by Tom Gaylord

Writing as B.B. Pelletier

Part 1

Part 2

Part 3

Part 4

Part 5

Part 6

Hakim is a large, heavy military trainer made in the 1950s by Anschütz.

This report covers:

• Bone-dry

• Synthetic piston seal

• Piston lube

• Mainspring lube

• Assembly

• Trigger adjustment

• Test-fire

• Eley Wasp pellets before

• Eley Wasp pellets after

• RWS Superpoint pellets before

• RWS Superpoint pellets after

• RWS Hobby pellets before

• RWS Hobby pellets after

• Evaluation

This has been a detailed look at a rare Hakim air rifle trainer that was made for the Egyptian army in 1954 by the German firm of Anschütz. In Part 6, I showed a detailed disassembly of the rifle that included solving a problem with a sticky screw. Today, I tell you how I lubricated the rifle’s action and how it performs after the lubrication.

Bone-dry

As I mentioned, every part inside this powerplant was bone-dry. It’s no wonder the gun was vibrating! The wonder is that it worked at all.

Synthetic piston seal

I started the lubrication with the piston and the synthetic piston seal. That’s right — I said synthetic seal! A lot of you guessed that because this rifle was made in the 1950s, the seal had to be leather. In fact, it was always synthetic. And not the kind of synthetic that dry-rots like Diana, Walther and Feinwerkbau used in the 1970s. The seal in this Hakim is over 60 years old and is still fresh and pliable. It’s in perfect condition. I haven’t seen another Hakim seal as nice as this one, and I’ve been inside more than 20 of these rifles over the years.

The seal is a parachute design, meaning that a groove around the edge of the seal inflates with pressurized air when the piston travels forward, pressing the seal against the compression chamber wall and sealing it better. The center of the seal is open, making it look like a donut from above. A cone-shaped steel nut extends ahead of the seal and fits into a similar depression at the end of the compression chamber. Diana uses a similar seal today, and theirs is a little larger, making it the perfect replacement when a Hakim seal is damaged.

The Hakim piston seal looks just like this Diana seal.

I have found these rifles with pellets, finishing nails and small screws embedded in their piston seals — all evidence of previous attempts at using improper ammunition. While they may not wear out in the conventional sense, these seals can be damaged by intentional acts. So, it’s good to know there are replacements. And the Diana seals available today are made from synthetics just as tough as the original Hakim seals.

Piston lube

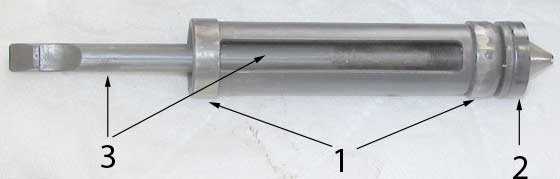

I used moly grease on each part of the piston and seal. The front and rear of the piston are larger than the main body, so they’re the only places that contact the inside of the spring tube. Each point received a heavy coat of moly grease — 1 in the picture. The piston seal sides and the washer behind the seal also received a heavy coat of moly — 2 in the picture. And the piston rod, which serves as the mainspring guide and also as the part that catches the sear in the back, was coated with moly — 3 in the picture.

The numbered arrows correspond to the instructions in the text.

When this was done, the piston was slid back into the spring tube that had been previously cleaned with alcohol and dried, though I must say it was pretty clean at the start. The heavy moly grease on all the contact points transfers to the walls of the spring tube and compression chamber this way. I used to also grease the inside walls of the tube separately, but I found it unnecessary because the piston grease transfers so completely this way. The moly particles bond with the steel in the tube walls, and the lube becomes almost permanent. Guns I lubricated this way over 15 years ago are still going strong.

Mainspring lube

Next, I lubricated the mainspring, which is in brand-new condition, by the way. Hakims springs aren’t under much preload, so they don’t tend to wear out when the rifle isn’t in use the way magnum springs are. So, this spring could easily be more than 50 years old!

The rifle had been buzzing when it fired, and normally I would use a heavy grease that Jim Maccari used to call velocity tar. I called it black tar, since that was what it looked and smelled like. It was probably a type of open gear lubricant. But I decided not to use it on this rifle. Instead, I reached into my bag of vintage tricks and pulled out a jar of Beeman Spring Gel. Don’t bother looking for it — the Beeman company stopped selling it 20 years ago. It usually doesn’t quite kill all the buzz in a vibrating spring gun, but I had a gut feeling this Hakim was different. It was so dry that perhaps this lighter, less viscous grease might work well. And the nice thing is that it doesn’t usually rob too much velocity. I coated the mainspring all over and slid it into the gun. Remember, the piston rod is coated with moly grease (number 3 in the above photo), so that will transfer to the inner coils of the mainspring every time the rifle is cocked and shot.

Beeman Spring Gel was a viscous silicone grease that quieted mainsprings while retaining velocity.

The end cap on the Hakim is a heavy piece of machined steel that threads into the spring tube. It contains the rear spring guide, which is hollow so the piston rod can pass through it when the rifle is cocked. This guide was also coated with moly.

The end cap holds the rear spring guide, which was also coated with moly grease (arrow). The mainspring was coated with Beeman Spring Gel, an obsolete silicone grease of high viscosity.

Assembly

The rifle was then assembled in the reverse of disassembly. I did put moly on both points of the trigger sear contact. When the time came, they would break crisply. I also coated the outside of the cocking linkage that slides through the steel guide with plain wheel bearing grease. That eliminates most friction and also quiets the cocking cycle. It might take some effort out of the cocking effort, but it is already so light (18 lbs.) that it’s hard to determine. If it does anything, it’s only a fraction of a pound.

Trigger adjustment

After the rifle’s action is assembled, it’s time to adjust the trigger. You’re adjusting the sear contact area, so this is critical. If it’s too narrow, the rifle could slip off the sear and fire on its own. The trigger adjustment is explained in the caption below.

The trigger is uncocked. The sear (hanging down) has to be pushed into position with the trigger by the piston rod.

The trigger is cocked. You can see the 2 surfaces that get the moly grease. Adjust the trigger by loosening the small nut and turning the adjustment screw in or out.

It’s time to install the stock and upper handguard and test the rifle. There certainly are a lot more steps to assembling a Hakim than there are for other air rifles!

Test-fire

Once the rifle is together, it’s time to test-fire it to see what the lube has done. I used both vintage Eley Wasp pellets and RWS Superpoints plus RWS Hobbys. With all pellets, the rifle now fires without a trace of vibration. There’s just a solid thump to let you know something has happened..

But I need to shoot the rifle through the chronograph to see what the tune has done to performance. Hopefully it won’t have slipped too much. The rifle was performing at the upper end of normal before the lube, and I’ll give you both the before and after numbers as I do this test.

Eley Wasp pellets before

Muzzle velocity averaged 454 f.p.s. Velocity varied from 450 to 466 f.p.s., for a 16 f.p.s. spread. Average energy was 6.64 foot-pounds.

Eley Wasp pellets after

Muzzle velocity averaged 445 f.p.s. Velocity varied from 436 to 454 f.p.s., for a 18 f.p.s. spread. Average energy was 6.38 foot-pounds. There was a slight power loss and a slight increase in variation.

RWS Superpoint pellets before

Muzzle velocity averaged 498 f.p.s. Velocity varied from 489 to 509 f.p.s., for a 20 f.p.s. spread. Average energy was 7.99 foot-pounds.

RWS Superpoint pellets after

Muzzle velocity averaged 491 f.p.s. Velocity varied from 482 to 497 f.p.s., for a 15 f.p.s. spread. Average energy was 7.76 foot-pounds. There was a slight power loss and a slight decrease in variation.

RWS Hobby pellets before

Muzzle velocity averaged 554 f.p.s. Velocity varied from 543 to 566 f.p.s., for a 23 f.p.s. spread. Average energy was 8.11 foot-pounds.

RWS Hobby pellets after

Muzzle velocity averaged 547 f.p.s. Velocity varied from 530 to 551 f.p.s., for a 21 f.p.s. spread. Average energy was 7.91 foot-pounds. T there was a slight power loss and a slight decrease in variation.

Evaluation

The lubrication was well worth the effort. The rifle now shoots like a Hakim should — solid and smooth. There’s no more buzzing when shot. Accuracy won’t increase, but this rifle will now be very pleasant to shoot, which is all I want from it.

Couldn’t sleep so I get to be the first commenter! BB, just how do you pronounce the name Hakim?

I’d suspect something like

hah-keem

Thank you, Wilfraued. When I saw the lack of replies, I decided to go to plan B and ask my Turkish friend, Kudret Oztap. I’ll let you know and the blog what Kudret has to say. And I hope I can sleep through the night tonight!

Fred DPRoNJ

BB,

Ok, so the sear sits on top of the trigger when it is cocked. You do not seem to have much contact there. Perhaps you should give it a good shake or thump? 😉

I really do like the way this air rifle is built. This is why so many of them are still around.

RR,

The bump test is always done after a trigger adjustment.

It’s fine, but you see how narrow the contact area is?

B.B.

GF1,

I hoped you enjoyed your shooting session yesterday afternoon.

I was referring to sproingers. American PCPs do indeed compete with the best that the rest of the world is producing. Regretfully, I have not had the pleasure of personally evaluating the Marauder, but I have heard nothing but good things about it. I do have an Edge and a Talon SS.

I believe I have stated this before, but I would like to see Crosman come out with a premier line where they take the cream such as the Marauder and put it in a nice walnut stock and pay more attention to fit and finish and maybe even give it a LW barrel. Yes, it would cost more and I would expect such.

RR

Yep I did enjoy shooting yesterday and I’m off today so getting ready to go do it again.

And I’m with you on a premier line of pcp guns from Crosman /Benjamin. Heck they have the premier line of pellets. Why not a higher cost gun with more of the fancy stuff. I would by a Marauder with a nice walnut stock and a special LW barrel. Maybe even offer one of those cool field target stocks. And I know some people don’t like them; but I love laminated colored stocks.

Yep the cost would go up but if I could buy it as a complete package and they warranty it then its worth the extra cost. Otherwise I would just have to add the things myself and would have to pay and not have a warranty on the stuff I installed. Maybe Crosman will do it.

Okay, I’ll ask the obvious question: I know the various high-viscocity lubricants might have slowed the mainspring and piston down, but with less friction and a better-sealing piston seal why didn’t velocity increase?

Great job on the detailed photos. This has been an interesting journey.

HiveSeeker,

That’s the balance that exists between viscosity and sealing. I think I was lucky to get what I got.

B.B.

I imagine the extra will lay down and are way for the piston shortly, maybe a couple hundred shots, but it should rise to a hair over your original velocities. Good job, BB, you are certainly going above and beyond, as usual, to bring us the full monty on these great airguns. Thanks!

Success! Beautiful & shooter friendly. I can see how easy it could be for someone to get carried away with spring lubrication.I actually could have been a little too moderate with the QB-36 but I’ve witnessed plenty of messes created by slinging grease. During my search for lubricants the ones I encountered most often appeared to be of the thinner Lithium variety and I quickly gained more understanding of the type of grease and amount of it I wanted getting slung around inside my gun by it’s mainspring and piston skirt once I had it disassembled, I also noticed room for improvement when I saw no buttons on it’s skirt, unlike my beloved little Slavia. I don’t recall seeing any on this Hakim either.

B.B.,Have you ever shared any of your experiences with this level of spring gun tuning? If so I’d like to review them before I do get into attempting such a modification. This has been a wonderfully detailed step by step documentation of the work done on this historically significant, highly collectible and valuable spring gun that any prospective buyer would be confident in purchasing and may have inherently also added to it’s value particularly if condensed on a mounting piece for it’s storage while not in use.

Thanks B.B.!

Reb

Reb,

Have you read this:

/blog/2006/08/spring-gun-tune-part-13-range-testing-the-r1-we-tuned/

And this

/blog/2011/02/a-shrine-built-for-a-feinwerkbau-124-part-15/

B.B.

B.B., one question I have is; are there flats on the nut used for seal retention?

Reb,

No,

It has a screw thread plus it’s held in by a steel crosspin.

B.B.

Does this crosspin go through the screw, if so that would seem to be a weak spot for that much mass coming to a dead stop in less than 1/4″.

Reb,

The cone IS the screw! It has a slotted head. The crosspin does go through it.

B.B./

Old Hakim. That’s what the doctor ordered 😉

*Hakim is doctor in Arabic.

jff,

I, too, was curious if “hakim” meant anything specific. I entered it into Google Translate, and it detected the language on its own — as Indonesian! Anyway, it translated “hakim” into English from that language, and it means “judge.” When I changed the language to Arabic in Google Translate, it couldn’t find the word and said it meant “hakim” in English, too. 🙂

Edith

As a followup, the word “hakim” also appears in 2 other languages: Malaysian–where it means “judge” and Turkish–where it means “judges.”

Edith

Hakim is a name in Egypt. The trainer airgun is named after the “real” Hakim firearm, and I guess this one was given that name in honor of somebody.

Buldawg,

I am not so much into pedigrees actually. When my BSA was built, it is what started that particular pedigree.

As far as the FWB Sporter is concerned, from the beginning I have thought about $300 of the cost was for the name on the stock. They further disappointed me with a beech stock instead of a walnut stock. Like you, I am not in the least happy about the buzz either. Now if it will put ten shots in a group at 25 yards that will hide under a dime, I will keep it on my short list.

I had never considered buying a Walther until BB tested the LGV. Those on my short list are there not because of their pedigree, but their performance.

If Crosman was to take something like the NP2, give it a nice trigger and put it in a nice stock, I would likely add it to my short list. To build one into what I would be happy with adding to my “collection” would cost more than buying a “pedigree”. I will still pick up other airguns at yard sales, etc. and tinker with them a little bit and then sell them, but fill a closet up with them, no. Right now I do not have enough time to shoot what meager “collection” I have now. What would I do with a bunch more?

That, RR,, is why you are NOT a collector. A collection,, in that person’s frame of reference, is not for using,, but for “having”.

Ed

Yay! I’m not a collector either! Not that my meager amount of airguns could be misconstrued as a collection anyway.

I got a bunch of guns but Im not a collector Im a shooter. 🙂

RR

I know all to well about not having time to shoot the small collection of guns I have also. I buy them to shoot and not to sit in a closet, although until about a year ago that is exactly where my old trusted companion from 45 years ago resided until the gun fell out on my feet one day while getting a shirt out of the closet. it woke up an old flame in me that had been out for over 20 years so I oiled it up and pumped it up loaded a pellet in it and went out back to see what it would do, and it shot with the same crisp pop that I had remembered it having the last time I shot it. I am talking about my first variant Crosman 1400 22 cal pump gun that has no plastic on it and a very nice plain wood stock that has killed more birds, squirrels, rabbits and raccoons than I can remember.

As I said before it did not need rebuilt because it has a piston cup made of nylon that will virtually never wear out, but because the parts are still available to rebuild it and the abuse it had been put through in my early years of hunting anything that moved I figured it would not hurt to tear it down and show it some TLC.

So I replaced the piston cup and all the o-rings and reblued the old faded orange tinted metal on the barrel and pump tube from years in the brackish waters of hunting in Florida and while having it apart found that the barrel’s rifling was no longer present so I installed a new steel breach with a disco barrel on it that added 4 inches to the length and improved the power some also. I had the new breach modified so as to not keep the gun from having the original barrel reinstalled if I so choose.

On the subject of the FWB where you could live with the buzz if it is very accurate I myself could not and if I had bought it and for the very slight chance that I decided to keep it I would be tearing into it to fix the buzz before it even had ten pellets put through it. Now if they would offer it in a plain Jane stock version at 300 dollars less the buzz would be less of an issue as I can fix the noise but I cannot fix the look of the stock which I do not like.

On the subject of Crosman spring guns and older pump guns I can only say that my old 1400 is a wolf in sheep’s clothing as it has stood the test of time and abuse with out even showing the least bit of age. I guess I have got lucky with the spring and nitro guns that I have bought as they shoot every bit as good and smooth as my friends 70 model 124 does and out power it also. I will agree that the triggers do require a GRTIII replacement be installed to work 100% better but that is only 33 dollars more to spend on making them shoot very well. The stock that my firepower came is a synthetic stock that does not have a cheap feel or hollow feel and in fact the stock on my AT44 hatsan is far worse in the cheap feeling department than the 40 dollar firepower stock. The hatsan has a very hollow and thumpless feel to it but the gun shoots like a dream. The nitro venom and nitro gr titan both have very plain wood stocks that fit my hand very well and look just fine in my book, although I do wish my nitro benji was not a thumbhole stock I can live with it because the gun is very accurate and smooth shooting.

I am just glad we have so many choices to pick from so both you and me can be happy in what we like and own.

Buldawg

BB

Looks like the gun turned out nice.

And the Diana seal that you show above is alot like some of the hydraulic seals we use at work. I wonder if they are the same?

Did Otho have to make another one of those screws that you had problems getting out on the last report. Or was he able to rework it?

GF1,

Otho turned off the first three threads of the large bushing. They were causing the problem. Now it fits the hole very well.

B.B.,

BB

OK good. I was wondering how that turned out.

BB

Glad Otho was able to fix that bushing for the Hakim and got it back to shooting condition.

I have a question that I have been wondering about since the American airgunner series and this report have been posted and that is about the use of moly as lube in spring guns versus the use of silicone chamber lube.

If you initially lube the piston and seal with moly during a rebuild as you stated in this report that it should last the life of the gun or most of the life.. Then as some companies like RWS for example use only silicone lube to coat the pistons and seals in their guns. Is it wise or even a good idea to mix the two types of lubes and if not how do you know what is the correct to use other than what the manual states if you do get one say when buying a used gun.

I was just wondering if it was ok to lube a gun that was built with moly lube and shot 1000 times to then be lube with silicone lube or if not how would you get the moly into the compression chamber or does it require a tear down to relube in that fifteen year span.

Buldawg

Buldawg,

Moly is a dry lube and silicone is wet. I don’t think it hurts to mix them, but so far that hasn’t been necessary. My moly-lubed guns have needed noting additional.

B.B.

BB

That’s good to know about mixing them, is there a way to know which guns use moly and which use silicone other than what the owners manual states and which is better in your opinion.

I believe I already know which you prefer but I am just curious for when I do build as I have been using moly that is used by GM for lubing the back side of brake pads to prevent squealing and also in the slip yoke of the drive shaft on the trans output .

Buldawg

Jim had 2 types of tar. The velocity tar that was dark brown and not quite as thick as the black tar. They were both glycerin based.

Still only 2 colors but clear was added to the list when I was researching lubricants a couple months ago.

Reb

I am on the brink of taking the beginning steps of the arduous journey into the dark side of airgun ownership by building myself a PCP! Got the cash for my scooter today! I’m sure I’ll be going through a few Co2 cartridges before that ever happens because I still have to buy a pump & Hipac but I got my head through the gate, I just hope it doesn’t slam shut on my neck and stay locked again til the procedure is complete ’cause I’m a Taurus and I know what happens to bulls in that position. Although it may seem less painful to some, it just takes longer that way to me.

Reb

Good I’m glad you got a plan. It sounds 2240 to me. I think you will be surprised at the performance.

Just get your parts and gun before the money goes is all I can say.

Please read below.

Scratch that, rewind. What happens when you give all your money to a woman who’s heading for Wally world? It seems I overlooked this law in my anxious rush to get the funds outta my hands before I reappropriated them myself but the last thing I heard was: ” I’m not gonna get everything we need, just enough to last a few days, we’ll have “.I knew I was in trouble when she headed straight for the computer before the car was even unloaded! Maybe there’s enough left to work a fishing license out but it looks like I’ll be chasing up my own bait.”We’ll just have to wait one more month”.

Reb

All I can say is sorry. But you know you got to live first before the funds go for other things.

I still feel like I got robbed out of 400 bucks for my little highway crater I hit. I still keep saying to myself I’m not going to get mad. And all I got to do is work some more overtime and have less of my time to just get back to even on the money before the crater situation happened.

Let me see. There went my Hawke scope and pellets I have been working overtime for.

I kept digging, trying to find a comment that explained what happened to your ride. $400,eh? That’s justa couple tires nowadays.Too bad about your scope too!I can’t wait to be able to try one out myself but this type of debacle seems to keep holding me back time and again.Guess I’ll have to take the 760 down to the fishin’ hole instead of waiting for it to show up this weekend. Aargh!!!

Reb

I had some messed up times also when I got sick. I have a friend that I have known since grade school.

He always tells me to be happy that I have what I have. He then starts telling me about all the things that he encountered and about other people he knows that ain’t as fortunate as some. He always looks at things like your time will come and it will get better. He goes look at me you know what I have been through and you Know what I have now. I always have to say I know and I can’t say no more.

The best thing I can say is take that 760 to the fish’n hole and be as happy as you can while your there enjoying that gun and the time you have.

You know and I know it could be worst. Gunfun1

Scratch the license too?! -_-

Ever since I started reading this blog I have been amazed at the amount of knowledge I have gained in the care and shooting airguns. I now know why our CO2 guns were doomed to leak (failure to put pellgun oil or its equivalent) and how to properly shoot a spring air rifle that I can now enjoy the process and hit the target. I am especially impressed by the comments section which have greatly slowed down my attempts to catch up to the present day (reading March 2008 now) as that the nuggets I have gleaned are truly good as gold. Thanks to everyone especially to BB!

Hey Siraniko.

The history is nice to look up something you need. But if you look every day there is also good news to read.

I still would like to see some of the guns you talked about. BB knew right away what you were talking about and where those type of guns were from. I will say this right away that I’m always interested in airguns that I don’t know about.

But remember have fun shooting.

I do read the blog daily, in fact my browser is set to open it when I click on the sites I read on a daily basis.

As to my gun, imagine a stack of three tubes. The brass barrel is soldered to the middle tube for its whole length. This second tube is the pressure tank and also contains the release valve which is cocked when I open the bolt. The third tube has been soldered to the bottom of the second tube this contains the foot pump mechanism. If you people think pumping a Benjamin is hard this is much more difficult as I have measured the force required at the last pump to be 75 lbs. I view this more as a primitive precharged pneumatic survivalist air rifle as out in the boondocks there are no stations where you can get your CO2 refilled or SCUBA shops which will readily refill your tanks.

BB is correct as the airguns here are running more to CO2 which is why the release valve dumps a lot of the air. There are some models similar to this rifle that accept filling with CO2 as well as having a foot pump. You might say we preceded Crosman’s dual fuel use by a good many years.

Spring powered rifles are not locally made and the ones that are available are expensive due to taxes. Until I started reading this blog I had absolutely no idea how to shoot a spring powered rifle properly that will allow me to get some accuracy.

Having fun shooting when life permits.

Siraniko

I don’t understand the third tube. Well maybe a little but not real clear.

And BB’s good ole artillery hold comes through again. 🙂

GF1,

That’s 2 CO2 reservoir tubes, topped by a barrel.

Look here

/blog/2005/10/air-shotguns-part-1-the-farco/

Enlarge your screen to see what he means.

B.B.

Thanks BB. And I just watched the link Siraniko posted of the video. Now I understand.

B.B., I think I’ve come to the conclusion that bluing the shroud on my Airmaster is gonna be too high maintenance for my taste and it is starting to turn a nice Plum color, which will work out for me just fine. Especially if I can get it fairly even. Is there a decent trick to getting that Patinaed look to cheap cold bluing that’s seen better days? Not trying to trick anybody but after knocking off the surface rust with extra fine steel wool and oiling That’s what it’s starting to look like and it’s much better than the glaring nickel finish it came with.

Reb,

Oil it with Ballistol and it will take on the patina-ed look. But it does take time — years.

B,.B.

Gunfun 1

For reference https://www.youtube.com/watch?v=n0SCHVMiKCo

Gunfun 1

If you go on Youtube and search for “How to pump an Eskopeta Foot Pump Air Rifle” you should bet a clear picture of what I have. Tried posting the direct link twice but cannot see my postings. Pumping this airgun up takes time and strength. The video makes it look easy and I may be overpumping this gun but since I have no chronograph, I have to depend on my ears to tell me if the power is down which it is after 4-5 shots. I don’t quite believe their claim of 1000fps probably closer to 650fps in my estimation.

Siraniko

Your link to that video did work. I like that gun. I wish I had one.

What kind of ammunition do you use? Pellets, round balls or bb’s?

And 650 fps is good enough for me.

We use .22 caliber pellets. Over here they are used for hunting which is why there are successive shots available. Accuracy is not all that great and the sights are non-adjustable as that they are permanently soldered into place by the manufacturer.

Well as they say beware the man with one gun.

Siraniko

What brand pellets can you get?

And I do know that saying about one man and one gun. I use to say that all the time. Now I got more than one gun and I have to keep notes now. 🙂

Purely local stuff, some good and a lot bad. But all of them are around 15 – 16 grains making them medium weight. As is advised I go looking for the pellet my gun likes and I stick to it. I am not that big on demanding accuracy so as long as it slings lead and hits my target I am happy enough. An inch at 10 meters offhand is adequate.

Siraniko

I forgot. Didn’t you say you hunt. What are you hunting?

And, are you stalking your game or ambushing? The 1″ would be plenty for Armadillo and possum around here but the rabbits are too alert and Fast and the squirrel too small.

Used to hunt birds and fish. Now with the rapid urbanization no more. I’ll stick to inanimate targets for now. If the rat population starts going up though I might start again.

That sounds like a good job for the $100 PCP that B.B. and Dennis built from a 2100 pump gun. I have a Remington Airmaster which is the same gun, only in a Tuxedo and it’s accurate enough to produce bird-head size 10 shot groups out past 20 yards. But the pumping for power wears me out anymore. Are Ya’ll filling from soda Co2 canisters? If not where do you get your Co2?

I can only dream right now as individual importation is rather restricted. Until recently airguns were defined as firearms. Imported items are slapped with a very stiff tariff also such that the price can balloon by a hundred percent from the original price including price conversion from the dollar.

I was talking about building yourself one out of one of the many of these found relatively cheap over here and thought maybe you could dig one up around there. That 20 guage will go through the lead rather quickly when used as a shotgun I’m sure

Reb

If you mean for me to make an air gun it remains a pipe dream for now (sorry couldn’t pass up the pun). My current need for something to plink with and occasional informal target shooting is met with my present rifle. I am familiar with the various home-brewed and scratch-built airguns over there. I regularly wander around the hardware stores looking at their inventories for parts. If ever I get the itch or the need to build one I will be ready, I just need to learn silver soldering and some other skills for the fiddly bits.

Siraniko

I use to take care of getting rid of the field mouse population in the barns on the farm. Pump guns are great tools for that type of work.

Hi Airgun users!

Wait for my Chrismas gift, the Hakim Rifle, verry rare here in Germany!

I just want to leave the conversion list for Arabic numbers:

Left: today right: Arabic

1 ١

2 ٢

3 ٣

4 ٤

5 ٥

6 ٦

7 ٧

8 ٨

9 ٩

0 ٠

١٩٩٩ = 1999

٢٠٠٠ = 2000

Now you can compare the numbers on your Hakim Rifles, numbers are written from LEFT to RIGHT like we do today!

Merry Cristmas to all!

Warmest Regards: Juergen from Germany

HW77,

Welcome to the blog.

Thank you for this information. All Hakim owners appreciate it, I’m sure. I’m going to print it out.

B.B.