by B.B. Pelletier

This TS-45 rifle is probably at least 30 years old, yet also brand new.

At every airgun show there’s always one or two special things that show up. At the 2012 Arkansas show this year, one of those things was a pile of new-old-stock Chinese TS-45 sidelever air rifles. Randy Mitchell had found a pallet of these vintage guns and was selling them for $20! Now, I’m as cheap as any airgunner, but a twenty-dollar spring rifle in new condition is more than even my frugal nature can ignore.

Yes, we’ve already looked at the TS-45 in this blog. Most recently, Vince gave us a look at two slightly different variations of that model — one of which was a rifle I bought at the Little Rock airgun expo many years ago from the late Paul Landrith, a well-known airgun repairman from Arlington, Texas. It was about 15 years ago, and Paul had several TS-45s on his table.

I was writing The Airgun Letter at the time and bought most of the airguns that I tested. I’d stayed away from the Chinese springers as long as I could, but the insistent battle cry of, “Real wood and steel for just a few dollars” finally overcame my resistance, so I started testing them. I did it mostly to poke my fingers in the eyes of everyone who had asked me to test Chinese airguns; but the more I ranted about their obvious shortcomings, the more my readers agreed with me. “Yes, they’re horrible! Don’t you just love them?” It was like attending a convention of bathtub Saab 96 owners. “They’re not supposed to start every time!”

Back to my story, I was at Malvern and saw a rack of TS-45s and immediately thought of Paul Landrith and the old Little Rock show so many years before. Paul warned me that the gun I bought from him was one of those that had amputated a few thumbs during loading, and I was never to trust the anti-beartrap mechanism. Always restrain the sidelever positively, he made me promise before selling the rifle. I always did. When I sent it to Vince, I told him the same thing.

Randy Mitchell was selling piles of these new-old-stock TS-45 sidelevers at the Arkansas airgun show.

And here was another cache of new-old-stock TS-45s, at the show that succeeded the Little Rock show. The clincher came when Randy Mitchel said to me, “These rifles remind me of Paul Landrith!” Apparently, there are many airgunners who dealt with the kindly man and remember him fondly.

So, I bought the gun, more as a reminder of the past than as an airgun project. But after examining my new-old rifle and comparing it to the two in Vince’s report, I see that this is a third variation. It resembles Vince’s beloved “Pointy” more than the other rifle he also tested, but it has small differences. What the heck; this one might shoot as well as Pointy, too, and then wouldn’t I be happy?

The rifle I’m testing for you is a .177-caliber sidelever spring-piston air rifle. From comparison with Vince’s rifle, I would have to say this one might be the earlier model — or as Vince guesses, another one made for export. Since the only writing visible on this rifle says MADE IN CHINA, plus the numbers on the rear sight, I’m inclined to go with the export-model theory. This rifle lacks any Chinese characters or the mountain logo found on the other two rifles on which Vince reported.

Randy has stripped this rifle and lubricated it with the correct grease. He also removed the anti-beartrap device parts from some of the actions, and I got to choose if I wanted them in the gun I bought. Since they’re notorious for failing, I elected to get the rifle without the anti-beartrap, and I’ll be restraining the cocking lever every time I load. That’s how I always did it with my other TS-45, and that’s what I advise all owners to do, as well.

To safely restrain the sidelever during cocking, tuck the sidelever behind your arm, as shown in the photo below. Never put your fingers into the loading port unless the sidelever is restrained this way. If the gun were to slip off safety, the lever would smack into your arm. It would hurt, but your arm would stop it from allowing the sliding compression chamber to cut off your fingers.

The sidelever is safely restrained by my right arm. My right thumb is loading a pellet into the breech. If the sear slips, my arm will stop the lever and the sliding compression chamber from closing on my thumb.

WARNING

The TS-45 is a vintage airgun made in China and does not have the same safety mechanisms found in similar spring-piston air rifles made today. If you fail to restrain the cocking sidelever while loading, as the photo shows, the gun can slip off its sear and send the sliding compression chamber forward with enough force to amputate your fingers during loading. This is a known fault of these rifles that’s easily addressed by this safe loading procedure.

I know that most of our readers are careful shooters who pay attention to warnings like this, but I’ve also witnessed enough people who act before thinking. I feel it’s necessary to emphasize this warning. It’s the same kind of warning as not loading a muzzleloading rifle with the muzzle pointing at your head. It makes perfect sense; and if you follow it, you won’t have a bad accident. But there is danger, and you need to be informed.

The rifle

This is a single-shot rifle that’s a whisker shy of 40 inches long. It weighs 7 lbs. on the nose. The barrel is 18 inches long and is fixed in the frame. The pull (length from the center of the butt to the center of the trigger blade) is 12-5/8 inches, which is short for an adult.

The metal has not been finished in any detectible way beyond tumbling with a black oxide finish, so the least critical description is a matte black finish. But there are a couple scuffs and scrapes that show this rifle in no way received any special handling at the factory. The finish is 100 percent, however, as befits a new gun, though not all Chinese airguns of this era have that.

The stock is a single piece of blond pallet-grade hardwood. It has been shaped on an industrial sander and has a smooth outer surface that’s covered with a clear synthetic finish. The internal inletting was done by a rabid beaver and resembles the rough sort of folk carving an Appalachian woodsman might do with a dull hatchet. The butt is protected by a blackened steel plate that’s larger than the wood and is one of just two metal parts on the gun that have a smooth finish. Apparently, the punch press is kept fairly clean of metal chips. The other shiny part is the end cap that houses the sidelever pivot point. It shows signs of being hand-finished.

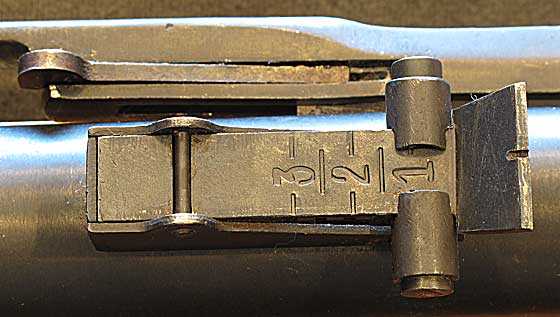

The sights are a hooded round post in the front and a rear ramp that’s adjustable for elevation, only. It has the button lock that Vince likes on his Pointy rifle, but the rear notch is laid back unlike any other other TS-45 I have seen. The rear notch is U-shaped and very well-sized to the front post. I’ll be able to take good aim with these sights.

The front sight is typical of a Chinese post sight, like the one found on an SKS rifle.

The rear sight adjusts for elevation but not windage. The rear notch slants backwards more than others I’ve seen. Notice the sidelever latch lock that takes so much pressure to unlock!

I’ve fired it a couple times just to familiarize myself with the operation and can tell that the bore is uncharacteristically small. I say “uncharacteristically” because, in all my experience with Chinese airguns made during this era (1970-1980), the bores have always been way too large. I have some hope that this may turn out to be a shooter.

The sidelever stays in position until the catch is pushed to release it. On this rifle, the force required is massive — on the order of 20 lbs., which is asking a lot of a thumb! The lever is under extreme tension — not from the mainspring, but from the geometry of how the lever and its parts fit. It’s not a pleasant rifle to cock, considering that it’s supposed to be a plinker. Give me a Bronco any day!

What’s the plan?

The plan is that I’ll test this rifle exactly as if it’s a new airgun. It doesn’t have a scope base, so I can only test it with the open sights that came with it. There’s a limited supply of these new-old-stock rifles, so don’t look for anything long-term from this test. If a few readers want one for themselves, just Google Randy Mitchell and airguns, and you’ll find the link to his website. He doesn’t seem to have these rifles listed there, so you will have to contact him to ask about them.

Dear BB

I am very sorry to bother you with something completely off topic, but I do not really know who else to contact about this.

My son participate in competitive 10m air rifle shooting (3P sporter class), but he is leaving school at the end of this year to start his university training and thus cannot compete in this class anymore. He would like to continue with the sport, but then has to start in the precision class and he does not like the idea of shooting with supporting clothing, so he is considering starting in competitive air pistol shooting.

Unfortunately, these air pistols are extremely expensive in South Africa and a Feinwekbau model 44 costs the equivalent of about $3000 here. He can now get a second-hand Feinwekbau Model 2 CO2 pistol with a 10 inch barrel (breech to muzzle) for the equivalent of approximately $625. This seems to be a really good price, but I don’t really know. The pistol is still in its original packaging and seems to be in good condition. Included in the deal are also an extra CO2 cylinder, fill adapter as well as a steel CO2 tank.

Regardless of the price, I would like to know whether this is a suitable match air pistol and does it comply with ISSF rules. Also, are you aware of any particular issues with the specific model? Does the temperature-sensitivity of CO2 powered guns also affect the accuracy of this gun?

Other affordable alternatives would be the Gamo Compact ($320 equivalent) or the Crosman 2300T ($375 equivalent), but I do not know whether these pistols are really suitable for precision target shooting. I can probably also import the Baikal IZH 46M from you guys at Pyramid Air for about the same price as the FWB Mod 2 with the advantage of the Baikal being a new gun, but I don’t know whether any technical support is available in South Africa for this brand.The Crosman 1700P is available in South Africa for about $900 equivalent and this will be about the maximum that I would be prepared to spend.

So my question is: do I go with the FWB and if not, which of the other pistols I have mentioned above will be suitable, not only to start with, but also to continue with competitive precision air pistol shooting?

I do have a Beeman P1 in .177 calibre, but I really doubt whether it’s accuracy will be adequate at all for this purpose.

I would really appreciate your help in this matter.

Regards.

Vasco.

B.B. (and others who are much more knowledgeable of these things), please step in if I stick my foot in my mouth as I usually do.

The FWB would be a very good choice if you do not have any problems with a source for CO2. Most, if not all 10 meter competitions will be indoors, so the temperature issues with CO2 do not come into play.

Of the other pistols you mentioned, only the Compact and the 46M are 10 meter pistols and the Compact would not be considered a serious contender. I have a 46M. It is an excellent entry level 10 meter pistol that probably shoots just as well as the big boys. As far as service, unless you abuse it that will likely not be an issue. If you buy it new from PA, it comes with extra seals and basic tools. With a little synthetic chamber oil, you are good to go for a very long time.

Vasco,

The FWB model 2 is an excellent choice! With it your son can compete in events up to the World Cup level. I have shot a model 20, which is very similar and I found it to be very nice.

The problems with CO2 are that it is temperature dependent, so the temperature of the gun before and during the match can affect the point of impact. Also, there is virtually no way of knowing how much CO2 is in a cylinder. It’s full right up to the point that it’s empty. I have competed with CO2 target pistols for ten years, and what I’m telling you is not idle conjecture. I have had my gun run out of gas during a match and I threw a 2 when I was holding a 10!

The shortcomings of CO2 can be overcome by certain practices the shooter must follow. One would be to top off the tank before the match begins. With the FWB model 2 there are enough good shots in a full tank to complete a men’s match with sighters.

The benefits of the pistol you are considering are its Morini-inspired grips and the legendary FWB trigger — which I believe to be the best in the world. The sights and other ergonomics are also very good, though not as good as the most modern pistols.

If your son succeeds in 10 meter and someday does get a top-level PCP, his discipline with the slightly recoiling CO2 pistol will stand him is good stead!

Go for it!

B.B.

Vasco,

The Feinwekbau Model 2 is a suitable ISSF competition pistol that will meet rule requirements as long as it is not modified. As far as dealing with CO2 he will have to be careful filling and exposing the pistol to high temperatures and at temperatures below 60 degrees velocities can start to get less consistent. Also one of the benefits of shooting in a sporter class or pistol class is the lack of all the extra gear if his practice range and competition ranges commonly don’t have CO2 fill stations then he will have to carry his fill equipment around with him.

As Ridgerunner said the Gamo Compact and IZH 46 are really the only other pistols you suggested as options that I would consider. I have both of these pistols as well as a FWB P40 and P44. The Feinwekbaus have nice stock grips but he still may have to modify them to get a good fit. The IZH (new) will come with a grip that is just a rough shape to start with and will feel much better after some rasping and sanding. The IZH is also very easy to pump and in my opinion isn’t that big of a disadvantage to PCP and CO2 guns in slow fire pistol competitions (you don’t have to brake position). I also like the stock sights on the IZH over the FWBs (let the flaring begin). The Gamo Compact is very awkward for me to pump and just doesn’t balance or feel like a true 10M pistol and no dry fire capabillity.

What model sporter rifle was he using?

Thanks guys!

I really appreciate your input and will probably go with the FWB.

Caveman, my son previously used a CZ 200T with an Anschutz-sight and then moved up to a Air Arms MPR with the same sight. The CZ (with a Gamo-sight) then went to my 15-year old daughter, but she now also uses a MPR with a Anschutz-sight. They both find the MPR to be a more stable rifle and their scores improved by about 10-15 (out of 600) in 3P.

Regards.

Vasco

Vasco,

The MPR is not approved for sporter class here in the US but some are used in the precision class here. It’s interesting to hear you mention the sights they use. I’m surprised how many competitors that “save” money and try to get away with lesser sight sets.

I have a C-20 which is almost identical to the C-2. I did a blog for BB a couple of years ago, and you can search it out and read about my (very favorable) experiences. As several experts have indicated, all those wonderful CO2 competition guns didn’t turn into pumpkins when the first PCP models hit the market (even if the manufacturers would have you believe differently).

pz

I’ll be the one dissenter about the choice between the IZH and Compact.

I was in your sons predicament a few years ago. I didn’t want to get into the local adult league air rifle as the clothing costs were greater than the rifle (used of course).

So I started competing in the pistol segment. I didn’t want to start off with an expensive gun right off because I didn’t know if I was good enough to seriously pursue the sport (likely not) and I didn’t want to buy used because there are no local smiths who work on airguns, the nearest being over 1000 mi away.

So it was between the IZH (hard to find at the time) and the Gamo.

All I know is that in a league of 23 shooters I usually finish in the top 1/2, and the only ‘cheap’ guns are two Gamos and an IZH…the rest ares shooting a mix of Steyr’s/FWB/Anschutz (though admittedly there are more than a few shooters who have deep pockets but don’t really shoot enough to get good…I practice nearly daily).

Also my Gamo crapped out last week…after 5 years and 20000+ shots and I found out this morning that a trigger part and overhaul is all that’s needed and the cost is expected to be around $80.

In truth I’ve never seriously shot the IZH (or the expensive Olympic guns)…but I would definitely suggest the Gamo as a possiblity for your son.

Appearance-wise, at least, the Chinese air guns have come a long ways since these were built. It is striking the difference in appearance between the stocks of the guns shown on the rack. Of course, we can only see one side.

The photo of the front sight shows a real rough level of finishing at the factory. It even makes my old Chinese SKS look sophisticated.

But maybe it will perform beyond its appearance.

If I were to buy one, I think I would like the anti-beartrap device to be kept intact, even if it is not to be trusted. It might possibly provide an extra layer of redundancy, just in case.

Les

These rifles look so crude but what can expect of a 20$ rifle… and they can cut your finger but they’re just 20$ and they’re a pain to cock but they’re merely 20$.

I think (I’m not sure yet, I’m really torn on this one) I’m glad these aren’t available to me (it will shoot above 500fps right?) as I would probably end-up buying one of those cheap looking, finger cutting, hard to cock piece of real wood and steel amazing piece of airgun… For 20$.

I mean what can you get for 20$?

You can’t let anyone shoot it either. I’d feel dumb enough cutting one of my fingers off I wouldn’t want to experience the feeling of having someone cut off one of his fingers with MY rifle. One of my uncles isn’t letting anyone use his chainsaw because of an accident where a potential Darwin award candidate almost lost his hand after borrowing the thing. He was holding the chainsaw by the guard and when it kicked because he wasn’t using it as he was told to the chainsaw ripped thru the hand he was smart enough to put in front of his face.

So always follow instructions and don’t let people use your hazardous stuff.

J-F

J-F,

I think this rifle will probably top 500 f.p.s., but we’ll see. Of course if this one doesn’t the next one might, so for Canada I think these are non-starters.

As for the safety issues, I definitely will not be giving this rifle to a new shooter!

B.B.

I couldn’t resist these either and I bought some from Randy a few months ago. Pulled apart and cleaned up one of them last winter. If you keep the leather seal and get the trigger pull down they aren’t too bad. The average deviation in velocity from shot to shot after I cleaned it up was as good as my Diana 24 does. Accuracy is ok ,but with only the open sights it is only as good as I can see . I cut out the center of the hood over the front sight on mine because it shot too low and when adjusted up to correct for that, it was hard to see the target center. Mine now has “ears” now instead of a hood, like some military front sights do. These seem to have good barrels despite their otherwise poor quality. The bear trap in them just blocks the trigger, watch out as BB and others have said.

Robert,

Just for grins, what kind of groups are you getting from your rifle(s)?

B.B.

BB:

I was getting groups that were quarter size at ten meters with RWS Miesterklugens from a rest indoors, for ten shots. A golf ball sized target would be no problem for me to hit out to twenty yards, maybe a bit further . The trigger pull I smoothed out so it’s not like the 15 pound deal it started with . The real suprise was that the velocity went from a low of 612.6 to 617.5 for ten shots with the Meisters according to my PACT cronograph. The crony string was shot outside and I ‘m almost scared to post it because everyone will think it’s bull, but that’s what I got. The plastic breech seal seems as dried out and is hard as a rock too . Go figure?

Robert,

Thanks for all that information. It will be interesting to see what I get with this one.

The trigger on my gun is a rough as a cob, but I’m concerned about cutting through a thin case-hardened shell if I try to stone the sear.

Any advice?

B.B.

Well… It probably costs more than this airgun did…

https://www.brownells.com/.aspx/sid=52952/pid=27119/Product/SURFACE-HARDENING-COMPOUND?utm_medium=shoppingengine&utm_source=googlebase&mc_id=10000&gdftrk=gdfV21820_a_7c187_a_7c3466_a_7c083000033_d_083000033_d_11288

Add a bucket of oil, and a decent torch… And some time to disassemble the trigger/sear parts…

BB:

I replaced all the pins in mine with ones I made of drill rod, and I polished everything, including the bear trap parts. I did stone the sear and the hook on the piston a tiny bit ,knowing that it could go south after a bit of use. So far it’s OK. I took it apart several times as I went along to test the pull and didn’t try for a hair trigger.As an aside ,I have always been curious as to the statements that the chinese guns all have issues with the metal in the sears. I had my wife take a couple I picked at random from my extras and test them for hardness on a Rockwell tester where she works(she is a machinist who sets up CNC mills and lathes). They came in at 38-42 on the scale . I think that maybe some folks just remove to much metal and alter the angles too much, not that the metal and heat treatment is always of poor quality. I know I’ve ruined a couple that way, but thats how you learn. I have also fooled around with a torch and oil to quench parts and temper them after drawing the temper. Usually I go with deep blue on screws and pins.

Robert,

Okay — I asked and you told me. Now I’ll get used to a 15-pound pull.

Thanks!

B.B.

Robert,

Interesting about the drill rod — did you test the pins that come in the rifles? I bet they could be hardened, quenched and tempered, although I doubt they are worth the trouble if you have the right sized rod.

RE: the sear parts. I may be misunderstanding your process. You could possibly get them a little harder by heating to red, quenching in oil to harden, then temper (non-spring parts) at 550 in the oven for an hour (let them cool with the oven). That is how I treat trigger components on my muzzle loaders when I modify them and they are plenty hard but don’t break. Quenching in water (I’m sure you know) will make them even harder, but sometimes too hard and they break (sometimes in the quench). One trick is to put an inch of oil on top of the quenching water, which will ease the transition a bit but give a faster cool-down and more hardness. I suspect the steel used in the chicom airguns is ordinary “high-carbon” of some far eastern variation/alloy and pretty forgiving.

I’m curious/skeptical as to the legend that the parts are only thinly hardened on sear surfaces. In an industrial setting, it would be much easier just to treat the parts all the way through. I suspect the parts that wear dangerously are defective in some way, either in treatment or geometry, but I don’t think it is the norm.

BG: the pins that came in the gun were little more than bent soft iron nails. Really bad ones at that, not worth the effort to salvage. I do as you describe with the pins and small parts. I heat to cherry red , then quench, then polish then reheat to blue with a torch, and quench again.

BG: BTW, A very good gunsmith taught me that the material used in grade 5 bolts makes good raw material for firing pins and other small round parts. He was right. I have a old double barrrel shotgun that was my first foray into gunsmithing from years ago that I made firing pins for that is still going strong. I didn’t have a lathe then ,just a old electric drill , a good vice, and files , but I got it done.

Robert,

I never quench after (drawing) temper, just let cool naturally wherever it is, but maybe I’m doing something wrong — I can’t see how it would make much difference. Just curious. There is more than one way to skin a cat (figure of speech, Edith) :)! The reason I asked originally is that I’ve found a great deal of confusion on the internet b/t “temper” and “anneal”. My definitions for clarity are: Annealing heats to red and cools slowly to soften the steel completely so you can work on it, whereas tempering heats to some intermediate temperature to draw some of the hardness out. Parts that need to stay fairly hard get tempered at lower temperatures (e.g. your bright blue), whereas parts that need to be more flexible get taken up to some higher temperature, but short of critical temperature. Of course, all steels are a little different. There is a certain brand of trigger for ML’ers that uses air-hardening steel, and the annealing process is close to impossible “at home” so you have to work them hot :)!

Grade 5 and up are excellent cheap sources for all sorts of things. My tip is that I use hacksaw and jigsaw blades for small “flat” springs. Anneal to work, harden (heat and quench) then temper in burning oil as I described below and they hold up well, although some people claim different results when they get into HSS, bimetallic, etc. fancier blades. Almost any steel with enough carbon in it to harden (even some strapping) can make a workable spring.

One more thing — if you are lucky enough to have a _good_ kitchen oven and a thermometer, you can get great results tempering to blue (~550dF) and slightly higher or lower, which covers a remarkably useful range. I have a flintlock frizzen that is too hard, and I’m going to draw the temper back in a can of sand. I like the non-visual methods because I am fairly indifferent to colors (some say color blind :)), plus if the part doesn’t need to be seen, you don’t need to polish. I just put stuff in cold and wait for the temperature to get right, turn on the timer, let it sit for and hour, then turn oven off and let everything cool. When you take the piece(s) out, you’ll see (or should see) the same temper colors as you get with the torch on polished parts.

Case hardening relies on coating the surface of the steel with a carbon containing compound. On heating, some of the carbon migrates into the metal — changing the grade of steel in just a thin layer. My old muzzle-loading “New Orleans Ace” pistol kit included such a powder. One had to apply it to the trigger and sear contact points and heat those parts (in the case of the “sear”, one would not want to treat the entire part to the same hardness as it was part of the hammer itself — and a hard/brittle hammer hitting a percussion nipple might fracture). Case hardening leaves the core of the metal “soft” and able to absorb impact forces.

Japanese swords are similarly treated — the majority of the blade is coated with a clay compound, leaving just the sharp edge exposed. The blade is then heated in the charcoal (a high carbon source) such that the edge takes in the carbon. Quenching then cools the edge, while the clay coating insulates/retains heat leaving the rest of the blade flexible.

Wulfraed,

Yes, it can be done (I have a gallon? can of Kasenit!) and has been done many times, but it is a hands on and time consuming operation. My point is why would they do that to the cheap airgun parts at the factory when they could have heated/quenched/tempered carbon steel all in one batch? In most cases/applications, adequate hardness (for wear) and toughness (for impact resistance) can be gotten all together with carbon steels. Kasenit is a home-user deal that gives adequate case depth for wear surfaces on mild steels (very low carbon — essentially they will not harden). The same or similar idea was (still is) used for making case-hardened or even through-hardened parts from mild steel and wrought iron (no/low carbon) by carburizing or pack hardening — adding carbon from some other medium while the steel is heated. Of course, in China, we assume labor is cheap, so maybe they do case harden every sear!

Remember — they can probably batch process the parts too… string a bunch of sears via the pivot pin hole and some other support (to hold them all in alignment)… dip in compound, heat, quench…

For all we know, they might actually cut a rod into the profile of the sear, treat it, and THEN slice it into the thin pieces that make up each sear. Only the sharp-edged bearing surface needs the hardening, not the sides that ride in some housing. True, the slicing needs pretty good equipment to avoid shattering the hardened edge yet do quick work on the soft core.

Nostalgia overload for me BB!

Back in the ’80s I used to drop in to see Paul, BS and see if he had gotten something desirable in the way of a collector for me. At that time he was the warranty and repair station for Compasseco as well as the maker of a scope mount that fitted onto the rear site bracket for the TS-45 and others that Compasseco was peddling. At some point he got a huge shipment of returned TS-45s from them. He had a portable building in his back yard that was stacked with them like cordwood. In order to fuel my own habit I started buying a few each time I visited (for $5 each!) to repair and resell. The proceeds helped me acquire a few nice old guns before I started feeling guilty about selling ‘digital shears’.

First opportunity you have compare that TS-45 sidelever side by side with the one on a FWB 150/300. I think you’ll be quite surprised.

BTW—-the proper TS-45 lever retaining grip is to use the rear of the arm as you are in the pic to restrain the lever but to hold the rifle with the right hand as well while loading with the left. In this manner the forearm provides a solid bridge directly in line from hand to back of the arm. MUCH more secure than your technique! Tom

Tom,

I have one of those scope mounts! Paul gave it to me with the rifle I bought from him.

And thanks for your loading technique, Tom. It does sound much safer than mine. I just made mine up for the entire host of sidelevers, and it works for this one, as well as all the others. But like I say, if the sear lets go, it will hurt!

B.B.

Er—-the anonymous TS-45 comments were by yours truly who hadn’t had enough caffeine when posted.

Tom,

I figured it was you because of all your experience.

B.B.

I;ve been shooting an CHEAP Chinese air-rifle for a few years now (actually TWO: the first one died, and my “spare parts kit” consisted of replacing the entire gun, for another $29!). They yiled 500fps w/Gamo Match 7.8s & 4.5 ft-lbs. I’ve heard that these cheap guns can last longer & perform better by improved heat-treating of the main-spring, and I DO have safe experience with spring removal (using a decent home-made spring compressor). Questions:

1) Do you agree that 450F soaking of a cheap spring, then letting it cool slowly will improve the lifespan, and possibly rifle performance?

2) How much “tar” and what brand is best to put back ON the springs, after heat-treating?

3) SLIGHTLY related to this, you recently recommended the Titan NP Low-Vel .17 springer as an ACCURATE, low–cost rifle, but it’s not available now! What would you now recommend, assuming ~$250 or so max? I’ve heard that the Hatsan 95 is good, though not the best scope included (UGT 3×9) upgrade there, maybe?

Barrika,

You have asked me a ton of good questions.

First, I am not qualified to comment on your heat-soak question. Maybe another reader can help?

Second, regarding black tar, it’s best not to use any at all. It’s best if the tolerances are and tight as possible, to eliminate vibration.

If you do use tar, use the least you can get away with and not lose too much velocity.

Back in the day I used to “butter” the spring with Beeman’s Mainspring Dampening Compound, but that stuff is less viscous than black tar.

For under $250 in .177 cannot recommend any rifle more than the Bronco. If I ever get my way, we will have a more powerful rifle to go with the Bronco, but I’m not being listened to at the moment. That rifle will have all the good features of the Bronco in a slightly large, more powerful package.

Other than the Bronco, if you want more power I vote for the RWS Diana 34. Buy used, if money is the issue.

I will test the Hatsan 95 soon, I hope. I had huge hopes for Hatsan guns, but so far everything I have seen has been mediocre at best.

B.B.

Hi Barrika

I recently acquired a Hatsan model 95 and fitted it with a Tasco 3-9×40 rifle scope on a BSA Mountmaster one-piece mount (essential for the recoil of these big Hatsans), but I plan to fit something like a Gamo 4-16×50 AO scope (rifle scopes which are suitable for powerful air rifles are quite hard to come by in South Africa). The gun has a beautiful walnut stock and the general fit and finish of the gun is much better than some of the previous rifles from this company. The receiver is polished mirror-smooth. The barrel is much less smooth, but this may be on purpose because you do not see finger marks as easily on the barrel. I don’t know whether the SAS (shock absorption system) is really that effective because the recoil feels much the same as on older models (85 and 125) without the SAS. The Quattro trigger however, is wonderful! I know that BB had problems with the trigger on other models, but the trigger, as it came from the box, was acceptable. I then played around with the adjustment a little bit and was able to adjust it from fairly heavy to a hair trigger which you barely had to touch, but this was dangerous. Trigger pull is now similar to that of my children’s competition PCP rifles at about 500 g (one lb). Cocking effort is acceptable, with my 15 year old daughter being able to manage it quite easily. Accuracy is fair with a group of about 20 mm (0.8 inch) at 20 yards, but I’m sure it can improve as the rifle gets shot in and I find the appropriate pellets.

I can really recommend this rifle.

Regards.

Vasco.

Vasco,

It sounds like the Hatsan 95 is a good one. Can’t wait to try one.

B.B.

For heat treating the spring, 450dF won’t hurt, but it likely isn’t enough; the spring could still be too hard. One technique that works for flat springs (get ready because it is a little weird) and should work for coil springs is to place it in a shallow pan filled with oil until the spring is just covered (some use motor oil, I’ve found soybean works fine) and set the oil on fire with a propane torch, letting the fire burn until the oil is gone: result is tempered spring. This technique works great on flat and vee springs after they are quenched/hardened. I’d say it is worth a try on a $20 airgun if you think the spring is too stiff and brittle! I know it would have helped my 36-2, where the original spring was like glass and broke into several pieces pretty quickly.

I’m so cautious that I would never buy a rifle that could amputate my fingers. The loading procedure in the picture is what I’ve evolved more or less with my B30.

Wulfraed, I thought that the hollowpoint design improves ballistics by moving the center of mass of the bullet backwards and making it more stable in flight. That would mean that hollowpoints are generally more accurate and release more energy into the target than other kinds of bullets–a difficult combination to beat.

PeteZ, I’ve always been a bit skeptical of the theory of wounding soldiers in battle as opposed to killing them. Regarding your 8 people tied up with a wounded man, wouldn’t you have to divide that number by the number of people the medevac team saves which should be many more than one. So the commitment to any one wounded soldier is not 8 but 8/100 or something like 1/10 of an extra person. And if they manage to save the soldier and get him fit for duty, than the opposing side has failed to achieve anything.

B.B., well with the number of hunting rounds you have sent downrange, I defer about the hollowpoints. Maybe I was confusing them with dum dum bullets which I understand are made by cutting crosses on the face of the bullets themselves. That is supposed to cause fragmentation in the same way that scoring on the face of a “pineapple” grenade causes it to explode, right?

Mike, actually I understand that the Springfield 1903 had no significant superiority to the American Enfield, and the Springfield received preference for largely nationalistic reasons since it was an American design (that copied a German design). However, I understand that the Enfield was, if anything, even more accurate. It is strange with the numbers of Enfields built for WWI that they are almost impossible to find as surplus rifles now.

Matt61

Sometimes a Medevac picks up two soldiers if they’re close. Otherwise, it shuttles back to base with only one casualty.

One of the reasons the Springfield was preferred was that there was no windage adjustment on the M1917 other than drifting the front sight. The Springfield was a better “target” rifle and it was easier for the “Gunnies” and Top Sgts. to shoot expert with them and get an extra $5.00 per month in pay. Also, the Springfield cocked on opening instead of on closing and most preferred the former. The Springfield also handles better feeling less like a post and more like a rifle. Most soldiers in those days wanted the open sights instead of the type aperture which is on the M1917. Of course the aperture is superior and it was used on the M-1 Grand and later even on the Springfield. You don’t see many M1917’s today. Many were stripped for the actions. I have a Pattern 14 in .303 Brit, it’s a shooter!

Mike

Mike,

I owned an American Enfield and agree with all you have said, save one thing. The Enfield feels better in my hands than the Springfield. The Springfield’s stock has a pull that’s too short, as a result of being made for both the Infantry and Cavalry, while the Enfield feels just right.

I hated the lack of windage on my Enfield, as I had to drift the front sight way to the left to compensate for a Monday job of reinstalling the front sight fixture during the arsenal overhaul.

My Springfield is an 03-A3, though I have owned several earlier models in the past. This one is so remarkably accurate that I ignore the huge kick that comes from the too-short stock. I sold the Enfield years ago, not being able to tolerate that off-kilter front sight any longer.

Cocking on opening is overrated, in my opinion. I don’t see any advantage, though I have read many reports that say there is a decided edge to it. But the Enfield feels like a rifleman’s rifle, where the Springfield doesn’t. But the Springfield looks better and shoots better, which is all that matters to me.

B.B.

On that argument, badminton birdies and diabolo pellets are all operating backwards (after all, if you put a pellet in backwards, you get a large hollowpoint with significant mass to the rear… and badminton birds actually turn around in flight to put the dense rubber nose in front of the hollow feather/vanes)).

A hollowpoint is a big air-drag on the front of the pellet, putting the center of mass close to, if not behind, the center of drag. They are actually less accurate than pointed target long-range target bullets; but in hunting situations, the difference in accuracy is made up by the effectiveness of dumping energy within the target rather than zipping through it leaving a small hole.

It appears that the front sight does adjust for windage, just like the old SKS and AK’s. Is this right?

Vince,

Elevation yes, windage no.

B.B.

BB: Vince is right , as you can drive ( or push with a tool)the pin that holds the front sight post from side to side just like on an AK. That is how mine adjusts for windage.

It will drift for windage. A large hammer is often needed!

Mike

I think a tool like this works on this gun… and it makes elevation adjustments easy as well.

http://www.ncstar.com/scripts/prodView.asp?idproduct=246

Robert,

Okay. I believe you guys. I just didn’t see how this sight could be drifted.

B.B.

TO: B.B. this is rather off topic, however i was wondering if i could bend your ear with a few questions i have. ive been looking for a way to contact you privately and can find it. is there a way to do that?

ctd12vfan,

I think we have more off-topic comments/questions on the blog than on-topic ones 🙂 Feel free to post your questions or comments here. Everyone does it, so make yourself at home & feel free to join in.

Edith

They are jolly junkers. The best thing about them is that I made a profit selling them. I sent a number back because they had problems but Compassco always sent a replacement. They were probably paying $1.00 each for them! Any more than that would be too much! I would test them by putting six cleaning pellets in them and hitting the butt on the floor. If it didn’t fire, it was a good one! I did have one that would shoot a ragged hole at 15 yards. I still have the receiver and barrel for that one. It got so the sear wouldn’t hold so I took it apart so no one would get hurt with it. All the rest are long gone. RIP. Life is too short to shoot these as I have a FWB 124.

While I wouldn’t be interested in one today, you might be!

Mike

ok, i was thinking about email only because this is long winded and going to get very technical. first a little background, i have been a mechanic for about 5 years, currently i am studying to get my B.A. in mechanical engineering. from this comes my questions.

when i was a little kid i learned to shoot a rifle using an old break barrel springer rifle in .177 cal, later we got a .22 cal underlever springer. neither of the rifles was all that powerful and surely did not kill anything. as i grew up i moved on to bigger and better guns and wrote off air rifles as just toys.

recently i came across some air rifles that sounded pretty good and it piqued my interest. a little research and i found some pretty powerful air rifles one of which was the Airforce line. long story short i started doing a lot of reading and studying on the subject and because i tend to be very picky i have decided to build my own air rifle.

in doing my research untold numbers of articles from this blog have come up and have been the most informative source of info i have yet found. so i am wondering if i could lay out my ideas and get them critiqued here.

before i begin i should mention i push everything to the limit so as to get the upmost efficiancy. my design so far is as follows.

.25 caliber, 24″ lothar walther choked barrel, bolt action. i know there is an ideal velocity/weight ratio that produces the best accuracy with lots of take down power. since i like efficency i also want to get the most shots with high consistency shot to shot.

of the designs available on the market the pcp looks the best to me however it has its drawbacks such as loss of velocity as shot counts rise. also as i am doing my calculations i am seeing that even with a 4500 psi system you still dont get many shots since the force i.e. tank pressure needed to acheive the desired velocities is pretty high. my target velocity is 1100 fps at the muzzle with a 43.2 grain pellet.

i know this is high and will take a lot of energy to achieve. also it is likely that in the end the operating air pressure and therefore velocity will be regulated down for accuracy. looking around of the operating pressures of other pcp rifles i found an article on here about early air rifles and some hand made current air rifles operating on very low pressures while still acheiving high power and high shot counts with high consitency. i was hoping to hear more on those setups and how they are doing it in the hopes that something will jump out at me and help me with my own design.

there is one idea the low pressure article helped me with. originally i was planning on operating my rifle with a regulated pressure somewhere around 1000 psi, with 4500 psi thats a lot of air to shoot with. the problem is the pressure is too low for the desired velocity. i dont have the numbers in front of my but i think i needed to be somewhere in the 3000 psi range which doesnt give me too many shots.

after reading the article i started wondering how they could get the power with such low pressures, and how could i get mine down that low or lower. well it dawned on my that i could use a high pressure accumulator in the system. for anyone who doesnt know an accumulator is used in hydraulic systems and fulfills one or more of a number of roles, one of which is energy storage. they are actually used in air rifles already as springers or more accurately nitro piston springers.

before getting into the accumulator i need to mention my design since its a little a-typical. starting at the air tank and ending at the pellet. im planning on using a paintball sized 4500 psi air tank with a regulator this will be sized to easily carry with you much like you would carry a pistol, from there it will go through a poly braided high pressure hose to a trigger assembly, the trigger is comprised of to simple fast acting one way valves one leading to and one from an accordingly sized or “tuned” chamber, this chamber will be the only air used to fire the rifle, from there it leaves through the second valve to the back of the reciever, through the bolt, to the back of the pellet, pushing the pellet out the barrel.

the problem i have is using the “tuned” chamber is volume, pressure, force, flow and a number of other variables, all of which will change drastically with air pressure. maybe i am wrong but i think this is something of the problem with all pcp rifles. enter the accumulator, my thinking is that by using a small accumulator connected to the “tunned” chamber the pressure from the tank can be lowered and i can still maintain the needed force and also increase velocity. all of which will increase power and give me more shots per tank.

another way to think about it is to think of a supercharger or turbocharger on a car. here i am supercharging a nitro piston springer but instead of super charging to increase power it is for consistency.

any thoughts? with your experience on so many rifles what are some unique qualities have you come across that might help.

ctd12vfan,

Firefighters take a carbon fiber tank with them for air support so I like some of your ideas. You put a lot out there to think about! Maybe making some type of adjustable chamber could help with figuring out some of this stuff.

ctd12vfan,

You have focused too much on the numbers and not enough on realistic performance.

For example, why 1,100 f.p.s. muzzle velocity? You have chosen the very velocity that will put your pellet right at the sound barrier and suffer the worst turbulence. Instead, why not go for 950 f.p.s. and get a pellet that is safely subsonic? Competitors with .22 rimfire target rifles pay ten times more for their ammo, just to keep it subsonic for the additional accuracy edge it gives.

Next, why .25 caliber? You specify a pellet weight of 43.2 grains, but no .25 caliber pellet of that weight is accurate. There are just two accurate .25-caliber pellets. One weighs 25 grains and the other weighs 27 grains.

With .22 caliber you can have many more accurate pellets. If the object is to hit what you are shooting at, that would be the better way to go.

Your accumulator idea has already been done. It’s called a pressure regulator and it keeps the pressure at the valve constant over a large number of shots. But the Condor is not well-suited for a pressure regulator. It works best as an unregulated gun.

You have postulated many interesting ideas, but they don’t work as you envision. Here is an automotive example of what you are asking for. We know that nitromethane is a powerful fuel if an engine is properly modified to use it. And Formula 1 cars are very fast. But AA fuel dragsters go even faster, so why doesn’t someone run a Formula 1 racer with an AA fuel engine? Because it wouldn’t work. Besides not meeting the Formula 1 engine displacement criteria, the AA fuel engine is not suited for long-duration operation. You simply cannot put one powerful thing into another application and get good results.

Thanks for commenting here on the blog, and welcome to the blog. I hope we hear more from you and I hope we can steer you towards the airgun that you will ultimately be thrilled to shoot.

B.B.

Wulfraed,

Your question about hardening parts deserves an answer.

The reason airgun companies do not harden their trigger parts all the way through lies with the word “carbon.” The steel they use to make the trigger parts is low-carbon steel, not high-carbon. The reason is this steel costs many times less than high-carbon steel, and the cost does add up when you are making a product to resell. Multiply the cost to build five times to find the actual retail price, so adding a dollar adds five to the price tag.

Also, the tooling needed to work low-carbon steel is less costly and can be set to run faster than the tooling needed to cut higher carbon steel. And the tooling doesn’t wear out or get dull as fast. So there are other costs besides just the price of materials that have to be added when you change the specifications.

As a result, “industrial hardening” has been using case-hardened parts for more than a century and will continue to do so. It is cheaper, faster and easier on the tooling — all valid reasons for doing it that way. And it works.

B.B.

Wasn’t my question — you’ve basically confirmed my feelings that they are likely using a carbon-compound surface hardening approach. I merely tried to visualize a system whereby such could still be done in a mass-production environment (a counter to the argument that using such is tedious and time-consuming — which it probably is if one is working on one gun/trigger assembly only).

BB,

I think it was my question/observation which Wulfraed was quoting and responding to. The “fact” that airgun makers use mild steel and only thinly case harden _just_ the sear contact surfaces was my main gripe, as I’ve seen it repeated over and over on the internet, but have seen only anecdotal evidence when some goofball messes up; it seems a roundabout way to do things post 1880.

Robert quoted Rc hardness of 38-42, presumably measured elsewhere on the sear (i.e., not the tiny contact surface[s]). That seems much too hard for mild steel (which cannot be hardened and is about 20 on the Rc scale, although technically it should be measured on the b scale), and even a thin case of extreme hardness over the whole part wouldn’t likely measure that way given how the test is done; there is a separate set of tests/scales for case-hardened material. It is either hardened (carbon) steel or mild steel which has been more or less through-hardened by pack hardening/carburization/etc. (which is a fairly easy option given how thin the parts are), which makes it for all intents and purposes carbon steel.

Anyway, given that there are only a couple of tiny parts with that requirement for wear, I can see it going either way without a huge cost differential in materials or tooling: mild steel pack hardened (a little more labor) or carbon steel heat treated (very slightly more material cost for plain jane carbon steel; if purchased annealed in bulk, it would work almost the same as mild steel). I would opt for the carbon steel approach, as it is probably more forgiving and reliable, but the airgun makers may opt for carburization (e.g.) to allow using one (mild steel) feedstock and based on past practice. Anyway, that is something you should ask Hans Weihrauch next time you see him, as I doubt we’ll be able to get through to the Chinese factories to ask :)!

B.B. i have to say in some ways you are my favorite type of person and at the same time my least favorite. i hope you dont take my response as flippant or that i am disrequarding your experience, that is not my intent. personally i think that good, livlely, and intelligent debate breeds inspiration and from that inspiration can come many good things, and the best way to get me to do something is to tell me it cant be done. now on to the rifle.

so the one comment you made that i want to focus on is the accumulator because the analogy to a regulator is actually the exact opposite of the accumulators function.

a regulator is a restriction that steps pressure down. it cannot, in anyway, increase pressure. a better analogy would be the capacitor in an electrical system. neither a capacitor nor an accumulator can boost pressure, however, depending on size and configuration they can be used to maintain pressure for longer. it is this capacity that i am trying to utilize.

air is a fluid just like water and so it follows the same laws of physics. the only characteristic that seperates air from all other fluids is air can be compressed where fluids cannot. this provides several advantages in certain applications. the main advantage of compressability is the potential for stored energy, thats what the air pressure is, potential or stored energy. most air systems have an air tank, the tank holds air, under pressure, so that the compressor can shut off and not work as hard. it also increases the response time of a system by taking air from the tank instantly instead of waiting for the compressor to sense the pressure drop and respond to the demand.

the accumulator is in other words a tank, but with one slight difference, it has two tanks in it not just one. on one side is a pressurized gas, typically nitrogen, being under pressure it has potential energy. on the other side (in hydraulics) contains fluid pressurized by the pump. when the pump is shut off the accumulator can release its fluid to supplement the system at system pressure. however, just like a capacitor the force is only for a brief period of time. also the accumulator can be used to absorb pressure spikes in the system to protect it from damage. this means that an accumulator has a nearly instantanious reaction time. in fact since sound waves are in fact pressure waves an accumulator actually reacts at the speed of sound. both of these attributes are useful in an air rifle. which is why they are appearing in place of the springs in springer rifles.

in the application i am designing it will function in all of these capacities. to help illustrate what its doing think of the air tank for a pcp. you fire a bunch of shots and the pressure drops to a level that does not produce enough power to keep shooting. well lets say your hunting and you dont have any more full air tanks, and you see your quarry. the problem is now that you have your shot you cant take it because your out of air. well what if there was a way to increase the air pressure in your tank right there in the field? and if you could get enough pressure you could finally take the shot. that would be great right? what if i told you there was a way? would you believe me? well if your tank is an accumulator it is possible.

the way an accumulator gets installed in a hydraulic system is pretty simple and might help explain my idea. to start the accumulator is empty on both side. the bottom side is attached to the hydraulic system which is at 0 psi. the top side is then charged to half of the systems operating pressure. when the hydraulic system is pressurized it fills and pushes against the precharge of the accumulator untill the forces are equal. depending on the set up it can hold this pressure even after the system is again brought back to zero. if a hydraulic component needs to be actuated while the system is at zero the pressure in the accumulator can be released allowing the component to move.

this is how i intend to use it. with the accumulator charged and then the bottom is filled with pressurized air from the tank when the trigger valve is opened the pressure in the bottom side of the accumulator will drop. when the pressure drops to less than that of the top side the top side will start pushing on the bottom, pushing it out of the bottom and to the back of the pellet. the top side will push on the bottom untill the bottom side reaches an equal pressure. since the forces are then equalized the top side cannot over come the bottom but it will keep pushing as long as the bottom is less than than the top.

all of this means that i can use pressures lower than pcp or co2 but higher than springers. as a forced induction nitro springer.

back to the automotive analogy in essence your right. however that is not what im trying to do. what i am attempting to do would be like putting a turbo on a naturaly aspirated engine. will its true there is no replacement for displacement you can make a small engine much more powerful with forced induction, and besides what do you do when you want/need more power but you already have the most powerful engine available?

one last comment that im sure will get some responces. the reasons for asking for such high velocities with such heavy rounds is becuase i dont intend to stay at that level. once i get things dialed in, i intend to dial up. i would like to be able to push .25 cal nosler tip 80 to 110 grain round meant for powder rifles. i think there is some interesting possibilities there and it looks like it might be uncharted territory.

ctd12vfan ,

I am very used to accumulators, as I had them on the M60A1 tanks I used to command. They kept the system supplied with hydraulic fluid, so the pressure never built too high in the lines, nor did it even drop below minimums and allow air to enter.

A regulator has a firing chamber that fills with air at a regulated pressure. That was how I was using my analogy. Perhaps it isn’t 100 percent accurate, but in the end, both devices control the pressure in the systems they are in.

B.B.

Hi- I recently was received a number of guns from the estate of a friend who passed away. Included was a side-lever airgun which, after some research online, I determined was a TS-45. My guess is that it is early 1960’s vintage and seems to be complete except for the rear sight which only has a graduated frame for the sight blade which is missing. I would like to be able to shoot the gun and wondered if you know where I can find the missing parts I need for the rear sight so I can repair it. Any help would be appreciated.

Thanks,

John

John H.,

TS-45s were imported into the U.S. in huge numbers and they are now obsolete. There are no dealers in old parts for these guns, because the entire gun is so inexpensive. If you want a rear sight it would be best to find a whole rifle, though more likely your gun should become a parts gun for another whole gun, as the sights are welded on.

Randy Mitchell may have what you need. Here is his website:

http://www.adventuresinairguns.com/index.php?osCsid=83fedb291901328a9c101330bbf954e5

B.B.

B.B.- Thanks for your quick reply. Since you indicate that parts are probably not available, would you have any suggestions for a retrofit or replacement rear leaf sight that might do the job?

Thanks,

John

John H.,

A rear sight will cost you more than an entire used gun ($20). That’s why I recommended getting one.

B.B.

I’m gonna look to see if an SKS rear sight might work. They can be had for about $10 + shipping.

It’s not an exact fit, but it does appear that the SKS sight can be made to work. It’s gonna take some filing or Dremel work, though…

Vince- Thanks for looking into the SKS sight as an alternative. Do you have one I can buy? I’m located in the Seattle area.

John

Well, I’ve got 2 I just bought – I’m planning to convert them to peep sights. You’d might as well just get them where I got them:

http://www.e-sarcoinc.com/sksrearsightleafwslide.aspx

You’d have to dig up a short coil spring too, but that shouldn’t be hard.

Which TS45 variant do you have? By any chance is it an EMEI gun?

/blog/2011/03/a-tale-of-two-ts45-rifles/

I did a lot of shooting on my TS-45 I purchased in the early 90’s, I think it was $40 or $50 through some mail order outfit it may have been compassco. Making this one of the few Chinese guns I would lose money on if I now resold it (remember SKS’s were $79 and AK’s were $199, and Tokarev’s $129 at the time)

Compared to Crossman 760’s, Daisy multi pump pellet bb combo’s and even Benjamin multi pumps other kids had at the time it was heavy artillery. I must have been lucky as mine was accurate, powerful and I still have all my fingers, but one of the first things I remember about that airgun was the medieval ratcheting sound and thinking boy I don’t want my fingers in the chamber if it slams shut.