by Tom Gaylord

Writing as B.B. Pelletier

A Benjamin 310 multi-pump BB gun from 1952.

This report covers:

- Point 1 — does it hold air?

- Discussion 1

- On to the velocity tests

- Test 1

- Test 2

- Test 3

- Test 4

- Other BBs

- Test 5

- Test 6

- Test 7

- Test 8

- Summary

This report is taking on a life of its own! I am going very slowly and thoroughly through the testing of this Benjamin 310 BB gun to record everything for posterity. In Part 3 I started the velocity test and today I intend completing the steel BB portion of it.

Does it hold air?

My last report is dated Friday, September 2, 2018. That means I tested the airgun on Thursday, September 20. While you are reading this report on Monday, October 8, 2018, I actually wrote it on Friday, October 5. That means the tests you are about to read were also performed on that day. First I wanted to see whether the gun is still holding the two pumps of air I pumped into it at the completion of the last test on September 20. A total of 14 days and several hours have passed and I have not touched the gun since the last time. Is it still holding air?

It is! That means that the automatic transmission sealant I used to repair the fast leak in Part 3 has fixed the leak, and the gun is now holding air indefinitely. So — the automatic transmission sealant I have been telling you about for many years really works as I have described. You can’t argue with success.

Discussion

We heard from several readers, the first of whom was a new guy who calls himself Oldradioguy. He has a Benjamin 3100, which is a more modern version of the gun I’m testing. He said his gun shoots Daisy BBs at 705 f.p.s. on just 5 pumps. He also said that 2 or 3 pumps are good for the mid-500s with air remaining in the gun. So the performance I reported in Part 3 might be common to the model.

Reader thedavemeister research the Benjamin 310 online and found a report from Dennis Baker of bakerairguns that said a 310 he was selling produced velocities of 688 f.p.s. with steel BBs. No other data was given, but that does support the power we are seeing with my test gun.

Reader Halfstep wanted to know if the inside of the 310 breech was made to interface and seal the hollow bolt in any way. I said I would look. I did and saw that the bolt is sealed by a angled shoulder behind the hollow probe. I already showed that to you in Part 2 of this report.

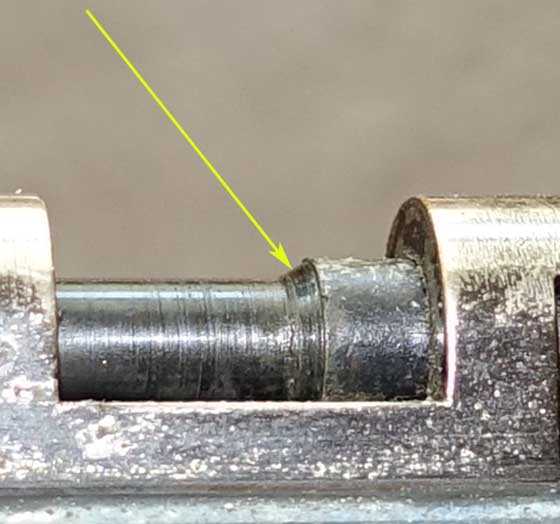

The angled shoulder on the bolt body (arrow) mates with the rear of the barrel to seal the air inside the gun.

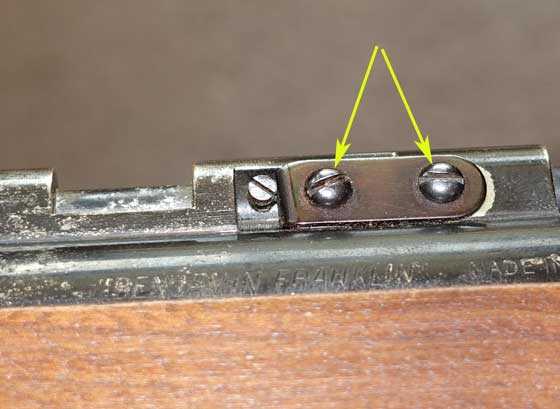

This cam plate on the left side of the receiver can be adjusted by loosening the two locking screws (arrows) and sliding the plate forward (to the left in this photo) As the bolt closes the screw on the bolt body rides up the cam plate, pressing the bolt shoulder forward into the breech and sealing the air inside.

Inside the breech that angled bolt shoulder mates to an identical and opposite angle in the breech to seal the bolt. There are no other seals of any kind, just these mating parts. The hollow bolt probe simply sticks up into the smoothbore barrel. I can’t see in far enough into the breech to see if the end of the bolt butts against a shoulder in the breech, but I would think it is designed that way. I guess that’s why it’s important to seat the BB in the bolt nose during loading.

Reader Shootski asked what kind of velocity one pump would give. I will test that today.

On to the velocity tests

Now it’s time to resume the velocity tests. Since others have reported such high velocities with their 310s, I decided to pump the gun 8 times to see what it will do. I shot a Daisy BB for this test. The gun was emptied of air then pumped 8 times before the shot.

Test 1

Daisy BB on 8 pumps

Shot…………Velocity

1………………509, 244

That was a surprise, since I’d gotten 655 f.p.s. with the same BB on 5 pumps in the Part 3 test. But when I read all of Part 3 I saw that I had also gotten as low as 561 f.p.s. on 5 pumps. I decided to rerun the test where I empty the gun then pump it two times, fire, and refill with one pump to fire again. I will do this until the velocity stabilizes.

Test 2

Daisy BB on 2 pumps

Shot…………Velocity

1…………….…477

+1 pump………446

+1 pump………420

+1 pump………399

+1 pump………387

+1 pump………389

+1 pump………393

The velocity seems to have stabilized around the 5th shot. And it’s low enough to make me wonder what the gun will do on a single pump. That test was next.

Test 3

Daisy BB on 1 pump

Shot…………Velocity

1………………351, some air remaining for one more shot without power.

I emptied the gun and ran the same test a second time. Here are the results.

Daisy BB on 1 pump

Shot…………Velocity

1………………361, some air remaining for one more shot without power.

Based on those two tests, I think the rifle on two pumps followed by one pump is gradually loosing air pressure. It doesn’t make it down to the velocity with a single pump of air though. That begs another test.

What will the velocity be if I pump the gun just one time and shoot, then pump once more and shoot and so on? I will try this for a few shots.

Test 4

Daisy BB on 1 pump

Shot…………Velocity

1…………….…357

+1 pump………386

+1 pump………393

+1 pump………389

Interesting! The gun builds to around 390 f.p.s. and then holds there. After the last shot there was still some air left in the gun, but not enough to power a BB. It seems the gun wants to stabilize at the same velocity, whether it’s coming down from an initial two pumps or increasing from just one pump per shot. This might be the best way to shoot darts.

Other BBs

I Part 3 I said I would test other steel BBs in the 310. I think the results are going to be close to what we see with Daisy BBs, but if not I can always design another test.

Hornady Black Diamonds

Next up are Hornady Black Diamond BBs. I will use the test where the gun is pumped two times, followed by one pump and so on.

Test 5

Hornady Black Diamonds on 2 pumps

Shot…………Velocity

1…………….…493

+1 pump………454

+1 pump………419

+1 pump………395

+1 pump………393

+1 pump………393

+1 pump………385

+1 pump………392

Like I thought, Hornady BBs preformed very similar to Daisy BBs. Maybe they are just a touch faster is all.

Test 6

Daisy Match Grade shot on 2 pumps

The last steel BB I will try is the Daisy Match Grade Shot that is made specially for the Daisy 499 Champion BB gun — the world’s most accurate BB gun. I will perform the same test as I did for the Daisys and Hornadys.

Test 7

Daisy Match Grade Shot on 2 pumps

Shot…………Velocity

1…………….…501

+1 pump………480

+1 pump………453

+1 pump………433

+1 pump………415

+1 pump………418

+1 pump………413

+1 pump………412

+1 pump………402

+1 pump………401

+1 pump………403

+1 pump………405

Another interesting result. I mentioned in Part 3 that we know Daisy Match Grade Shot is slightly larger than other steel BBs, so a slight velocity increase is expected. Since the velocity was remaining pretty constant I tested this one a little longer to see where it would stabilize. I looks like the Daisy Match Grade Shot will remain around the 400+ f.p.s. velocity.

These results made me want to try one final test. How will the Daisy Match Grade Shot do when we start with one pump and keep adding one pump after each shot? We can compare the results to Test 4 where I did the same test with standard Daisy steel BBs.

Test 8

Daisy Match Grade Shot on 1 pump

Shot…………Velocity

1…………….…354

+1 pump………399

+1 pump………407

+1 pump………406

+1 pump………402

+1 pump………404

+1 pump………400

Very interesting and enlightening! The Match Grade Shot rose in velocity faster than the standard Daisy BBs and then stabilized at around the same velocity that it did when it came down from two pumps. I think that means these Match Grade Shot, being slightly larger than other steel BBs and also more consistent in size, are best-suited to the bore of the 310. That tells me to expect the larger lead shot to perform well when we test it for velocity next time.

Summary

The Benjamin 310 continues to provide intrigue. It seems to be changing in power as the test progresses. By the time we get to the accuracy test I should know the gun quite well.

B.B.,

Very interesting indeed!

I was most intrigued by the comparison between Test 7 and Test 8;

whether you started with one pump or two, once you kept adding one pump after shooting,

the velocity seemed to want to stabilize around 400 fps.

I don’t think I’ve ever seen another pneumatic perform like this one.

I’m curious to see how it does with lead shot and darts.

Great test so far!

Keep up the good work,

dave

B.B.,

This 310 really is sealed up tighter than a drum. It is also incredibly efficient with air, more so than any other multi-pumper I am aware of. Perhaps air gun designers should simply favor well-mating steel-to-steel and go without breech seals.

I have a Benjamin 130 (the pistol version of the 310?) with wood grips but none of the black nickel left. At some point an owner must have decided that there was so little of it left that should just all go. It does have a nice patina now, however. I paid $40 for it, probably about right given the lack of the original finish.

It shoots like a dream, and I have not ever pumped it more than four times, to my recollection. Yes, it has no breech seal, just tight-fitting petal parts and a hollow bolt probe. The trigger is a bit spongy but light and short.

Michael

Michael,

I think you paid about half what your pistol is worth. Good deal!

B.B.

B.B.,

Thanks very much for the good news. Because I assume it did not come with the gun new as a Benjamin accessory, I decided not to mention the nifty leather holster it came with. No box, however. Then I would almost be embarrassed to have made such a score. “Almost” is the key word, though! ;^)

I now intend to chrony it to see if it is a miniature blaster like your 310.

Michael

What surprises me is that it functions well at all with just 2 +1 or even 1 +1. That gives a whole new meaning to multi-pump,…. in that it does not need 5 or 8 or 10 to perform.

Good Day to one and all,…… Chris

Here is a photo of a Benjamin 312 bolt it is similar and has the transfer port hole in the hollow bolt probe.

Don

Don,

I don’t believe that is the right bolt for a 312. I think someone has replaced it with a BB bolt. The 312 bolt nose should be solid and rounded at the end to stick into the skirt of a pellet. Because all these guns are made with similar parts, though, that bolt will work.

B.B.

B.B.,

I spent some time checking the bolts on the 312 and 342 I have both guns purchased new they have the bolt shown above with the exception the 342 bolt has a larger knob on the bolt handle. I can’t find my owners manual for the 312. I think it had the parts diagram for the 310, 317 and 312. If you have yours you can check and see if the bolt numbers are the same for the 310 and 312. I checked on the 340, 347, and 342 parts list and they have the same bolt listed for the 340 and the 342, but a different part for the 347. I think the 347 is rounded, I don’t remember for sure. One thing that is different though for the 312 and 342 is that neither has a large enough hollow bolt for a BB to fit in. So maybe the 310 bolt is a little different than the 340.

It looks like the .22 caliber guns seated the pellet pushing on the skirt and the .177 caliber guns bolt probe fit inside the skirt. I don’t have a 317 or 347 gun to check. Maybe someone with one can chime in.

Don

Don,

You may be right, though I can’t be sure. The bolt 3465 seems to be for the BB and .22 rifle and the bolt 34765 seems to be just for the .177. I have learned something. Thanks,

B.B.

B.B.,

I did not find a copy of the 310, 317, 312 owners manual on line. It did not look like there was one with your 310 from Part 1. I hope I have one from my 312 I will look.

If anyone has the owners manual an electronic copy would be much appreaciated.

Thanks

Don

Don,

It’s in Dean Fletcher’s book, the St. Louis and Benjamin Air Rifle Co’s. Unfortunately its also copyrighted and can’t be copied. Find one to buy and you’ll have everything Benjamin.

B.B.

Thanks,

I will keep a eye out.

B.B.,

Glad you got the valve to seal. It sure looks like the gun has not been shot much, it is in great shape. I am very interested in the accuracy tests. I think it may do very well with the Daisy Match Grade shot and one or two pumps. If it is accurate I am not sure what darts may do to the brass barrel. Maybe they are no worse than steel BBs.

Don

BB,

I do like the cam plate. It would be nice if something similar were on my 101. Crosman’s solution was to braze a brass bead onto the base of the bolt handle to make a tight seal with the bolt and barrel.

BB,

My question about the shoulder inside the barrel was answered when the velocity went up with the larger Match Grade shot. The bore would have been so much bigger than the BB, had there not been a shoulder, that the fit of even the larger BB would have been too loose to gain any velocity. The barrel has to be stepped down to a diameter close to the BB’s.

Thanks for responding.

Half

B.B.,

Thanks for running the one pump shot series from empty.

I makes it clear to me that playing darts inside with this rifle at 10 or perhaps as close as five meters could be lots of fun with very little chance of damage to a quality Bristol board.

The valve on this rifle was apparently very well designed or perhaps worked on by some master runner.

Thank you for an interesting test series.

I hope your long arm is very accurate!

shootski

BB and All,

Yesterday, while playing with my “new” chronograph I shot my Webley MKII Service air rifle ( /blog/2016/08/webley-mark-ii-service-part-4-2/ ) to see what it would do. After shooting it for a bit, I was oiling it down and a small part fell off. OH NO! It was one half of the barrel pivot pin. Fortunately, I went to John Knibb’s site and he had the part I needed in stock. It is on the way.

I had also noticed that while shooting her she was buzzing real badly and dieseling almost to the point of detonations. I need to replace the piston ring and check her innards out. I guess I will be going into this old gal pretty soon.

RR,

Oh, boy!

Take lots of pix and we will have a guest blog about that! 😉

B.B.

BB,

That’s what I was a thinking. I’ll try my hand at composition.

BB,

Thank-you for the informative article. You have maybe already answered this question but I shall ask it again. Does the STP automatic transmission sealant work only with sealing pump values or will it also work with Co2 airguns. I have an old Daisy 44 Powerline Co2 revolver that must be 20 years old, and it has just started to leak Co2 as I can hear a small leak when the Co2 is first seated and then for a few minutes until the leak becomes to soft to hear. I have used a lot of Pell Gun oil and even o-ring safe silicone oil thru the Co2 port to clean/clear the valves before seating the Co2 and the initial leak continues. As projected cost to repair is more than the cost to replace and the leak is so small that I am able to use it with no obvious loss in power or duration if I act without any delay, I have been willing to live with the situation. If the STP automatic transmission sealant injected into the Co2 port does not cause any harm I am tempted to try. What do you think?

Waldorf1,

I started with ATF sealant on CO2 guns. Once I knew it was good for them I moved over to multi-pumps.

You describe the ideal leak that I am sure can be fixed. Do it and report back.

B.B.

BB,

Thank-you for the quick response. I would appreciate any assistance or suggestions as to a specific product name, product number and any other specific information as to what STP automatic transmission sealant is best for this kind of use. If I go to a typical auto parts/supply store I want to get what you know will work and not what the store manager has a large supply of and they want to get out of inventory.Hopefully it is still available, as typically if a product is found to be safe. effective and affordable, business makes sure they do not make those mistakes again.

Waldorf1,

As far as I know any of the sealants will work. They all should be pretty much the same.

Mine is Bar’s Leaks Transmission Stop Leak Concentrate.

B.B.

BB,

Thank-you for the product suggestion. If I may forgive me to trouble you by making one further request of your time, I am sure there are many, like myself that would be greatful. If you could, at your convenience, prepare a SOP, SJP, SIP, (Standard Operating Procedure, Standard Job Procedure, Standard Inspection Procedure) on the tools if any,on the level of concentration of sealant, how to apply and how often to apply the STP automatic transmission sealant to seal the leaking air gun as well as any learned lessions doing it, and have it in the knowledge base of your blog, I am sure many would be greatful and feel more confident having a written detailed record of your experience to go by. Just a thought, as a quick search for such a document on your blog for me was not successful.

Waldorf1,

Wow! Over-thinking it a bit!

Just lube the pump head for a multi-pump or the tip of the CO2 cartridge for the gas gun. If it’s bulk fill, fill the fill port before connecting the source of gas.

Lessons learned? It works a high percentage of times.

B.B.