The HW 30S.

Part 1

Part 2

Part 3

Part 4 — Rekord trigger

Part 5 — lube tune

Part 6

Part 7

Part 8

This report covers:

- Is the Weihrauch mainspring bad?

- The Vortek kit

- Vortek grease

- Vortek piston seal

- The welds

- Check for burrs

- Assembly and lubrication

- Don’t do this

- Assembling the barrel to the spring tube

- Lube the end of the cocking link and the slot in the piston.

- Install the pivot washers

- Install the Rekord trigger

- Summary

Today we install the Vortek PG3 SHO tuning kit in the HW 30S. There was a big surprise along the way, so I made today a complete tutorial.

As you remember, in Part 8 I disassembled the HW 30S, thinking I could give it a lube tune and compare that with the Vortek PG3 SHO kit I planned to install next. But on the discovery that the mainspring was bent, I decided to go straight to the Vortek kit. I had to buy it direct from Vortek, because Pyramyd AIR was out of them at the time. As a result I had the chance to talk to Tom Gore about the kit a little.

Is the Weihrauch mainspring bad?

I have read several comments that the Weihrauch mainspring ends are not ground properly, plus a You Tube video makes the same comment, so I first decided to take a picture and show you what this one looks like.

The mainspring that came out of this HW 30S was perfectly ground flat on both ends, and one coil was collapsed, which is just as it should be.

The Vortek kit

The PG3 SHO kit from Vortek consists of a spring guide, a mainspring and a tophat. The spring guide has another guide down inside that keeps the mainspring from kinking as it’s compressed. There is also a small plastic jar of grease that you are supposed to only use a third of when lubricating the new mainspring. I will have more to say about the grease in a moment.

I also bought a Vortek piston seal on Tom Gore’s recommendation. I know what some of you are thinking — he sells them so of course he’s going to recommend them! And no doubt that is the case. But I have used many Vortek piston seals and I know they are superior to what the factory puts out.

The Vortek PG3 SHO kit with the Weihrauch piston.

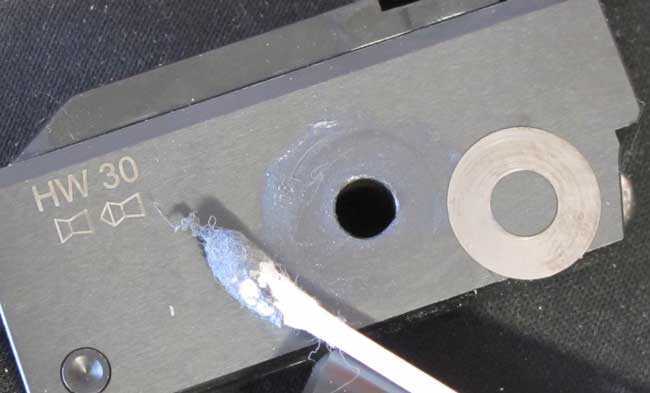

There is a second spring guide deep down inside the rear guide that fits outside the mainspring. This one keeps the spring from kinking inside the rear guide as it compresses. The white threads you see are threads of the special grease Vortek uses.

Vortek grease

Tom Gore told me to stick my finger into the grease in the kit then pull it out and watch what happens. So I did. The grease clings to the finger and draws out in a long tenuous string.

The Vortek grease clings to things with tenacity!

Vortek piston seal

I also bought a piston seal, so the factory seal had to come off the piston for the new seal to go on. I stated prying the factory seal with the blade of a pocketknife, and once there was room I got a screwdriver blade underneath. The factory seal is soft and it pried off easily.

The factory piston seal comes off easily.

Now it’s time to install the new Vortek seal. In the past these seals have been hard and difficult to install, but this one went on right away. This seal is chamfered underneath where it fits over the piston head and that chamfer guides the seal to a good fit.

Once on the piston the seal is loose enough to rotate easily. In my experience that’s what you want, unless there is a specific reason not to (like alignment of the air transfer port with a part of the piston — I’ve seen that once). The HW 30S has no such reason, so this seal will probably still be with the rifle at my estate sale.

The Vortek seal went right on. The seal rotates easily.

The welds

Reader Yogi made a disparaging comment about the welds on the bridge that keeps the cocking link parallel with the piston. I looked at the picture and had to agree. So I promised to take better pictures so you could see the welds more closely.

This weld is ugly as sin, but it penetrated the steel and will hold. Probably put on by a novice welder.

The other weld is ugly, too. But it may have flowed better.

The bridge is on the spring tube to stay. And the ugly welds hide beneath the stock.

It’s time to clean the powerplant and install the kit. I already cleaned the piston so the new seal could be installed.

I use some paper towel wrapped around thin screwdriver blades to get into tight spots like the inside of the piston. And a long screwdriver blade gets the inside of the compression chamber. There was very little grease in any of these places..

Check for burrs

After cleaning I run my fingers around the cocking slot and every other hole that penetrates the spring tube, checking for burrs. There were none on this rifle. That means Weihrauch left it in the tumbler long enough for the media to get rid of all the burrs left by machining before the tube was blued.

Assembly and lubrication

Now it’s time to put the kit into the rifle. Unlike other tuneup kits I’ve installed, this one slid right in with no obstruction of any kind. That was probably because there were no burrs, as I mentioned.

The Vortek spring is shorter than the factory spring, so it goes into the spring tube deeper.

The Vortek kit slid into the spring tube deeper than the factory mainspring and guide.

Here is how far the end cap slides into the spring tube with the Vortek kit installed.

And this is how far the same end cap stuck out with the factory mainspring.

Don’t do this

And this is where old BB went wrong. I assembled the spring tube all the way to completion with the Rekord trigger installed before it dawned on me that I couldn’t put the barrel on that way!

Don’t do this! I was going to show you a clever way to avoid using a mainspring compressor, but I forgot that the barrel had to be assembled to the spring tube before the end cap was installed.

Assembling the barrel to the spring tube

You see, to assemble the barrel to the spring tube, the cocking link needs to push the piston back just a little. If it doesn’t, you can’t get the hole through the base block (where the pivot bolt goes) all the way into the forks of the spring tube. You can get it to within fractions of an inch, but it won’t quite align. So BB had to take out the trigger and the base block at this point and use a mainspring compressor for the final assembly. If you have two people you can probably make do without a compressor, but that little screw that holds the end cap against the mainspring is difficult to align and start for one man, if he’s also fighting the mainspring.

Lube the end of the cocking link and the slot in the piston.

The end of the cocking link (shown upside-down here) fits through the bridge and into the enlarged hole in the spring tube. There is no separate sliding “shoe” for the link to attach to. I lube all contact points with moly grease. You can drive the pin back through the bridge at any time after this is done.

Install the pivot washers

Weihrauch uses paper-thin steel pivot washers on either side of the base block, where the pivot bolt goes through. I lube them with Moly grease, as well as the inside of the pivot bolt hole and the outside of the bolt. It’s a little fiddly to get both washers in with the base block, but the moly holds them in place and a small screwdriver or pin punch will move them to where they have to be.

Put moly grease on both sides of each pivot washer, through the pivot hole and on the outside of the pivot bolt.

Now bolt the barrel to the spring tube and tighten it. The barrel needs to stay in place wherever you put it after the gun is cocked, so that pivot bolt needs to be tight. But don’t over-tighten the nut on the other side! Once assembled, the rifle can go into the mainspring compressor for assembly of the end cap.

The rifle is in the mainspring compressor to install the end cap.

Install the Rekord trigger

Now that the rifle is assembled, it’s time to install the Rekord trigger. I lubricated the sear with moly grease in the last report, so it is okay. To install the trigger I like to cock the trigger, just so it goes in its slot easier.

The Rekord is uncocked.

The Rekord is cocked so it will go into the end cap easier.

Install the trigger pins, pull the trigger (because you put it in cocked) and the barreled action is assembled. Now install the barreled action in the stock. Then cock it, insert a pellet and fire. It cocks easily, it shoots smoothly and it feels right. Job done!

Summary

There were a lot of steps in today’s report, but I found the Vortek kit very easy to install. It was the rifle that threw me a curve. Now that I have warned you — you can avoid my mistake.

I had hoped to test the velocity of this tune today, but when I made my blunder it cost me a lot of time backing up. So this is the end of this report, and I’m not sure I want to test velocity next time.

Perhaps next time I will test accuracy with another peep sight and then test velocity after that. That will give this tune a chance to settle in.

B.B.,

Wouldn’t the break in period also affect the accuracy test? How many shots will it take to break this in after installation of the Vortek kit?

Siraniko

Siraniko,

Probably, but I think it will break in quickly.

BB

I put one of these steel Vortek kits in my hw30 a couple weeks ago. After 100 shots it was at 630fps with jsb exact. ES of 11, SD 3.8 over the last ten shots.

B.B.

My concern about the weld had partly to due to its not covering the entire length of the cocking bridge, but also the top one seems that you could fit a credit card underneath. I guess alignment is not critical?

Also, is the Vortek grease only for the spring? I see you used “good old moly” for the barrel forks.

-Y

Yogi,

Yes. I used moly where there is high friction, which is in the pivot point area.

BB

Yogi,

The welds on my HW30s are identical, so it is likely standard procedure at Weihrauch. Mine has had over 5 years of regular use with no issues. That makes the welds fit for purpose in my book. They are not pretty to look at, but are of course hidden from sight when the stock is on.

The other side.

What I liked about that weld was that it wasn’t done by a robot. That means they are having real people make them. A little ugly weld like on this 30 is something you’ll never see in use, and still plenty strong.

BB

I think you can check for coil bind also of the spring with the action out of the stock.

Cock the gun and look through the slot. You should be able to see how compressed the spring coils are.

GF1,

I don’t understand your concern. If the rifle will cock there is no coil binding. And up to that point, the mainspring can be compressed thousands of times and function perfectly.

What is your concern?

BB

BB

If your right at the point of coil bind and even just a little more than right at coil bind the gun can still be cocked. That would depend on how hard the person is cocking the gun if they don’t know any better.

And the main concern is you could end up with a bent spring and worn or broke cocking linkages and trigger parts at some point in time.

To me checking for coil bind is essential. You don’t know how many spring guns I have taken apart with coil bind and excessive preload on the spring.

If a person is taking the time to go inside a spring gun to make it better why wouldn’t you check for coil bind and excessive preload. At least for peace of mind and knowing more about your spring guns tune.

Heck I even check for coil bind and preload on my pcp guns striker/hammer spring. It does make for a smoother shooting pcp too.

GF1,

Wow! Thanks for that. This is the first time I have ever heard this complaint.

BB

BB

Thinking about what you by saying it’s a complaint.

It’s more about being aware of how the gun was set up and how your now setting it up.

I said this before and I know maybe not air gun related. But maybe it is also. When you are (close) to coil bind on a 4 stroke engine it can make multiple bad things happen to that engine.

The goal is not only to make it work better but also to make it last longer and not to work as hard.

Gunfun1,

Sorry about not being able to link my answer to B.B. about spring bind. It is down aways on this thread.

shootski

Hi folks,

I can tell you my experience with these springs and also what I read on the German Internet forums.

What I have read (with no means to verify) is that until some years ago, the springs for the German 7.5 joule (F) versions were created by simply cutting off the “full power” spring without collapsing the end of the spring. If this is true, it should not have affected you Americans in the first place.

I recently replaced a (probably) 40 year old Weihrauch (F) spring with a brand new one. The old one had straight ends and it was, in fact, still in good enough shape that you could stand it on its ends and it wouldn’t fall over. The new one had perfectly flat ends as well, so no problem there.

Kind regards,

Stephan

Stephan,

Thank you for that. It’s good to know.

BB

Stephan,

Canada has a similar threshold for air guns that don’t require a license and airguns that require a firearms license (500 fps/5.7J) that are just a bit lower than the German F-mark limit.

What’s fascinating is that I think the HW30S, and HW57, which start off at a lower power already don’t have detuned versions available.

The other Weihrauch springers all seem to have detuned versions available alongside the full power versions (HW35, HW50S, HW77, HW80, HW85, HW95, HW97, HW98). Although some models look like they have both detuned .177 and .22 versions, while others only have one calibre or the other.

Of course, they’re all currently out of stock too, so… At least that means business is probably pretty good at Weihrauch?

Nathan

BB,

I really need to contact Vortek. I am wanting to have some custom springs made for a couple of these ladies around here. I was thinking of taking some of these springs to the shop and have them cut down a bit, but at Vortek’s prices this would not be a very smart thing to do. I can buy a new spring made to length and shipped to me for not much more than it would cost me to drive to the shop and back to have a spring cut.

BB-

Did you mention what position- low, medium, high- you placed the top hat?

Paco,

I believe you mean the rear spring guide, and it’s set at the lowest position.

BB

BB,

While it obviously works,….. what keeps the spring end held into/onto the step?

Like,…. you put it on the top step,… and then down the road it works its way/rotates to the bottom step.

Chris

Chris,

I guess pressure. Like you said — it does work.

BB

GunFun1,

IT made a change to WordPress to fix the phone/text problem. Did it work for you?

BB

BB, That weld is irritating because it is substandard compared to the rest of this charmer.

Those holes are called porosity. Dirty metal or gas flow, too little or too much will do that. Contaminated tungston will do as well, but it looks like a MIG weld, the kind you would do on a lawnmower, it will probably hold just fine, but who knows. Because of the thin spring tube, it would be easy to over penetrate and distort the inside of that, so a wide, shallow weld is what they are going for. Ebay has plasma cutters for under $200., dual voltage would be nice to have around the shop!

Good job.

Rob

Well friends, I just cancelled my order with Pyramyd AIR. I ordered it on the 9th. It shipped out on the 10th. As of right now it is scheduled to be delivered to my PO box on the 28th. For whatever reason, my package has been bouncing back and forth between Concord, NC and Kernersville, NC since the 14th.

I guess I am going to have to find a 2240 elsewhere.

RR

Or just wait awhile and your 2240 will be delivered. If it’s already shipped and been at multiple locations its not going back to PA.

You will have to get a return request number and also PA will probably send you a email with a return shipping label. Once they recieve the returned gun then they will credit your bank account.

Been there done that. Hopefully that helps. If it goes different post and let us know. Will be waiting to hear.

GF1,

I called PA and the lady at customer service said because of the shipping issues I am to be refunded now. She looked at the tracking information and could not believe it herself.

There is absolutely no guarantee it will ever arrive here.

RR

Wow.

Lucky you. I had 2 different times out of my gazillion orders I made at PA where the order went arond the block several times and I know you know what I mean. PA did not cancel my order.

To me that’s good customer service on PA’s part.

Oh and if that 2240 does arrive I’ll send you 8 bucks and ship it to me and I’ll take the gamble if I get it or not. Of course for free with the shipping I paid. 😉

Well that is if you get my 8 bucks first.

LOL! I am not going to hold my breath on the 8 bucks making it either. It depends on how you send it. 😉

RR

Right how I send it. 😉

BB

Done deleted my email that I got from you asking if the text is working right now if someone posts a link because IT has been working on that problem. Don’t remember what blog report you asked about it on.

But don’t know right now. Nobody has posted a new comment with a link in it. I’ll see when they do.

GF1,

Simple question — are you now able to see all the comment text on your phone?

BB

BB

I went back to previous reports and now I do see all the text. As far as right now if someone posts a link I don’t know.

Post a link and I’ll see.

Oh and since we are talking about blog issues. I totally don’t like that if multiple replies are made to a comment there is no reply button to the comments made by others. That would only happen if the thread was running thin on the old blog. Now it happens only after one or two replies to a comment.

I have to go back to a persons first comment to have a reply button for thier comment and most of the time can’t reply to others that have commented.

B.B.,

I think you two are talking past each other. My take is that what is of concern is that the spring is not able to turn at both ends on the bearing surface as it cycles from compressed to uncompressed. The sound springs made on aircraft sounded like a ping or bang when the spring finally rotated at one or both ends.

I wonder how much of spring vibration is undiagnosed spring bind?

shootski

Shootski

Yes spring rotation could be a problem too.

Hi BB.From one oldie to another – the 30S is a nice smaller style air rifle that will suit both younger and older generations. The quantity is certainly to an acceptable standard that is reflected in the price.

A nice mid range priced shooter.

In my experience people are likely to be happy with the lady either as an oem, or tweaked as you’ve demonstrated in this blog. Either will likely work fine for them.

I’ve seen some people who expect too much from the lady but used over distances and targets for what it was designed it will give long and faithful service. She’s a lifelong friend.

Best wishes. R.

Hi Rick,

Yes, she is a sweetie. I’m having lost of fun with her.

BB