by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- Updates

- Early leather seals

- What’s next?

- Now that you understand…

- No magic

- Don’t be depressed!

- Leather piston seals

- The better way

- It’s all the same

- Leather’s shortcoming

- Summary

Updates

Pyramyd AIR has shipped me the replacement Fortitude, so I will be restarting that report soon. Leapers is sending me a micro dot sight that I showed you recently. I wanted that to test on the Beeman P1 pistol that I stopped testing months ago, but now I also want to put it on the Chaser pistol and perhaps on a rifle or two. And yes, GunFun1, I am going to test the Gauntlet at 50 yards with the tightened shroud/barrel.

But today I want to talk about something different. As you are aware, this blog gets many new readers all the time. Often when they come in they have a question about a topic I have addressed in the past. If their question is easy to answer I will often just give them the links to the past report — if I can find it. But sometimes their question isn’t so easy to answer, and when that happens and I know that I have many other new readers who might perhaps benefit from it, I will write a special blog. Today is such a day.

Reader Arvizu joined us two days ago. He had some questions about various things, including the following statement.

“ I noticed, too, that the seal plays an important role to define performance (sometimes small variations in diameter makes the difference). I would like to clarify that this is only my appreciation and limited experience with airguns.

I would really appreciate an article from you, with your vast experience in this regards talking about this topic.”

I gave him several links to past articles, but I could not get his comment out of my mind. So today I would like to address the importance of piston seals.

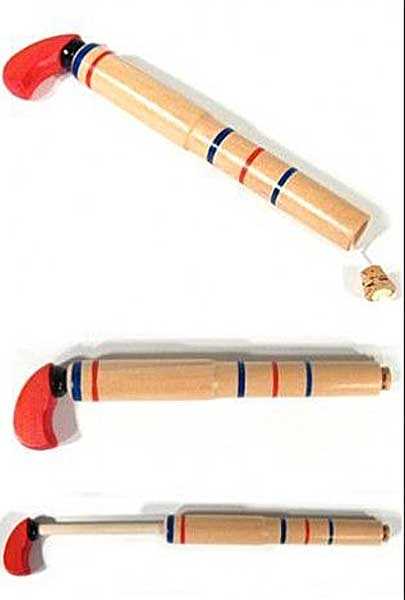

Let’s start with a look at a popular toy that many of us have played with — the toy popper gun!

Pull the handle back and the cork is drawn into the muzzle by the string that’s attached. If the string is too long you can just stuff the cork in the muzzle yourself. Push the handle forward and the dowel it’s attached to pushes air in front of it to pop the cork out of the “gun.”

You can see the length of the dowel at the bottom.

The popper toy works exactly like a spring-piston airgun, except it has no piston seal. Just the close fit of the wood dowel inside the larger wood tube compresses enough air to pop the cork.

Early leather seals

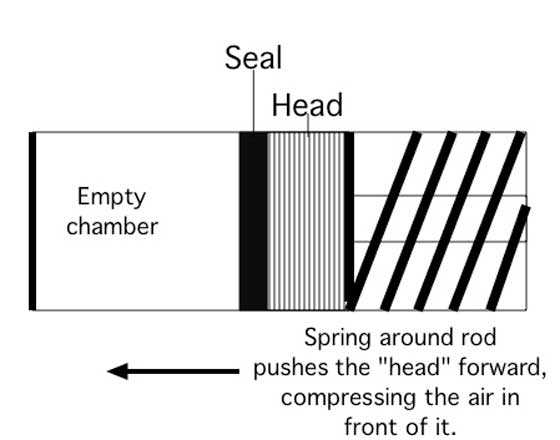

If that is clear, the rest will be easy. You don’t need a wood dowel that’s as large as the compression chamber. A steel rod can be much smaller and it only has to “push” a small “head” that’s sized to the chamber.

This simple compression chamber and “piston” works exactly like the popper toy.

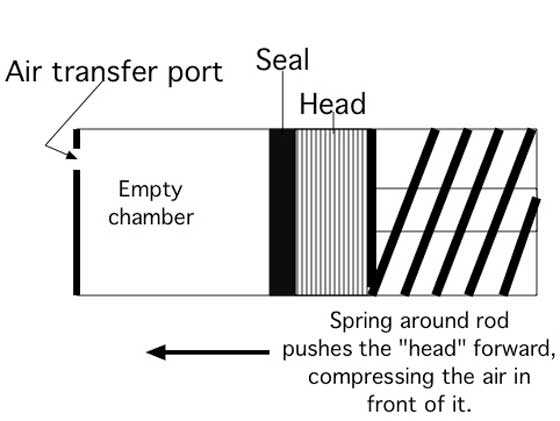

My graphic is interesting until you realize that the air, once compressed, has nowhere to go. Let’s add an outlet that we’ll call the air transfer port.

Now that we know how the air is compressed, it’s easy to see that it exits through the air transfer port.

What’s next?

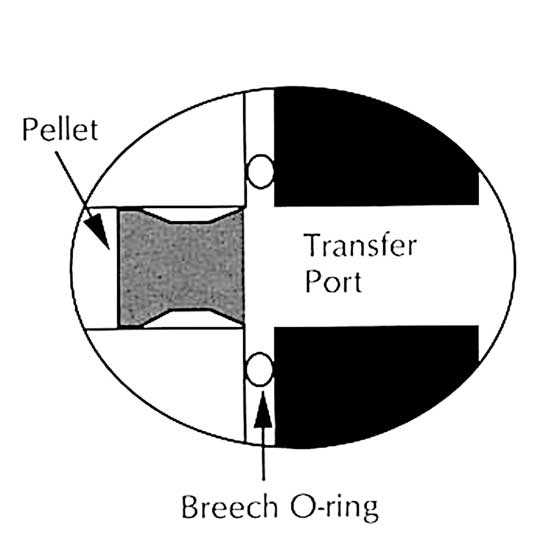

Next we put something in front of the escaping air, like the cork in the popper. The popper pops when the cork is overcome by air pressure and can’t remain inside the wood tube any longer. That’s similar to what happens when a pellet blocks the air from an airgun air transfer port.

Now we have put a barrel in front of the air transfer port and blocked the escaping air with a pellet. The pressure will built in the compression chamber until the pellet has to move.

Now that you understand…

So the wooden dowel is sufficient to compress air to a point. And the “head” on a steel rod will do the same thing. If we put a seal on a steel piston instead of just a head the extra weight of the piston will give us more force for compressing the air. But, here is the important thing — the amount of air doesn’t change, regardless of what compresses it!

A wooden dowel will compress air but will also allow some air to escape around the sides of the dowel. A “head” with no piston body will compress air better, as long as its seal remains tight against the walls of the chamber. But the head alone may be too light to compress air beyond a certain point. If the pellet refuses to move we could end up with the sealed head resting against a bubble of compressed air inside the compression chamber.

By adding a heavy piston body we are adding force to the moving piston seal, ensuring that the tiny lead pellet cannot withstand the force of the compressed air behind it. But the piston body compresses no more air than the piston head, if the other things (diameter of the compression chamber and length of the stroke) are the same. And that fact, readers, is important to dwell on.

No magic

There is no magic in a piston seal. It can only compress the amount of air that’s in front of it. If you replace a mediocre seal with the best seal possible you will get some improvement, but how much? Let’s say the mediocre seal compresses 90 percent of the air in front of it and the best seal compresses 98 percent. What, then, is the difference? Eight percent!

And we know from experiments done in the 1970s by the father/son team of Cardews, that the pellet produces roughly a third of the potential energy that’s driving it. Many things like friction and the energy loss due to translation from momentum to compression diminish the force that’s generated. What I’m saying is a 100-pound mainspring can produce no more than about 33 pounds of energy at the muzzle. The actual amount, however, is usually far below even that, with the 100 pound spring producing about 20 pounds of energy maximum at the muzzle. So, an 8 percent gain in potential power becomes no more than a 3 percent gain at the muzzle and probably less.

Don’t be depressed!

Now that you understand what we are dealing with you can cheer up. There have been major advances in piston seals in the past 40 years. We don’t have time to look at all of them today, but we can certainly get started.

Leather piston seals

Leather piston seals have been around for centuries. The air pumps that filled airguns in the 1700s had either no seal or a leather seal. If they had no seal, they were worked-in by hand to the point that the fit between the steel pump rod (which served as the piston, as well) and the pump chamber was perfect. Just oil the pump rod and it worked without the hint of noise. I have operated several of these centuries-old hand pumps and could not feel anything beyond air being compressed. But hand fitting like this took countless hours to achieve, so a better way was created.

The better way

The better way was to attach a pad of leather to the end of the piston. Make it slightly larger than the bore it was going to work in and then oil it thoroughly and work it back and forth many times. In far less time than a steel piston seal takes to work in, the leather seal conforms to the inside of the pump walls and makes an airtight seal. As long as the leather is kept pliant with oil, this kind of seal works very well.

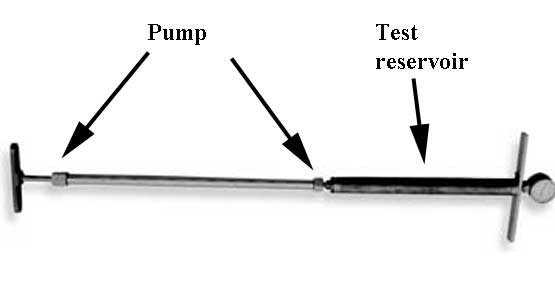

Dennis Quackenbush made this pump and reservoir with gauge so he and I could test the efficiency of vintage hand pumps.

The pump Dennis made doesn’t look that different than this real antique airgun pump.

It’s all the same

Don’t think that the seals in these hand pumps are any different than leather airgun piston seals. They’re not. They do the same thing and work the same way. Pistons are pistons and leather is leather. It needs to be supple to seal and when it is, it seals very well.

Leather’s shortcoming

A leather piston seal can last for a century and even longer, all the time doing what it was designed to do. But leather does have a weakness. It doesn’t like to get dry or hot. And spring piston airguns get very hot. They can get up over 1,000 degrees, F for a millisecond or two when the gun fires. Only because the heat doesn’t last long do leather seals work at all. However, as the guns become more powerful, the peak heat rises to the point that it starts burning the edges of the leather seal. First it dries out all the oil through combustion (detonations) and then the leather starts getting hard and crumbly. Eventually such a seal will be reduced to powder if you persist.

The leather seal in a Diana model 27 that shoots a .22 caliber pellet at 475 f.p.s. may last for half a million shots, while a Diana 45 that shoots the same pellet at 850 f.p.s. may only last 10,000 shots — and only that long if it is kept oiled regularly. Leather piston seals have their limits.

Summary

We are not finished by a long shot. We still have to look at PTFE seals, older synthetic seals, newer synthetic seals, parachute seals, the fit of the seal to the chamber and more. I don’t know if I can finish this discussion in one more report or if there has to be a Part 3. We shall see.

B.B.,

You probably should add the metal piston rings used in the FWB 300s and older Webley pistols on your list for discussion.

Siraniko

Siraniko,

Nice “While you’re at it…”.

Siraniko,

Yes. I will.

B.B.

A nice re-fresher. I see the cork guns that are made of wood dowels and PVC pipe. They are pretty common if going up to Amish country. I have never made one. Of course, the first thing I would do is tear it apart and look for ways to “tune” it. The string would have to go. Second would be to try different ammo types. Marshmallows? Could I add spikes to the cork? What is the FPE? Would a chrony pick it up? What would be my hold over at 3 feet? Scope or Red Dot? Mmmmm? 😉

Good Day to one and all,…… Chris

Chris,

LOL! You really need an AirForce air rifle. That will keep you busy for a while.

Chris,

What about adding a latch, valve and trigger so you could pre-compress the air before shooting??? Oh, no – forget that – its already been done, they call it a “Single Stroke Pneumatic” 🙂

I had one of these cork guns as a kid – yeah, the string was removed real quick. LOL!

Have a great day eh!

Hank

Chris

Listen to RidgeRunner about the AirForce guns.

I found a place that sells Lothar Walther barrels in .30 caliber and .357 and if I remember right .257 barrels that will fit the Condors and such small bore guns..

I’m about ready to buy a .30 caliber barrel from them for my Condor SS. Yep got the big bore bug. Getting ready cross the big bore dark side. 🙂

GF

You might need to get a few more parts besides a barrel . A .25 is about as far as you can go with the stock breech slide and tophat .

tt

TT

This place is green mountain out of Georgia.

Here’s what is in their description.

“AirForce Condor and Escape 30 cal. kits using your barrel bushing’s, breech, and top hat. $240 and up depending on length of barrel. .257 and .357 kits also available…”

Only thing I have to do for the barrels to work in my Condor SS verses a standard Condor is drill out my barrel bushings to 16 mm instead instead of the 12 mm that the Condor SS uses. Done checked it all out with them.

GF

They must have changed some specs on the Condor since I bought my Talons then.

tt

TT

Rember the breech that cocks the gun has a o-ring in it to seal the smaller diameter on top hat.

All that’s going to happen is when you cock the gun the o-ring will have a little more drag on the turned down diameter of the breech end of the barrel.

It will work just fine.

And right now I just measured the wall thickness on my Condor SS barrel. It is right at .038″. If you take .0025″ off of that the thickness will still be.0355″ thick. That will be plenty thick. There is no way I’ll bend a steel barrel loading a lead pellet with the barrel being that thick.and I do not think the air blast will blow .035″ thick steel open.

I think it will be alright.

GF

You just saved me the trouble of measuring the breech end of one of my barrels.

tt

Clicky

Yep that’s it. Just didn’t want to post the link. Sometimes Pyramyd AIR don’t like if a link is posted that is competition to them. That’s why I just gave the name. Then it’s up to someone to find it if they want to see it.

It’s a small custom builder dealing mostly with modifying airguns, nothing I would consider competition for a emporium like Pyramyd AIR. Besides, I like to keep all the mods busy!

TT

Oh and think about it. A .30 caliber barrel is only .005″ bigger than a .25 caliber barrel. So that would mean the wall thickness on the breech end of the barrel would only be .0025″ smaller. That’s 2 and half thousanths smaller. It will work fine being .005 thousanths over all diameter bigger.

GF

The breech end of the barrel is going to get pretty thin . Definitely would not work with anything bigger with what I am used to.

tt

TT

Posted in the wrong place. It should be ok.

Measure a .25 caliber barrel if you have one and let me know what it measures.

And when I say wall thickness I mean outside diameter to inside bore diameter of the breech end. Not the overall barrel out side diameter that goes through the bushings.

GF

Don’t have a .25 . My 24″ .22 barrel measures .308″ outside at the breech end.

tt

TT

So inside bore diameter to outside diameter on your.22 caliber barrel has roughly a .088″ wall thickness. That’s real thick.

TT

Read my last comment to Bugbuster about calling green mountain again to see about dimensions.

GF

Airforce may have changed some dimensions . Can’t see how else it would work.

That means that my barrels are not interchangeable with the newer ones.

tt

TT

Not sure what’s going on. But I am going to order a barrel from them this Friday or maybe next Friday. But first going to talk to them more before I make the order. I will post what I find when I talk to them.

Gunfun !,

.30 caliber = .308″, .25 caliber = .257″ .308″ – .257″ = .051″ or .0255″ on a side.

Bugbuster

Bugbuster

Then that means my .25 Condor SS barrel at the breech ends outside diameter is bigger than .308″.

I just measured and it’s .320″.

And is a firearm bullet .308″? Or did you measure a .30 caliber JSB pellet head diameter? That’s what they say they use for the green mountain .30 caliber barrel for the Condor, Escape barrel they have.

Bugbuster

Plus I’m guessing without having their barrel in hand. They probably bumped that .320″ diameter up to give more wall thickness on their barrels.

And now looking at my .25 caliber barrel that .320″ or Twotalon’s .308″ diameter can go to all the way up to .480″. That’s how big the diameter is of the cocking breech is.

So that means green mountain bumped up the outside breech diameter on their barrels to give a thicker wall thickness.

I’m sure they know what their talking about or they wouldn’t be selling them.

And it’s probably not clear what I’m saying without having pictures of the barrels and breech and top hat with dimensions and the parts all setting in front of a person to see the changes if the green mountain barrels were made and how they fit.

I work with dimensions all day long and make parts to fit when I don’t even have a mating part. From what I see there’s all kinds of room for even their .357″ barrel that green mountain has doe the Condor and Escape.

Bugbuster and TT

Just did more measuring and it is close on the outside .320″ diameter of the barrel on the breech end if the inside diameter gets opened up to .308″.

The big diameter of the top has alot of room. But not the breech end of the barrel .320″ diameter.

Not sure what green mountain did. I’m going to call them again.

Gunfun !,

I used the diameters for projectiles for firearms which are sized to the barrel groove diameter. Pellets are normally head sized to ride on the top of the lands which would be bore diameter. In this case, we are talking about .250″ for .25 caliber and .300″ for .30 caliber. Not accounting for the actual groove diameter of the replacement barrel, going from .25 cal to .30 cal will reduce the wall thickness of the barrel shank at the breech by .025″ on a side, not .0025″.

Bugbuster

Bugbuster

Yep your righton reducing the wall thickness .025″ instead of .0025″.

Brain was not engaged yesterday. It was one of those hard days night I guess.

So that makes me question the green mountain .30 caliber barrels more. They say they work. Like I mentioned above. I’ll find out more when I call them again before I order.

Not seeing something here that I guess they got figured out. We’ll see.

Gunfun,

Don’t feel bad, I have many days like that myself. I have been out of the machine shop for thirty-two years now and what used to be simple calculations are becoming more complex. If you don’t use it on a regular basis, you lose it! Thank goodness for my copy of Machinery’s Handbook (nineteenth edition).

Bugbuster

Bugbuster

Yep got what you said.

But I’m still thinking about how their barrels are working in those calibers in the AirForce guns they list.

But I’m going to find out.

I would like it to be a drop in like they make it sound like. But I’m skeptical now until I talk with them.

If it works that means it makes the AirForce guns more modular or I guess I can say universal to caliber change. That’s what I always liked about the AirForce guns.

GF1,

I am (more than good) for the moment. 😉

Chris

Chris

At least you said for the moment. 🙂

Chris,

Thought you might be interested in this video by Dennis Baker. He is very impressed with this airgun.

Testing the Daystate Red Wolf with the new JSB redesigned Monster Pellets

https://www.youtube.com/watch?v=cWhHB8uj5CQ&feature=push-u-sub&attr_tag=f7pRasejeoPyp8PQ%3A6

Geo,

Thank you for that. Mine is a .25 and did 70 shots just fine. That is the standard version as it is more black and a std. power version with the shorter barrel. Mine is the HP version. But yes,…. nothing to complain about for sure. I am hoping to see some more .25 pellet options in the future.

Thank You,…. Chris

Hi B.B.

I like these technical articles a lot! I would like to hear you opinion on o-ring seals. I have experimented with these also. Bowkett wrote some cool stuff about them and supposedly in a true round compression tube they are very nice.

I found two typos I think. It says pistol instead of piston in the middle of the first paragraph of ‘Now that you understand’

And in ‘don’t be depressed’ you probably mean advances instead of advantage.

Best regards,

Carel

Carel,

Thanks. I fixed both of them.

B.B.

BB,

I think this blog is a great idea, not only for the newbies but also as a refresher for us old-timers. This way the knowledge is “written down” so as to be researched and referenced more readily by us and others.

RR,

Yes. I come back to these basic reports all the time, just to help my rememberer.

B.B.

BB,

I actually know much about seals and their various materials already, because of the work I did before I retired, but I was still able to learn some important new stuff from this report. I had no idea that the pellet only converts 30% of the powerplant’s energy in a best case scenario. That explains a lot about why it is so difficult to build a manageable high power or big bore spring piston gun.

This is off topic, but when you return to the Gen2 stormrider, could you put your thumb against the rear of the bolt as you fire a few shots to see if you feel a real hard thump. I have mentioned before that my Gen 1 gun has developed a mushroom in the bolt handle’s slot from the hammering it is getting from the bolt handle and I would like to know if it is just my gun or is it to be expected on all of them. If you could check the Gen 1 gun too, that would be icing on the cake and might tell a story about whether or not that is an issue that was addressed in the Gen2 version, as well.

Half

Half,

Yes, I plan to.

B.B.

B.B.

May I suggest a series of reports to elaborate on: “What I’m saying is a 100-pound mainspring can produce no more than about 33 pounds of energy at the muzzle. The actual amount, however, is usually far below even that, with the 100 pound spring producing about 20 pounds of energy maximum at the muzzle.”

I am surprised that with modern manufacturing and proper lubrication that the energy losses are so great.

Automobile engine builders estimate that the difference in measuring engine energy at the crank and at the wheel is only 15-20% energy loss. Why are they 4 to 5 times higher in a spring gun?

Thanks,

Yogi

Yogi,

You can’t win,

You can’t break even,

You can’t get out of the game.

Siraniko

Huh???

-Y

Yogi,

It’s a shorter version of the Three Laws of Thermodynamics.

As to efficiency the British boffins have claimed to have engineered up to 70% efficiency which is up from the average 40% or so most run in their sub 12 fpe air rifles. “What was done to gain efficiency? Lose friction, reduce piston diameter, increase stroke, get the right spring and last the right seal. Then barrel length and barrel lead in come into play also. One downside in supreme efficiency is its not always that consistent, some friction off the seal aids consistency…so sometimes you lose some efficiency to gain some consistency.” I’m just quoting what I read from a post by a respected airgun engineer. Clearly pushing a pellet faster than 12 fpe requires more energy and a diminishing return for your investment.

Siraniko

Yogi,

Gears?

Michael

Yogi,

If the engineers measured the potential energy in gasoline and compared that to the power at the rear wheels you would see a relationship closer to the one I am giving.

B.B.

Yogi

I have built race cars for close to 35 years.

Don’t know about now days with crank horsepower verses wheel horsepower. But in the old days engine dyno would always produce more horsepower then dyno wheel horsepower. It was closer to 70% loss back in the old days.

It was

Thanks B.B.!

My favorite kind of blog – please feel free to write as many parts as you can.

Hank

I enjoy these reports as well, mainly because I skipped the whole spring (or gas) piston gun segment and jumped into airguns with CO2 and a PCP. I respect history, and ‘ how we got here’ information. It helps you understand exactly where you are, and where you are going. Of course, this is not just with airguns, but with most pursuits. It doesn’t mean I want to live in the past, although I do find myself considering a break barrel rifle as my next purchase. In fact, I might even kill two birds with one stone by buying a .177 breakbarrel. I think this would really ‘fill in gaps’ of my airgun experience, since I’ve never shot a .177 caliber, and have very limited time with a piston gun (mr friend has a Gamo Magnum).

Toddspeed,

My first break barrel was an RWS 45 in .177 caliber that I bought used

(B.B. posted about it here: /blog/2008/04/rws-diana-45-a-bridge-to-the-past/ ).

It was a good gun and pretty accurate with a 4X scope.

But being unused to spring guns (I had only owned a Sheridan pumper before), I removed the “thing”

behind the scope; ten progressively-higher-shooting shots later, the scope walked off the rifle.

Luckily, I caught it; and that was my introduction to the importance of scope stops on springers.

My son borrowed that rifle for a few years, so I bought a Beeman R7 in .177 caliber.

With a small 3X scope, and no scope stop needed due to low recoil,

this was one of the most accurate and super-fun air rifle I ever owned.

Sadly, I got stupid, and sold it; and I’ve regretted that ever since.

So last year, I replaced it with an HW30S in .22 caliber, since I mostly plink at close range.

The R7 was sold to get an HW97 for Field Target; the HW97 (.177) was a great gun;

but when I was moving away, I sold it to another Field Target guy before I left.

Long story short, the RWS 45 and HW97 were both great guns, but heavy.

The little R7 was the coolest and most gun little .177 rifle I ever owned.

If you try an R7, or HW30S (which has the Rekord trigger like the R7),

you will not be disappointed; you may buy another springer later for more power.

But those little 7 to 8 pfe rifles are addictive! Just my 2 cents. =>

take care,

dave

P.S. “most gun” should be “most fun.”

With almost no recoil on that R7, you could watch the pellets impact through the scope.

I liked to clip dandelion stems at 10 yards; and I shot many Carpenter Bees with it, too.

I may have to add a BugBuster scope to my HW30S so I can re-live the past. =>

Davemyster,

I’ve thought about the HW30S many times just because I read where they are nice guns. With the .22 having the “low” velocity, can you reach out very far?

Doc

Hi Doc,

My backyard backs up to woods, but it’s pretty small.

My rifle is sighted in at 15 yards; and I’m mostly plinking at 10 to 20 yards.

(note: at 20 yards, it’s down just over half an inch)

I am shooting H&N FTT .22 pellets at 14.66 grains;

I could get a bit more velocity with lighter pellets, but these are the most accurate ones.

I like how they “put the smackin'” on small targets…sends them flying.

You could pick up another 10 yards of useful range with a scope (I’ll attach a couple charts).

My R7 in .177 had a bit more range, and I was able to hunt squirrels with it, at modest range.

But I do like the .22 for plinking; I’m using a rear peep sight, and I like it.

[Williams peep sight (5D-AG, part No. 70809) from PyramydAir]

Yet I’m thinking of trying one of those UTG BugBuster scopes just for fun. =>

Hope this helps,

take it easy,

dave

P.S. In the attached charts, the left side is with my open sights, 0.75″ above the bore

The right side is with a scope at their default setting of 1.875″ above the bore.

from: http://www.airguns.net/trajectory.php

P.P.S. If the charts are hard to read, you can go to the website and punch in 470 fps for 14.66 grain .22 pellets.

Davemyster,

Thanks for the info! Very nice. I thought at those “lower velocities” the .177 would have a little more range. I’m very interested in peep sights too! I think most of the shooting world looks past them and they shouldn’t! Thanks again!

Doc

Doc,

Yes, my R7 was putting out 7.8 fpe, Beeman Silver Bear 7.1 g pellets at 705 fps,

while my current HW30S puts out 7.2 fpe, H&N FTT 14.66 g pellets at 470 fps.

I think you will be happy with either, though the .177 will have more usable range.

The nice thing about the peep sights is, since they sit closer to the bore,

sighting it at 15 yards puts the gun on target at 6 yards, too.

Hence, I can shoot in the house on my 5-meter range and aim dead on

at small targets like empty .22 hulls. =>

If you do get one, please do post a pic; thanks.

take care,

dave

Thanks for the suggestions, those guns are exactly what I would want if I decide to experience piston guns.

Unfortunately, money dictates I aim lower. The 2 guns I currently have cost me just over $300. Urban $200 + QB78S $110, so there’s no way I’m going to spend that much on a piston gun ‘just for the experience’. My ‘next to buy’ list starts with a chronograph, then includes the parts to convert my QB to HPA. But I do like the Umarex Forge, or maybe the Stoger A30 S2. Pyramids deal a day had the Benjamin Titan for $100, that would have been perfect except it was only the .22 and it didn’t have any sound suppression.

I hear you, man! I’m living on a tight budget at the moment.

My HW30S was actually a gift from my wife.

In fact, I told my wife that any time she is not sure what to get me,

like for Christmas, my birthday, our anniversary,

she should just get me a gift certificate to PyramydAir (and she does). =>

Yes, the Stoeger A30 S2 with the gas piston would be nice to try.

I bought the .22 Stoeger X20 S2 from PyamydAir for the sound suppression

(close by neighbors; my wife said she couldn’t hear it out front when I shot it in the backyard…cool).

It was a nice gun that put out 15 to 17 fpe, depending on which pellets I used.

I wound up gifting it to a friend who had squirrel issues and needed a quiet solution.

There are many cool guns from which to choose at PyramydAir; best of luck to you.

Funny you mention the X20, there is a lot more info out there about it than the A30. You’d think an X20 with a gas piston should be better than th

Funny you mention the X20, there is much more info out there than there is for the A30. I’d think the gas piston version would be better but sometimes ‘new and improved’ just isn’t as good as old and original. If I ever get the extra $150 I’d have a hard time picking between the X20 with lots of great reviews and the A30 with it’s technically better gas piston. I really like the idea of the Umarex Forge because it seems like a real mix of classic looks and desirable features. The picatiny rail is great, I’d like to avoid the, ‘wow! my scope just fell off’ part of piston guns. Then there is the suppressor, I live in a suburban neighborhood so I need to be as quiet as possible. Then of there is the nice wood stock. Unfortunately, there are not many reviews about it, I’d hate to buy a great looking gun that doesn’t shoot well. Oh well, I have plenty of time to think about it, I’m still saving for that chrony.

+1 for the R7 recommendations. It’s likely my favorite to shoot. A d34 is a nice one too after they settle down.

I’ve been eyeing the Diana 34 as a replacement to my RWS 45.

I’ve never shot one, but would like to try; thanks.

Dave,

I own a Diana RWS 34P in .22. This was my second break-barrel airgun purchased in the spring of 2013. My first was a Crosman Nitro Venom in .22 which is very powerful but I could not achieve the 1″ groups at 25 yards that I required. As it turned out, I could not achieve the goal of 1″ groups at 25 yards with my Diana 34 either. Several folks here in the blog tried to help me with shooting techniques. I kept posting and finally, Mr. Gaylord took pity on me and offered to test the Diana 34 for me. He installed a nice Vortek kit and a BKL scope mount. He demonstrated that my Diana 34P was able to shoot 10-shot groups of 1″ at 25 yards with the artillery hold and sent the rifle back to me.

I thought at this point I would be able to duplicate his results. But no, after practicing his recommended hold and the RWS Superdome pellets for several months, the best groups I could get were 1.5″ to 2″ at 25 yards. I needed to dispatch harassing sparrows from my bluebird’s nesting boxes at 25 to 35 yards and the Diana 34P was just not going to get the job done for me. I really gave the Diana every opportunity to perform for me, but finally I had to go a different route. Don’t get me wrong, the Diana RWS 34P is a very nice high quality airgun with an excellent trigger. Many reviews rave about it’s accuracy, but for some reason which I have never been able to determine, I am not able to shoot a break-barrel airgun accurately.

The answer for me was to buy a Gamo Urban PCP this spring with a cheap hand pump. I am able to shoot 1/2″ groups at 30 yards and my accuracy problems are a thing of the past. Break-barrels are so hold sensitive that they are difficult to shoot accurately. My Urban PCP is smooth, quiet, and very accurate with whatever hold is required to dispatch those pesky sparrows. My bluebirds fledged out two broods this spring and were very happy to not have to fight off the sparrows. I also dispatched about 20 starlings from my feeders as well. The Urban is just a great economical tool for pesting.

I have told this story several times here in the blog and continue to recommend the Urban for anyone who wants an economical tool that just works right out of the box. I’m done now 🙂

Geo

Dave,

Also, B.B. did a six part review of my Diana RWS 34P .22 here in the blog in June / Judy 2017. You probably followed that series as you are a regular blogger, but thought I would mention it just in case you, or any of the new bloggers, have not read it.

Mr. Gaylord:

You asked how hot does it get, in the BSA wilderness survival program, your first graphic (without the spring) is called a fire piston. Put a bit of tinder on the piston head and the heat of compression will produce an ember sufficent to start your campfire.

Boys of a certain age are still amazed when their adult leader can pull fire out of the air. A clear acrlic fire piston is also a useful tool to explain Boyle’s law and deisel ignition to older students.

Seems that all this science stuff just hangs together. Again, another good eduction blogg post today.

Yours,

William Schooley

Rifle Coach

Crew 357

Chelsea, MI

William,

Now I am being schooled. I was unaware of that and will look into it. Thank you!

B.B.

They are powered by magic!!

William

Ain’t that like rubbing to sticks together rapidly to make fire?

William, I start all my fires with flint and steel but I read about fire pistons,

and have been meaning to try one. Thanks for the reminder!

B.B., I love these types of posts; they are educational for the newcomers, and cause us old timers

to pause and re-think things. Keep ’em coming! Three parts, or even four, will be good. =>

Anybody ever see a pcp valve poppet stem managed by a cam lobe? Then we could measure ft lbs at “the crank”.

A la Ducati style? Those bike motors dont have hammer bounce, or a redline indicator on the tach, but they do have metal piston seals. The hammer spring would need to drive a geared mechanism rotating the lobe.Anyway

At what point in the piston seals travel does the pellet begin to move in the barrel B.B? Is there a difference between a long travel piston and short travel piston, swept volume, and the begining off the pellets movement? Is the same amount of air used between a spring system and hpa system the same for equal work?

Its allot easier to just shoot what came in the box. Have a nice day, R

1stblue

That’s the question I always ask. At what point does the pellet move in relation to piston movement.

Throw in variables like pellet fit and weight. Then when does the pellet move car mpared to other fits and wweight pellets.

Trainees, Tinkerers and Tuners

What a wonderful introduction. This talk of piston seals and hints of springs in springers reminds me of my power obsessed days with break barrels.

The critical piece overlooked by me and many is the compression tube. Out of round or leaking and you can chase peak performance with many different springs and seals without joy.

Kevin,

Yes, an out-of-round compression chamber will make grown men cry. Thanks for the reminder! 😉

B.B.

Especially with guns that use a cast iron ring.

Oh and thanks for keep reminding me your going to do the 50 yard Gauntlet test again after finding the shroud loose then tightening it. 😉

Have you actually done the test yet?

GF1,

No.

B.B.

BB

That’s what I figured. Tell ya what. No need to remind me anymore. I’ll just remind you if you don’t post about it. 😉

B.B.,

My biggest frustrations were with leaking compression tubes. Re-brazing or soldering isn’t a good option. Had a slavia that was stamped so hard with the factory markings that it created a leak through the compression tube. As you know, since new tubes are usually the only solution you’re often stuck with a gun that will never shoot to spec no matter what seals and springs you try.

My long story made short. If you want to be a happy airgunner leave your chrony in the closet since ignorance is truly bliss. 🙂

Thought I would post this today. A bit off subject but transfering air related.

I found that with my tethered regulated pcp bottles and pcp’s that a bit of wait time between shots matter with how well the guns group.

Definitely better groups even in windy conditions if I give the gun about 30 seconds between shots.

I think it let’s the guns air resivoir stabilize to the tetherd regulated bottles pressure. All I know is it’s working really well this way.

Halfstep maybe this relates to your Diana chaser tests. Stabilizing the valve is what I’m talking about.

GF1,

My guess is that the waight time is allowing for temperature stabilization that results in air pressure, air volume and air mass equalization petween shots. With that system you have a lot of expansion/cooling and compression/heating. The amount of air in each reservoir is controlled by both temperature and pressure. Lower temperature means more air, higher pressure means more air.

Some rapid fire shots over a chrony might be interesting with the tethered-regulated gun. Don’t hit the chrony.

Don

Don

I think the same thing. Takes time to fully equalize. But it sure made a difference in group size by waiting. And that’s with my Maximus, Condor SS and the Gauntlet.

And I do have my WildFire tethered. So that would be a good gun to test over the chrony to see if velocity’s change from fast firing or slow firing. I can’t tell when I’m plinking. And haven’t target practiced with it tethered yet to see if it affects accuracy by fast or slow firing. I will have to try that this weekend.

GF1,

I think there is some similar stuff going on in the chaser, but the CO2 vaporizing and the valve and barrel temperature normalizing also throws in a few additional dynamics.

When BB last tested the Fortitude it was speculated by some that waiting gave the small space between the regulator and the valve a chance to get stable before the shot. Are you suggesting that a larger area between the regulator and the valve benefits from a small wait, as well? I may not have a good understanding of how your gun is set up.

Half

Halfstep

Read my comment above to Benji-Don.

But yep I believe that it takes a bit for the pressure to equalize between shots with a regulated gun.

BB

You got .30 caliber JSB pellets for that .30 caliber Hatsan break barrel you were testing.

Can you measure some head diameters so we know actually what size they are?

Now I’m curious after the talk above and what green mountain has available in barrels up to .357 caliber for the Condors and Escape.

For sure looking for more info now the deeper I’m digging. ???

DanLK,

If you see this,… thank you for the reply on the WP of schedule 40 pipe. I have a Mc Master Carr catalog and they are pretty good about listing stuff like that,…. but I had yet to look. Sounds like a definite no-go as I am looking to go 4,500 psi.

Chris

Chris USA,

DAQhas various length and diameter pressure rated tubing for sale on his site’s (Airgun Table) section.

He may still have something that will work. He might even be willing to thread it etc.

Give him a call.

shootski

Shootski,

Thanks. I will add that to my list of options.

Chris

B.B.,

On .25 pellets,…. when would you see more options coming out? Like the .177 and .22,.. how long does it take? Is it based on industry sales and the (perception) of a “potential” market? .25 seems pretty common now and .30 and above are the odd ducks.

You have been around the block enough to have a “feel” for things like this. I just thought that you may have an opinion on the matter.

Chris

Chris,

As a part of your research i would suggest you contact Joe Brancato he can be found here, http://experthpa.com/cart/cart.php?m=cart_home&pageNumber=&catID=&c=&v=&r=&id=&sortBy=PriceLoHi&search=&shopByPrice=&viewAll=&customListIds=&venID=

Two products he sells are here, http://experthpa.com/cart/cart.php?m=product_detail&p=233 and here, http://experthpa.com/cart/cart.php?m=product_detail&p=79

You may already know of this information but he may be able to help you in your quest to build a high pressure filter, it’s not rocket science but it is something to look into deeply before you begin. I am sure you know that, just looking out for the safety factor.

Mike

I recently traded into a diana model 24 that turned out to be shooting way low when I recieved it( several blog readers helped me figure out at least part of the issue there) turns out it was bone dry internally and a few drops of balistol through the transfer port and a little bit more on the piston body had it shooting generally to point of aim at close range. I now have a couple more questions namely is it likely that the piston seal is worn out? It looked ok to me when I took it apart but the fact that it only seemed to seal with oil added is concerning me. Also i have been told that the model 24 is rated at 575 fps in .177 is that a reasonable number to expect? I know that some companies inflate velocity numbers by using ultralight alloy pellets while others, weihrauch comes to mind ,seem to be conservative with factory velocity figures. Where does diana fall on that spectrum? Should I expect much lower velocity with a standard lead pellet like JSB exacts out of the diana? I dont currently own a chrony but this project might just prompt me to buy one and it would be good to know what would be a normal result for this gun and what would be an indication of a further mechanical issue?