by Tom Gaylord

Writing as B.B. Pelletier

Michael’s Winchester 427 is a Diana model 27 by another name. The rifle pictured is my Hy Score 807/Diana 27.

This report covers:

- How can a ball be a sear?

- Three balls instead of just one

- How the trigger works

- Seen it before

- Discussion

- Summary

- Last word

Today I’m going to try to explain how the Diana ball bearing trigger works. This is a design that seems complex, but once you understand it you understand a lot about how the Diana 27 goes together.

How can a ball be a sear?

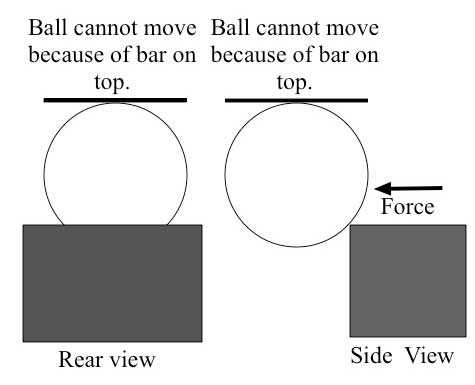

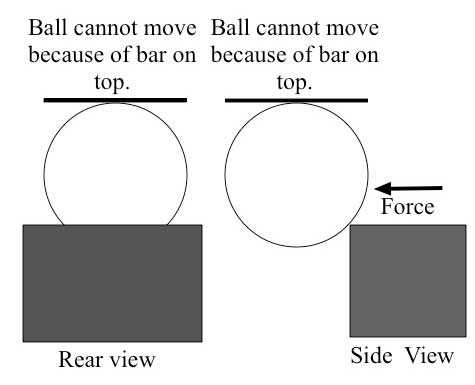

A ball can restrain something from moving by blocking it. When the ball moves out of the way, the item that was restrained is free to move. Let me show you.

In this view, the ball blocks the large bar (which represents the piston) that is being pushed by the force from a spring. As long as the ball doesn’t move, the shaded bar/piston cannot advance. The ball cannot move because there is another bar restraining it on top.

When the bar above the ball is removed, the larger bar that we know is a piston pushes the ball up out of the way by the force of the spring that’s pushing it.

Three balls instead of just one

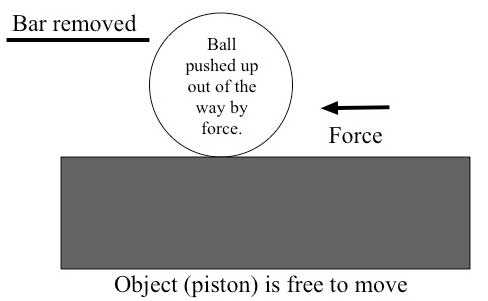

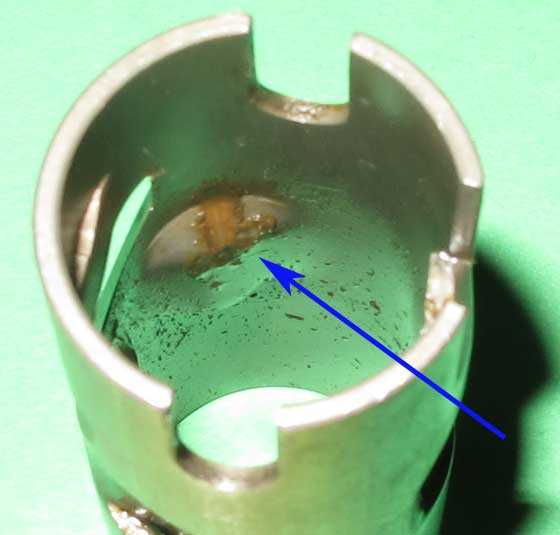

The Diana trigger uses three balls in the same way you have just seen. The piston is under pressure to move forward and the outer (silver) “cage” pushes the balls down into the groove at the rear of the piston rod.

This is how the three balls in the Diana trigger act as a sear.

The silver “cage” has three ramps stamped into it. The arrow points to one. These ramps push the balls down through the black inner “cage” and into the groove at the rear of the piston rod.

How the trigger works

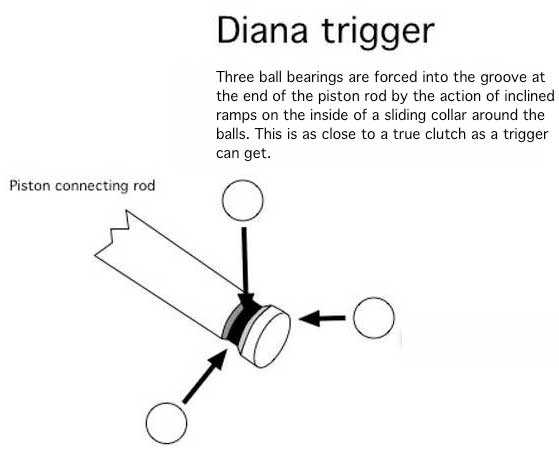

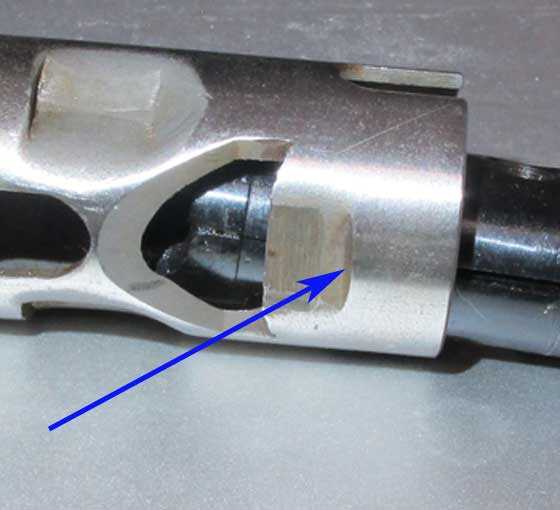

Let’s take a closer look at the inner cage. The holes that the balls fit into are not cut perpendicular to the axis of the cage. If you look closely you will see they are cut on an angle. That makes them easier to push out of the way.

This closeup shows the ball bearing hole in the inner cage. As you see, it’s drilled on an angle to make pushing the ball out of the way easier.

When the Diana 27 is cocked, the piston moves to the rear and the piston rod pushes into the inner cage, pushing the three balls up and out of the way. The rear of the piston rod is shaped to do this. Then the balls are pushed back down on the piston rod by three ramps inside the outer cage.

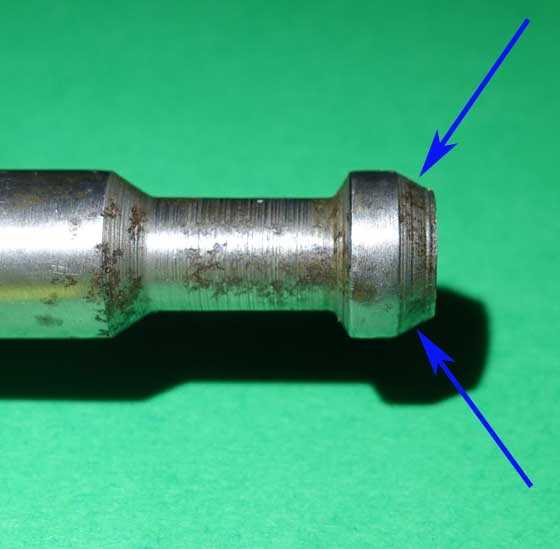

The end of the piston rod (arrows) is shaped to push the balls out of the way as the rifle is cocked.

Seen it before

Before you get a headache, let me show you that this function is familiar to you. Where have we seen this before?

That’s right. A male Foster fitting looks like the end of the Diana 27 piston rod. And it does the same thing — pushes the balls out of the way, then they come back and grab it on the other side.

The Foster fitting works in the same way as the Diana ball bearing trigger. Balls in the female coupling hold the male fitting captive until released by an outside action.

I could probably stop right here, because the Foster fitting analogy explains the Diana trigger so well. But let me show you a few more key pictures to cement the idea.

This is an inside view of the ramp (arrow) that’s pressed into the outer cage. This ramp pushes the ball into the piston rod end. When this cage moves just a little, these three ramps move, allowing the piston that’s under spring tension to push the three ball bearings out of the way. The rusty bearing has left a mark where it worked for 48 years.

Here is a better look at the outside of one of the three ramps that are pressed into the silver outer cage.

Discussion

So the principal part of this “trigger” is actually a ball catch that is similar to those found in many quick-disconnect hydraulic and pneumatic couplings. When the trigger is properly adjusted, the inner and outer cages remain where they are positioned during cocking, with the three balls just barely blocking the piston rod end until the slightest pressure on the trigger releases the outer silver cage. A small but powerful coiled steel spring then pushes the silver cage slightly forward, moving out of the way the three ramps that are retarding the three bearings. Once the bearings are free to move, the piston rod end pushes them out of the way and the piston slams forward to fire the gun.

Here is the thousand-word picture. First, note the coiled spring that pushes the silver cage away from the black inner cage. See the two holes in the black cage? They are for the two crosspins that hold the Diana powerplant together inside the spring tube. The black inner cage never moves. Notice that the silver outer cage only has a U-shaped slot. It is free to move back and forth over those two crosspins. See where the arrow points? That is the sear contact point with the trigger. Of course all of these parts would be in alignment if they were inside the spring tube with the piston rod in their center.

And there (arrow) is where the trigger contacts the outer cage. When the trigger blade releases the cage, that coiled spring on the other side pushes the cage forward. Remember, the black inner cage is pinned in place and cannot move. When the outer cage moves forward the ramps release their pressure on the balls, allowing the piston to push them out of the way.

Summary

This report is the most detailed explanation I have ever seen of how the Diana ball bearing trigger works. I hope you understand that the parts in this mechanism work in unison and the trigger doesn’t actually come in direct contact with the piston. If I could make an analogy, this trigger operates similar to the way a multi-lever set trigger works, though it uses different parts to do so. When you adjust the trigger you are adjusting the amount of contact the trigger blade has with the sear point on the outer bearing cage.

When these parts are inside the rifle, the spring tube and piston rod keep them aligned. Outside the gun they are just a mess of parts. Inside they work together as a unified mechanism.

Assembly of this trigger, which goes together as the rest of the powerplant is being assembled into the spring tube, seems daunting to the beginner, but it’s not that hard. Use a tacky grease like Tune in a Tube (TIAT) grease to hold the balls inside the inner cage as you install the parts.

Last word

I’m cleaning the parts and working on replacing the piston seal right now. The screw that holds the seal assembly to the piston is fighting me because it has rusted tight. I’m using every trick in the book to free it. Heat will probably be my last resort, which means I may have to buy a few more parts before I can install the new seal.

B.B.,

Magnificently done!

The use of the Foster male and female fittings is spot on.

The photographs are excellent and fill in what the words just cant get across.

Bravo!

shootski

Morning B.B.

Gotta second Shootski’s comments. Even I now understand how that trigger functions. He is correct about the Foster fittings. They sealed the deal for me. The proverbial light went off in my mechanically challenged brain.Thank you

Mr B.

“The Foster fitting works in the same way as the Diana ball bearing trigger.”

B.B.

I must concur with Shootski and Mr. B.

That was a really helpful comment for brain recalibration purposes. =)~

Seriously, those were great pics and a very well-presented explanation; thank you!

take care & God bless,

dave

Not only a foster fitting but any quick release air hose fitting.

David Enoch

Yes, David; that’s a good point of clarification; thank you. =>

B.B.,

Nice report. It was very innovative to use this concept in a trigger mechanism.

Q: Now the question,…. Which was first? Foster type pneumatic and hydraulic fittings (or) this trigger design?

Good Day to one and all,…. Chris

B.B.

Very good explanation, I think even I understand. This seems very complex and dependent on tight tolerances and strong springs to move the outer cage. I would think dirt and old lubrication could cause problems. The Rekord seems simple and straight forward by comparison. So what releases the spring of the outer cage? Wouldn’t better materials than stamped steel offer more precision?

Santa is on his way,

Yogi

Yogi,

The tolerances really are not that tight. You may remember from a picture in part 1 that the piston is rolled sheet steel. Would this trigger assembly be better if it was constructed of machined steel components? Probably. It also would have been expensive.

In truth, the looser tolerances work in its favor. Think of the 1911 pistol. A properly maintained military grade pistol should rattle slightly when you shake it vigorously. This allows the pistol to operate even if it has been through mud, snow, sand, etc. on its way to the battle. This does not mean it is not accurate. When in the battery position the barrel is locked up tight to the slide, which has the sights mounted to it. Where many mess up is they “accurize” these pistols with tighter tolerances. Then they start experiencing feed problems, stove pipes, etc.

The very same problem arises with the Mattelomatic versus the AK. The tight tolerances of the Mattelomatic causes issues that almost never happen with the AK. I know there are many young whipper snappers out there that will disagree with me, but IMMHO the AK and the 1911 make for a most formidable pair of battle weapons.

Sorry for the rant, I was on a roll. 😉

R.R.,

I can’t restrain myself anymore! Mattelomatic…SMH!

The AR-25, AR-10, AR-15 and M-16 family of weapons, but especially the original issue got off to a really bad start because of instructions that they didn’t need to be cleaned and some said would operate dry!!!

Well not being in the US Army when I got my first CAR-16 to replace my CAR-14 (lost during a sapper attack at DaNang) I kept the bolt and carrier wet with lube and cleaned rifle and magazines every time I got bored…as in any time I wasn’t flying. Yes I wasn’t a ground pounder most of the time but if I was I think I still wouldn’t have done it much differently.

My Mattelomatic never let me down!

Interesting how the Stoner rifle family have remained the go to battle rifle of lots of average and outstanding units around the world. Are there better rifles…maybe; but only in the hands of highly trained operators.

END of counter RANT ;^)

shootski

Shootski,

LOL! I am thankful it never let you down.

As for myself, the small battle rifle cartridge for me was the 7.62 NATO. I’d druther lug a M-14 around.

I used to use the .223 for groundhog hunting. It was a superb varmint round. What I really like is the 30-06. Ah, the M-1 Garand. Now that was a battle rifle. It could stop anything short of a tank.

BB,

You have once again illustrated for us a complex mechanical operation in a method that is simplified enough to allow even the most mechanically challenged to comprehend. Bravo!

B.B.

I’ll have to add another title to “The Great Enabler”. How about “The Great Explainer?” Your excellent photos, photoshopping, and analogy make the seemingly complex, most clear.

Bravo!! Well Done! and thank you.

Dan

Dan,

LOL! Bravo to you! I was trying to think of just such a title, but was not quite there. Thank you!

B.B.,

Very nice presentation. I like the mark ups on the great shots. I can just see you walking into a boardroom ready with a well researched and persuasive powerpoint on the case for something airgun related, and succeeding!

I learned why the Diana 27 is unique, and look forward to more tid bits from your armory. Thanks, Rob

Hi B.B. , a 50/50 mix of acetone and ATF makes a super penetrating oil that works wonders on seized bolts, might be worth a try if all else fails on that piston screw

Red Beard Forge,

I’m at that point. I just spent two hours working on that screw. Gonna tackle another job right now.

Thanks for that tip. I will mix up a batch.

B.B.

B.B.,

I’ll second Red Beard Forge’s acetone/ATF 50/50 mix since MEK or Tetra use are mostly banned.

If you have access to a big tuningfork and can get the stem in firm contact the vibration will move the fluid into microscopic crevices. I don’t think the hammer tap method would be a good option in this case.

https://www.amazon.com/SWB-256-432Hz-Tuning-Fork/dp/B00H4973IC/ref=asc_df_B00H4973IC/?tag=hyprod-20&linkCode=df0&hvadid=312195717264&hvpos=1o4&hvnetw=g&hvrand=10532030692239144717&hvpone=&hvptwo=&hvqmt=&hvdev=t&hvdvcmdl=&hvlocint=&hvlocphy=9008163&hvtargid=pla-570360604938&psc=1&tag=&ref=&adgrpid=61623488545&hvpone=&hvptwo=&hvadid=312195717264&hvpos=1o4&hvnetw=g&hvrand=10532030692239144717&hvqmt=&hvdev=t&hvdvcmdl=&hvlocint=&hvlocphy=9008163&hvtargid=pla-570360604938

The tuning fork does the same thing a hammer tapping rythmicly on a frozen/corroded fitting. My dad taught me both techniques.

And, if it works, you can really say you TUNED Michael’s Winchester 427!

shootski

PS: Fred formerly of the DPRoNJ now happily in rainy GA,

I had not read to the end of posts, as I usually do before posting any post of my own, your use of the impact driver actually does the very same thing the tuning fork does with the added rotational force.

shootski,

Ha ha! On Monday you guys will learn that I am doing just that.

B.B.

B.B.,

I am really feeling guilty that you are going through this with my “screwy” 27, LOL. (The guilt is real, though.) This job is becoming the very definition of “the extra mile.”

Michael

Michael,

Don’t worry. Things are on track now.

B.B.

Shootski,

Interesting about the tuning fork. Most of us probably know about ultrasonic corrosion removers. What do they operate at, 60hz?

I used to have a tuning fork that was supposedly not A 440hz but one or perhaps even two octaves below that. It was huge and weighed a few pounds. I could hear it very clearly only if I put it against something like a metal garbage can, so it must have been down below 30hz, perhaps below 20hz. It shook the can quite a bit.

I have no idea what it was made to tune. Perhaps it was not so much for an orchestra rehearsal room as for a lab.

Michael

Michael

Well, I just looked it up. Turns out there’s this internet thing.

Ao is 27.5hz, so it must have been that, four octaves below concert pitch. I used to have A 440hz in my head. I memorized the pitch when I began learning guitar. Perhaps I still have it memorized. I will check it out against my old Peterson tomorrow.

I suppose there is such a thing as A-1, but that would be 13.75hz, so humans would perceive it only as a shudder.

Michael

Michael,

Even my baritone sax would have a hard time with that LOW! Maybe a Bass sax could get closer. I’ll bet your big fork would have been fun for diping in various pans of liquids.

I know 440hz as Stuttgart A…I have no idea why since it was agreed to in a World convention held in Italy back in the 17th Century.

shootski

Shootski,

I am jealous! The bari sax is perhaps the greatest of all Rock ‘n’ Roll instruments. And not just Bill Hailey stuff. Check out Morphine from the 1990s. Drums, slide bass, and bari sax. They rocked and grooved.

Also check out Contrabass Saxophone. Other than the largest pipe organs, they go lower than any non-electronic instrument (i.e. synths).

Michael

Michael,

I’m much older so I played in Jazz and in Dance Bands…think Gerry Mulligan one of my clinic instructors…I have been invited to sit in with a few Rock ‘n’ Roll bands. I’ll let you in on a secret; Adolphe Sax designed and had a Patented on a Subcontrabass Sax a very few have actually been built! I could hardly afford the 125 Gs my Bari cost me some decades back. I don’t even want to guess how much a Subcontrabass would cost to have built! I really love the Bari for the range it covers and that unique sound it can produce; from the voice of the upper register to the floor/rhythm it provides a band when you are going LOW. I love RANGE and sat with the organist at the John Wanamaker Store in Philadelphia almost every weekend when I was a kid.

shootski

Gerry Mulligan and Cool Jazz RULE!

Michael

Shootski,

Seriously, though, listen to some Morphine. You’ll dig it. It has a Beat vibe. Anyone who digs cool jazz will dig Morphine. Dean Moriarty, Dean Moriarty, Dean Moriarty!

Michael

Michael,

Unsehlige to dig; but I got a brain hit on Honey White. So I pulled it up and I remembered it…so last Millennium…kidding!

The sax man has better sound on Tenor Sax, as is often the case; it takes really great air control (no blown out cheeks! G.M.) to play the Bari with great sound.

But you know the miserable “listening” stuff of just now! So it is still way more nice to the ear…women respond to that style better too! Even young ones ;^)

shootski

Shootski,

Honey White grooves for sure.

For more sax in rock you might check out the first three LPs by the Psychedelic Furs. I saw them live in 1985 or 1986. There is something about a tenor sax blasting through a Marshall guitar amp!

Michael

As you probably know by now I like to understand how things work and so I follow with great interest your technical articles as well as the comments from your knowledgeable readers. In this case the combination of explanation, pictures and examples work together perfectly to explain this otherwise (apparently) complex trigger. Bravo to you, sir! Well done! Keep ’em coming!

“The Great Explainer” – that was brilliant too Dan.

Henry

B.B.

Thank you for showing us how elegant this seemingly complex assembly really is. To me the three balls are like a bearing without a cage.

Gerald

BB,

I’ll just echo everyone’s praise for your explanation. I will probably need the knowledge as I am about to install a Vortek kit in my 1987 RWS 52 that has, near as I can tell anyway, a T01 trigger.

Just received my Sun Optics Spring compressor yesterday and I am waiting for a call back from PA to advise me on which kit I’ll need. Do you have any special advice for this repair (suspected broken mainspring and breech seal replacement). I’ll take help from you or anyone else out there. This will be my first journey inside a springer. Wish me luck!

Half

Half,

Some advice? Sure.

It’s a Diana, so the piston seal is probably fine, if it is blue. The mainspring is also probably broken. One inch off either end is the norm.

The breech seal is also probably fine, and you will have the opportunity to examine it closely when you have the sliding compression chamber out of the gun.

Use Tune in a Tube lightly on the new mainspring.

Other than that, go slow and be careful. The rear crosspin goes back in the gun first on assembly. Disassembly makes no difference. They will probably both fall out.

B.B.

BB,

Rear pin back in first. Got it and thanks. Is the Vortek kit required the same regardless of what trigger type the gun uses?

Half

Half,

No. There is a Vortek unit for the T06 and a different one for the T05. At least that was the case for the 34P. I’m guessing the 52 will be the same, because it’s the trigger lockup that makes the difference.

B.B.

BB,

Finally heard back from a tech rep at PA (backed up because of Xmas, no doubt) and he said that the kit for the 48/52/54 would work, no matter the trigger group. On their product page for the kit they show a link to a parts diagram for the 48 TO6, specifically, so I was led to think it was just for that trigger group. It is good to have the help that they offer their customers.

Half

B.B.,

That reminds me of something I was going to just throw in here a few weeks back.

I was at a nationwide big box store buying BBs. Lo and behold, another old fogie stopped next to me and asked if that was a close-out price. (It wasn’t.) We got talking, and it turns out he’s a Daisy guy. I asked him if he collected, and he said no, he was just a backyard plinker. Then he offered that as such he had “only about two dozen BB guns”!

I asked him if he had any pellet guns, and he said, “Just two Dianas, newer ones, not vintage. They’re both 34s, one with the TO5 trigger and the other with a TO6 trigger.” I asked him what he felt the difference was between the two triggers. He looked at me and said, “I have no earthly idea. They seem the same to me. I like ’em both.” We both laughed.

I’ve decided there is quite a bit of wisdom in his comment. I wish I had gotten his name and phone before we parted. It would have been a riot to plink with him now and then.

Michael

John,

Here is a link to part 4 of the review of my Diana 34P where B.B. discovered the broken main spring. I don’t know if there are any similarities to your 52, but you might find some tips by reading the report. There are six parts to the review done in 2017, but part 4 was the one showing the broken spring. Good luck with your project. /blog/2017/07/checking-out-a-diana-rws-34p-part-4/

Geo

Geo,

Thanks for that, but my 52 is a side-cocker and isn’t very similar. I hope there are some vids on YT that will at least keep me from killin’ myself with the mainspring, broken or not. :-)>

Half

Well, at least you can see how the main spring usually breaks like B.B. told us.

Half-step,

Take some time to research the T01 trigger. I believe you have to make two short pins to replace the two long pins to keep the trigger group from rapid disassembly before removal.

Siraniko

Siraniko,

I believe I’ve seen that in a video. I’m not sure why he did that, but I wasn’t really impressed with his methods in other areas of the disassembly, such as the absence of a spring compressor and some other fumbling around that he did. I’m going to search for some better instruction and if I can’t find any single source, I hope I’ll at least be able to use a little from here and a pinch from there and get enough to get the job done. PA’s site has put a bit of a scare in me, though. They have a very ominous warning in BOLD print warning that the kit is for PROFESSIONAL INSTALLATION ONLY, although the Vortek site, who are out of the kit, describe it as an easy DIY drop in tune. I guess I’ll find out.

Thanks for the tip, in any event.

Half

Half,

Well wishes my friend. I put a Vortek kit into a .22 TX200 and spent 2 days taking it apart, cleaning, de-burring, lubing and just plain studying,… just what did what. The 2nd time “in” was a HO kit and that is where I left it. The 2nd time took one hour,…. tops. Take your time. You are doing everything that I would (and did). Research. I do relate to your trepidation. You will do fine.

As they say,…. “At some point,… you have to get your feet wet”. 😉

Chris

Chris

The Tx’s are easy guns to take apart and change springs. No spring compressor and everything slides apart easy and same going back together.

I’m thinking that 52 would be a bit harder to take apart and get back together.

And you should exsperiance taking a FWB 300 apart and putting it back together. It’s a little different too. Got to get the pieces together right for it to work. Which is true for anything. But the 300 does have some things that need paid attention to if you don’t want to do extra work.

B.B.,

This is an excellent explanation. After I read it a couple times and studied your superb photos carefully, I got out two of my many mismatched ratchet handles to complete the mental picture with an in-hand visual aid. To the computer I brought an old Snap-On F-70 I found on the side of a road a dozen years ago and one called Truecraft. The Snap-On has the familiar on-off lever below the gearing, while the Truecraft has a switch behind the gearing that selects rotation direction. The square posts interact with the sockets using a similar principle to this trigger, right? The securing and releasing is accomplished with spring loaded bearings. It’s just that the Diana has three ball bearings and the energy involved is linear, while a ratchet uses the shoulders of the square post to take the stress of rotational force.

I like that the Diana design features a 360 degree groove instead of a single hook. It seems to me that would promote smoother operation.

Again, this is a great series.

Michael

BB,

just in case you don’t know this trick for rusted/frozen screws, after soaking in the atf/acetone penetrating solution, put the screwdriver in place and as you try to turn it, tap the end of the screwdriver handle with a hammer. It’s a poor man’s solution to the impact driver those of us who owned Japanese two-stroke motorcycles back in the 60’s and 70’s with Phillip head screws securing the side covers, used to remove those darn, strippable head screws.

For those who celebrate, a very Happy Xmas weekend to all (assuming some of you have been given Monday off).

Fred formerly of the DPRoNJ now Happily in rainy GA

Fred,

You have just written a portion of Monday’s blog. I have an impact driver from the ’60s because I had a Honda 305 Superhawk. 😉

B.B.

LOL! And I had a CL77 – the scrambler version of the Superhawk and I also still have my impact driver. Good memories. I still have my kidney belt which, of course, doesn’t fit me anymore. For those of you in the dark here, these bikes, well all bikes in that time period, vibrated so much that one wore a kidney belt to protect your kidneys from the vibration.

Fred formerly of the DPRoNJ now happily in rainy GA

Fred,

I had a kidney belt for my ’48 Harley panhead. And, no, it wouldn’t fit me anymore.

B.B.

B.B.,

A ’48 panhead! Forget the belt, I think the panhead saddle wouldn’t fit my wide, er, my wide me, anymore!

Michael

Michael,

The panhead saddle was a 2-person saddle on a spring-loaded post. The rider floated along while the hardtail bike bashed up and down.

B.B.

B.B.,

Well, then it would have fit me fore and aft. Starboard and port might be a different matter!

Michael

BB

Good write up on the trigger.

B.B.,

Thank you for this very informative report. In reality, the design is not that complicated. It’s more difficult to explain the function of the workings. Great pictures to go with the explanations too, I might add. This is an ingenious design and I am wondering why it is not used in modern airguns. It would seem less expensive to manufacture as compared to the many parts of modern trigger assemblies. How does the actual function compare to the triggers used nowadays? Looking forward the testing of it.

Have a great weekend 🙂

Geo

George,

How does this trigger compare to others? Well, when adjusted correctly it’s light, crisp and positive. Maybe not in the Rekord class, but pretty close. And the stamped parts do make it less expensive to make, though the machines need to be kept calibrated so they make the parts right each time.

B.B.

Well, there is a new permanent resident at RidgeRunner’s Home For Wayward Airguns.

RR,

How old of a gun is that? Looks good. Have you shot it?

Half

Half,

Not yet. Likely tomorrow. 😉

/blog/2016/08/webley-senior-straight-grip-part-4/

Halfstep,

Same pistol: /blog/2016/08/webley-senior-straight-grip-part-4/

I think B.B. traded it for RidgeRunner’s modified Edge.

Siraniko

Siraniko,

It is the perfect mate for my Webley Service Mark II, which I also acquired from BB.

Ridge,

That’s much cleaner than mine, judging by the photo. Very nice. I got mine specifically because of B.B.’s reporting on that one. You have a sweetie there.

Are those vintage Wasps or the newest version? I think the new ones are close to being 5.56, and they are cleaner than those from a few years ago, but the tin was dented and a bunch had dented skirts as a result. Chambers should learn from Pyramyd AIR when it comes to shipping tins of pellets. P.A. is the Undisputed Heavyweight Champion of the World when it comes to packaging pellet tins for shipping.

Michael

Michael,

It is in pretty nice shape indeed. I am looking forward to daylight.

These pellets came from BB’s stash, so these are the old ones. The tin says they are 5.6mm. Now I am going to have to try and get my hands on some of the new ones and see how they do in both of the Webleys. I would hate to burn through all of these, but with two airguns to feed them to they will not last long. Also PA has some H&N FTT that are supposed to be 5.56mm. I am going to have to get some of those in pretty quick.

RidgeRunner,

My mistake. I meant 5.6mm, not 5.56. Wasps are made again, and have been for some time, but for a while there they were terrible (bent skirts, dirty, not uniform). I think they are better now, but try getting a tin of lead pellets from the U.K. that hasn’t been bashed around. Mine had a lot of bent skirts, but there were two separate dents on the side of the tin, too. It was not padded adequately.

Michael

Michael,

Well, we will see how mine turn out whenever I get another round tuit.

Golly Gee Whiz! Some young’n wants to move in also. I guess I will just have to find a spot for her somewhere here. Maybe she can room with the other sproingers.

RR,

I’m beginning to think you may have a problem. Look around you. Do you have airguns stacked up like cord wood? You might be a Airhead.

Half

Hello, my name is RidgeRunner. I am an Airhead.

Half,

This one is actually for my grandson, an HW30.

I am also giving my Diana 46E to my son-in-law. There is going to be a lot of lead flying around here Christmas afternoon.

RR,

A dedicated air gunner could not ask for a better Christmas than that! 🙂 Hopefully the weather over your way will be conducive to some extended shooting sessions.

Chris

Chris,

That would be nice for a change. Right at the moment it is dank and breezy.

RR

I emailed you about a gun let me know if you got the email.

B.B.,

Regarding the piston seal are you aware that the screw is pinned from the side? The pin is usually very hard to see on the side of the piston but it’s there. I’ll see if I can dig up and old pic.

Mark

Trying to post the pic

As you can see this is a pic from the side of the piston after the seal has been removed. The screw laying on the piston is the one that holds the seal from the front. Notice at the bottom it’s flattened somewhat from the pin that is pressed into it on assembly. And notice the pin at the left of the screw sitting just slightly proud of the side of the piston.

The pin is (from my limited experience) what really needs to be loosened first to allow the screw tp come out. Usually a little lube and back and forth on the screw will get it out.

HTH,

Mark

MarkinJHawkland,

I hope BB sees this. He’s probably busy with Christmassy stuff or he would have commented by now. You just don’t get this kind of time saving, confidence building, instructional back-and-forth anywhere else on the web. It’s why I keep coming back! Glad you are a part of it.

Half

Mark,

That was it! Unfortunately, I sheared off the screw while trying to remove it.

I ordered a replacement set for the rifle, so we won’t lose much time.

B.B.

B.B.,

My apologies for being late to comment. I actually meant to comment earlier (part1?) because I ran into this issue with my first attempt at a lube tune with a Diana of this vintage. And subsequently I have seen and helped a few others with the issue. I do think my pic is a “pic worth a thousand words” for those of us that have gone down this road!

The reasons for my delay in response are only difficulty with photobucket and also passwords for here. Normal stuff but I became frustrated when I saw you were having issues with the seal.

Halfstep- Thanks for the kind words.

Merry Christmas,

Mark N

Mark,

I can see one side of the pin now. I will drive it out and hopefully the screw stub will be easier to remove.

Thanks,

B.B.

B.B.,

I’ve never seen the pin come all the way removed but my experience is minimal.

The really IMPORTANT thing I meant to mention by now is that the pin must be completely flush when reinstalling or it will score the inside of the compression tube when fired.

Don’t ask me how I know! 🙂

Mark N

BB,

This stuff is pure gold! Well done! The description, the photos, the additional drawings are all simply first class! Thank you.

Chuck

OFF Topic but not off target.

FASTER is something we all need to learn about to be responsible!

https://slowfacts.wordpress.com/2018/12/05/is-this-mere-coincidence-or-a-cultural-change/

If you live in New York State or even plan to pass through you need to keep an eye out on this legislation; or even own an air gun in NYC:

https://slowfacts.wordpress.com/2018/12/21/new-york-state-demands-insurance-for-me-but-not-for-thee/

So some good news and some bad!

shootski

Shootski,

Never had much use for that bunch up there. Try my best to stay away. The sad part is that all of the voting block is centered in Albany and NYC. Most “Upstate” New Yorkers do not want to have anything to do with that bunch. What is REALLY sad is it has become pretty much like that in almost every state.

Very clear, understandable explanation of the “trigger works.” As for freeing badly rusted parts, has anyone tried Marvel Mystery Oil successfully, for that purpose? Regardless whether this suggestion is helpful – or not – a Blessed Christmas, in advance to all, and to all a good night, Airmen…Airwomen too.

B.B.,

Well, my mother always said I was nothing but trouble as a child. Maybe that is still true to a degree. I will take her out to lunch and update her computer Monday, so I will ask her to remind me of the specific instances of grief I caused my father and her as I grew up. Knowing my mom, she might ask, “You grew up?”

B.B., You have gone so many extra miles I have lost count. Thank you.

Michael

Bummer. I crawled out of bed this morning, expecting a new blog review to read with my morning coffee and slowly came to the realization that this is Saturday.

That’s OK though. We have to give BB some time to breath. It also forces me to look elsewhere for my fix. Hard Air Magazine just put out a review of the Sig ASP20.

https://hardairmagazine.com/reviews/sig-asp20-air-rifle-177-caliber-test-review/

It will likely be very difficult to not invite one of these ladies to take up residence at RRHFWA, especially when they introduce the synthetic stock.

RR,

It always make me giggle when I see Hard Air Magazine reviews with their “speed and accuracy” sections. I keep expecting them to give muzzle velocities (speed) in miles per hour, like George Clooney’s assassin-for-hire in “The American”. There’s a scene in the movie where he is sighting in a Ruger M14 and the client asks him the muzzle velocity and he answers “About 360 miles an hour. That’s including about 20 miles an hour off with the sound suppression.” LOL (360 mph is 528 fps, I might add – less than the muzzle velocity of an R7/HW30)

Well kind of going to eat my words. Sort of.

Had to do some quick talking with Santa yesterday. Got a gun on the way and had to get it approved by the big guy first. Luckily it was a yes.

And here’s the eat my words thing. BB tested one of these last year around November and December in .22 caliber. I’m getting a .177 version. But I said it was kind of a ugly gun in synthetic stock. I said a wood stock would of been nicer but I could over look the looks if it was accurate. Well I guess I’m going to find out about the accurate part.

But couldn’t pass it up because of the price. They normally sell for $899.00. Hatsan USA had 8 refurbs for $349.00 a piece plus free shipping. So I got one. And I checked today and they was already sold out.

And yep I know it’s a refurb. Had to take the chance though. We’ll see.

But here it is. And it will be my first bull pup.

/product/hatsan-bullmaster-semi-auto-pcp-air-rifle?m=4334

GF1,

That is a HECK of a deal for someone considering a bull pup design. Your optic choice? Semi-auto is nice. 14 shots in .177. Looking forwards to seeing what you think of it. Not for lefties.

“Santa”,…. ehh? Are you sure that wasn’t Mrs. Santa? 😉

Chris

Chris

Yep your right. Mrs. Santa too. 🙂

And yep I couldn’t pass it up for that price. I have had the semi-auto Hatsan Sortie-tact on my radar for some time. It’s around $549.00 new. So figured I better jump on the bull master while I had the chance. Plus have wanted to try a bull pup but never really pursued them much.

And no I don’t know yet what scope. I’m going to see what the gun is like when I shoulder it so I can get a idea of my line of sight with it since I never have had a bull pup yet.

And you know what. Maybe after watching what Vana2 has in store for us with his stock making reports maybe this bull master will get my first stock that I make. Since I did mention in BB’s report that I wasn’t crazy about the looks of it’s factory stock. We’ll see how it all goes.

And what I have seen in different reviews and reports is that the Hatsan semi-auto guns resemble the FX Monsoon type design. The mags from the Hatsan semi-auto’s even look like the FX Monsoon mags. Even pellets load the same. So I want to see if the Hatsan is a lower cost version of the Monsoon. Heck the Monsoons are up in the $1500-$1800 range. So that makes me feel good about spending only $349 on the Hatsan bull master.

I’m excited to get it. I miss my Monsoon I had. Well the good one I had anyway. I just hope this bull master is a good one.

GF

You gonna put a bag over that thing so you don’t have to look at it while you are shooting it ??

tt

TT

Haha you know I like shooting with both eyes open. Maybe I’ll have to shoot this gun with one eye closed again so I don’t see it.

Or better yet. Maybe it will be accurate enough that I can shoot with both eyes closed and do some trick shots with it. 🙂

Gunfun1,

Both eyes closed, of course…

And May The FORCE be with you!

and Mrs. Santa too!

shootski

Shootski

Yep the Ninja Jedi Clause.

You combine them all together and you got some super power going on there.

No need to aim. Just point and shoot.

And you know Mrs. Santa has the Force. 🙂

GF1,

LOL! I just watched an episode of The Rifleman Friday where Lucas was temporarily blinded by an explosion and he learned to aim and shoot his rifle at sounds. Of course he killed the bad guy.

RR

I haven’t watched that in years. And I know you remember Gun Smoke too.

I should watch both programs sometime this week since I’m off for the holidays. I know I seen them on the TV guide listings.

GF1,

We have Amazon Prime. There are all kinds of old TV series on there. We find that we do not watch much at all of the new stuff, which most of is not fit for human consumption.

RR

That’s the truth about TV. I hardly watch it anymore.

And yep I could sit down and watch some of the old shows too. Always looked forward to watching them shows when I was younger.

RR & GF1,

I too enjoyed those old westerns. As a youth, I would try to outdraw Matt Dillon at the beginning of the show. The earlier episodes showed the bad guy get hit and then later, they only showed Matt drawing and firing. Gunsmoke was one of the longest running westerns, I think over 20 years. It was one of my favorite shows to watch. I liked the Rifleman too, and Wanted Dead or Alive with Steve McQueen. I like Have Gun Will Travel too, but my wife didn’t like the character Richard Boon’s character, Paladin.

Great old westerns, better than anything on TV nowadays.

tt,

Ohhhhh!,…. that was GOOD! 😉 Ya’ never know though,… the closer center of gravity might feel really “right”? It would be fun to try one.

Chris

GF1,

At nearly a price point PCP it sounds like you got a heavy, powerful wi-fi with 2 extra shots. That puppy should be a whole lotta fun and if you get the accuracy, well that is just gravy.

If it does not work out as expected I hope Hatsan has a respectable return policy, but I think that will not be needed, I look forward to how it works for you.

Mike

Mike

Yep my wi-fi is fun to shoot. Makes pretty good power too for what it is and is pretty accurate too.

But I had those FX Monsoon’s and it was nice to have good pcp power and the ability to pull the trigger as fast as you can. I use to shoot them at spinners and feild targets set up in my yard. Use to go from target to the next as fast as I could pull the trigger. That was some fun stuff. The wi-fi doesn’t quite have the power or accuracy out at 35-60 yards like the Monsoon had. So that’s what I hope I get out of the Hatsan bullmaster. We’ll see.

And yep I don’t know what the return policy is for Hatsan USA refurb guns. I hope that they at least will have parts available if they won’t warrenty it. And as it goes. I hope I don’t have to go there. Keeping my fingers crossed.

GF1,

I looked it up so you don’t have to, Hatsan offers no return for refund on refurb but they do offer 90 days warranty on referbs, you pay the shipping.

Guess it won’t be in till after Christmas, and I will bet it will come out of the box shooting just fine, perhaps you can slice up some melons or apples like the guy in the video, that was cool.

Mike

Mike

Thanks for looking it up. And I can live with a 90 day warrenty on the refurbs. At least they are offering something.

To me buying a refurb is like buying a used car or air gun. Manufacturers warrenty is done. So the 90 days is a good thing. I think anyway.

And yep that was a pretty cool video. He was do’n some blast’n.

Definitely glad we got semi-auto guns. And then full auto. There was some full auto pellet guns at one time. I almost bought the full auto Evanix Speed but waited to long. The only thing available was the semi-autos when I got one. I didn’t like it. The battery operated action that is. But I could of overlooked that in a full auto version. They was basically pcp pellet gun with a air soft DNA.

GF1

The Air Ordnance SMG .22 full auto is a good example, Rossi gives it a look over here https://www.youtube.com/watch?v=XJKjundJ7bY&feature=player_embedded

One thing for sure, with a semi auto or full you are going to go thru some pellets.

Mike

Mike

As long as we’re having fun is all I can say. 🙂

GF1,

I think I remember you saying something about having some old phones that were unused and you were going to do a video shooting them. I do not recall you actually doing that but the Hatsan may give you a chance to do just that.

Yea, 14 shots into a phone rapid fire, that might make a cool video, now we are having fun. 🙂

Mike

Mike

I do still have some old phones. And I still got the I-scope phone scope adapter setting on my work table.

I’ll have to see what I put on the bullmaster first. And I was actually thinking about trying my red dot sight on the bullmaster. The I-scope adapter will go on the red dot sight. I did take some videos plinking with my wi-fi with the red dot and the I-scope adapter.

So yep I should be able to do the video taking care of business on the old phones. Yep sounds like fun. 🙂

And just thought I would throuw this out there.

I’m surprised Pyramyd AIR didn’t have any last minute holiday discount codes.

I was hoping for a good one and was going to stock up on some pellets. Oh well I guess there is next year.

GF1,

With that new two bagger of yours, you are likely going to go through a lot of pellets in a very short time. A bunch of bags also.

RR

I have a good enough supply of pellets right now. But yep your right. I’ll be using some pellets with the bullmaster. And I’m not going to be shooting Daisy wadcutters out of it either. It’s going to get the JSB 10.34’s. They ain’t as cheap as the Daisy’s so I need all the discounts I can get.

GF1,

Me too on a sale. Having several days off,… more time to look and choose something. We had our big family Christmas last weekend,…. so just chillin’ like a villain for the next few. All of these huge piles of cash just sitting around collecting dust and nowhere to spend it,……. ya’, right!,…. I wish! 😉 Maybe something for the New Year’s weekend?

Just an observation,… but some sales seem to be more of a clearance/get rid of it/it ain’t sellin’ well,… type of sale. Good if your in the market for whatever it is they are blowing out. General overall discounts, with few restrictions and free shipping works best for me.

The Hatsan’s and Ataman’s make me nervous on being available. Parts too. Given the World stage these day’s,…. it is a wonder that they are even imported at all. The same could be said for Chinese goods,.. which last I heard,… has yet to be resolved. In retrospect,…. maybe the tariffs and such are aimed at the (highest worth) imports? = Causes the most $ pain. The lesser total value items that are maybe “small time”,.. like maybe our air guns?,… are allowed to “slip by”. If so,… good for all of us.

At any rate,.. A Very, Merry Christmas to one and all!,….. Chris

Chris

That’s what it looks like to me too. A clearance sale.

And yep no restrictions and good discount and free shipping is what I look for too.

And the Hatsan’s being imported I don’t think will be a problem. The Atamans might be a different story. But who knows now days. Anything could happen.

You been shooting? It’s not been to bad here the last few days. Winds been calm and it’s been reaching the low to mid 50″s. I have been shooting everyday. But wish I had the bullmaster already. For sure would be depleting my .177 pellets if I had it.

On the Hatsan USA website they have a video of a guy reviewing the bullmaster. He’s wasting a watermelon then a apple. It’s blowing it apart every shot and he was squeezing them off fast. Looked like fun stuff to me.

GF1,

No shooting except with the 499 on occasion (indoors). The RW, M-rod and Maximus are not so fun to shoot indoors. I am not that bored,…. yet. 😉 I (DO) however shoot any and all of my air guns at least once a month. At least 2-3 shots. I think that is good to do. Even if it is just a load, walk up to the pellet trap and fire situation, or fire out the door. Kind of like a 2nd car,…. you leave them sit undriven/started for a month or two and things are not likely to be good when you do try to drive them.

36 F here now. Been wet and cold. Maybe someday I will have an indoor (to) outdoor shooting “Man Cave”, like you have with your enclosed breezeway. Till then,….

Chris

Chris

I think they should be shot also instead of just sitting.

And if you can swing it you should see about a small sun room. Not to big but big enough. That way it would be easier to heat in the winter and cool in the summer. Plus it will add value to your house. To me it’s a good move. Again if you can afford it.

GF1,

That is an option. It would have to come with a patio door out the end of the house. I could easily do it now,… but keeping a substantial savings back and paying off the house (now less than 5 years) is priority in the mean time. I will get by. However,… it is a bit like learning to shoot all over again in the Spring when I can get outdoors. 🙁 Well,… not like ALL over,.. but you get the idea.

Hey,… we all do what we can do,.. with what we have to do with. 🙂 Having this house for about 10 years,… and getting into air guns only about 4 years ago,…. I would have given MUCH more consideration to a house with indoor (to) outdoor shooting facilities/capabilities, knowing what I do now.

Chris

Chris

Yep I would not consider a house now days if it didn’t have a breezeway or sun room looking out to the back yard.

And another option on house buying would be a split level where the first floor was under ground in the front and in back

of the house it would be exsposed to a patio that is above the ground back there.

That way you could just open the patio door and shoot out in the back yard. That would also keep the cold or heat away from the above ground living area of the house. Keep the door closed going upstairs and you still got heat or a/c downstairs where your shooting from. Maybe not the same amount of heating or cooling as upstairs. But you would at least have some.

Definitely things to think about with air gunning. And you would probably not even disturb the neighbors. Probably couldn’t happen shooting firearms though. They are just to loud.

Had the two new residents of RidgeRunner’s Home For Wayward Airguns out yesterday afternoon for a little sight in session.

WOW! I think that pretty much sums up the HW30S. This sproinger gets the coveted RRR rating hands down. If you do not have one of these, you need to see about getting one. I have been missing out for so many years.

As for the Webley Senior, I can see her and I are going to have to spend a lot of time together. I am going to have to relearn my pistol shooting techniques. Yesterday, if you had been the 3/4 inch dot at 10 yards you would have felt quite safe. In her favor though, the old gal has a very smooth and quiet shooting cycle. It will be quite pleasurable learning how to shoot her and testing various pellets.

A large time was had by all.

RR

The hw30s is a great gun. If a person has trouble shooting springers they need to get a hw30s. Very easy springers to shoot. And they are nice quality guns at that.

And I’m sure you and your pistol will work out just fine together. That’s what this air gunning does. They like to teach us. All you got to do is listen and watch and they will learn ya. 🙂

Geo

Nowhere to reply to your comment above.

But yep with you on the old westerns.

RidgeRunner

I have to concur with your praise for the HW30. If I’m out and about ,there’s probably about a 95% chance that is what I’ll grab to take along. It’s just a fun gun to shoot, and you are so right about anyone being able to be proficient with it. When the kids, grandkids, and their friends show up it’s the gun they all seem to want to pull the trigger on!

Now on to something important to all of us living in the ” WET ZONE “. Was talking with my uncle the other night and we both agree that if it doesn’t stop raining soon, bad things are going to happen. But, he told me not to worry because he had some inside info that would make everything alright. He told me to just call this # 1-800-1WETASS and ask to speak to Noah. I did and found out that the first 100 callers will all be upgraded to first class berthing should the SS minnow actually have to set sail. Put in a reservation for two, and now have peace of mind should the ” BIG ONE ” happen.

All joking aside, I want to wish everyone on the blog a Very Merry Christmas and a safe and Happy New Year!!!!

BFrey56