Chronograph tips

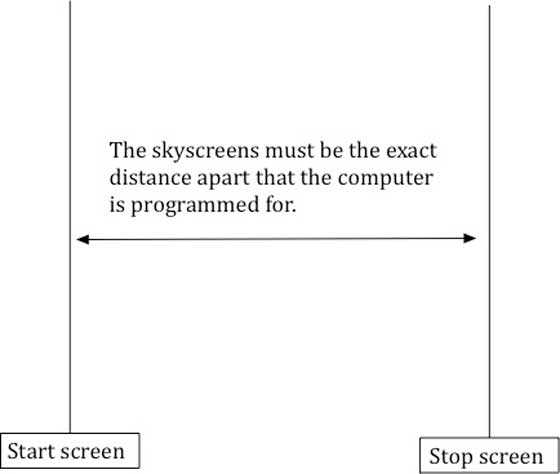

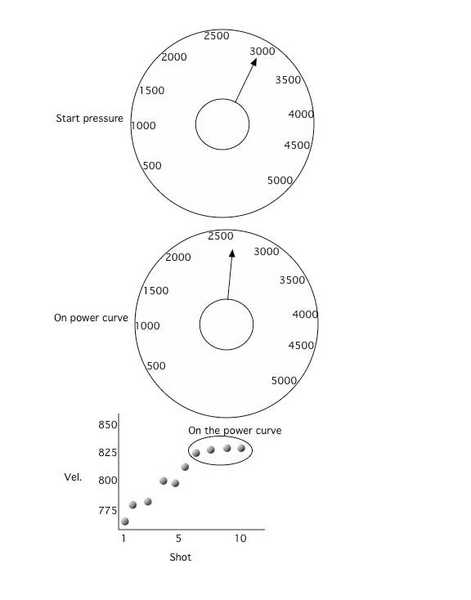

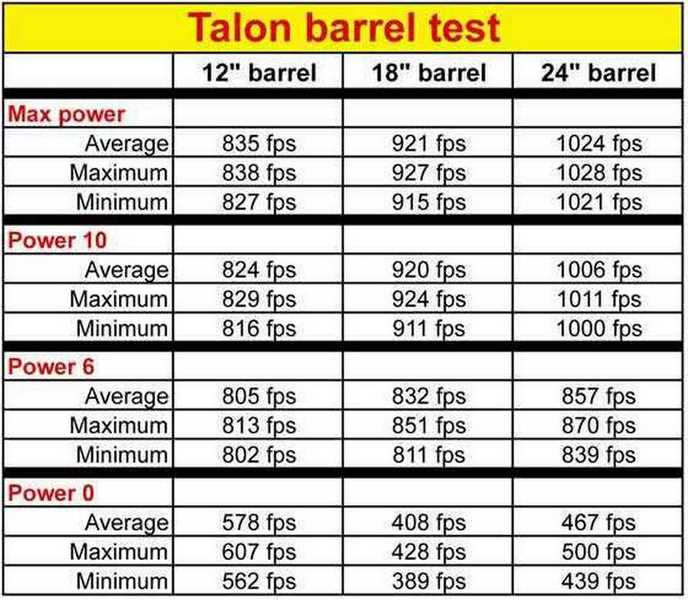

by Tom Gaylord Writing as B.B. Pelletier This report covers: How it works The evolution of the personal chronograph The advent of the skyscreen Advantages of skyscreens Fly in the ointment Screen placement problem one Screen placement problem two Shooting perpendicular to the skyscreens Lighting Odd chrony info Summary Reader Buldawg asked for this report, … Read more