by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- How old?

- It starts with straight razors

- Shape of the blade

- Shape of the scales

- Blade profile

- Airguns

- Generations/ages

- Very old steel and wood

- Seals

- Spring guns

- Funky parts

- Other finishes

- Post WW II steel and wood guns

- Breech and piston seals

- Look for plastic

- Painted guns?

- Summary

How old?

If you are new to the field of airguns there seems to be an ocean of things you need to know. If you want to become a collector, some of these things are crucial. Today I will explore how you can determine the relative age of a vintage airgun.

It starts with straight razors

Don’t worry, I’m not going to talk about straight razors very long. But they were the thing I used to rediscover what it feels like to be a new guy in an established hobby. Although I am not interested in collecting them, I couldn’t help but pick up some clues to their relative ages (when they were made) along the way.

Shape of the blade

Before around 1800, straight razors had no real tang. That’s the skinny part behind the blade where you hold the razor to shave. Razors from 1800 and earlier simply don’t have one. They just end the sharp blade and remain almost as wide but become dull as they go back to the pivot pin on the scales.

This straight razor blade was made before 1800. Notice there is no distinct tang (on the right) behind the blade.

After 1820 the tang became a very developed part of the blade. Makers started putting their names there.

This straight razor blade was made between 1835 and 1850. Notice the tang is fully developed.

Shape of the scales

Before around 1800 the scales (handles) on straight razors were squared off at both ends. Now, bear in mind that scales are easily replaceable and anyone can square off an end if they choose. So this clue to age isn’t 100 percent reliable. But if other things, such as the patina of the scale material, agree with the shape, chances are the razor they are on is probably from that period.

The end of the scales on this pre-1800 straight razor are squared off.

These 1830 scales are rounded at the ends.

Blade profile

Before about 1810, straight razor blades were not hollow ground. They were simply wedges that tapered straight to their edge. After 1810 and up to 1885, hollow grinding was practiced, but it was done by hand. That meant it took longer to make the blade and was an extra step. A hollow-ground blade was considered a big deal and a feature in straight razors made before 1885. The UK makers, particularly those from Sheffield, were the last to embrace real deep hollow grinding, which is why their blades are often thicker and heavier than the blades from other countries.

I was surprised to discover that all these early blades were made by blacksmiths. Of course they had to be, because the manufacturing technology simply didn’t exist in these times before the Industrial Revolution. Samuel Colt was one of the principal inventors of the modern production process, and he didn’t get started with that until sometime in the 1850s. Straight razors didn’t adopt modern production methods until the late 1870s.

A wedge blade tapers straight from the spine to the point.

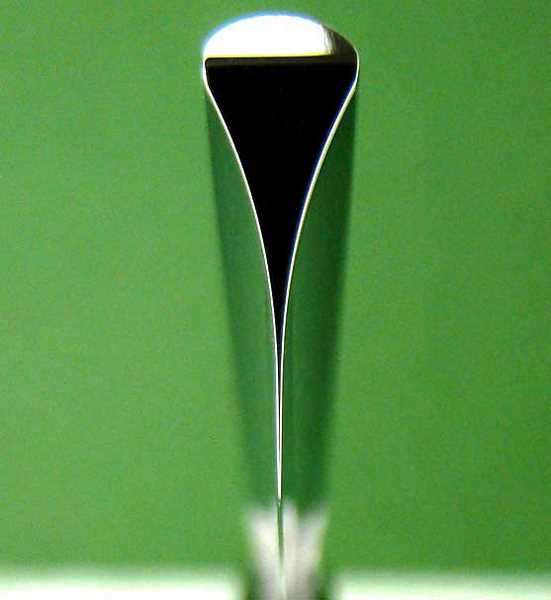

This half hollow grind looks like a wedge at first glance. This was all done by hand!

In 1885, hollow grinding became a machined process and the razor-making world immediately rushed in that direction, to the extent that any other grind is difficult to find for several decades. Still later it was realized that a thicker blade flexed less in use, making it smoother and easier to use, and many premium makers went back to making thicker blades.

This is the deep hollow grind that machines have put on straight razor blades since 1885.

Airguns

Enough about straight razors. Let’s talk vintage airguns and how you can determine their relative ages. Please understand that what I am about to tell you is generalized. There are clever individuals out there who can make something that was made last week look a hundred years old. But big manufacturers don’t usually do that. There are exceptions, like the Remington firearms company that in 1995 made a commemorative 1816 flintlock rifle to celebrate the company’s long history. It was made in their Custom Shop and a LOT of handwork had to go into it! But things like that never make money for the company, so the larger firms stay away from it, as a rule. So, what should you look for in a vintage airgun?

Generations/ages

“Vintage” means different things to different people. In this article I will look at three different generations or ages of airguns:

Very old steel and wood guns

Post WW II steel and wood guns

Vintage airguns made in the past 60 years — the modern antiques

Very old steel and wood

These are airguns made between the late 19th century and the start of World War II. The golden era for this group ranges from around 1905 until 1939. Look for real rust bluing on polished steel surfaces. Black oxide on surfaces that are both too shiny and also have worn lettering and rounded edges are the telltales of a gun that’s been buffed too much and re-blued when it was refinished. This can take some experience to see. For example, when I see a gun with a real blue finish, I often smell it, looking for traces of sulphur like old kitchen matches. That’s the smell of a cold blue.

When I look at wood I am looking for honest wear on checkered diamonds, not checkering that’s been buffed or sanded flat, or whole diamonds missing. Is the wood finished properly, or is the finish too shiny? A too-shiny surface is indicative of Tru Oil that’s been applied too deeply. Look at my Crosman 180 from last Friday’s post. That’s what Tru Oil looks like. Many older wood stocks and grips appear almost dry if they are original.

Even when you think there is plastic, like the grips on Webley pistols, it’s not really plastic. It’s actually hard rubber and Colt was using the same material on their handguns at this time.

Seals

I can almost guarantee a gun in this category will have leather seals. You can’t tell what the piston seal looks like without taking the gun apart, but the breech seal should also be leather in most cases, or fiber on guns like Webleys. If the breech seal is a synthetic o-ring someone has worked on the gun and there may be other clues to that if you look closely.

Spring guns

Spring guns in this category almost universally have weaker mainsprings. If you try to cock a BSA Standard from 1914 and there is a lot of resistance, someone has replaced the mainspring. Look for other modifications.

Funky parts

These older airguns will have parts that appear odd and out-of-place today. For example the cocking linkages may be massive castings that have been polished beautifully, or they may be made from machined steel, where after WW II they are usually made of sheet steel that’s been folded, welded and blued or black oxided. There are a few post-war airguns with funky parts that look older, like the machined cocking link on a Diana model 50. In my mind that puts that airgun into the same category as these older, better-finished guns.

The same holds true for triggerguards. Not even Air Arms will normally make a triggerguard that has to be machined from steel and then polished on a wheel before bluing. Sometimes today’s leading companies will stretch and produce a machined triggerguard, but you can bet it will be made of brass or another metal that’s easier to machine than steel.

Other finishes

Not all vintage guns in this category are blued. Benjamin plated their airguns, and so did Quackenbush and several others. Crosman painted theirs. To know whether these guns are original and right you need to know something about the guns, themselves. But understanding those finishes is just as important. Here is a tip. No vintage Benjamin airgun ever left the factory shined up like a brass trumpet! If you see one that is, it’s missing one or more original finishes. And the paint on a 1924 Crosman multi-pump should not look like it was sprayed yesterday. Because, if it does it probably was.

That’s it for the older airguns. After a half-century of looking at them, I can usually spot one quickly. That Millita rifle I reported on earlier this year is a prime example. When I held it for the first time at the Findlay airgun show this year I didn’t know what it was, but I knew it was old right away. It exuded all these clues I have given you.

Post WW II steel and wood guns

Many of these airguns are blued, although black oxide is also common. Some have ultra-high finishes like the Webley Mark III (1947-1975) but finishes on airguns in this category are generally not up to those of the pre-war guns.

The wood will remain the same as the earlier guns. Look for too-shiny and too-smooth. Is the wood flush with the metal, or even slightly higher? If so it’s probably original. Or, is it slightly lower, indicating a lot of sanding?

Breech and piston seals

If the breech seal is leather the chances are strong the piston seal will be leather, as well. It’s also a real sign the airgun hasn’t been worked on.

Even if the breech seal is an o-ring when you think it should be leather, don’t despair. The breech seal is so easy to remove and replace that anyone can do it. It doesn’t mean the leather piston seal was also replaced. That involves disassembly, and not as many people will do that.

One codicil here is that the HW55, and perhaps some other Weihrauch airguns, went through a transition period during which their owners replaced the original leather seals with synthetics. They may have had to also replace the piston to get the new seal to fit. The only way to know for sure is to look.

Look for plastic

Guns made after World War II are often a lot like the guns made just before the war. Some of the older, more conservative companies like Webley didn’t change their ways for many years after the war. As time passes, however, things like plastic parts start to appear. Sights, grips and triggerguards are the first to turn. The more plastic parts you find, the more recently the gun was made.

Painted guns?

I first encountered paint on a spring gun when I saw my first BSA Meteor Mark IV. Paint starts to appear on spring guns sometime in the 1970s, I guess. That’s really the end of the classic post war wood and steel gun era, although airguns like the TX200 Mark III carry on the tradition even today.

The post war airguns look more like today’s airguns, except they are generally finished better and have better materials. Gone are the solid parts of the pre-war guns, but their replacements still looked good for a long time.

Vintage airguns made in the past 60 years — the modern antiques

These are the guns of the post-war period that are not wood and steel. A 1950 Schimel made from cast parts fits in this category, as does a Crosman 111 pistol made of steel, brass and cast aluminum parts.

The Schimel pistol was an early attempt to use materials other than wood and steel. All the original black paint is gone from this one.

Crosman’s model 111 target pistol was the first bulk-filled CO2 pistol they made. The 111 was .177 and the .112 was .22.

These classic vintage airguns are often painted, made from cast potmetal (zinc alloy) parts, have lots of plastic on them, yet they are still true classics because of how they are designed.

The Crosman M1 Carbine started out with a wood stock that turned to plastic very early in its production run. They called that plastic “Croswood” and it was a marvel for its day. A Crosman 600 semiautomatic pistol is painted, made from cast parts and has plastic grips, yet it is still extremely desirable.

Crosman’s M1 Carbine may have a plastic stock, but it looks like the real deal!

The 10-shot semiautomatic Crosman 600 is painted, is made from potmetal parts and has plastic grips. It’s still a classic!

Daisy Red Ryders picked up plastic stocks and electrostatic paint in the 1950s. Even way back then we kids knew that wasn’t the right way to go, but what could you do about it? In an ironic twist of fate, Daisy realized what people wanted and switched back to wood on the Red Ryder in very recent times, and their Centennial commemorative Number 25 pump gun was even blued!

A Daisy 853 has plastic and potmetal parts. Yet it also has a Lothar Walther barrel and shoots quite well. The model is no longer made, so it’s a classic from very recent times.

The one thing I can say about these later classics is you won’t find very many of them in original condition. They were both played with a lot and they are also the easiest airguns to refinish. That’s why I went so ballistic over that Hahn BB pistol that was like new in the box at the 2017 Texas Airgun Show.

The modern classics are the most dynamic group to collect because they are sometimes not as well made as the airguns of today. Yet they are still the classics.

Summary

I thought I was going to help you pin down the age of an airgun by its characteristics when I started this report, but I haven’t done that very well. There are more detailed things to look for, like the early plastics that shrank and warped. We can spot those and guess the manufacturing date to be roughly 1950-1965. Machined parts also help to a degree, but companies like Webley and Haenel kept making airguns that way for so long that you have to know a lot more than just that single detail.

I have broken down vintage airguns into three general categories, and I hope that helps a little. I guess you still have to go to the shows, see lots of airguns and develop a knack. But what’s wrong with that?

B.B.,

With regards to airguns of German manufacture when did they make the distinction of manufactured in West Germany? Considering that the Wall was constructed in 1961 and subsequently fell in 1989 can that help tell age of manufacture?

Siraniko

PS. Did you go overtly ballistic when you saw the Hahn BB pistol? How much of value was lost where it was restored? Did you talk it over with the seller?

Siraniko,

The Hahn was not restored. It was 100 percent original. That was why I went ballistic.

B.B.

Siraniko,,

Regarding West Germany, it can be a clue, but it wasn’t applied as uniformly as we might think. Some did it after the war. Others dragged their feet. Some stamped guns Made in Germany West.

B.B.

B.B.,

On the one hand that tells the seller that you are very interested in the item. On the other hand it also signals to them they shouldn’t back down on their asking price much. How was the tarantula dance?

Siraniko

PS. I was also subtly pointing out in the sentence, “That’s why I went so ballistic overt (over) that Hahn BB”

Siraniko,

Got it.

My mornings are so busy that things have to be obvious or I will miss them.

B.B.

B.B.,

I can re-read a post 10X and still get something wrong! Like clockwork,… it becomes (very obvious) the very second I hit post and do a quick re-read. 🙁 It is usually something stupid like leaving out a (a, the, at, an,) etc., sometimes worse. My mind just puts them in there, even though they are not actually there. You do great.

Chris

Hoping this will post … I’m new to this blog …. had someone offer this JGA today not really knowing too much about it until Tom thinned out the mud … I would like to make the guy an offer now that I found it in the Blue Book(again thanks to Tom). Anyone have a suggestion on price based on condition in pics ? Gun is functional

smfyr241,

Welcome to the blog.

Thanks for posting here. I have over 100,000 registered readers who will see this.

Good luck,

B.B.

B.B,

Thanks … I’m excited to be part of the group. I value the knowledge of others in the group as well as yours …. I’m always learning something new about the hobby … Just seems no one around my area is as enthused about it as I am. I’m going to take some of my collection to the next, local gun show and start networking there …

Smfyr241,

Like Tom said, welcome. I have the 11th Blue Book and could (not) find it. Does it show under a different section than “J”? I keep my Blue Book within arms reach and is the first thing I grab when I see something new to me.

It reminds me of something that B.B. featured awhile back, though I do not recall the spring out front. The Blue Book was of no help determining a value?

Chris

Chris,

It took some digging but BB directed me to Anshutz who was the manufacturer. Like you I live in the Bluebook but was recently bit by it as well… private sellers are using recent auction sales as a baseline for value … they refuse to honor the book claiming that estamates are too low and incorrect. Makes it hard to buy a gun you really want…. needless to say I’ve lost a few buys but still use the book for every purchase…. the best research tool money can buy

Smfyr241,

From B.B.s articles,.. it (is) what they are selling for that sets the bar and the Blue Book is a guide. In a poor economy, the Blue Book may be high. A good economy has people looking for somewhere to spend their money so demand and prices will go up on average and the Blue Book can appear low. At least that is my understanding.

If I was serious, I would look at what things are going for,.. both the asking and purchase end of things. Once I find what I can expect to pay, then I would just try to do better than that. It sounds as if you have a very good handle on it all. Best wishes on finding your next gem.

Thanks

Looks to shinny for me.

-Y

B.B.,

Nice write up, both on the razors and the air guns. As with both, you have shown us that there is a lot to know. As for the laminated stock on the rifle from the previous (Fri.) report,… I went to Wiki and did some research. The best I can figure is a product called PSL, parallel stranded lumber. Short strands of wood that are mixed with glue and then pressed and heated. Whatever it is, it still has me fooled. I was unable to find an image of the product showing an example of the “grain” though.

Good Day to you and to all,… Chris

Chris,

That must bee what it is — PSL. I will show it in the next report.

B.B.

BB,

This is primarily the reason that I like the older air rifles. They are made the way I would make them. This is also why they are still usable. Sometimes I may have to replace the springs or seals, but it is well worth doing such to have an hundred and eleven year old air rifle that I am not afraid to use as a daily plinker.

By the way, I was wrong about my “new” Crosman. It is a 101, not a 100. It is .22 caliber. It has a rear notch sight, which I may replace when I rebuild it. There is also a very good chance I will refinish it. I know the “collectors” are cringing, but I bought this to be a multi-pump shooter for me. I do not envision this ever leaving RidgeRunner’s Home For Wayward Airguns.

RR,

I have negotiated the buy of a 100. It’s tied to another rifle that needs resealing and when that is done I will get both. So you will get your report.

B.B.

BB,

That would be great. I might even have the chance to follow along here.

B.B.,

Please do not take this the wrong way — I mean it as a high compliment. Sometimes I am struck not only by the main point of your essays, but also incidental items you choose as examples that pique my interest. For example, every time I see a photo of a Schimel I want one. Then, I remind myself that they are of too frail an alloy for shooting. But they look so fine! Schimels should be put in a nice glass case and hung on the wall as an example of Machine Age design. I feel the same about the Markham Chicago BB gun. It is a work of Tramp Art.

I also read many of your pieces that reflect on the past that get me thinking of what a bright air gun future could promise. For instance, every single time the Crosman M1 Carbine comes up here, I practically scream for Umarex to make it one of their Legends line. If not them, then Gletcher. Daisy/Winchester already has the M14; simply re-skin it with first-rate materials. Furthermore, not that it appears here often, but the same goes for the “movie star” Ingram Mac 10. A relatively cost-efficient re-skin of the full-auto mini UZI would do it. And if the MP40 was do-able, how much trouble would a Legends select-fire AK-47 be?

The market is still strong for these iconic firearms to be rendered in CO2 versions, but it will not last forever. Already everything is more and more looking like little, black plastic, bricks. Black patio pavers with triggers is all they seem to be.

“Ma’am, can you get a good look at the weapon he had?”

“Yes, I was only a few feet away. Let’s see. It was black and square. Yes, that’s it, black and square, with a hole in the end.”

Umarex should be congratulated for landing the big Glock fish, but air guns are like sex symbols. Curves sell.

Michael

Michael,

Wow! Pavers with triggers! I wish I had said that! 🙂

B.B.

Michael,

You should know that the Schimel was one of Edith’s favorite airguns. I bought her one that wasn’t working and always intended to put it in a shadow box for her office.

She called German Lugers Schimels!

B.B.

:^)

BB,

Curious if you got that 100x magnifier you ordered for looking at razor edges. If so, how do you like it? Is it worth getting one for viewing blade edges?

Fred formerly from the DPRoNJ

Crosman M1 Carbine made of wood stock only one year! Followed in 1967 I think they went plastic? I have the wood and in great condition with a magazine! Most won’t have a mag! They hard to find? Dennis Baker has one for sale right now that is wood! Semper Fi!

I have wondered what type of wood was used for the stocks of WWII-era rifles. Surely, they’re not all walnut. I suppose they are of whatever hardwood was most available.

Matt61

Matt,

Walnut for the American rifles. Beech for a lot of European rifles. Birch for some of the Soviet and communist bloc rifles. I’ve seen both walnut and beech on British SMLEs.

Can’t say about the Japanese and Chinese rifles.

B.B.

Wow, I thought that walnut was a luxury item. There were a lot rifles made from that wood. I don’t know anything about beech. But I remember in Lord of the Rings, there is an Ent named Beechbone who was described as very handsome.

Matt61

Funny to see the post on sharpening. This was the weekend where I put my newly dressed waterstones to the test by sharpening. And the result was (roll of the drums), the blade was only slightly sharper than before! 🙁 It could barely cut a pineapple. It is frustrating, but I believe I’ve learned something. At least the problem is not the stones. I felt good contact such as I have not felt in a long time. Presumably the culprit is me, specificially an inconsistent blade angle. My next step is probably to try the method of marking my edge with a felt tip pen as suggested by Grandmaster Frankbpc. Actually, waterstones have a built-indicator for blade angle. As you move the blade it will create a small wave from the standing water, and the wave form will tell you a lot about the position and speed of the blade. It feels like surfing stone. Unfortunately, it didn’t work out for me this time, but it was only my first try.

Matt61

Matt,

I will share this tip in the next report, but you need it now. Put 6-8 strips of electrician’s tape on the spine of your knives and hold them flat (spine and edge both touching) against the stones. That will ensure the angle stays the same.

B.B.

Thanks, I need all the help I can get. The tape idea makes sense. I sounds sort of like the old lost process for casting metal.

Matt61

B.B.,

Some times life gives a punch right to the gut; I know you understand that (and others here do as well). The severity of the blows varies, but that is a different story. Looking at the title of today’s blog, I though of our old friend, Sir Nigel Tetlington-Smythe, who always had some project going to restore old (and often in bad shape) air guns. I connected to his blog at:

http://angryangryguncompany.blogspot.com/2017/06/its-hard-to-know-how-to-start-this-post.html

and learned that he died on June, 24, 2017 following an accident resulting in serious brain injury.

I can’t say I really know Nigel, but I do feel I have lost a friend.

Although, it borders on pointless now, I will still address a bit of trivia. Mind you, I understand that the Daisy, Crosman and Gamo dot sights are cheap. The older Daisy sight with the little round window actually has a permanent diagram you can use to sight in. The newer sight that looks like hologram knockoff has no such permanent image. This is also true of the Gamo and I suspect, of the Crosman (it look suspiciously like the Gamo sight). I have no idea how I can use these as a sight (in the strict sense of the word); they are like a scope with no reticle.

~ken

Thanks for the news. So, that’s the Wing Commander, Sir Nigel. Best wishes.

Matt61