Marksman model 70 breakbarrel rifle.

Part 1

Part 2

Part 3

Part 4

Part 5

Part 6

This report covers:

- How much spring was removed?

- Measuring coiled steel mainsprings

- GunFun1 checks in

- A lot to consider

- Velocity test

- Eye-opener

- More can be done

- Summary

Today’s report will be a very important one. We test the velocity of the .22-caliber Marksman model 70 after I cut off the bent part of the mainspring.

How much spring was removed?

Remember that when I cut the spring I allowed for some of the bent part to remain. I was going to grind the end flat and also flatten the final coil, and I felt some of the bent spring could remain because of that.

I just measured the spring part that was removed and it’s 1.478-inches long. Call it an inch and a half. The rest got ground and flattened into the rest of the spring.

The bent part of the Marksman 70 mainspring that I cut off.

Measuring coiled steel mainsprings

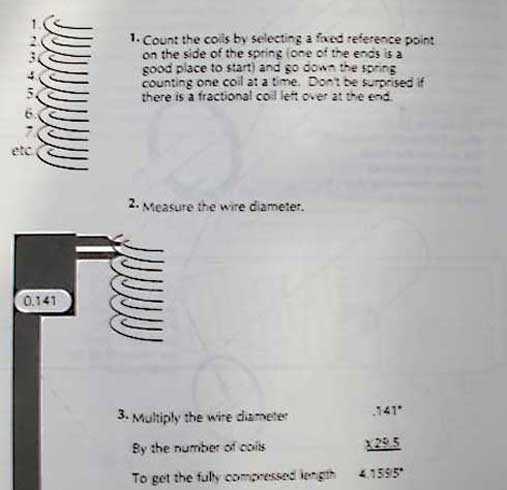

I’ve read some of your comments and it appears some of you don’t know how to measure the fully compressed length of a coiled steel spring. You don’t have to compress it fully to determine the compressed length. I covered this procedure in my R1 book, and my method will get you to within a few tens of thousandths. Rather than explain it, the illustration from my book tells all.

From my Beeman R1 book.

GunFun1 checks in

Okay — here we go. I removed about 1.5-inches from the mainspring and probably another quarter-inch when I flattened and ground the last coil. Reader GunFun1 asked me how much preload remained after that and I told him I thought about an inch, but that was just from memory. I didn’t measure it. Here is what he then said.

“BB

So when the gun is not cocked the spring has about a inch of preload still.

That’s not bad. But I found that about a 1/4 inch to a 1/2 inch preload seems to work the best. The gun will be very easy to cock and the safety sets easy. You don’t need that little extra cocking pressure to set the safety. And that pretty much always still gives good velocity.

And you know that sales pitch about nitro piston guns. You can leave them cocked and not worry about velocity loss like a spring gun. Well the less preload the less chance for that spring to take a set with it always having the extra preload.

I want to see the velocity test. Then I would like to se [sp] you take more off the spring to get zero preload then shim back up to get the preload and velocity you want.

Oh and you might of weakened the spring by heating it up. Cutting the spring with the cut off wheel was the right idea. That keeps the heat out of the spring and that is absolutely what you want to happen. Next time take that cut off wheel and use it as a grinder to get your flat on the spring right. Do not heat the spring. Grind it. And quenching the spring in oil would of been better than water or “coffee”.

BB you are just something else sometimes. 😉”

A lot to consider

Like most of you, GunFun1 packs forty-‘leven things into one comment.

He wants me to grind the flat on the base of the spring with the Dremel. That’s a good idea. But I still do have to heat it to smash it flat. There’s no way around that.

He thinks coffee was the wrong quenchant to use. It may be, but since it is mostly water, it seems to have worked. If I had planned ahead I would have had water on hand for the quench. And remember, the heat was only a dull cherry red in one spot on the spring, so I’m not worrying about oil versus water as the quenchant.

He wants me to cut the spring down to have no preload, and then add preload back in with washers. That’s how airgunsmiths do it and although I hadn’t planned to go that far, it’s a good thing to cover and I’ll do it. But I plan to test it with no preload, and then with a couple lengths of preload.

Velocity test

Here we go. In Part Six I told you all that was done to this airgun. And in Part 2 we learned that from the factory the rifle shot ten RWS Hobby pellets at an average 715 f.p.s. From the low of 709 to the high of 724 f.p.s., the spread was 15 f.p.s. And the cocking effort was 28 pounds.

Today with the shorter and un-bent mainspring, the same Hobby pellet averaged 746 f.p.s. That’s right — cutting the mainspring shorter gave a 31 f.p.s. velocity increase!

The low was 741 f.p.s. and the high was 753 f.p.s., so the spread was 12 f.p.s. Let’s look at every shot.

Shot…….Vel.

1………..753

2………..749

3………..744

4………..748

5………..746

6………..750

7………..741

8………..744

9………..750

10..……..741

And, we learned in Part 6 that the cocking force of the rifle is now 22 lbs. — a 6 lb. reduction from before the spring was cut. Plus, the rifle now shoots smoother.

Eye-opener

That’s the lesson for today. Sometimes a longer, more powerful mainspring does not add velocity. In this case, it took some away — more than likely because of the bend. This is the sort of thing a custom tuner will do for a spring-piston air rifle.

More can be done

Besides what you see here it’s possible to make a new custom spring guide to reduce any vibration at that spot. A forward spring guide that fits inside the piston (called a top hat for its resemblance to one) also helps reduce vibration there, plus it adds weight to the piston, which changes its performance with pellets. A heavier piston will usually shoot heavier pellets better.

Sometimes, when the piston is loose inside the spring tube, putting “button” bearings around its front and rear also helps reduce vibration. I did that for the RWS Diana 45 when I tuned it. But in the case of this Marksman 70, I don’t think they are needed. The piston seal is what keeps this piston from vibrating in front and the piston rod and spring guide in the rear keep it calm there. This piston isn’t even larger at its base, which is uncommon for a spring piston, but it tells me that Weihrauch didn’t experience much vibration from the piston.

Just cutting off the bent end of the mainspring has made a tremendous difference in the performance of the rifle. I did lubricate the mainspring with Tune in a Tube grease, and that no doubt helped some, but I think cutting off the mainspring was the biggest change.

Summary

That’s a little report that has a heck of a lot of important information. As I told you, I’m going to continue to play with this air rifle for a while, to determine even more about mainsprings and their relationship to the rifle’s performance.

“…cutting the mainspring shorter gave a 31 f.p.s. velocity increase!”

Cool, B.B.,

Now that’s really interesting! I remember the “old days” when people thought that stuffing in the biggest spring you could just HAD to increase the power. I can’t wait to see the rest of this set of reports.

Take care & God bless,

dave

B.B.

Less is more sometimes!

-Y

B.B.,

Hooray for physics! Elimination of the canted portion spring along with decrease in total mass, produced less friction to the walls allowing faster spring movement. I might have called it done at that but the experimenter in all of us wants to see if we can see further gains by losing the preload and if we can regain what we lost simply by shimming.

Siraniko

Siraniko

I believe the piston speed is slower after removing some of the preload. That allows the piston seal to seal better to the cylinder wall too.

When the spring had that extra preload it pushed the piston faster and harder. That allowed some air to leak past the seal as it was compressing the air before the pellet moved. Sometimes you have to slow down to go faster.

Gunfun1,

Maybe Tom can show us how well the piston seals into the cylinder wall next time he takes this thing apart. Until somebody can show us how to view the physical working of the rifle while it is working all we got is conjectures and theories. Your belief that the cut down spring leads to a slower rate of piston travel allowing a better seal comes from your experience in working engines. My reasoning is from what I have read and seen from my limited experience. Either way the gun is performing better.

Siraniko

Siraniko

Read my reply to Chris.

Siraniko

That is one thing I done with each o-ring I tried before assembling the gun with the next new o-ring. I seen how it moved in the cylinder.

Then I would do what I call the syringe test. I would push the piston all the way forward then pull the piston back while my finger was over the transfer port. I could feel if the piston was loosing seal as I pulled the piston back. Also then if it still felt like it had good suction I could let it go and see how hard it was when it went forward. And mind you. That was with no pellet involved.

Starting to see what I mean about how important the right piston seal to bore fit is?

Gunfun1,

Yeah, I gets it. This Model 70 has a parachute seal, which is less forgiving than a leather seal if the cylinder wall is not concentric. The suppleness of the synthetic material also affects how it grips the cylinder walls as it is pushed by the spring forward.

Siraniko

Siraniko

Yeo exactly.

Hmm maybe we should be replacing our synthetic piston seals with leather instead of the other way around like everybody does.

You think the leather conforms better than synthetic?

Gunfun1,

Well the leather is softer than the synthetic seals that I’ve encountered. O-rings are softer than synthetic too.

Siraniko

Siraniko

Then maybe leather or o-rings is the ticket.

I did get a Vortek kit for one if my springers once. The piston seal had a groove for a o-ring that was in the kit.

And that’s another thing maybe people are missing. The piston seal serves as a piston stop on most springers. The piston stop on a FWB 300 is attached to the front of the piston. It doesn’t contact the bore. Wonder if we should be putting a softer compound (bumper) stop on the front of the pistons to eliminate the piston thump. That would also stop the piston sooner. That could also lower the compression of the piston. Or maybe it would raise compression like a dome piston does on a race engine???

Gunfun1,

You can take the fuel engine analogy only so far because of the high temperatures, pumped lubricant and coolant. That’s why Dynamometer runs are so important to engine tuners/builders.

I wonder if any of the airgun Builders/Tuners bother with the level of testing you are asking Tom to accomplish in his one man operation. I think I know one and have heard of maybe two or so more!

Maybe we need to start a SPEED Shop for airguns….

;^)

shootski

GF1,

I am not so sure that I am ready to buy into all of that.

Chris

Chris

Done proved it to myself when I was trying different o-rings on the piston of my modded FWB 300s instead of the cast iron ring FWB used on them.

I had to find the right (size) fit o-ring. Too tight of fit to the bore then the piston had to much drag and lost velocity. To loose of fit and the piston went faster but didn’t seal as good (blow by) and gave less velocity.

When I got the right fit o-ring then it sealed good and had miniamal drag and velocity increased.

If anybody knew about blow by I figured it would of been you. I thought hey would of taught you that about tolerances and what happened when you was working on those big diesel engines.

Maybe think some more after reading my comment. Blow by is one of the most important things you learn to understand when you build a race engine.

Gunfun1,

That’s why I was thinking that Tom ought to see how tight the fit of the parachute piston is in relation to the cylinder wall. Is the cylinder wall concentric enough that there is no loss of compression? Does the parachute seal expand to provide a tight seal? Does it expand too much creating friction slowing down the rate of travel of the piston?

Siraniko

BB

Also you need to do a accuracy test right now to see if the gun improved. And again a accuracy test after you go to zero preload. And I figured the gun was going to increase in velocity.

After all that’s what were looking for. A smoother more accurate gun when we tune a spring gun.

BB,

Very nice. I expected the same fps, but not the increase. Maybe the cant was slowing it a bit. Looking forwards to what else you come up with to try.

Chris

There is a lot of science involved in the design of a spring piston airgun that even many manufacturers do not know or comprehend. One of these days I might figure out a small bit of it.

Personally I think Siraniko and Gunfun1 are on to something. I do believe that canting contributes to slowing down the airgun through friction. I also believe that more spring is not the answer to more velocity. Yes it works sometimes, but at other times it fails.

Now, as for the air escaping around the seal, I am not so sure of that. I am more likely to believe the pellet is moving prematurely, increasing the volume behind it before the air is fully compressed.

Hey, what do I know. I’m just a dumb ol’ country boy who likes to play with ol’ airguns.

Gunfun1

Hoping BB will test accuracy along the way also. May turn out to be exhausting however. So many variables come into play, especially human error, with a springer. Maybe he’ll do it on the chance this rifle becomes a FWB300S at 25 yards. Now that would shake up the airgun tuning industry advertising.

Another favorite report series in the making!

Deck

Deck,

Compete with a FWB300S at 25 yards? I am afraid I would have to put my money on the FWB. I have been inside a couple of those FWBs. The technology and engineering that goes into that FWB300S is absolutely incredible. BB may be able to take that sow’s ear and make it into a real nice purse, it will still not be a silk purse.

RR

Yes sir, I know. I have one.

Deck

Deck,

Well then you must know, “It ain’t gonna happen.”

Does yours still have the two counter wound springs? Are you still using the piston seal ring or have you replaced it with o rings?

RR

I meant it to be the holy grail. Just guessing that BB won’t want to take lots of time trying to correlate accuracy to each step of the way unless he believes there is probability for dramatic improvement.

My FWB300S was bought from and tuned by Carel. I’m not going inside.

Deck

Deck

That’s the thing about tuning anything for better performance you have to (and I stress have to) test after a change. It’s the only way to know if you made a improvement or not.

If your not going to do it fully then your just waisting your time.

BB,

This is some kinda really awesome experiment. I am so glad you are giving me a front row seat on this. I have that Webley/Hatsan Tomahawk I am wanting to tear into and experiment with the spring length. TIAT got rid of the vibration, but it still has a lot of cocking force and is quite a thumper when you pull the trigger. I believe that calming this gal down a bit will really help her out.

RR,

Cutting the spring did reduce cocking effort, but the rifle still thumps.

BB

B.B.,

Just for curiosity, is there a tight fitting pellet in your inventory that you can try? See if it reduces the thump compared to shooting the heaviest pellet you have.

Siraniko

Siraniko,

I’ll see.

BB

Siraniko

You just explained basically what the pellet does in the equation.

Pellet fit and weight does affect the thump.

I have had spring guns like different pellets after spring tuning.

There is so many variables it ain’t funny. And when you think you went the right way you find out differently. Its like your running on the edge of good or bad when you finally hit that right tune.

PCP’s too but in a different way.

Gunfun1,

The balancing act with two sets of moving parts (pellet and piston) is indeed something that can drive anyone batty. Especially if there are bean counters rushing the item out the door and into the show windows. Yes, once you have found the best pellet giving accuracy for your barrel and you still want to reduce the forward thump you now have to take a hard look at the piston and start thinking of reducing it’s weight. That forward thump is the excess energy of the piston moving forward after it has pushed out the pellet.

Siraniko

Siraniko

Yep done that too. I lightened up a piston and it did reduce the thump.

GF1,

This is another thing I will have to keep in mind when experimenting with this Tomahawk. I will also be trying to find out if I can install and get my hands on an Hatsan adjustable gas sproing. That would likely be the cat’s meow for this thing.

BB

Then I’m going to make a prediction after what you just said about reducing cocking effort and the rifle still thumping.

I’m going to say your guns going to still see the increased velocity with zero preload. Or maybe go back down to the guns original velocity. But your going to loose more of the thump.

That’s why I always cut a spring for zero preload and shim back up to get the velocity and shot cycle I want.

BB-

I believe what GF1 was getting at with his comments about grinding and heating is importance of minimizing the amount of heating so that you don’t anneal or harden the spring steel. If you heat it to annealing temperature, which we can’t really know without knowing what the recipe of the that particular steel is, you will lose some “springiness” in that focused area of the coil which could lead to it compressing there. If you get it too hot you can harden it and the spring might shear. I’m not a metallurgist and it is probably fine, but in my experience spring steel can be very temperamental when you start putting heat to it.

One quick question- Tune in a Tube as I understand it is used primarily as a spring dampener, yes? Lubrication is sort of secondary, just to keep the coils sliding smoothly against each other and the cylinder walls? I noticed there was no dieseling. Does TIAT ever migrate enough to worry about that?

ProfSteelToe

Yep exactly with heating the spring.

Steelie,

I understand about the heat and I am very cautious.

No, TIAT doesn’t migrate much.

BB

RR

Don’t know about the cats meow.

I had a Hatsan gas ram gun. I changed it to a spring gun. RDNA got the gun. Bulldawg got the gas ram. The gas ram was refillable. But the fill device needed made if I remember right from what Buldawg had going on.

So probably the wrong timing to own a gas ram. Can you pressurize them now days to adjust the pressure how you want? And from what I remember they was kind of sensative to get the pressure set right to make the gun work how you wanted.

And I had a magnum.25 caliber Hatsan Hatsan spring gun. By time I got the spring cut and reduced cocking effort and shot cycle it was only shooting the. 25 caliber pellet at about 450 fps.

So good luck tunning your Hatsan springer. Let us know how it goes.

BB

Something else. All this talk about piston seals with synthetic, leather and o-rings.

Do you recall any pump guns having leather seals on the pumping piston on the older guns. I know that they had felt wipers. But I’m talking about the pump piston. I could swear I remember leather piston seals on the piston on a pumper I had when I was a kid.

GF1,

The old pump guns all have leather pump cups.

BB

BB, This is great stuff. I’d say a well tuned springer is like a musical instrument in that it is either tuned or it is not. In the case of my victim underlever, I cannot put my finger over the transfer port as GF1 suggests and do a leak down test. (Thanks Gun Fun). I wondered what would happen if I sealed the port off completly with a bolt, and fired it. What part would blow up? Hmm. If it leaks down allot will the piston slam into the end of its stroke, or will it bounce? Can the seal be ruined by too much sudden pressure? In a healthy springer, when the piston moves the pellet must also move,

but at just the right balance. What about a transfer port shutter, that opens but not untill there is enough pressure bult up. Luckily the R10 makes very nice groups at 42 yds so when I mess the Synergis up I will stil have a gun that works well. Cant have too many of those. The improvement in the cocking effort alone seems to me a good enough reason to try getting the spring length right. While this Model 70 will never be an FWB 300, it does have some power to it.

Rob

Rob,

I have shot Hakim rifles with the loading tap open and it stayed sealed for close to a minute. But with a Synergis I don’t know how you would do it.

BB

BB

Just figured if people are not getting what I mean you don’t physically use a syringe.

The piston of the gun and the piston tube turns into the syringe the gun your testing.

You pull back on the piston and feel the resistance then you let go of the piston in the guns air tube and see how hard the piston pulls forward.

Probably didn’t need to say that but figured why not.

GF1,

I did get it.

BB

BB

I know you did. That’s why I said people. Not BB.

I was just trying to emphasize the point that the seal can get blow by and how the syringe effect can help get a grasp on how and why.

Rob put a cleaning pellet and then a regular pellet in the barrel and a close the breech in your underlever with of course your piston all the way forward first then do the syringe test.

After that add some oil with the cleaning pellet and regular pellet in the barrel with the piston forward down the transfer port hole. Preferably silicone oil. Then do the syringe test. You will see real quick what that oil does. The piston will have some good compression. It will show you some about how well that piston seal is working.

And all this we are talking about is to make a person aware of what thier gun is doing. Once you do it enough you start knowing what it feels like. No rocket science here please. Just do it and see what happens and compare. 🙂

BB

Thought that.

Do you recall when they stopped using leather on the pump seal?

Maybe that is why my old rifled barrel 760 liked getting a dose of oil before I shot it. It was a very strong gun.

GF1,

Leather seals ended about the decade of the 1970s except in China, where it took another 10 years.

BB

BB

Ok at least I know I’m not crazy now. 🙂

I thought I seen leather seals in pumpers when I was a young’n.

B.B.,

The pumpers I remember with leather pump cups were NOT that old!

Well okay I guess it IS all relative once we get to our seventh decade and beyond ;^)

Very interesting topic!

shootski

Shootski

I know. How time flys.

I was talking cars with one of the young maintenance guy that is just starting out in this field at work.

He says to me. That’s why I like talking to you old timers. You always know what your talking about.

At first I’m thinking ok I’m a old timer. Then it hit me yep that’s what us old times do. We just say what we know. He said when he talks to people his age they don’t have a clue.

I guess that’s one good thing I learned about getting old today. 🙂

Gunfun1,

BIG Ditto!

shootski

Shootski

🙂

Shootski

Up above.

BB started a speed shop for airguns a long time ago. He just didnt know it. 🙂

What do you think we all have been doing here. 😉

Gunfun1,

Why all we do is:

Shoot the Breeze!

LOL!

shootski