This report covers:

- Start

- So what?

- The Benjamin Discovery

- What happened

- So what? number two

- The electronic PCP valve

- Not finished

- Discussion

- People

Today we look at the mysterious world of airgun design. Last Friday reader Bob M. commented, “I wonder what the education and training requirements are for airgun design and manufacturing jobs?”

I answered him, “Training for jobs in the airgun industry? Not so much.” But what his question triggered was a firestorm of thoughts in my head about all I have seen regarding this very subject over the decades. I just had to address it for you today!

There are no schools for airgun design. It’s too small and narrow a field. But mechanical engineering is a great start. I told Bob that the various airgun companies do not share their secrets. So there are no books. But their products are simple enough that just looking at them tells a lot.

Start

I’ll begin this report with something I heard back in the 1990s when I was writing The Airgun Letter. A guy who was a few years from retirement told me he thought he might like to dabble in airguns after he left his current full-time job. I told him it would be easier to just put all his money in a big pile and set fire to it now, because he was going to lose his shirt.

Let me contrast that with something that actually happened. John McCaslin, the owner and founder of AirForce Airguns had a full-time job with the federal government. It involved law enforcement though he wasn’t actually a cop. He had an idea for an air rifle he wanted to see and he turned his garage into a small machine shop just to build it. The 12X36 South Bend lathe he purchased new then is today in need of an overhaul from use. When he talked to a friend who lives in the UK about his desire, that friend brought to the SHOT Show an airgun he was selling to show John what was possible.

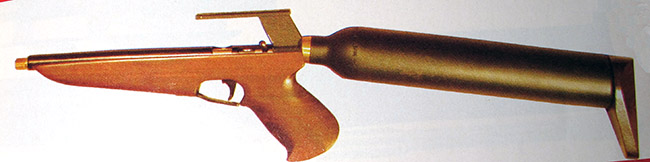

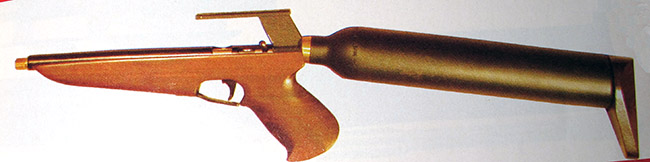

The airgun Geoff Darvill showed to John McCaslin at the SHOT Show. It was powered by CO2.

When John saw the gun he said, “I could do better than that!” to which his friend challenged him to try. The result was the rifle that became the AirForce Talon.

John went on building airguns for several years while holding down his day job. Eventually the sales became so brisk that he had to hire full-time employees and he only came to the shop after work. Yours truly was one of those early employees. And, as they say, the rest is history that has played out in front of our eyes. The Chinese and Koreans have tried to knock off John’s designs but they haven’t succeeded. But the Chinese have made a plastic toy Condor. They say that imitation is the sincerest form of flattery, but I don’t know how flattered John feels.

John is retired from the government now, but he still works 70-90 hours each week, running the company that he started on a dare. That’s not “dabbling” folks. That’s commitment! Oh, and Bob, John’s formal training? He trained as an accountant!

So what?

Here’s what. John McCaslin demonstrated that a straight flow-through of compressed air is more efficient than making air turn 180 degrees (coming back through a firing valve then up into the breech where it turns 90 degrees to push the pellet down the bore). He demonstrated that power can be controlled by regulating the tension on the striker spring that hits the striker to open the firing valve. Make it right and you get an air rifle with power that’s user-adjustable. Many of you forget that the Talon was the first airgun to do this. The Koreans jumped on it a few years later but the Talon was first. He demonstrated that controlling the size of the orifice through which the compressed air passes is an ideal way of controlling power. He demonstrated that 3000 psi is all the air pressure that’s needed to generate extreme power.

These airgun design attributes are all attributable to John McCaslin and I’m just hitting the highlights. There are things in the works that I cannot mention that will change the future of airguns. Or, you could just copy an existing design, give it a way-cool tactical name and hope the orders come rolling in.

The Benjamin Discovery

In 2006 I proposed to Crosman that they build their own precharged pneumatic (PCP) air rifles in New York, rather than importing guns from the UK with their name on them. I proposed that they build sporting PCPs that were only filled to 1,800 psi and that they sell high pressure hand pumps with them. They were curious and invited me to their plant near Rochester, to discuss my ideas. I took several mocked-up proof of concept items to demonstrate my ideas.

Lest anyone think I thought of this myself, I got the idea from Tim McMurray and Larry Durham, whose USFT rifle worked this way and was filled to even lower pressure while achieving over 900 f.p.s. with H&N Baracuda pellets. In other words I used what they had done to advance the sporting air rifle world because their guns were strictly for competition.

The USFT rifle is for competition, only.

What happened

When I arrived at Crosman I was surprised to learn that their engineer, Ed Schultz, had already built two prototype rifles, a .177 and a .22, to test my hypothesis. Of course I knew it wasn’t a hypothesis because I had seen the USFT in action. But Ed, and also the management at Crosman, was shocked to learn that an air rifle that was filled to only 2,000 psi (yeah, Ed changed my spec, but who cares?) could be just as powerful as one filled to 3,000 psi. Ed built the prototypes in a couple days from Crosman 2260 CO2 rifles.

The vice president of sales told Ed the .177 rifle had to get up to 1,000 f.p.s. which in his world was the magic number for generating sales. Ed got his prototype .177 up to the mid-900s in just three days of fiddling and he knew he could top 1,000 f.p.s. without a problem. And the rest, as they say, is history.

My ideas didn’t stop there. I wanted the gun that was to become the Benjamin Discovery to be sold in a box that also contained pellets, a hand pump, and a manual that explained how PCPs work in general as well as how this one worked specifically. And I wanted the price for the entire kit to be $250 out the door. We didn’t quite get to that price but we came close.

So what? number two

So — the sub 3,000 psi fill was “born.” It was of course really brought into being by Mac-1, but by moving it over into the low-cost sporting airgun world more people knew about it. And that isn’t all.

In 2017 Umarex brought out the Gauntlet PCP at a retail of less than $300, starting the price-point PCP race. My dream of affordable PCPs was finally realized. And look at what has happened there!

The electronic PCP valve

As far as I know, Daystate was the first company to use a computer-controlled solenoid to open and close the firing valve on their air rifles. But Lloyd Sykes was the first one to do it and let the user adjust the program. Unfortunately his invention was put into the Benjamin Rogue, a committee-designed big bore air rifle that looked like the offspring of a battle rifle and a coffeemaker. It sold about that well, too. Unfortunately while the train was being derailed in 2010 BB was in the hospital for 3-1/2 months with pancreatitis.

The Rogue was a brilliant concept that was executed poorly. In a way it was similar to the 1903 Springfield that the U.S. Army adopted and then ordered the magazine cutoff switch to be thrown in combat so the troops had to shoot single shot and not waste ammunition. That makes sense — right? I mean, if there is a water shortage we want to be sure to place limits on our firefighters because if we don’t they’ll just spray water all over the place!

Not finished

What about springers? What makes them work best? Well, the Springman, Jim Maccari, told us that loose tolerances in the powerplant were the cause of vibration and losing power. Then British airgun genius, Ivan Hancock, brought out the Mag-80 Laza kit for the Weihrauch HW 80/Beeman R1. By buttoning the piston and reducing tolerances within the spring piston powerplant, plus using a thick grease that I dubbed Black Tar in The Airgun Letter, he boosted my .22-caliber Beeman R1’s power while making it absolutely vibration free.

Ivan also gave us the Venom Mach II (the progenitor of the TX200?). And then Air Arms followed on with the TX200 Marks I, II and III.

And, guess what? Sig also got it right with the ASP20 breakbarrel rifle, but they left the building before very long. Oh, and remember who was one of the three engineers on the ASP20? That’s right — Ed Schultz!

Discussion

So, Bob, there both is and is not a lot known about airgun design. The sharp folks know how to glean the information by looking at what works. The others know the phone number and email address of their counterpart in China where their company’s airguns are made. And that, ladies and gentlemen, was what I tried to drag out of you last Friday!

People

The answer I was hoping to see in the comments to last Friday’s report was PEOPLE. It’s people who make the difference in airguns, automobiles and any other manufactured item you care to name. I thought by mentioning Ed Schultz twice in that report and by mentioning the cronyism between the hypothetical marketing VP and her lawyer friend/college roommate, you would realize that having the right people in a company makes all the difference in the world. Readers shootski and fish came SO CLOSE to getting it! In fact, I think they got it and just didn’t say it that way.

College degrees and education in general are meaningless unless the people who have them are motivated to give the job their best. People are not plug-compatible and interchangeable, just because you give them a job title. And that, Bob M. and everybody else, is the answer to how airguns are designed.

My wife, Edith had a business degree. She loved alternative medicine. She wrote Dr. Atkins’ (the diet doctor) monthly newsletter. But when I taught her how to shoot with my Sheridan Blue Streak she developed an affinity for airguns. It began as a way to eliminate mice in the house. It ended with her writing and editing the descriptions for all the products on this website.

It’s people, not education or training. People.

Indeed it’s true that people are the key to success. However, it’s the ability of people to COMMUNICATE what they know that is invaluable. A fine idea individual, sitting at his desk drawing up his plans for the world’s finest airgun is of diminished value unless those ideas are communicated to other’s on the manufacturing team. The answer my friend, is PEOPLE COMMUNICATING. Orv.

Well, I never! 🙂

If “people”, as in the right people, are so important to design, then there must be an awful lot of other people involved. 🙁

———

By the way, what a sad sentence, so sad, I don’t know what else to say but to repeat it:

“There are things in the works that I cannot mention that will change the future of airguns.”

🙁

hihihi

Indeed it leaves a very sad feeling when friends don’t share their knowledge with the rest of us…

LOL! You and Bill will just have to wait with the rest of us! BB over the years has been entrusted with many secrets. He may from time to time tantilize us, but will never reveal THE secret. That is why he is entrusted with them.

I too am very curious concerning what is in the works. I remember when the Talon was brand new. I had an inkling of the Texan from John McCaslin shortly after the Condor came to market. I own one of John’s Texan LSS with CF tank. It is awesome. I just hope it does not take as long this time.

Over the years I have had the honor and privilege of meeting and/or talking with many of the movers and shakers of the modern airgun world. The vast amount of knowledge contained in their heads is incredible. If you pay real close attention here, you will have insights into most of it. 😉

RR,

Thanks for that. You are correct about being entrusted with secrets. That’s why people trust me with them.

As far as the length of time before we see them, that’s impossible to say. One of these things will be something that’s never been done, yet ten minutes after everyone knows about it, it will be old business.

BB

RidgeRunner, I am not interested in secrets, you see, to me, secrets are nothings while they’re secret. 🙂

But I feel sadness at the need (!) for secrecy. 🙁

BB,

You failed to mention that the very old PCPs operated on 600-1000 PSI and were capable of bringing down big game and were also weapons of war.

I know, how much can you cram into a day’s blurb?

RR,

I came very close to mentioning Gary Barnes’ .25-caliber Outside Lock that ran on 800 psi and developed 28 foot-pounds of energy.

/blog/2015/11/the-magic-of-the-outside-lock-part-2/

BB

Tom and RR,

About 30 PCPs (OK, a few are CO2) from the 1700s and 1800s are in Rock Island Auction’s May 19th – May 21st auction. A bunch, including a pistol, are Girandoni patterns.

Michael

BB,

I got it – but at corporate level. You were actually thinking at entrepreneur level. And you were right; even in a corporate environment, isn’t every air rifle a new venture itself? Still, it’s hard to find the passion of an entrepreneur in the cubicals of corporates. And the problem with the entrepreneurs is oftentimes they get too passionate to stop before it’s too late. If that passion is balanced with a good exit strategy, then the risk is at minimum. Management is science after all.

I have an MBA. These last two reports can be thought as a case study at an AACSB accredited Business course.

Fish

Fish,

Yes, it does sound like I’m speaking at the entrepreneurial level, but I have seen this work at the corporate level as well. It goes back to what we have learned from W. Edwards Deming and Joseph Juran about management styles.

Motorola’s Six Sigma program angered many employees, but I contend they are the very employees who were just there for a job. Get the right people and you start handing out diamond-studded gold belt buckles like Motorola did in Six Sigma to the ones on the team.

BB

BB,

I’m a believer of entrepreneurship and the excitement of the starting of a new business venture. New ideas, inventions, and passion. The passion never happens in corporate level new ventures though. Trends like Six Sigma are almost always toxic. They will suck the passion and joy of life out of people and turn them into slaves. Only the extroverts are rewarded. And many good inventors are introverts – oftentimes. A true entrepreneur should leave that toxic environment and start his own business. Nowadays, kids with good ideas are competing with each other to find well paying jobs at big corporations. Their dream is to work hard to realize someone else’s dream. I have so much respect to those small businesses that start in garages. Unlike corporations, they have more than just profit in their minds. The science of management helps such small businesses as well. And that portion was what I concentrated my studies on. The science behind a solid business plan can achieve any goal from scratch. This country was built on such entrepreneurship after all, not landing on a corporate position with a fancy title. There is nothing American at jumping high for a diamond-studded gold belt buckle. Perhaps, that kind of toxicity is why we are shooting Chinese air rifles these days.

Fish

Fish,

I see where you are coming from and unfortunately the tendency toward toxic environments is more evident in larger organizations but how do you account for the small organization or even in families/tribes?

I have found that the toxic environments are traceable to individuals in almost each case study. I have seen the Change of Command on large ships (mostly in Aircraft Carriers) that have changed a ships well functioning culture, a self organizing entity, to one where the Captain has tried to take total control resulting in at best near nothing getting done to at worst cases of active sabotage.

My personal view of most organizations is that approximately 80% of the people do their tasks the other 20% are divided between those who advertently cause failures and the 10% who are trying to plug all the leaks. The task of the leadership is to find the leadership problem people and retrain them or get rid of them after appropriate efforts to remediate their knowledge or inappropriate attitudes. If leadership accomplishes at least some of their primary task the top 10% are freed to get on with progress and improvements that benefit everyone in the organization.

Have seen it happen, both ways, in the real World and many times.

shootski

Military is completely different than civilian organizations. Not a good idea to compare.

There are different organizational behaviour approaches for different fields. Sometimes you need to manage a chaos, sometimes a drudgery job, or sometimes an innovative dynamic. All are different, but there is a science behind them. Success is seldom luck.

It’s management’s fault if there is no passion in any new business venture. It was a good management decision to hire BB and make his vision come true. But under bad management, he wouldn’t have been successful. It’s not the people only actually; in the end, it comes to the management. It’s management’s job to keep the passion alive, find the right people for the job – the folks who BB talks about – and keep them motivated.

In a small venture, it’s the founder’s passion. In a corporation, it’s the management.

In a toxic organizational culture, which corporations tend to turn into one in time, it wouldn’t matter if you have the right people. Even the brighest folks would be miserable in that atmosphere. I was just making a point. Of course, there are many well managed corporations, and plenty of toxic entrepreneurs. Oh, and there are many, many failures among entrepreneurs as well. It’s all about how you manage. The management really makes the difference in a new venture at the end of the day.

Phew, I had to edit that a lot. 🙂

Fish,

Lest we forget, management is made up of people, too!

BB

BB,

But management in corporate environment doesn’t have to be made up of the people you’ve described today. Anybody can become a good manager with education / training and experience. After that he gains the merits to manage. If the people whom you’ve described are brought to the right positions, working happily, and unleashing successful new business ventures, it means that there is a good management somewhere up there. Otherwise, such organizations quickly become toxic.

If a product is low quality or unsuccessful or unprofitable, just replace the management and leave the rest of the team as is; the problems will more than likely be fixed. Sometimes just the CEO is the problem.

You are spot-on for the entrepreneurship; I’m taking about large corporations.

Fish

I aver to much of what you say. I left the parish ministry full time to go to work for the State of Ohio. I worked in our state veterans home providing alcohol and drug counseling and social services. I went from being, essentially, a small business entrepreneur, to a technical service “wonk.” THEN came computerization and the mandating of an electronic medical record. [Play the Darth Vadar March theme here.]

The team I worked on was very small and had bright and ADVENTUROUS people who were innovative and not afraid to take a chance and be wrong. Our unit had a client population with lots of issues – far more than those in the larger side of the home that were largely medical. Our clients had LOTS of personal behavioral issues that could vex and try the patience of us from time to time.

We explored the initial computer E-med record and learned to use it while the rest of the organization continued, as I used to put it “with octopus’ ink and papyri” – resistant to change in work and thinking. In cross over clients, we would sometimes have to provide services in the big unit and would be accused of “not making clinical notes in the record” when we had made E-notes in the E-med record. They big team members would deny that the E-med record was a valid record (which it most DEFINITELY WAS!) so we would, at first, return to the other side of the house and scribble a not with pen, but later would print our E-notes and stick it in their charts (which, deviously, would mess up their pagination, i.e., subtle revenge).

We developed more and more electronic tools as time went by that met VA requirements and their standards by which we were annually evaluated. Resident care standards and evaluation criteria were imposed on our practice for our clients and measured and recorded electronically. We worked efficiently and hard but not stupidly or mindlessly. All of this was ENCOURAGED AND PROVOKED by our first boss, an old school RN who was always prompting and encouraging innovation and thoroughness and NOT afraid to experience the inevitable train wreck or blind alley.

We also learned to confuse upper management by ADMITTING when things “blew up” and accept responsibility – something rarely done in the bureaucracy of a state agency. Such a novel concept! The managerial “politicians” don’t know what to do with honesty because it doesn’t fit the Byzantine games that often were played.

We had no choice but to be extremely efficient, and the computer was the way to manage huge amounts of data quickly, legibly and efficiently. We could all type and fill in assessment forms faster than we could write with pen on paper. That, then, allowed us MORE TIME with our clients in interviews, less time with the record and more time with the client! What a concept! Indeed, we brazenly would turn our screens so that the clients could see them and participate in the interview data capture and that built trust – they knew what we wrote since they saw it.

I retired ten years ago this past New Year’s Eve. I was told last fall that the VA, in the annual review, was markedly impressed with the Level Of Care computerized assessment tool the teams used to measure resident status. They wondered who built it. They were told that a long-retired team member made it (me!). Actually, it was made by the inputs of an entire small team of people who cared for what they were doing for our clients, who had supervision that was motivated to do the most with whatever resources we had, AND who were not afraid to be innovative and bold in moving FORWARD.

I am mindful of Edison, whose hometown if just a few miles from me in Milan, Ohio. Edison didn’t invent the incandescent light, but his team, through innovation, hard work and desire to improve things made that light possible on a large scale. Now, Thomas also had his dark side about AC vs. DC current, but successful teams need leadership that encourages innovation and risk-taking and creativity in their people. They are THE SERVANTS OF THE WORKERS; they lead from front and back and know which is which. Most importantly, information is SHARED and that promotes GROWTH of the whole team.

In the end, the tech aspects can be dealt with by people who have particular knowledge bases, what matters more is a management team and personnel who are able to encourage all their members to enjoy the challenge of being the best there is at what they and the institution are doing. And a good sense of humor and humility never hurts!

A good read. TY.

I don’t know much about non-profit world.

Shootski.

Totally agree with you. The two best squadrons I had the privilege of serving with were pretty much void of upper management, Officers. And those that were present were Warrant Officers (Prior enlisted men)

In one they were in a different location away from the flightline and the other they were Reservists who only showed up occasionally and it was usually just to fly. Even the Commanding Officer and XO. An acting O in C held down the fort. I was the Squadron Duty Officer as an E6 after normal hours when I had duty that day.

Someone getting promoted to CPO or a new person transferred in were the only occasional fly in the ointment till they figured out how thing worked, settled in or got over trying to prove themself worthy by showing everyone how to rule the world properly.

Same in the civilian world. I ran San Diego, and my boss was in LA. We had a 99.9% reliability with Hawaiian Airlines being on time, best in the industry, and about the same for Airborne… Older aircraft.

The people doing the work had it all figured out and made it work. Not much needed in the way of leadership with responsible, happy people doing the job.

Speaking of which aircraft technicians are nothing like backyard car mechanics as in the old TV show Wings. We occasionally have to remind pilots how the aircraft actually works. But never Navy pilots, no, they knew everything.

Bob M,

“We occasionally have to remind pilots how the aircraft actually works. But never Navy pilots, no, they knew everything.”

Lol!

Some of us tried to know as much as we could squeeze into our pea brains…i must admit it was difficult what with those big watches always hitting us in the head everytime we needed to scratch our heads about some new to us glitch!

My first Chief taught me that the best Order is the one you never need to give in the first place.

shootski

B.B.

Bob M. asked, ““I wonder what the education and training requirements are for airgun design and manufacturing jobs?”

Please inform us what education and training that YOU had that made AirForce hire you in the first place?

Was it just extreme interest?

Most mechanically inclined guys that I know started as kids taking lawn mover engines apart…

-Yogi

Yogi,

I was hired for EXACTLY the reason I mentioned in this report. I have a bachelor’s of science in liberal sciences, with an emphasis in psychology. And I had just published 99 issues of “The Airgun Letter” plus 3 bi-monthly issues of “American Airgunner”.

It was extreme interest, plus a track record of doing what I wrote about.

As for lawnmowers — keep me far away from them. I break them by laying hands on them!

BB

BB

So, you didn’t know what you wanted to be when you grew up? An enabler perhaps? 🙂

Thank you for answering my question. I’m sure we all have a better idea of what kind of magic goes on behind the curtain now…. Just not what to expect!

Using stackable slugs in a detachable mag would be a nice innovation. So would a detachable drum for that matter. A mini–Rail Gun? 🙂

If I had to go into the armed service, as in drafted, I was for sure going to try to get some sort of training and experience for a civilian trade out of it and I sure did.

I once asked an ex-serviceman working in the post office, why on earth would he or anyone volunteer for EOD disposal. Was he planning to get a job with the post office in letter bomb disposal?

“I was all gun-ho after 911 and was not planning to stay in long”. He also got what he wished for but not the way he expected. He was now disabled as a result of his job in the military. And I felt like a jerk for asking when I found out and thanked him for his service.

Thanks Bob M!

I’ve got a headache now, just from questioning the different meanings of:

being disabled,

able

and enabled… 🙂

3hi

Exploding bombs had resulted in him loosing part of his ability to function as a normal human for the rest of his life. Unfortunately, I do not recall the exact condition he is in or any specific problems he has. Just that he was discharged from the military for medical reasons and is receiving financial compensation for his injuries.

My biggest concern was to avoid being blown overboard in the middle of the ocean by some jets exhaust, being sucked into a jet engines air intake or walking into the arc of a spinning propeller. Especially in the dark. Never mind all the moving aircraft and equipment being driven around the flight deck during flight operations that could run you over if you turn the wrong way.

But most of the time it was trying to survive a hangover when on shore. The rest and relaxation could be hazardous to your health as well, being in unfamiliar foreign countries. But someone had to do it. A lot of local businesses depended on us! 😉

“It’s people who make the difference in airguns, automobiles and any other manufactured item you care to name.”

B.B.,

Aha!…now that I see that sentence and contemplate it, it becomes so obvious. 😉

Thank you for another interesting and educational report. 🙂

Blessings to you,

dave

I thought I surely was pointing to the people (and their skills) in my comments, albeit, I didn’t reply with just “the people.”

It is always the people—even large corporations give this lip service, “People are our most important asset.”

BB

Glad John took the challenge. Glad you worked there and glad you got Crosman in gear.

Wonder what directions things would have switched to if those events didn’t occur.

People are important reminds me of…

I heard from an employee of a relatively large company that, on their shop floor, there are multiple in-house letter boxes for workers to post their ideas.

If the evaluation department (this really isn’t a small company) finds the idea to have merit, it is implemented and the worker is paid whatever difference this makes to the company over the first whole year.

I was amazed when I heard this! 🙂

Personally, I cannot imagine what it must be like to work where management listens to what a blue collar ant has to say… 🙂

I work for a VERY large company and any idea which has had merit was “already being drawn up” at the “home office”.

There should be an emoji for sarcasm as some miss it if it is subtle.

Ed

I rarely (never) use an emoji but as for sarcasm, I’m full of it.

FM’s late father-in-law was a brilliant man from Hickory, NC and from a farm family. He was a self-taught electrical and mechanical engineer who went to work for Western Electric after WWII. He did not have a college or technical school degree but he was blessed with a lot of common sense and the ability to learn just about anything thrown at him being a very fast learner who could fix whatever he decided he would learn to fix. Those abilities are gifts. Sadly, because of his lack of a formal degree, as the Mrs. said, “he was always paid less than the degreed guys with little or no experience and who knew a heck of a lot less than my father.”

Bet if he’d been alive when his far less able yet college-degreed son-in-law decided to dabble in airguns again, he would have come up with ways to improve both the form and the function of the piece. Wish FM could have soaked up more of that knowledge and skill before his fondness for cigarettes took him away too soon.

BB,

Interesting topic.

Recently, Jay Leno was taking a drive in a Bricklin SV-1, owned by Jeff Dunham. If I remember right, it was made in Canada for only two years. One of the problems that they noted was that it was built by people who were just holding down a job, with little knowledge of car construction/manufacturing, using parts brought in from outside. The other was that people were unwilling to buy a new car that had a lot of squeaks and other flaws.

And shootski, the 80% & 20% figure that you quoted sounds an awful lot like the figures in the quality control classes that I took (pareto analasys?).

We’re human, and for good or bad, it always comes down to people!

Bill

Billj,

I first learned it as the: Law of the Vital few and the Trivial many.

An example of which is when we had Special Forces in a Country and everything goes well because we have such a small footprint and very low logistical budget. Then somebody decides to get promoted/(re)elected by dumping many Regulars into the country and the Special Forces wind-up doing perimeter security and rescue missions!

I did study Pareto’s work directly in some Program Managers classes.

shootski