powered powerplant. One of the participants was a gunsmith who predicted the end of the spring-piston powerplant among top level competitors and a short transition period with single-pump followed by the Era of the Presluft rifle and pistol. Talk about a long evening of STRONG opinions at the Lutz families’ I’m Dachswald Bunker Kegelbahn. The Stuttgart hotel, I’m Dachswald, was the former hunting lodge of none other than Erwin Rommel and members of the Luz family prior to WW-2. I was a guest and a visiting American just kept quiet and bowled my best.

The main idea under discussion was that the powerplant was limited by the short impulse nature that meant barrel lengths longer than 38-40cm (15-16 inches) was counterproductive. The nut of the issue discussed was spin stabilization had reached its actual limit since faster twist slowed the pellet and shortening the barrel required faster twist which required a more powerful impulse of air and round and round they went…. I finally had swilled enough great brandy to get my courage up enough to make an observation from my experience with the Coffin Corner while flying. Basically the Coffin Corner exists in the flight envelope of aircraft where it becomes impossible to maintain control of the aircraft either because your wing goes supersonic or the angle of attack to maintain altitude becomes to great and causes the wing to stall; at high altitudes the speed differential/∆ (fancy word/symbol for difference) involved gets less and less until you reach a point you stop being in controlled flight.

If you want more information about the C.C.: https://en.m.wikipedia.org/wiki/Coffin_corner_(aerodynamics)

So what! Well spring-piston powerplants were considered to have reached their limit more than three decades ago. Most of the gentlemen in the Bunker didn’t want to hear that the end of progress had come for their favorite 10M airgun and that they needed to look to the PCP for the future. The gunsmith knew it then.

Here we are still talking about it to this day; Yogi even brought up the folks that want 30FPE from a .25 spring-piston powerplant…Shaking My Head (SMH) which isn’t as offensive I hope now that I have joined the Sproinger club by finally owning a spring-piston airgun; albeit equipped with an Air Spring. The much maligned air spring is a way to eliminate most of the parasitic dynamic Mass of a coil spring.

shootski

BB and friends. Golly! um… heck.

A couple of clarifications: the Gamo CF-S in stock configuration uses the 3 mm dia wire spring. The F.E.G telly relum used the 2.3mm main spring with a smaller one inside that. I swap between the gamo 3mm spring and the F.E.G 2.3 spring. ( both have rough enough over all dimensions)

So whats the deal?

Well it I shoot the gamo with the 2.3mm spring it is very nice to shoot. Will reach out to 20m and embed pellets in ply. ( .177 !!! )

If I shoot the gamo with the 3mm spring it shoots with a bit of fuss , no issues with 20m and blows through ply.

The deal is that the 3mm dia wire spring startles me ! I was flinching and the TWANanangk…. Maybe I am just new !!!

I went to the range last night and got in the grove, shot with peep/iron/diopter sights at a target I did not like! ( I prefer 45mm black dot tbh ) uh, yes, using the stock gamo 3mm spring. : – )

A funny thing… I actually got used to the 3mm spring! I changed my but plate back a about 15mm and pushed the sight fwd about 20mm and stopped getting bashed in the nose. oh I have installed cheek rest. It’s a work in progress.

Really enjoying the blog and the chit chat. Thank you! Robert.

PS I am shooting for grouping. Aiming at centre target, no fiddling with sight adjustments yet. Just mechanically doing the same thing over and over. Trying to settle in. Will get there! 21 m, H&N Field target trophy, peep sights, Gamao CF-S Cutstom. Sitting with elbow wrap. FPS ? No idea. Seems quick imho.

Robert,

Sounding good! 🙂 A cheek rest is a step in the right direction. I am a big fan of them (if needed). Nice that you got to shoot it a bunch and fine tune a few things (like the rear sight).

Chris

Robert,

It sounds like you are doing everything you can. Hang in there!

BB

Chris and BB.

Chris: Cheek rest is really necessary tbh, it has to also be adjustable. This is technical side…

BB. Yes Sir! Hanging in sir! ; – ) – Robert.

PS: SS-VI looks very much like a monster! Just what is the barrel OD dimension? It looks like the same dia as the foresight…. 21 mm on my sight… or even more? Wow. That must be hard to hold up for long shooting off hand!

Robert,

I am sure you might get an odd look or two when you take it out in public.

I had a boss one time. He said growing up, there was a very poor family outside of town. They had a car?/truck? given to them, but the body was gone. The man built the entire body from wood. Sure, he got odd looks, but when he drove into town,… he and his family were proud as peacocks of that car.

I would have liked to have seen a picture of that. From what I gather, this was in the Great Depression Era in the U.S..

Chris

Chris. Awesome. Good as wood. : – ) I grew up being ferried around in the back of a mid 50’s Morris Oxford ute swaddled in blankets back in ’76. We were not made of money but we got the whole family into the two seater ute out into the country to pick fruit from abandoned orchards. Great times.

Funny looks. None so far. Not that I would take notice or care. I am a proud peacock! I respect my rifle and do the best to make it special. and it is. It is a pleasure to shoot! it feels great. if it had a really good trigger group I would be very happy. It has a very … no feeling trigger. I have done the best I can but I cannot fix the design! ( theoben type ) it is just terrible. no break all mush. Oh well, I am used to it now, just pull straight back in one movement, don’t mess around. and with time I will get my eye in for 25yards and groups will tighten up. It’s a bit like a hot rod, or a cafe racer or a special air plane etc. Everything is polished and tweaked and lubricated and fitted. It is special! Anyone who has done this knows the feeling. Make it better! : – ) Robert.

B.B.,

A question.

Has someone come up with a way to Dry Fire a

Spring-Piston? I’ll make the request harder! I want to be able to feel the piston slap/reverse recoil and if it has a coiled metal spring any of the vibrational perturbations; all without destroying the powerplant.

shootski

Shootski,

Are you offering up your new SIG for a test bed?

How about??? a piston (attached) to the spring (both ends of spring anchored),…. and no matter what, the piston will (NOT) bottom out?

Chris

Chris USA,

SSG ASP20 has an AIR SPRING!

I was hopeful that there was an existing “thing” you could insert in the bore to slow/stop the piston from slamming to a stop. Some kind of small diameter bleeder port to keep pressure up but not launch out of the bore. More complex approach would be a hydraulic snubber approach but .177 is awfully small area to work with.

shootski

Shootski,

Yes, I am aware that it is an air spring. I was addressing your desire to dry fire.

The (actual) spring and piston mass would “stretch”,… to a point,.. and then relax. If it can not “stretch” to bottom out,… is there any harm done?

Chris

Chris USA,

Okay I get your conception of a solution to the problem.

I’m just not certain it would provide the feel of the complete shot cycle. The spring, it seems to me, would need to start stretching too early.

That is why my thought was for something in the bore that might come closer to mimicking the back pressure cushion and bleedoff created by overcoming the initial pellet inertia and then pushing it down the bore.

Does any of that make any sense?

shootski

Shootski,

Dry-fire a springer? Not that I know of.

BB

B.B.,

Thank you for that.

I can not believe it is simply no one has thought about Dry Fire capabilities for Spring-Piston before. That probably means it is too hard, too expensive, or no one is there to create a market for it.

shootski