by Tom Gaylord, a.k.a. B.B. Pelletier

Today, I’ll apply what I learned about bending an airgun barrel to a real problem. As I said in several earlier posts, I have a BSF S70 breakbarrel that came to me with a peep sight installed but no open sights. BSF rifles aren’t common in the U.S., so finding a correct rear sight would take some time; but more importantly, I like the peep sight that’s on the gun. It was one that Air Rifle Headquarters sold as an optional sight, but the owner of this rifle removed the original sights and didn’t replace them when he sold the gun. So, all I have is the peep.

When I tried to sight in the rifle, I discovered that it was shooting 2-3/4-inches high at 10 meters, which would put it even higher at 25 yards. Either the front sight had to be raised (because the peep was adjusted as low as it will go), or the barrel had to be bent. Since the front sight is dovetailed into the barrel, I decided to bend the barrel. That was two years ago. Since then I’ve been researching ways to bend barrels and thinking about the equipment needed to do the job.

This report has already documented the simple fixture I constructed, and you can read how it worked in the earlier parts. Now, I’m going to bend the barrel of this pristine collectible air rifle so I can shoot it and hit what I’m aiming at.

The barrel-bending fixture is quite simple to set up. It uses a c-clamp to apply steady pressure on the barrel and a ratchet wrench turns the clamp slowly, so the bend is under complete control.

This was the final bend. This barrel is softer than the first one, but it springs back when the tension is released.

The S70 didn’t fit the fixture the same as the first rifle did. I had to make some adjustments, but there’s enough flexibility built in to allow that. As I started the bend, I noticed right away that this barrel was bending much easier than the other one had.

Metallurgy

Remember what I said about metallurgy of the various airgun barrels? I said that you should treat each new barrel as though you were bending a barrel for the first time. That was good advice for this job, because the S70 required a lot less pressure to bend. So I went slow.

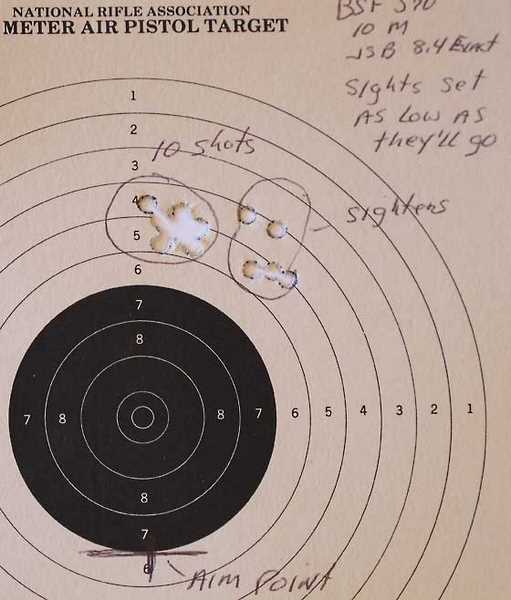

This is how the BSF S70 was shooting before I bent the barrel. The point of impact is about 2-3/4-inches above the point of aim at 10 meters.

The beauty of this fixture is that you can take the rifle out and shoot it after each bend. So that’s what I did. Let me show you the first target, which explains how the work went. I shot the same JSB Exact 8.4-grain pellets as were used when the gun was first fired.

This target documents all the work that was done. It is explained in the text below. The group below the bull is the final 5 shots, 3 of which are in one hole under the number 5. The one at the lower left was fired before I was ready but didn’t bother me.

I knew the rifle was shooting high, and I had the former target that told me how high. So, I first bent the barrel a little then shot the rifle to see what had happened. The first shot after the first bend was still high, but the point of impact had dropped over a quarter-inch. That told me the S70 barrel was bending very easy.

I bent the barrel a second time and put another pellet in the same hole as the first. Then, I bent it once again (three bends so far), and the third shot was the same height but to the right of the first two. Obviously, I had to be more aggressive.

The fourth bend was more aggressive, and the shot that followed dropped into the black bullseye for the first time. Next, I bent the barrel more aggressively, again, and the shot dropped to almost the middle of the red center.

Bend six was even a little more aggressive, and the shot dropped a little more and went to the right. Bend seven was about the same as six, and that shot went into the same hole as shot six had.

Now I knew the barrel needed a lot more pressure to go as far as I wanted. So, bend eight was the most aggressive of all. It’s the one pictured in the photo above. The shot that followed was below the aim point for the first time, which was what I was after. Four more shots were in the same area, though one of them went off before I was ready and struck the target low and to the left. From this result, I knew I was done bending the barrel.

It was time to sight in the rifle with the adjustments on the Williams peep sight that was on the gun. This was the first time since that rifle first got the peep sight back in the 1970s that it’s been able to shoot to the point of aim at 10 meters!

This is the sight-in target. You can see that a lot of upward adjustment was required to get the rifle shooting to the center of the bull at 10 meters.

The sight-in took a long time because the peep sight adjusts in very fine increments. But I managed to walk the pellets up the target until the final one was at the correct height. Now it was time to verify that the gun still shot well. I have the original target for comparison.

This target confirmed that the rifle still shot well. The group made before bending the barrel measures 0.532 inches between centers. This 10-shot group measures 0.506 inches between centers.

As you can see, the rifle shoots as well as before. All that’s been done is adjust the point of impact so the sights can be used at close range.

The Williams sight has a number of screws that are used to lock the sight in position, once it has been sighted in. They all have to be loose to adjust the sight; and when you tighten them at the end, they can make the POI move just a little. You have to check your work after you think the sight is locked down.

So, the fixture I made works for real-world applications, too. It doesn’t take up much space, and I’ll keep it around for any jobs that might arise in the future.

Bending an airgun barrel isn’t something to do lightly; but if you have to do it, it’s nice to know the job can be done with a minimum of tools and time. Today’s project took a total of 45 minutes, which includes bending, shooting and sighting-in the gun at the end of the job.

For some reason the comments were closed on this report. I’ve fixed that so you can now make comments.

B.B.

BB,

I want to download all of your daily blogs all the way back to 2005. They are an invaluable resource, and I don’t want to rely on anyone keeping them posted on the internet forever. What is the best way to download all of them? Do I have to go to each daily blog and copy/paste? Thanks.

5678qqqq,

Edith will have to answer that for you.

Edith?

B.B.

BB,

you do good work. I’m going to try to bend the barrel of that FWB 124 next week and let you and the blog know how I do. On another topic, I hope to pick up my .22 High Standard this Saturday with the Bushnell Trophy pro-point red dot installed (PA doensn’t sell this model but do have a Bushnell Red Dot in their inventory) and then finish the sighting in on Sunday at the local range. By the way, last week thanks to some suggestions from Victor and one of the fellows on my “team”, I managed to break 190 (out of 300) at the .22 rimfire weekly competition, which I’m very happy with. That was with iron sights. Of course, the 8 top guys who shoot typically score 260 to 280 but I’m happy with my progress.

I’ve broken out my IZH 46M and even thought it’s trigger is much lighter and the gun weight is much more than my High Standard, I’m using it to practice and refine my techniques as Victor suggested. I’ve put a red dot on it but it’s the large BSA one, which has a much wider field and is heavier. I figure the techniques can be transferred easily enough.

Fred DPRoNJ

Howdy Fred D,

Victor helped me a ton as well. Secret ta all the knowledge he shares, is the dry fire practice, practice, practice. While no where near where I’m gonna be the improvements in my shooting have been awesome. Victor knows his schtuff! Mr. B.B., Ms. Edith & the Gang, thanx. Shoot/ride safe.

Beaz

Fred,

I am interested to know how you score your targets. I also use a scoring system with 300 possible points. I use a 6″ Shoot-N-C target at 25 yards and take 30 shots at it. This is a system I came up with to compare my shooting with different guns and pellets.

How are you doing it? Is it a standardized system?

Les

Les,

I am competing in what’s called 25 yard Bullseye competition. It follows NRA rules – pretty much. We had to adapt as the range is only 30 yards long so we have 3 targets at 25 yards – one is 10 rounds timed (10 minutes to get off 10 rounds), 10 rounds slow fire (5 rounds per 20 seconds at a slightly larger target area than the timed) and 10 rounds rapid fire (5 rounds per 10 seconds at an even larger target area). Best possible score is 30X’s for 300 points. Targets are NRA reg paper. We almost all have spotting scopes to see where our rounds are landing

If this isn’t clear, try this link but remember, we don’t have the room for 50 yards and at 50 yards, I would want a scope! http://www.bullseyepistol.com/getinto.htm

Fred DPRoNJ

Thanks, Fred.

I’m always interested in how others do this, and would like to establish some sort of standardized scorekeeping for the range.

Les

I can foresee a problem with the ” 5 rounds in 10 seconds” part when using a breakbarrel springer.

Other than that, it sounds like something we could do with airguns.

Les

Has anyone heard of this guy? http://www.hegmans.de/theo/luft.htm

It’s all in German and the google translator is far from perfect but you can still see and understand most of it. I like the “flycatcher” with the “barrel” used as an air reservoir and the ejector tube is the real barrel.

The oHenry rifle is really my style too!

There’s no mention (that I could find) of selling price or quantity so they as well be one of one guns but he seems to be pretty darn good!

J-F

Wow J-F. Theo Hegman is a true ‘Jack of all trades’. I was just perusing his site for the last 45 minutes. So much too see. And he makes some very interesting guns. Both air and powder. There are so many things this guy does, and the pictures tell most of the story without translation. I’ll have to get my German speaking buddy to read and translate the stuff I’m interested in. At times like this, I just sit and wonder what does he have that I don’t. Well, a bigger imagination for one. Thanks for the heads up J-F.

Caio Titus

Looking at his work I wonder what it is we have in common! LOL

J-F

Tom,

Thanks for risking a good rifle for our sake. You are a brave man, willing to be a chance taker, with patience beyond the norm. Looking in my crystal ball I see a future with a lot of bent barrels chronicled on this blog.

-Chuckj

Victor,

Because of your willingness to share your shooting experiences, do you realize how many lives you’ve touched on this blog? You have many new, grateful friends.

-Chuckj

That’s for sure. What a world of difference from my nutcase coach in high school.

Matt61

Lives and wallets. 😉

kevin

chuckj,

Your kind words matter a great deal to me. I enjoy the sport of shooting so much that I find that helping others is as satisfying as doing it myself.

This past Saturday a buddy came down, who I hadn’t seen in a long time. He grew up on a huge ranch where he did a lot of high-power shooting. He’d never shot an airgun before, and in fact never would have considered them. Anyways, I let him try 4 different types (under-lever spring-piston, spring-piston break-barrel, nitro-piston break-barrel, and a PCP) of air-rifles at 10 meters. He was hooked right away! Five hours later he had to leave because his girlfriend was getting impatient with him being gone so long. They may have had other plans. He took his targets as “his ticket out of jail”.

I got to take 3 shots, while he took countless shots. I enjoyed watching him enjoy himself. He can’t wait to do it again.

Thanks again,

Victor

Well, this series has been a revelation. A rifle barrel to my mind was an image of something perfectly straight–like a ruler. Where possible I hope to keep it that way.:-)

BG_Farmer, you’ve got a point about adjusting sights once. When on the rifle team, I thought it was peculiar to go through the same routine of sighting in the rifle at every single practice. I suppose that was to correct for the various positions and for subtle changes at a high level of precision–but it was pretty much lost on me. Maybe that’s why the British and some other armies of the WWII era had a policy of having the armorer tweak the sights for each individual soldier–generally the front sight for windage–and then just leaving it.

Wulfraed, thanks for the explanation about the little peepholes. Fascinating. It looks like this is a winner as an addition to a sighting mechanism!:-)

Matt61

It’s also the principle behind http://www.eabco.com/store/products/Merit_Eyeglass_Shooting_Aperture-414-41.html

BB,

Looking at your barrel bending kit. Wouldn’t it be easier to use the effort for bending at the muzzle? Seems that less force would be needed due to the length of the lever (barrel). Maybe a car jack at the muzzle end after clamping the breech end with the c clamp. I have never bent a barrel nor have a need to but just wondering.

Ton,

What apparently is not coming through is the fact that leverage is not the issue. The issue is holding the barrel rigidly. If I were to try to bend it the way you suggest, the barrel would need a multi-ton press to lock the breech solid. The way I’m doing it here eliminates the need for that kind of equipment.

You can’t just clamp the barrel in a vise. You would crush the bore if you used the kind of clamping pressure needed to hold the barrel stable while it is bent from the muzzle.

B.B.

Bronco question. Is the ”Dad” version of the Bronco still in the works? Any ETA ?

Johng10,

Yes and no. My idea for a companion rifle is dead. But PA is trying to create another dad rifle using a different manufacturer. We’ll see how it turns out.

B.B.

It’s the Tech Force M12, and it’s made by Mendoza (same company that makes the Bronco). Pyramyd AIR just activated the guns (some come with scopes). Click here to see it.

Edith

Tom,

Must have been a long day of testing since you didn’t have time to comment. Hope it was outdoors on the range.

You must be very satisfied with your results of the barrel bending. I’m guessing the reason this BSF S70 didn’t get shot much was because no previous owner could overcome the poa vs. poi issue. You did. Kudos.

The other issue I remember about this BSF S70 is that the stock screws worked themselves loose quickly during shooting sessions. Have you had time to address this? Did you use vibra-TITE on the threads of the screws? Magical stuff. The only “trick” I’ve learned in using vibra-TITE is to let it completely dry on the threads before re-installing the screws.

My pet peeve is that once I work through all the issues on a certain model of gun when I go to sell it no one seems to appreciate the time and effort I’ve put into resolving the issues and compare my “fixed” gun to those that sell with issues. The BSF S70 is a great example since the buzz is that the peep sight didn’t fit the gun (couldn’t be adjusted to hit poa) and stock screws always worked loose.

These types of issues typically depress the value and even when they’re fixed I’m fighting an uphill battle to overcome average sale prices in these types of models with issues that are never fixed and therefor overshadow the true value of a fine gun that has been properly fixed.

Although results are frustrating when trying to add value to these types of guns I’m drawn to them since most can be found in pristine condition. It’s the outta the box guns that work flawlessly that get shot to death and therefor abused in the process. The epitomy of a conundrum.

I’ve really enjoyed this series on barrel bending and considering the evolution of your very effective, inexpensive, one of a kind barrel bending device have gained new appreciation on how meticulous (Edith would reject the an#@ word) you are. Well done.

kevin

Kevin,

I haven’t shot the S70 enough to notice the screw loosening problem yet.

After reading your comment about the unsung hero who fixes guns before he sells them, I think you will appreciate Friday’s blog.

B.B.

Hey i was sweating & my barrel did slip and my rifle has an automatic safety. Not that anything is important other than i am yet again grateful to have this blog. I have been shooting break barrels for just over 10 years and this is my first bent barrel and hopefully my last, but i am very apprehensive about doing the bending but i have no alternative but to do the work. I like the jig though i think i am going to gouge some slight channels on the spacers just to insure no left to right slippage though i am sure just the pressure from the clamp will make enough of an indentation. My only problem is going to be the C-clamp as i have a couple of large 8″, but if thats not enough i will have to buy another. Just glad to have the blog.

Mike,

Welcome to the blog.

If you read all 5 parts of the report you’ll see that some airgunners bend their barrels without a jig. They just apply force to a barrel that has been restrained.

The jig just makes the process more controllable.

B.B.

I did read it all and i am making the jig because i want to get it done in as few bends as possible & as it seems to have bent just foreword of the block i would like to correct it at the same spot if possible. I am not positive and this is a guess that when a softer metal is bent it tends to become hardened somewhat so putting an even pressure spread over the length of the barrel might allow the correction to occur in another area and let me be clear i am in no way sure that that would not be better. My only concern besides not having it shoot18″ high @ 25yds, but to also try and preserve the bore integrity as much as possible. I curse my mistake that caused this, but i will likely spend much more time than necessary making the best jig i can only to use it once, no worries as the C-clamp is going to be enough or i will likely try and borrow a large vise i can adapt to the task. My feeling in the moment was to just find a place to wedge it and do what i could however the prospect of overdoing it and i had no previous experience do not know what it can take so i will just use a jig and play it safe as i cant just replace the gun and i use it or rather need to on a daily basis so i will spend a little extra time on the jig. Thanks for your input though and the article [all of them] hope you had a good weekend.

Hi B.B.Pelittier,

I have a hatsan at44 Pcp and the barrel is bent up by about 2mm/3mm! Will this still be usable or does it need to be bent back? I don’t have anywhere to shoot at home so it isn’t as easy to just test it won’t have chance for a little while. If it does need to be bent how far would I need to bend it to remove the few mm bend? Thanks for any advice you can give!

Jake

Jake,

Welcome to the blog.

There is no way to know how far to bend a barrel to straighten it because their metallurgy and thickness determines how they react. It is a trial and error thing.

I would first remove the barrel from the shroud and shoot thew gun, to determine that the barrel really is bent. A bent PCP barrel is not common. Maybe the pellet is just hitting a baffle on the way out?

You will need a lot less tension to bend your barrel because it is so thin. And also because it is made from better steel than my test barrel was.

Good luck.

B.B.