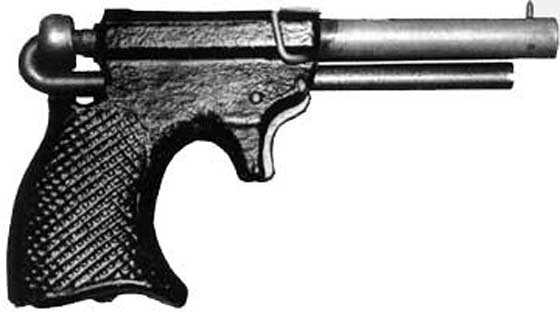

A rare Quackenbush pistol comes to light

by Tom Gaylord Writing as B.B. Pelletier A history of airguns This report covers: From Airgun Revue Wes Powers find! Toy pistol? Powered by rubber bands I had a glitch writing today’s historical blog, so I pulled in this one from the past. Oddly, Edith did the same thing when I was unconscious on a … Read more