by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- Importance of round air chambers

- My best advice

- Out of round pistons

- The deal

- Plain seals

- Leather piston seal assemblies

- Parachute seals

- The PTFE seal

- Last subject — seal materials

- Piston rings

- Summary

Today we will continue our discussion of the piston seal. This report was prompted by the comments of new reader Arvizu, who said, “ I noticed, too, that the seal plays an important role to define performance (sometimes small variations in diameter makes the difference). I would like to clarify that this is only my appreciation and limited experience with airguns.”

In Part One I attempted to show how a piston does its job. Arvizu’s question seemed to imply that he thought there might be an unlimited horizon for the piston seal, if only the technology could extract it. I tried to show that a piston is limited by the volume of air it compresses and improving piston seals is asymptotic. In other words there is a limit on the power that’s possible and we are now shaving small percentages as we approach that limit. To put it bluntly, we will never see the power of a spring piston system doubled by the seal. Never!

That being said, I’m not ready to say we have reached the end of improvement. But this report is not going to address that. We are looking at what the piston seal does and at the different types of seals that have been developed.

Importance of round air chambers

One comment that came in last time from reader Kevin reminded us of the importance of a round compression chamber. If you don’t have that, there is not much that can be done to improve it. I have owned spring rifles with out-of-round chambers and they definitely did stall out at a certain power point. It only takes a few thousandths out of concentric to make a big difference.

We can talk all day long about how to fix a compression chamber that’s out-of-round, but it is much more difficult than it sounds. The main problem is getting the air tube aligned with the axis of the cutter, so the cutting tool will cut in a straight line. That isn’t as easy as it sounds.

My best advice

The best thing I can tell you about this is to hold onto a spring gun that performs well. Maybe that would be a gun you tune and are amazed by how well it responds to the things you do. Remember the RWS Diana 45 I tuned in 2015? That gun really came out sweet! On the other hand I have tuned FWB 124s that simply would not go past a certain velocity limit that was disappointingly below 800 f.p.s. In fact the 124s seem to have this problem a lot. After listening to professional tuners, I now know those guns had compression chambers that were out of round. You can hone them until you are blue in the face — they will not go past that certain point.

The Diana 45 piston had a very fresh leather seal, but the improvements from a tune were impressive.

Out of round pistons

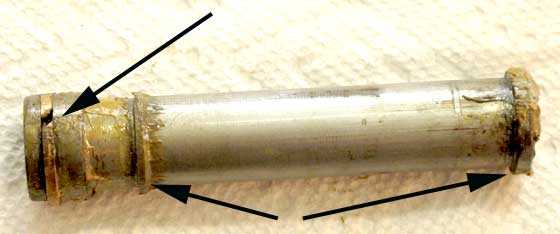

Let’s start looking at pistons and their seals. Since we have looked at out-of-round compression chambers, let’s look at a piston that was out of round. Remember the BSA Meteor Mark IV I tuned several years ago?

This piston in the BSA Meteor Mark IV was formed from sheet metal that was rolled and then welded into a cylinder. This one had broken welds at both ends, making the piston out of round.

After welding the piston back into a sort of cylinder the out-of-round problem went away.

The deal

Okay, I have been hiding the point, which is, as long as it isn’t too gross, an out-of-round piston doesn’t matter, because the piston seal itself is round and centers the piston in the compression chamber. In other words, don’t worry too much about the concentricity of the piston. It’s the seal that really matters.

Before we move on, I would like to point out that the “seal” in the Meteor isn’t what you expect. It’s an o-ring backed by a thin ring of another synthetic material. The front of that piston is steel and that is what contacts the end of the compression chamber at the end of the stroke. HOWEVER, it does not (or should not) hit the end of the chamber when the gun fires. When the piston gets to within a few hundredths of an inch of the end of the chamber, it stops on a cushion of highly compressed air. As the pellet starts moving down the bore the air pressure decreases and this cushion is squashed down. The piston then comes to a soft landing. That assumes the rifle is tuned correctly. All of this happens in thousandths of a second so we don’t perceive it, but the lack of damage on the piston end and the corresponding part of the compression chamber prove it.

Plain seals

Have you ever heard of a plain seal? Let’s look at one now. This one came from the “Steel Dreams” rifle that tried to break the sound barrier with a .22 caliber pellet.

This piston seal from the Steel Dreams rifle was plain. And it got burned during operation, which you can see as that flat spot in the center of the picture.

What this shows is it doesn’t take a lot of technology to push a pellet. This seal is as simple as can be, yet this rifle was as powerful as a tuned Beeman R1. That said, it was supposed to be much more powerful, as it was 125% larger and heavier and took 53 pounds of effort to cock. What that proved was it isn’t just the mainspring, the weight or diameter of the piston or anything else that many new airgunners think will make a spring gun shoot faster. It is the correct combination of all of those things, and can actually be realized in a smaller, lighter rifle.

Leather piston seal assemblies

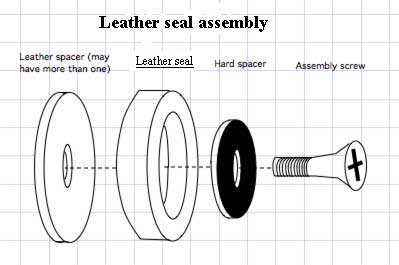

Let’s now look at the old standby leather piston seal. These can be ever-so-simple, or they can be made as an assembly. Let’s look at one now.

Some leather piston seals are actually assemblies, comprised of several parts.

Instead of just a seal, this is an assembly of parts that comprises a leather piston seal.

This seal was made for a modern Chinese airgun. RidgeRunner can tell you that the leather seal in his vintage BSA 1906 rifle is simpler than this. It probably looked like some wadded-up old gym shorts that hadn’t been cleaned for a month when he first saw it. I have seen many of these old seals all squashed up and out of shape. Yet when you shoot the gun they still work — as long as they are well-oiled.

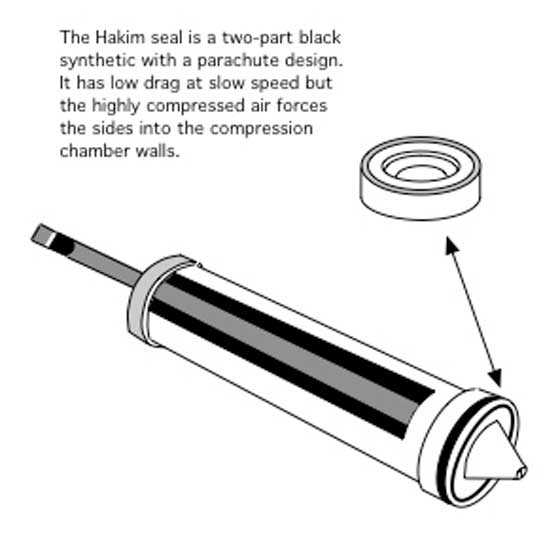

Parachute seals

Okay, Arvizu, the parachute seal is an advance in piston seal technology. The first ones I know of date from the early 1950s. Anschütz and Falke put them in their rifles. The Hakim from 1954 has an example of one.

The Anschütz-built Hakim had an early parachute seal.

Parachute seals have become the standard today — so much so that I am surprised when I see anything else. But there are other seal types. Let’s look at a strange one now.

The PTFE seal

Polytetraflouroethylene or PTFE is commonly called Teflon in the United States. Teflon is a product of Chemours, a 2015 spinoff of DuPont, which discovered the product in 1938. What you need to know is that PTFE squashes when hit, and that is how the piston seal is sized to the compression chamber. There are several examples of airguns that have PTFE seals, but the Beeman P1 pistol is perhaps the best-known.

The Beeman piston seal is a plain seal that squashes into shape when dry-fired.

The process of fitting this seal to the pistol is to dry-fire the gun several times. The PTFE squashes out to fit the compression chamber in just a few shots. If your P1 still detonates when you shoot the cure is to dry-fire it a couple times. Works like a charm!

Webley also installed PTFE seals in their rifles years ago. I remember that my Beeman C1 had one. That seal broke in over time and just got smoother and smoother.

Now, the PTFE seal isn’t to increase the power, though the P1 is a powerful pistol. It is more about fitting the compression chamber better and also lowering the friction.

Last subject — seal materials

One problem with piston seals over the years has been the materials from which they are made. In the 1970s several companies had piston seals made of synthetic material that did not last well over time. Feinwerkbau, Diana and Walther all had problems with seal materials that degraded over time. Such seals can fail inside a gun with no warning. In recent decades guns made during this time by these manufacturers have failed and had to be resealed. The good news is the new seal materials show no sign of similar degradation.

A fresh 124 on the left. In the middle is the same seal that’s been in a gun for many years. This seal has been ruined by dry rot. On the right is an aftermarket replacement seal for the 124.

Piston rings

We started this report with a piston that was sealed with an o-ring. Now let’s look at a different type of seal that’s similar to an o-ring but very different from anything we have seen. This is the metal piston ring.

Like the piston in a car engine, an airgun piston can also be sealed with a metal piston ring. We know that the front of the piston doesn’t have to be protected because it doesn’t slam into the end of the compression chamber, so the metal seal works well even though the piston will rest against the end of the chamber. A car piston never touches the top of its compression chamber, but an airgun piston does every time!

You can see the split metal piston ring on this 1935 Webley Senior piston that has been lubricated, front and rear.

Summary

That is my discussion of piston seals. Can they increase performance? Certainly, however only within the limits of the compression chamber in which they operate. Will there be improvements in them in the future? Undoubtedly. But we are at the place where the improvements in performance potential are down to gains of just a few percent.

B.B.,

Thank you for a very clear and concise explanation of what piston seals are being used. The British airgun tuners are going for efficiency with their sub 12 fpe rifles. They have not yet settled on a particular seal as that each type has shown variation in output due to external temperatures. Some have even tried a hybrid seals. Results are still to be determined though.

Siraniko

PS: Section Importance of round air chambers Second paragraph Second sentence: The main problem is getting the air tube alined (aligned) with the axis of the cutter, so the cutting tool will cut in a straight line.

Image: The Dian (Diana) 45 piston had a very fresh leather seal, but the improvements from a tune were impressive.

Siraniko,

Got them. Thanks,

B.B.

B.B.,

The 499 has a PTFE seal similar to the white 124 seal, but the center area is raised slightly. When I did the Red Ryder spring tune, I put a TX200 seal in as a replacement. Similar in style but softer/different material. Stock spring and just the seal comparison boosted the fps by 15-20. Just some info. on seal swaps for a 499.

Good Day to one and all,….. Chris

BB,

My 1906 did not have a leather seal when I got it. It should have, but it was either disintegrated and/or removed. There is the imprint of a screw head in the end of the chamber. The screw was broken off when I disassembled it and had to machine out, drill and tap for a new screw to mount the new leather seal which was a tightly compressed stack of leather washers with a countersink to accept a countersink washer and screw.

I may one day machine a new piston for a synthetic parachute seal, but the leather one works just fine and I really do not expect much improvement.

One thing that should be mentioned about leather seals is they need to be lubricated periodically or they will dry out. That lubrication will cause dieseling and/or detonation in the higher powered sproingers, therefore leather seals are unsuitable for such.

Having said that, I wonder if that issue would arise if you used only synthetic oil and/or grease?

RR,

Thanks for weighing in. Dieseling with smoke is normal for all spring piston guns of a certain power. That’s above 450 f.p.s., or so. It’s detonation that we don’t want.

B.B.

RidgeRunner,

How high a temperature can these synthetic oils and grease withstand before igniting? Then again at that level of pressure one would probably be using a synthetic material for the seal anyway. The British experimenters are now trying dry lubrication using graphite powder. They have to take their guns apart more often though for reapplication, but the initial results show promise.

Siraniko

Siraniko,

I do not know, but it can be pretty high. Diver’s silicone grease is used for tank seals, hand pumps, etc. I like to use silicone oil for my leather seals also.

As far as lubrication of other piston seals, any lubrication should be used very sparingly.

RR,

I have been using an STP/light oil mixture for my low to medium power sproingers and Dow Corning “food grade” silicone oil for anything over 700 fps.

Never did any formal testing but decades of use with good performance and no problems implies that it is a good approach.

Cheers,

Hank

Hank,

I mostly use silicone oils and greases where compression occurs. That way I do not have to worry about whether I need this or that. I try to keep my life simple.

RidgeRunner,

If I recall Duskwight recommended using synthetic oil in his lubrication blog article: /blog/2012/02/how-to-lubricate-your-spring-piston-airgun/

Siraniko

Siraniko,

Precisely. A good quality silicone oil can lubricate well at the high pressures without concern of ignition. When filling my PCPs I will on occasion add a couple of drops of silicone oil to the input. It helps prevent rusting and will migrate to the seals and lubricate them. It is a great way to seal a slow leak in a PCP.

Most sproingers do not need much lubrication of the chamber. Use perhaps a drop or two every few thousand shots. The leather seals need more lubrication to keep the leather pliant. The manual for my 1906 BSA recommends lubrication every 50 shots or so. It does not get nearly that much, but I do keep it well lubricated.

WAY OFF TOPIC :^)

BB, I’m sure someone’s already told you this, but on page 29 of the Blue Book of Airguns 12th ed., you say the Umarex Colt SAA sports a 4 3/4″ bbl when it actually has a 5.5″ bbl. You and I and many others are still awaiting the gunfighter version, as you well know.

—Joe on Maui

Joe,

Once it’s in print it’s impossible to change.

B.B.

BTW, I am now the proud owner of 6,000 Dust Devil BBs. It cost the same ($20) to mail me 4 boxes here on Maui as for 1. The only drawback was that it took nearly a month to get them here. —Joe, who turns 72 this year!

B.B.

You mentioned the difficulties in manufacturing a truly round compression tube. Could you please elaborate on the effects that brazing can have in making an out of round compression tube?

I understand that the Air Arms Pro Elite had this problem and almost drove the company bankrupt. Maybe you could do a report on this rifle?

Thanks,

-Yogi

Yogi,

I owned two Pro Elites. I didn’t like them that well. They were smooth but recoiled a lot and were hard to cock.

I don’t know enough about them to report on them, though. nI never heard of the brazing problem, but I know the application of heat distorts thin metal.

B.B.

B.B.

I once e-mailed Air Arms and asked if they would ever make a break barrel gun-I did not know about the Pro Elite at the time. Their response was we made the Pro Elite, NEVER again will we make a break barrel air gun. I was very surprised by their response!!!!!!

-Y

Yogi,

That is surprising. And now look at what Sig is doing!

B.B.

Perhaps you could do a report on the problems with the Pro Elite? If a quality company like Air Arms can get it so wrong, anybody can.

-Y

Yogi,

I’ll look into it but no promises.

B.B.

Thanks.

BB,

Aligning the compression tube with the axis of the cutter isnt the problem. In honing, the cutter floats and the tube is fixtured. The problem is that the cutter wants to follow the shape its in making it difficult to correct for roundness issues unless you have a lot of stock to work with. And then you need a seal to fit that oversize tube…

Derrick,

The way I read what you said, you said the same thing as me. The hone follows the tube, rather than honing “straight”.

By the way, when you fixture the tube, what do you use to determine what “straight” is? Probably the outside of the tube. So if the hole through the tube doesn’t align with the outside you have a problem.

It’s like “leveling” a scope reticle, when there is nothing on the rifle that is level.

B.B.

B.B.

I would use a reamer to get the bore straight and round and a hone to finish the surface.

Excellent blog BTW. Really like these discussions.

Hank

I don’t believe the inside diameter needs to be concentric with the outside. I’m also not convinced that straightness of the bore is all that critical given the radial contact of the piston seal. The honing process does not favor concentricity. Since the hone floats, it doesn’t maintain any relationship to the outside diameter that doesn’t already exist.

To clarify, I think a consistent diameter and roundness are the most critical criteria for the ID of the tube.

Everyone that dislikes in-week sales,

Here’s your chance.

Airgun Depot has 15% off Fri – Mon of this week for Halloween “Orange Friday” sale.

Half

Half,

With me, I do not have enough money to take advantage of any sale no matter when they have it.

BB

Thanks for giving us readers refresher reports like this one. Comments are helpful also.

Decksniper

Thanks BB, I really like this technical blogs. Keep ’em coming.

Some things that appear obvious at first glance (better seal = more speed) are important, but not that critical. So, if I understand this correctly then, the ‘secrets’ to maximize efficiency (pellet power for a particular charging effort) in a spring powered plant are (in no particular order): 1) smooth cylindrical piston chamber. 2) the correct (Goldilocks?) weight of the piston, 3) good piston alignment with smooth movement, 4) size and alignment of the transfer port and 4) a decent piston seal. And of course, no leak in the barrel seal.

In my mind, it would seem that a smooth chamber and slick piston would provide shot-to-shot consistency, although not necessarily increasing much the power level.

This leaves the question of a chamber shape. For a given air volume, the trade-off is then a small diameter-long tube vs. a large and short tube. Any comments?

Henry

Henry,

The small-diameter tube with the long stroke seems to be the ideal. The large tube and short stroke runs out of power too fast.

B.B.

Off topic for today, but spot on for yesterday.

I just watched the Airgun Depot review of the Aspen. I might have to rethink this.

RR,

Impressive. 35 yds.,… from what I saw. Note: No topping off with pumps between shots. In truth,.. I did not watch the whole thing. I had to click on the current video to see the Aspen one. The link to the Aspen did not work any other way. Still,… very interesting. We should be in for a good “B.B.,… run it through the mill” review.

Chris

Chris,

I am really looking forward to BB’s review. It is really starting to tempt me over the Fortitude.

RR,

If I had to choose right now, it would be the Fortitude. Lighter and feels great,.. as well as points great. Not sure if they have a Hunter version like the Maximus? That allows muzzle accessories. They (Fortitude and Aspen) are really two different animals though. Yes,… too many choices does have a downside,…. 😉 ….. but I love it at the same time!

Chris

Chris,

You seem to be forgetting that the Fortitude barrel is shrouded with baffles. What muzzle accessories do you want, a grenade launcher maybe?

The truth is I do not “need” either one. Also, upon reflection I would still take the Fortitude over the Aspen because it would suit my usage for it better.

Either way I will have to make room at RRHFWA before another moves in. My self imposed limitations on my “collection” insures that I give much thought to my purchases.