by Tom Gaylord

Writing as B.B. Pelletier

I am not running an historical report today because we have two guest blogs this week. Today I’m running the first of them. This is a guest blog from a reader who goes by the name Motorman.

If you’d like to write a guest post for this blog, please email me. Now, over to you, Motorman.

“Spring Doc” Spring Compressor Review

By Dean Speidel, alias “Motorman”

This report covers:

- Decisions

- “Spring Doc”

- Diving In!

- Flies in the ointment?

- Wrap-Up

Decisions

For some time I’ve been thinking about learning to disassemble, repair and, perhaps most importantly, re-assemble spring piston airguns. Making or buying a spring compressor is the first and unavoidable step.

I’m reasonably good with my hands, so I searched the internet and found a number of plans for build-it-yourself compressors. Some were pretty crude and, frankly, looked dangerous! Some were better, but I just never found one that I liked well enough to put the money and effort into building it.

Then I started looking for complete spring compressors already made up. A little more expensive, but expedient. Again, some were well thought out, but others seemed less, umm, impressive. Some were just flat out expensive.

My research at least helped me to figure out what was important — first, it needed to be as safe as possible. I didn’t want anything that was likely to damage me or the air guns I was working on.

Next, the easier it is to use, the better the result, and likely, the safer it would be. Since I would be working on both pistols and rifles, I wanted something that had a pretty broad range of adjustability…short to long guns, some with a pretty extreme range of preload.

I also wanted a compressor that would stand by itself and not have to be secured in a vice, clamped to a bench or something. My vice is in the garage and it’s too cold to work out there at this time of the year. It needed to sit by itself on a table or desk.

And, it needed to be both affordable and available from stock. I once had a boss that told me I could have it cheap, I could have it good, or I could have it fast, but I only got to pick two of the three. Well, I wanted all three here!

Spring Doc

About a year ago I was looking thru the online air gun ads, and there on the American Airguns websitesite was a spring compressor that seemed to fulfill all these requirements. It’s made by Greg Lindsey out in California. He calls it the “Spring Doc”. It looked well-made in the photos; I liked the design, and I thought the $150 price tag (plus shipping) was reasonable. It’s available in different woods; ash, African Sapele, African mahogany, and hickory. I took the leap and ordered the hickory one.

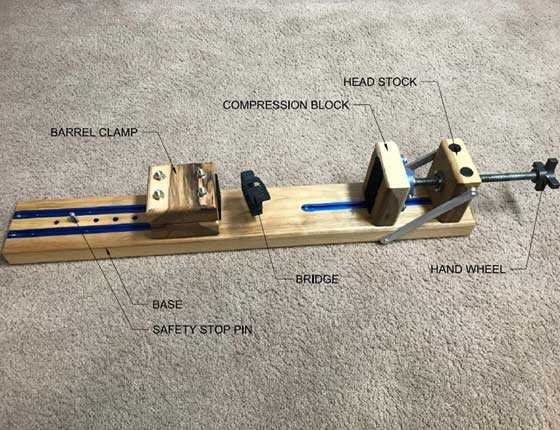

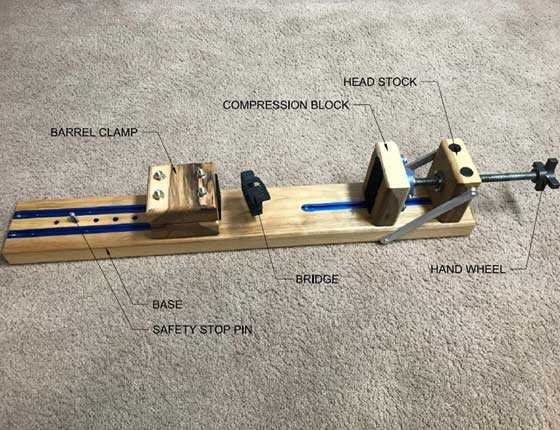

These are the parts of my new spring compressor.

When it arrived my first reaction strengthened the impression I’d gotten from Greg’s ad. The craftsmanship was excellent! The hickory base is 5” wide, 2” thick, and 36” long. All wood surfaces are smooth, corners are radiused and everything is given a nice polyurethane finish. The aluminum rails for the barrel clamp and compression block T-bolts are beautifully flush-inletted into the wood. The holes for the stop pin are nicely chamfered. The hardware seems heavy duty throughout…in fact, the compression block screw rides on an industrial bearing block! The aluminum braces for the head stock are made from ¼” X ¾” bar.

I really liked the nice, thick rubber bridge for supporting the gun’s spring tube. It improves safety for the user while helping to avoid scratching the bluing, and it couldn’t be easier to adjust for different guns. The rubber bridge can be screwed up or down into the base, while the strap has several notches to accommodate different spring tube diameters.

Reinforcing the impression of being a heavy-duty tool is its weight! Mine weighs 21 lbs.! I wanted something stable and this is it!

The adjustability is also a plus. The compression screw moves the compression block thru 7” — I can’t imagine that there’s a gun out there with more spring pre-load than that! The barrel clamp provides another 7 ½” of travel on the other end to adjust for different spring tube lengths. While it didn’t come with an instruction manual, everything seemed pretty intuitive to me.

Diving In!

My first victim was a well-abused 1960’s-era Diana model 5 pistol that I purchased just for this attempt. I figured if I screwed it up I didn’t have too much to lose and it should be a relatively simple gun to disassemble and then get back together. I first removed the wooden stock from the spring tube.

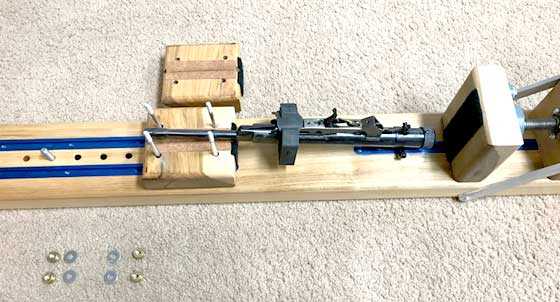

Mounting the gun in the spring compressor was pretty easy. This is a relatively short spring-piston pistol, so I loosened the hand wheel to retract the compression block (on the right) enough for the spring pre-load this gun is likely to have.

Next, I removed the barrel clamp thumb screws and took the top off. I noted that the top and bottom jaws of the barrel clamp have a felt lining to prevent scratching the gun’s finish! That’s a nice detail touch. I put the spring tube in the rubber support [The bridge? Editor] and adjusted it up and down until the gun’s spring tube and barrel are level and making full contact in the barrel clamp grove.

My Diana model 5 pistol is in the compressor.

Then, I positioned the back of the spring tube against the compression block. I also noticed that the compression block has a felt surface to prevent marring the end of the air gun — even if you have to rotate things while they’re under compression. Again, a nice detail touch.

I placed the barrel in the slot on the barrel clamp, replaced the top and lightly tightened the screws…not too tight because we need to slide the barrel clamp until we find the approximate lateral position and insert the safety stop pin into the appropriate pre-drilled hole. Seat the spring tube against the barrel clamp and finish tightening the barrel clamp screws. I don’t think it’s necessary to clamp down on the barrel too tightly because the end of the spring tube being against the barrel clamp is enough to keep it from sliding.

We can now start screwing the hand wheel in until a moderate amount of pressure is placed against the end of the spring tube. Remove end cap set screw on the gun, or the retaining bolt, or whatever secures the end of the spring tube. Then gently rotate the hand wheel counter-clockwise to release pressure on the gun’s mainspring as you unscrew the spring tube cap (or whatever the right procedure might be for your gun) until the spring has gone slack. Now you can remove all the pieces from the spring compressor!

The gun’s mainspring is now relaxed and the action may be disassembled.

Re-assembly is pretty much the proverbial “assemble in reverse order”.

I later dis-assembled and re-assembled a Feinwerkbau 124. The compressor was easy to adjust for this much-longer gun and the spring stop’s hand wheel screw had plenty of range to release the 4” or so of pre-load this gun has.

Are there any flies in the ointment?

When I disassembled a pre-WWII Diana Model (V), which was even shorter than the Diana Model 5 in the photos, I found it necessary to drill an additional hole for the safety stop pin. It was no big deal and Greg tells me he’ll be drilling this additional hole in all future Spring Docs.

As with any spring compressor, some allowance has to be made for guns with the safety on the back of the spring tube. This wasn’t a problem on the Diana Model 5 p;istol, but I had to roll up a piece of cardboard and put it on the back of the Feinwerkbau 124’s spring tube. Some of the Dianas that have a safety release on the back of the spring tube (i.e. Models 34, 36, 48, 52, 54…more?) will require some additional creativity to avoid putting too much pressure on the safety and breaking something. None of this is unique to Greg’s spring compressor.

Wrap-Up

The “Spring Doc” spring compressor (made and sold by Greg Lindsey in northern California, email: airgunafrica@gmail.com) is well-designed and well made. I particularly like the safety features built into it. It seems to work well on a wide variety of spring piston gun designs. Would I buy it again? Yep!

Motorman/Dean Speidel,

Thank for this review. This gives me further ideas for when I make my own compressor. The endcap is the one variable that is hard to cover for in every design I have seen. In some cases there is a shoulder underneath the safety that you can butt a piece of wood against, especially when the material is made of plastic. I’m wondering if a cup filled with a malleable material (duct seal?) might do the trick to support the endcap’s contact with the compression block?

Siraniko

Motorman,

Thanks for sharing and giving B.B. a well deserved day off!

However, I fail to see how the spring compressor that you bought is any better than this cheaper one?

/product/air-venturi-rail-lock-spring-compressor?a=7764

Perhaps you could explain?

-Yogi

Yogi,

His Section Decisions; Sixth paragraph: “I also wanted a compressor that would stand by itself and not have to be secured in a vice, clamped to a bench or something. My vice is in the garage and it’s too cold to work out there at this time of the year. It needed to sit by itself on a table or desk.” Which is something the Air Venturi Rail Lock Spring Compressor cannot do.

Siraniko

I use mine on a table or just in my lap…

-Y

Yogi,

I’d agree with you regarding the Air Venturi Rail Lock Spring Compressor. What happens when you run across the odd old airgun without a rail you can hold onto?

Siraniko

Yogi,

As Siraniko just pointed out, I have three sproingers with no place for that to clamp on.

RR,

I would have guessed your “Airgun Rescue” shelter would have more than just three of them! I have fewer vintage air guns than you have, but I’ll bet I have six or seven old air guns with no rails or grooves of any kind. That’s why I did not consider purchasing the (obviously quite well-built) Air Venturi compressor. I also feel more comfortable having wood around my air guns than steel. The more soft material the better, to avoid scratches and rub marks.

Michael

Michael,

Well, right now I have a Crosman 101 that I am in the middle of restoring. I have a few more modern air rifles also. As for the compressor, when you go big bore a hand pump is out of the question.

Hi Yogi

I just got the rail lock compressor which I ordered direct from Vortek. Cost $109+$34 shipping. Its a very high quality, well made piece & most importantly takes up NO space while doing the same job very well as BB showed us.I fully agree with you. I ordered two gas pistons for my Hatsan 125 & Striker. Waiting impatiently for them to arrive so I can try out the Rail Lock.

Errol

Dean,

Very nice report. That spring compressor looks better than most of my guns. If I ever pull the trigger on a TX 200 and it ever needed a spring compressor, would it work the same on an underlever?

Don

Don

Tx 200’s don’t need a spring compressor..

Don and Gunfun1,

It is also true that TX200s do not need to be opened up! ;^)

Michael

Michael

True sort of. Anything can break or seals and such need replaced. It’s all a matter of time.

Shows what I know.

Don

Don’t worry you know enough about air guns. 🙂

But the Tx are probably one of the easiest spring guns out there to work on.

GF1,

A TX 200 has been on my wish list for a long time. I seem to go a different route when I make an order.

I am waiting on the Fortitude but the Gauntlet will be hard to beat. I also am waiting on the pump gun, I forget the name it is based on the QB 79 I think.

Don

Don

I wish they would release the Fortitude. I’m wanting to see if it’s accurate like the Maximus.

Yep

I looked up the pumper I was trying to remember it is going to be from Air Venturi and is called the Dragonfly. Same gun as the Artemis LR700W based on the Diana Stormrider. Maybe not the best pedigree but I will probably give one a try when they are available at PA. I am a sucker for multi-pumps and my luck has to change soon on getting a good accurate gun.

The Dragonfly has been discussed on the blog a few times already.

The date on the Fortitude has just been moved back to May 18. My buddy at the pellet gun shop said June so he is getting closer all the time.

Don

Don

I would like to hear about it too. Maybe you might get one and let us know. 🙂

Gunfun1,

Stormrider multipump, for sure https://www.airventuri.com/av/featured-products/dragonfly/ The stormrider has had a lot of bad press, I would think this version may have similar issues but time will tell.

Mike

Mike

It is a good looking gun and has nice features.

Hopefully someone will get one so we can see what it’s about.

Don,

What you know is wisdom, better to use a spring compressor and not need it than to not use a spring compressor and discover you did need one.

That could leave a mark.

Mike

Mike In Atl,

Here is an example of it: /blog/2008/07/when-bad-things-happen-airgun-accidents/

Siraniko

Siraniko,

Indeed many times we can make our own accidents/stupidents by just not paying attention to what we are doing. That blog should be required reading for all.

Mike

Mike,..

Indeed,… required reading. I was adjusting the trigger (read: modding) on the Maximus, out of the stock, (quite awkward by the way),… and doing crony testing at the same time,… (again, awkward). 1 hole in the wall and 1 that that went just above the stove.

Yes Mike,… a must read.

(2008 by the way ya’ all,… and still very true today)

Chris,

Be very careful, too easy to make a bad mistake, and that cannot be taken back.

Mike

I doubt that apes live for very long in the wild with the way they behave. Their fighting method is to attack the face and genitals in case you come across one. That explains the fate of the one unfortunate woman who was attacked by her neighbor’s pet chimp. I don’t know that any studies on ape life span have been done in labs. If it was possible to make them live as couch potatoes, I don’t think their metabolism can be too high. Given the similarity of their physiology I doubt that their metabolism is much different from ours. I suspect that their great strength and ferocity are due to the construction of their muscle fibers and the way they are attached to their skeletons. They are also probably missing the inhibitions of a higher intellect. There was a comic book episode where David Banner turned into the Hulk while retaining his intellect and he couldn’t summon up the same strength as the pure Hulk.

Matt61

Matt61

Probably so.

Matt61,

Per Wikipedia, the Gorilla lives on average 35-40 years in the wild, with zoo specimen’s having lived to 50 and even 60 years. The 60 year old was in Columbus, Ohio and recently passed.

Chris.

Moto Ma Man, 🙂

Did you opt for this over the compressor Yogi linked to because it wasn’t dependent on a 11mm dovetail on the gun? That would not have been an issue very long ago, but as more gun producers go with Weaver and Piccy rails on springers to help deal with recoil, I can see the wisdom in a one size fits all approach if you are going to be doing this for hire. You won’t know what you may be asked to work on.

Half

Hi BB

Off topic here, but I got a Roosevelt dime 1989 P like the one you use, but I see the reverse side( tails) is minted upside down. Is this correct or have I got a valuable mis-mint?

Errol

Errol your a millionaire.

🙂

GF 1

You kidding me, right? At least I’ve got an accepted standard for measuring group sizes?

Errol

Errol

Wonder if there is a million dollar dime out there. You just never know what something could be worth.

And yep now for some pictures of groups with your coin by them. 🙂

Errol,

The reverse (back) is supposed to be upside-down from the obverse (front) of the coin. That’s the way they are made.

B.B.

BB

Thank you Sir.

Errol

And another off topic post.

I was searching the Air Venturi spring compressor and ran across this.

/product/freedom8-shoebox-electric-air-compressor-max-4500-psi?a=7921

If I remember right this compressor has been going for a thousand bucks and some change on the PA site. Of it’s the same compressor it’s a good deal.

Is all theses bargain guns and compressor’s driving cost down?

It seems that way don’t it. Good for us air gunners.

And I guess I’m not thinking clear. Why choose this spring compressor over the Air Venturi spring compressor?

GF1,

Interesting. It had to happen at some point. I have the pulley and belt to convert mine to the 10 model. It is a fine compressor and compact and light weight compared to some of the “beast” on the market now. It just lacks the insane speed at which the others can pump.

I might add,…. the Shoebox line is MUCH more simple in construction and # of components.

Of course, you have a very nice alternative too. Yours is truly amazing at it’s price point.

Chris USA,

I almost bought a lightly used Shoebox a few years ago but decided against it. It was cheap enough, but I would have had to buy a new shop compressor. My existing shop compressor, which sees limited use and is only about nine years old, is just a bit under-powered for the Shoeboxes but most importantly, it is oil lubricated, which is a no-no for the Shoebox.

Michael

Michael,

Compared to the competition, the Shoebox seems over priced, even at the new discounted rate. Your 350 would seems about right. Sometime simplicity has it’s definite benefits.

As for supply air, I use a California Air brand 5510E and it puts out 2.20 cfm @ 90 psi. I forget the specifics, but I do believe that is under the posted recommendation. But, I think that I remember too, that it is more than enough and perfectly safe. It has been awhile. I would not have bought it if I had not done my research and felt assured. It was 178 total, shipped to a local Lowe’s and is way below the typical decibel level of most oil-less compressors. 1.0 hp., twin cylinder. 5.5 gal. horizontal tank, wheels and handle and compact. I recommend. Lower rpm too = less heat = less condensation. I use a 5 micron LP air dryer. No HP air dryer. I have been inside the M-rod tube and the Maximus and have seen 0% issues with any moisture indicators. The LP filter has yet to yield a drop.

Just some FYI since we are on the topic.

Chris,

All good points and info, although I already have a nice shop compressor (oil lubricated) and don’t need a second one. And for the cost of a new Shoebox plus new oil-less shop compressor, I could get TWO Chinese compressors, delivered.

Michael

Ooops,…. 5510SE,… not 5510E

GF1,

For what you get, I still think that price is high. You still need to provide a first stage compressor and it has no moisture trap or particle filtration. If the price tag was about half that it would be about right.

RR,

Agreed. For $350, shipping included, one now can get an all-in-one HPA compressor.

Michael

RR

But like Chris said they are simple. And can be easily rebiult with out taking the whole compressor apart.

I still think that’s a good price for the Same compressor.

GF1,

First, this one is wood, and the less metal around my air guns the better, and second, many vintage air guns lack a rail or grooves, despite having more than a little pre-load.

Michael

Michael

Probably so for older guns.

Motorman,

Thank you for the fine report and thank you for showing us another option in the spring compressor world. I like the concept of using wood as a material for construction. This fellow did that, but also took it to the next level with all of the metal and hardware added. Nicely done.

Good Day to you and to all,…. Chris

Motorman,

Nice compressor! Thanks! Not only does it work, but it does it with style! Thanks for the email address also.

Nice job, Motorman, and good labeling on the parts in the photo.

Motorman,

An excellent report, congratulations!

I purchased a “homebrew” compressor a couple years ago that pales in comparison to the professionally finished and appointed one you have here from Greg Lindsey. He thought of design touches most folks might forget. There is at least one feature of this compressor I think I’ll try to replicate on the one I bought online from a fellow air gun forum member.

I am impressed by Lindsey’s price, too. His compressor appears to represent an awful lot of design, materials, and manufacturing time and labor for the money, a real bargain.

Again, very well done,

Michael

Motorman, like you, I don’t want to work out in my cold garage, and would like a nice stand-alone spring compressor.

Thank you for the great review on this one. =D

Motorman

Thanks for a well writen review. I do not see me needing a spring compressor any time soon but I read all the reviews with interest. I also like to limit my garage time this time of year. I was out there yesterday with cold fingers doing snow blower repair. I will need it later today.

Gerald

Motorman,

Nice blog – thanks for sharing!

Looks like a very versatile spring compressor with some nice features.

A couple of years ago I needed to change the piston seal on my FWB 124 so I made up a spring compressor to suit. I did allow a fair range of adjustment for my other springers in case I wanted do some internal work on them.

The compressor is cobbled together from a 2×4, some 1/4″ plywood, a length of 1/2-13 threaded rod, a some bits of hardware. Nothing fancy but it works OK 🙂

Hank

Hank,

You have a knack for functional designs that also look good. Most of my stuff is from repurposed junk and looks like it.

I have the parts from two old swamp coolers to make my automated hand pump. But now with two large fill tanks I no longer have the incentive to build it. Also it would take up precious space in my workshop I just spent a week on getting rid of junk.

Don

Benji-Don,

Thanks Don 🙂

“repurposed junk”… like that phrase to describe the finished project. Wouldn’t use it around my wife though – I try to use the “previously used recycled raw materials” phrase instead of the word “junk”. I think it might cut me a bit of slack but after 45 years marriage I am sure she sees through my subterfuge 🙂

Spring cleaning as well. Done the first “hardware rediscovery” stage and have twenty (LABELED!!) 2-pound coffee cans of hardware that I can now root through if I am looking for something specific. Stage 2 (the garage) should be easier now that I have the cans to sort the stuff into.

Hank

Hank

Nice.

GF1

I don’t know if are familiar with Hajimoto Productions or not. He has some great instructional videos. I know you said that you weren’t going to mod the Gauntlet but you may want to take a look at these videos. He has several on the Gauntlet. I just watched the one where he shows the results of his tune kit and how to adjust it for power and number of shots. He drilled a 1/4″ hole in the stock so he could access the hammer spring with an allen wrench without having to remove the stock. He demonstrated that on the low power setting he could get 200 shots before the fps dropped off. You might want to check it out. I get notices of his videos and when I saw this one, I thought of you 🙂

https://www.youtube.com/watch?v=6GHgfOhKPR8&feature=em-uploademail

Geo

Geo

Thanks for the link. I will check it out.

And after spending more time with my .177 Gauntlet. I’m still happy with it’s performance right out of the box.

Sorry, guys, I’ve been out of the office for much of the day today and wasn’t able to respond immediately to some of the questions.

Siraniko: I agree, trying to accommodate the many types of cylinder end caps out there is a problem. I could only imagine someone developing a set of adapters for each different style of end cap and selling them to be used with whatever type of spring compressor you might have…all of them share the same problem!

Yogi: I agree that Air Venturi sells a very nice spring compressor also. However, if you don’t have a scope rail to clamp to you’re pretty much dead in the water. A lot of the old spring piston air guns that I find myself working on don’t have scope rails, so although the “Spring Doc” may cost a few dollars more, it provides as much or more flexibility than any of the other spring compressors that I’m aware of.

Many thanks for the kind words about this review!

Motorman

St. Louis, MO

I finally finished my chores today. So I gave the Crosman Wildfire a run and 25 yards. That is the limit I expect much from it. I got a group of 12 shots at 1.38 inches. It was 0.96 inches wide so maybe a velocity variation. I will run three cylinders (36 pellets) over the chrony just to check it out some day. No more leaks so far.

I tossed a soup can out at 25 yards and hit it 12 for 12 shots. That is all I have been looking for. It should now make a fun plinker for some action targets.

Happy Camper

Don

Dan,

Good! That is what “we” are all about here at the Air Gun Academy,.. trying to make “happy campers”. 😉 I must say though,… you have gone far and above on your own behalf. I am happy for you. A 1″, 25 yard, Wildfire seems good to me. Best wishes that things continue on a good path.

Chris,

Well I paid $99 on sale at PA for the gun. It now is what I hoped for in a $99 PCP repeater. It also gave me a challenge to get it working so that counts for something. I might have been bored if it worked right out of the box. On a higher priced gun I would expect it to be great out of the box.

I hope they are working out all the bugs on the Fortitude. These delays in shipment don’t give me a good feeling. I wont mind some work to get it up to snuff but I expect it to give good groups at 40 yards and maybe beyond.

Don

Don,

Getting inside “counts” (a lot) in my book. On the Fortitude, from a now regulated Maximus owner, I do not like the shorter barrel. That runs counter to PCP builds. All at the expense of stuffing in some baffles and not making it “too long”. We shall see. I would love to have one. I DO NOT appreciate the dates getting pushed out one bit.

Marketing? 1) Tease?,.. 2) See/judge the demand/interest?,…. 3) ((Try)) to make them fast enough to keep up with orders?

On the Maximus,… I was shooting the 2240 the other day and the bolt was much nicer than the Maximus. How could that be? Why? It is the same basic set up. Go figure? I have the Maximus set up nice now,… but still. Why?

Oh well,.. like you,.. I will be waiting to see how the Fortitude does too.

Chris

No it’s not the same set up.

The 2240 works on around 900 psi. The Maximus works on a higher pressure.

Remember what I got my Maximus regulated at. 800 psi. That’s why the lighter 1322 striker spring works in my Maximus.

Didn’t we talk about this already. I’m sure we did.

GF1,

The 2240 just seems to have better tolerances. I am not concerned with cocking force. That is what it is, unless changing out the spring like you did. See reply to Don.

Chris

What do you mean by better tolerances.

The spring does make a big difference in how smooth and easy or hard these guns are to cock.

Put a Maximus spring in your 2240 and you will see what I mean.

Chris U,

Not sure what you mean by the bolt being much nicer. In what way?

Force to cock, Roughness, Seating the pellet?

I have had some steel breeches that were rough and needed a little polishing, I have not seen a bolt that was rough.

Don

Don,

Not force. The Maximus was bit rough at first and seemed sloppy. A clean and re-lube and some tubing on the handle, to add some pressure/tension,.. fixed everything up. The 2240 just seems to have better (tolerances). The cocking force is of no concern.

That was with the same Crosman Premiers 7.9 gr. I have been using so far.

Don

You should try those Daisy wadcutters. They thump the cans nice with the velocity the WildFire makes. I think you will like them.

GF1,

I have been looking around here but didn’t find any. I hate to use my buy four get one free when the rest of my pellets are costing in the high teens or twenties. The Daisy Wadctutters are less than five bucks for 500. Guess I could buy 4 boxes of Daisies. Do they work in your other guns?

I guess I would shoot at least 4 boxes with the Wildfire.

Don

Don

I’m lucky the Rural King farm supply store by my house carry’s the Daisy wadcutters. So I get them there unless they are out. Then I get them at PA. And I won’t order the cheaper pellets at the same time when I have to order my JSB pellets for just the reason you said.

And 4 tins of the wadcutters will go quicker than you think in your WildFire. Trust me. I know. 🙂

GF1,

Yep they will be on the next order, now what do I order to get free shipping?

I bought a Hawk spotting scope on my last order. It works good but the tripod is light and not real stable It has too much movement for my likes. I will be trying one of my better tripods and I think that will take care of it.

Don

Don

Finally. Glad you got it going.

GF1,

Well heck I refilled my Wildfire to 2000 psi today when I was finished shooting and now it is down to 1500 psi. I will see what it is tomorrow. That gun is testing my patience. If it is the valve maybe it will get better with some more use.

Not so Happy Camper

Don

Don

You need a stethoscope or something so you can hear where the leak is.

That is a shame you have that much problems with that gun. I bet the stethoscope will help.

GF1,

I used a stethoscope last time to tell it was coming from the valve area.

This morning it is still holding right at 1500 psi. So I will just leave it alone. The leak is very show enough it wont affect shooting right after a fill. I don’t think there are too many more times the gun can go under the knife and survive.

I may just toss the whole gun in the bathtub and see where the bubbles come from. I am getting that frustrated.

Don

Don

Now that would be a different way to test. Although you wouldn’t really know exactly where the leak would be coming from. The air bubbles would exit wherever they could. And then you would have to take a air nozzle and blow dry it with your shop compressor.

And you remember I have my WildFire tuned to run at 1400psi down to around 800psi. I have said all along that Crosman didn’t do their homework and setup the hammer spring and such to work closer to Co2 pressures.

Just think they could of had a hand pump friendly pcp that only needed filled to 1500 psi.

And I just don’t think the components in the WildFire was designed to handle 2000 psi without having leak issues. Mine does just fine at 1500 psi. And also I have found from doing 2240 hpa conversion’s that they like a max operating pressure of 1500 psi. So maybe 1500 psi is what will have to be lived with the WildFire.

GF1,

I agree. I can fill to 2000 if I am going to shoot right away. It is still holding at 1500 so good to go.

Don

Don

Yep.