by Tom Gaylord

Writing as B.B. Pelletier

This FWB 124 Deluxe is not the exact gun I’m writing about, but it is the same model.

This report covers:

- The motivation

- What did I get?

- Now what?

- Why???

- The lesson

- History

- Long stroke piston

- Summary

I had planned to tear into the Beeman R8 again today, to see whether removing most of the special new grease I put in when I lubed it would improve the velocity, but I’m not at home so I can’t do that. My other plan for today was to begin telling you about another new/old airgun I found at the 2017 Findlay airgun show. That I can do, so here we go. Let’s look at an FWB 124.

The motivation

Before I begin describing the gun I want to tell you why I’m writing about yet another FWB 124. I have already written about so many of them! The last report was titled A shrine built for a Feinwerkbau 124 and ended in February of 2011. It was a 15-part report that probably turned many readers off because it went on too long. I vowed never to write about the 124 again, but that was before this year’s Findlay show.

As you recall, Pyramyd AIR brought a lot of vintage airguns to the show that they acquired when they purchased a local dealer’s inventory. One of the rifles they had on the table was this 124 Deluxe that I told Tyler Patner I thought would be the first to go. I had already snatched the Beeman R8, and this 124 was an equally desirable airgun. I purposely did not buy it, wanting to give somebody else the opportunity. Well, the rifle sat on the table for three-quarters of the show, and the price was reduced several times. I even told people about it and sent them over to see it!

When I went by the Pyramyd Air tables in the early afternoon and discovered that it still was there, despite a reduced price of $250, I just bought it. I didn’t want it or need it, but when the stars align, you just make your move. My friend Mac taught me that.

What did I get?

As I mentioned, this is a 124 Deluxe, which is the rifle with sling swivels, a cheek piece and a checkered pistol grip. Other than that, there is not one iota difference between the Deluxe and Sport versions of the rifle. This rifle is an early one with a serial number below 14,000. I have owned them with numbers in the 40,000s, so this one is early. It has the black plastic trigger blade rather than the silver blade that Feinwerkbau put on later models. Personally I like the black one better and neither one affects the pull a bit, because the trigger operates through a leverage system.

I would estimate the condition is about 90 percent, but without the rifle in hand to examine that is as close as I will go. It has both the front and rear open sights, which is not that common these days. Once people start putting on scopes, the sights get lost and 124 sights are running at a premium today.

The front sling swivel was removed by some Bubba in the past. 124 swivels are for European 3/4-inch slings and Americans often replace them with one-inch straps for reasons I cannot fathom. You can’t use a hasty sling on a breakbarrel rifle, so I fail to see any advantage to a heavier strap. But the deed was done and probably cannot be reversed because of the way the front swivel attaches to the gun (it’s riveted on). They did install a quick-detachable sling swivel anchor to the barrel, which is the last place I want it. I don’t use slings anyway, so I will either remove it or just leave it alone.

Now what?

Now we test the rifle. It came out of the same shop as the R8 so there’s a chance the same grease monkey got inside and did his magic. I shot it during the filming of American Airgunner a few weeks ago, but that is all I’ve done with it. It’s at home right now while I am on the road, so we will all have to wonder a while longer.

If the rifle is stock we know that the piston seal needs replacing. FWB 124 piston seals were made from a synthetic material that always degrades over time, so there is no chance it still works today. If it was replaced (and it probably was because it does shoot), the rifle may still shoot well. The good news is that Pyramyd AIR is the official Beeman dealer for all their high-end airguns and they have invested the money to recreate the 124’s piston seal in a modern synthetic material. They also stock the 124 breech seal and the super-long 124 mainspring. Those are the three items that are needed most for an overhaul. So we are living at a time when this rifle can still be rebuilt to factory specs.

Why???

The question I ask myself is why did this rifle not sell at Findlay? Since I bought it, offers for the rifle have been streaming in to me, so I know people want them. And this one was priced so much lower than what they typically sell for. Were people worried about the condition? These air rifles are so rebuildable that you almost can’t stop one. I once had just an action in the stock that I sold to a man who owned just the barrel!

The lesson

My plan for this one is to once again test it and then rebuild it. You will see how easy it can be to put one back on the road, though we don’t even know if this one needs that yet. And after I finish I guess I will hold onto this one. I’ve owned about 15 of these over my lifetime — everything from the one in the box with all the parts (see the link above) to a beater I bought for $35 and rebuilt into a fine air rifle. I always think I don’t need one and get rid of the one I have, then something comes up and I wish I had one again.

History

I’m putting the history last today, because the story of the acquisition was the most important part. I bought the rifle — not because I wanted it, but because at the low price it was selling for it needed to be bought!

The FWB 124 was an outgrowth of an earlier FWB model — the 121. Feinwerkbau made target rifles and pistols, and the 121 was their first foray into the world of sporing air rifles. This is a company whose barrels are renowned the world over. We talk a lot about Lothar Walther barrels but people only buy them because they can’t get FWB barrels. So the 121/124 had no chance of being anything but accurate.

Long stroke piston

But FWB did something exceedingly clever with this rifle. They gave it a long piston stroke. That did two things. First, it gave the rifle a forward recoil that is so pronounced that the 124 is the poster child of forward recoiling air rifles! Second, the additional swept volume of the piston generated far more power than had ever been seen. The result was an easy-cocking breakbarrel with a muzzle velocity over 800 f.p.s. at a time when 800 f.p.s. was the top threshold for air rifles. The 124 started the horsepower races we are still seeing today.

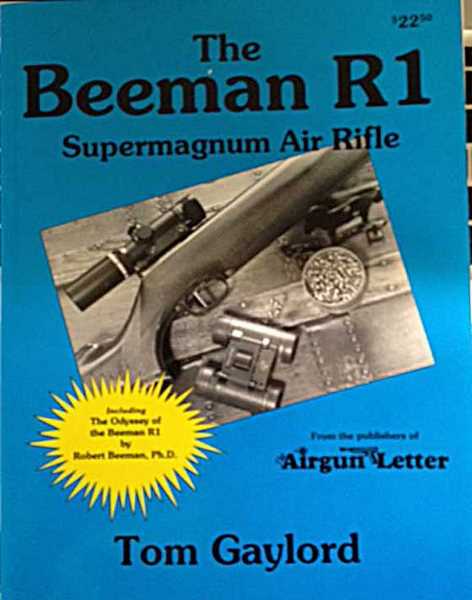

Robert Beeman was very impressed by the 124 and he touted it highly in his colorful catalogs. He made many of us want one, and I bought my first one after returning from a 4-year tour in Germany. A couple years later the Beeman R1 came out and I was no longer king of the hill. That turned me into a dedicated airgunner (translate that as a crazy person) and I eventually wrote a book about the rifle that changed my life.

I wrote the Beeman R1 book as a partial homage to it’s displacement of the FWB 124.

Summary

The FWB 124 is a classic air rifle. Like others in this class, it introduced some important things to the world of airguns. It its case it was the long stroke piston and breaking the 800 f.p.s. “barrier.”

Hopefully this will be the last 124 I ever tune, and I plan to do it up right. I’ve seen everything from the $35 junker I resusatated to the “Queen Bee” rifle I once owned that is now some collector’s treasure. My plan is to make this one the best of all.

BB—In the early 1980,s, a member of my chess club brought in a pretty , plastic chess set. It was made in the 1930,s. As we examined the pieces, several members saw tiny , hairline cracks in some of the pieces. One club member was an engineer ( at Grumman ). He said that all thermoplastics had tiny, invisible internal stress cracks, that formed as the plastic cooled. In time they would grow and the plastic would self destruct. I have a few Cox engine powered model air planes from the 1960,s in my toy collection. One in particular, has become so brittle, that its wing has broken like glass. Modern plastics may be more durable. However, many toy , fountain pen and gun collectors ( in my circles ) felt that things made of old, early plastics were weak and fragile. Perhaps that is why shooters wanted metal triggers in expensive, top of the line guns. My Diana 65 has a plastic trigger, and I always worry about it breaking, when I shoot it. —–Ed

Ed,

Thank you for that explanation. I learned something.

B.B.

Ed,

I believe you and the Grumman engineer, completely.

I have a very early, San Anselmo address FWB 124 Deluxe with the original plastic trigger. Frankly, that plastic trigger could be as delicate as the horn of a glass unicorn in a wallflower’s menagerie, but it would not matter. The first stage on mine must be two or three ounces and the crisp second stage six ounces at the most, perhaps only five. It is almost as good as the trigger on my FWB 601!

After I bought it and fired it once, I took it out back, cocked and loaded it, pointed the muzzle at the berm in my back yard, and whacked the butt with a rubber mallet to make sure it was safe. It was, but I was expecting it to fire. I had never before owned an air gun with a trigger adjusted so light that I did not trust it without testing it. There are very good reasons the 124 is legendary.

Michael

Hi Ed,

“Back in the day” just out of college, my first job was selling industrial chemicals for Eastman Chemical. We supplied all the basic raw materials that Kodak used to make film, cameras et al. They didn’t use everything we produced so we also sold to other manufacturers too. A big market for us were the people making “plastic” things. In the simplest of terms, any plastic part is composed primarily of two things…resin and plasticizers. There are other components, of course, but the overwhelming majority is just those two things. Plasticizers make the resin flexible and are really a solvent of sorts. And that means that they will migrate out of the product over time. When you slip behind the wheel of that beautiful car at the auto dealer and breath in that “new car smell” you are inhaling nothing more than the escaping molecules of platicizers and other solvents used to make the various parts, like the non-leather seat covers for example. Over time the concentration of solvents decreases to the point where we can’t smell it anymore and that new car smell goes away(boohoo!). But it is still there and still migrating out. Eventually almost all of it is gone and the brittle resin is all that remains and your friend’s description comes true. We are at that point in time now when a lot of the plastic parts made in the past have made it to the end of their useful life. Some will survive, if their construction was primarily resin and the engineering was good, but many, like your airplane wing and the piston seals in many vintage airguns, will not.

Sorry for rambling on but I hope this adds a little to the story of why so many old plastic parts fail over time.

Regards, Jim H.

Interesting, thanks. This process you describe must be the same as “off-gassing” which, I’ve heard, is a good reason not to reuse plastic bottles.

Matt61

Matt61,

If you are talking about not reusing plastic bottles because of the health effects of “off-gassing” I would have to pass on commenting cause I just don’t have a clue.

If I misinterpreted your question and you meant something else I apologize in advance.

Regards, Jim H.

Jim H.,

You are no doubt correct, but I wonder if that information might now no longer be entitrely accurate. I will pass on your post via e-mail to a childhood friend of mine who for the past 30-some years has been a polymer engineer for one of the world’s largest food packaging designer/manufacturers. I won’t share their name, but they design and manufacture a large percentage of the plastic and metal packaging for liquid food sold in grocery stores that is wholesaled by U.S. companies. I would wager no one reading this has not drunk or eaten a product not designed and made by this company.

The last conversation I had with him, at a high school reunion eleven years ago, was about how they were continually developing synthetic (i.e. plastics) materials that were for practical purposes impervious to earthly conditions of temperature or dryness, extremes of corrosivity, and, to any degree that could be tested, age. They had developed, for instance, plastics that were comparable to industrial glass but almost unbreakable. I vaguely recall that they were licensing innovations to defense contractors, NASA, and other non-food interests. For all I know they have made materials that are on Mars as I write this.

I am confident, however, FWB 124 triggers were not of such stuff. ;^)

Michael

Michael,

Your friend had a cool career. Sounds like a guy who it would be great to reminisce with over a cool beverage. Undoubtedly there are new products that are much better than the ancient stuff we had back then. That’s why I told Matt61 that I didn’t have a clue about the plastic bottles. But your friend will also tell you that if it’s “plastic”, it has to come from one of two things…either natural gas or crude oil. And that is why the products act In the way I described. I would venture a guess that 90% of the stuff we buy today isn’t of the spaceage material variety.

Regards, Jim H.

Jim H.,

My old buddy loves cold ones, especially if they’re from Germany!

I agree with your educated guess that 90 percent of plastics are still run-of-the-mill. But even some of the stuff designed for everyday folks uses incredible science every bit as sohisticated as NASA. (And hey, NASA gave us Corning Ware and Tang!)

One of his team’s biggest and longest-running projects was to develop a plastic that was sturdy yet flexible, maintained its flexibility down to 32 degrees Fahrenheit, transparent, and, the kicker was, it had to be impervious to tomato and chili pepper juices. It was a long time ago, but the way I remember it was his telling me it ended up having eight or nine layers. That was for a huge foods company.

Michael

Ah,.. another project gun that we will get to see the insides of,.. my favorite type of article. Always lot’s of info. and history offered from the article and knowledgeable readers.

As a side note, I received the Red Ryder plunger assy. and plan to put the spring into the 499 as reader Cobalt327 did in, hopes of boosting performance without loosing any accuracy. Having parts in hand, I noted the piston seal looks like it would work in the 499 and is made of much more pliable rubber/plastic. The Red Ryder seal has a tube that runs through it, but once the seal is removed, it appears the hole could be plugged at which point it looks as if it be a drop in replacement for the 499 seal.

I have a reply into Cobalt for his thoughts on the matter, but either way, I will be “going in” on the 499 this weekend. Just as well as the weather all weekend is predicted to pure crap.

Hi Chris

I’ve not tried a RR piston in a 499 but I think the hard durometer of the nylon-like 499 piston seems to be a very good match to the 499 compression chamber’s wall finish and concentricity- which may be held to a closer tolerance than the RR. The softer rubber piston used in the RR would more easily conform to any irregularities, where a hard piston like used in the 499 might not do as well. But that same conformability may well result in more ‘stiction’ from the RR piston- and combining that conformability with more surface area in contact w/the walls of the compression chamber could result in a slower overall piston speed compared to the 499 piston. But until it’s tested, this will be an unknown.

What I still want to try is the 499 piston modified for use with an air tube so I could use it in a RR. If my theory about stiction holds true, AND if there’s not too much eccentricity of the RR compression chamber, that could result in a fairly significant increase in MV. But again- until it’s tested… 😉

Cobalt,

Good to hear from you. The work will occur today. Pre-mod testing is done. Trigger pull came in at 2#9oz, 2#.5oz and 2#4oz with a Lyman gauge. Cocking was 5.5# when measured with a hook in the end portion of the cocking lever. I used a dial type fish scale for that as you said the cocking effort was in the 12-13# range and my Lyman only goes to 12#. If it stays below 11 or so, I will check it with the Lyman.

As for the seal,.. all good points and ones I did consider. The hole in the seal has been plugged with a silicone plug. The RR seal has a very strong back taper. .066 over a .316 distance. Also, the front of the lip is square faced with about 2mm of face. I took a brand new razor blade and put a taper to that and now the lip face is 1mm or less. The “corner/edge” of the seal is still in tact. The idea here is to further increase the flexibility in the lip edge. I think it is a very well designed seal. Chrony is 255fps.

The increase in stiction may be overcome by more efficient compression and the stronger spring will help with extra stiction as well. As best I could measure, the RR seal is .918″ and the 499 seal is .904″. And you are right, that 499 piston/seal has 0% give to it.

It will be interesting. I should have something by the end of the day.

Chris, have you photographed your endeavor?

I would be very interested in a guest blog post from you on your RR/499 experiments.

Belgrath04,

I do not own a camera or a good smart phone. I do have a newer flipper phone which does have a camera but it is pretty poor. Nobody likes a poor picture.

Now,… on the other hand,…. Cobalt327 is quite the accomplished photographer. Look on this site and search around a bit. Search his name at the home page and you can find all of his post and pics. From the looks of it, he is quite the skilled craftsman on all things pertaining to lever action bb guns. He would be the one to write an article on the subject/modification.

https://www.thehighroad.org/index.php?threads/putting-a-little-more-power-in-a-15-00-daisy.807316/page-9

The 499 is back together and does shoot. Next up is to collect some data and then I will post my results. Back later.

Cobalt327 and Chris USA,

There is no way I wopuld be able to do the 499 modifications you are describing, but would either of you entertain doing one for a fee? :^)

Michael

Michael,

I am honored that you would ask. I will have to pass though. It is not hard and if I had not had trouble with the new spring, the whole bit would have taken a half an hour. Cobalt I do believe is retired and may have more time. I do not. Check out The High Road gun site and look under air rifles. That looks to be Cobalt’s usual haunt.

Really, it is not hard and I am sure there is some you-tube videos. Cobalt also posted some links on the 4/6, 4/10 and 4/24 blogs. It is worth doing and seems to have dramatically improved the already great accuracy. Not to mention the range. I do need to do some more shooting with it. As of now, I could not be happier with the tune.

Chris

Michael

If it’s not too much trouble please consider registering at the High Road forum. Once there, PM me and I’d be happy to swap the spring for you. No charge but you’ll need to supply the spring. We can discuss how to go about dealing with that little detail when we next talk.

Until then, take care.

Mark

Cobalt,

See,… you already have your “first customer”! 😉 That is what I meant by “bottling and selling the stuff”,… as I am sure you caught. You really stumbled onto something great there.

As a side,.. I moly’ed the inner ribs of the “latch rod?” to insure smooth sliding incase of any inward bending of the latch rod due to extra pressure. Of course, that could be outward bend as well. That would of course be pertaining to any spring retainer “clip?” contact.

I recommend avoiding grease on the actual spring except as a UBER light film, because these Daisy springs are already the lowest rate airgun springs I know of, other than some of the “toy” type BB pistols, etc. But using some on the plunger tube (I believe that’s the part you’re referring to)- as long as the amount of grease doesn’t cause a loss of MV, I’d say that it’s worth doing. A smudge on the ‘sear’ area on the end of the plunger tube and the trigger might help a little, too.

I still haven’t done the well-publicized 499 trigger improvements either. I need to make some time for that, too.

And yes- I did catch the reference earlier to bottling it. haha But truth be told, I’m not money driven, at least not with my hobbies. And besides, the liability issues that could result aren’t worth forming a LLC or whatever else it might require. As long as I’m not losing too much, it’s all good. 🙂

Cobalt,

I was not aware that there was trigger improvements that could be made. I will have to check into that. Do you have a quick link to get me started on looking at the topic?

As for lube, I did the spring ID and OD with some lithium and the trigger sear got some moly as well as the sear on the plunger tube. Silicone chamber oil on the sponge behind the seal and some silicone oil on the plastic to plastic parts within the trigger. Moly on the cocking lever sides and contact areas. That trigger is a real pain with that pin that falls out and that safety spring. I thought that trigger is pretty good and smooth. I do not think I would bother messing with unless there could be 1st and 2nd added and/or a stop for over travel.

Trigger mods

http://www.txsmith.net/4hshooting/bbgun_trigger.html

499 ASSEMBLEY/DISASSEMBLY GUIDE

http://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&ved=0ahUKEwim3KyT69_TAhXJ34MKHS2FB8cQFggnMAA&url=http%3A%2F%2Fwww.georgia4h.org%2Fsafe%2Fdisciplines%2FRifle%2FBB%2FDaisy%2520499B%2520Take%2520Down_small.ppt&usg=AFQjCNGlQAXUblrBP4cGT7fBi8fWz3jwwA&sig2=XQLRQJFbSf1UOpGlIN2RYw&cad=rjt

Cobalt,

Thank you. I saved to favorites and will check out later this week. The first one viewed ok but the 2nd. one said I needed Office to view it. Either way, let me check it out first. I think I have seen that trigger mod. stuff before.

Thanks again, Chris

I just reread my reply to you and wanted to clarify: You in no way have to register there for me to work on your 499. I only mentioned it as being a convenient way for us to converse via PM so as to not clog up the blog here w/our goings-ons. Hope you didn’t think otherwise. If you are a member at a different airgun or powder burner gun forum, maybe I am too and we can get together that way.

Mark,

Will do, although it will have to wait until my school year ends, in mid-May. Until then, I will be swamped with grading. :^(

But yes, sounds very good!

Michael

Michael

I’ll keep an eye out.

In the meantime, check out the links I gave Chris USA a few posts above this. One link shows the complete dis- and re-assembly of a 499. After seeing it you may find it to be within your capabilities- it’s really not hard, and we’re here to lend support if you hit a bump in the road. Also, the only ‘specialized’ tool that’s needed is a spring compressor. The one I made is in a post below this. This is only a suggestion so after checking out the link if you still want me to do it, no problem.

Mark,

Thanks. I’ll take a look at the photos, but the issues with the (safety?) spring alone put a deer-in-headlights expression on my face.

Oh, I do have a spring compressor, so no problem there.

Michael

Michael,

The typical spring compressor will not work. Check out the 2 pronged homemade fork that Cobalt made. That is what you need. Plus, add the washer at reassembly time. All will be good. The safety spring is not too bad, but it is a pain. Watch pulling the trigger assy.. Do it carefully. There is a pin that will fall out and things will go flying. Go slow going in and use a flashlight to get a good look at things before proceeding. 2 hours plus the first time,… 20 minutes the next.

Check out Cobalt’s resources and you should be good. Hey,.. you got to jump in there at some time or another. 😉 Like he said too,… we got your back. 🙂

Ah, OK.

Michael

Cobalt327,

Well, I am pleased. Very pleased! 🙂 x 10

Chrony avg. was up to 412 fps from 255. Spread was 409 ~ 414.

Trigger pull stayed the same at 2# 6oz. avg.

Cocking effort went to 10 1/2# from 5 1/2# but is still very smooth and easy.

Shooting was another story all together. As in,…. THE BEST GROUP EVER! Yup,… 10 into 3/8″. I have never had just one small hole like that with 10 shots. That was at 24′ indoors and I can not say that my steady was any better than it usually is. Nothing special today.

When I did the tune, I pulled the rear peepers. I reinstalled and shot. I have done this before and never had to re-sight. Well,… this time I am blasting away and I can’t even see the group getting bigger. After 10 shots I go and look at the target and here the whole time the bb’s had been landing 2 3/8″ higher than the aim point,.. right into the already shot Bullseye right above. So yea,… the ol’ girl is pumping out some more power! I cranked the peepers up for what seemed forever to get it on target again.

Cobalt,…. you da man! Thanks a bunch! I think if I was you that I would “bottle and sell that stuff”,.. if you get my drift?

One more thing,.. what is the easiest way to compress the main spring to get the keeper tab in? With the heavier spring, this time it was not fun. I use 2 bamboo bbq skewers and catch the spring edges,… but this time they kept slipping off. What’s the trick?

Thanks again,… one happy, happy camper! Chris

Glad to hear you’re getting good accuracy and velocity out of your modified 499. I believed that would be the case based on my experience, but having only my gun to draw conclusions from left room for doubt.

I made a spring compressor from a piece of scrap wood and two lengths of steel rod. It is shown in the photo linked to below.

Specs:

The wood is 1-1/2″ x 5/8″ x 10″ long. I smoothed the end and edges for ease of handling.

The rods are 5/32″ diameter having >/= 6-1/2″ exposed length. 1/8” would work fine, too.

The rods are inserted into drilled holes that are ~1″ deep and JB Welded in place.

For the spring installation I use a 13/16″ OD washer with an ID large enough to fit easily over the plunger tube to give the tool something more than just the end of the spring to purchase on. The washer goes on the tube first followed by the spring then the wiper and piston. If you don’t have any on hand, I found some that were a perfect fit while rummaging through the hardware drawers at my local Ace hardware. IIRC they were in the bushing area. Cost was like a nickel each.

http://www.crankshaftcoalition.com/wiki/images/1/1b/DAISY_SPRING_COMPRESOR.jpg

Cobalt327,

Ah,.. the washer! I did think of that. Perfect ID and not too big on the OD. I most likely had something but I was getting pretty frustrated. Though,.. this time in will hopefully be the last time in. Our principles were the same though.

I did the safety spring trick. A little easier with the stock still off. Duh! 🙁

Another tip I can offer is the front peep sight. I took a 0 type front sight aperture and fit it with a small washer,… very small. Metric I think. It would “almost” press in by hand, but took a light whack with a hammer to seat it and colored it black with a marker. I use ringer binder paper reinforcement stickers for targets at 24′ and they work perfect. I color them black and put them on white paper. The combo is super accurate and easy to see if you are steady enough.

Thanks again for the idea and your effort. I am happy to provide “back up data” to (your) idea. Please feel to share it. (It works guys!) 150 fps increase in fps and better accuracy from the (already) “The world’s most accurate bb gun”.

Cobalt,

On the seal,… it seems to have worked. The trimming of the front may have helped it to be more pliable. I guess that it is a toss up either way as the data (mine/yours) was nearly the same. The plus to the Red Ryder seal is that it (may) break in some and move easier while at the same time providing a more efficient compression stroke due to lip expansion.

One other thing of note,.. the RR seal is a bit taller. That means that the latch rod assy. is longer by a tad. That also means a bit of “new” slop in the cocking lever (at the start) as the contact plate is moved a bit further back.

Just some more thoughts.

Cobalt327,

I got logged in over at THR and was reading through your thread. (I left you a comment too) I noticed people having issues with chronographs and also realizing that fluorescents were a no-no. When I first got mine, I had trouble too. B.B. told me what he uses and I continue to use it to this day.

Set up indoors and shine a 500W construction type halogen aimed at ceiling. Works great and cast a nice even light down on the chrony. They are cheap too. Mine was 15$ at local big box home improvement store. No need for the sunscreens either. Someone doing it in a basement with the joist exposed might want to attach some white poster board to the bottom of the floor joist to make a good reflection surface.

When chrony testing yesterday, I had several errors. bb’s are harder to pick up and now that the 499 is doing 412 fps, it showed up in testing. The pre tune chrony results went off without a hitch.

I like doing chrony work indoors as conditions are fully controlled. Hope that helps someone.

Cobalt 327

Haven’t heard anybody use that term in a while. Stiction. We use that term at work when particles of stuff gets trapped in places in hydraulic and air valves and cylinders.

The stuff would be like seals breaking down along with the metal surface wear. And of course particles of dirt or whatever that always seems to make it into the system.

Just thought I would mention how we use the word stiction. Sounds to me like what you mean the fit of something like the seal to the cylinder wall being tighter could slow the piston down.

Is that what you meant by stiction?

GF1,

I have always used to refer to interfearence fit and the force it takes to overcome that fit. I suppose that it could be called resistance to motion or resistance/power required prior to movement too.

Chris U

I think resistance would be the better term.

VIVE LA STICTION!!

Here check this out. This is what we refer to as what stiction is.

http://www.hotshotsecret.com/what-is-stiction/

Hi Gunfun1

Yes, that’s what I meant. The first time I heard the word used was in a Cycle magazine article about motorcycle front forks. This was in the early ’70s, when average bike riders were first becoming aware of the importance of fork and shock compliance/performance as it related to ‘performance’ street riding. The thought was that the amount of force required to set the forks into motion (stickiness) along with how much energy the seals needed to stay in motion (friction) was preventing most as-delivered street bikes’ forks from performing as well as they might. To simplify things, they started using the term “stiction”. But it’s not surprising that the term was also used elsewhere- it’s a ‘natural’.

Cobalt327

I think Chris probably has the right term. “Resistance”.

Anyway we all know what we’re talking about. 🙂

Cobalt327, The ’70s cycle mags were the first place I heard of “stiction” too. Yes–the term was obviously devised to describe the undesirable sticking of mechanical parts, due to the fact that greater static frictional forces must be first overcome in order to obtain a desired relative motion of the parts and the resulting lower dynamic friction of motion.

I can’t get my wife to stop using the word “ginourmous” so I guess I can live with the word “stiction” too!

HA! 😉

Cobalt,

See above,… Mr. Michael is looking for someone to do the “Cobalt 499 Hyper Tune”. I can not think of a better guy than you,… if you are up to the task.

Chris

Thanks. I didn’t see that. I get notifications only when my post is responded to and I’m not sure if there’s a way to know about other posts being made outside of directly to me, so I’d never have seen it otherwise

I’ve asked him to PM me @ THR and we’ll go from there…

Cal

Yep it seems the main thing with the term stiction is it makes a moving part “stick”.

In the hydraulic would stiction means a build up of how should I say this “crap” gets trapped in a place that has a very precise fit. That build up will then make those parts slow up in movement or stop working. Or even start deteriorating the contact surfaces.

And yes I heard the term stiction to back in the day when I was racing motocross. Around the early to mid 70’s.

Bet even back then when the forks was fading or slowing up it was from stiction. 😉

BB,

This looks to be another one that would have a home at the RidgeRunner’s Home For Wayward Air Rifles. Eventually that break barrel sproinger spot will be filled.

I’m looking forward to the new FWB124 blog series… I wouldn’t mind if you could manage another 15-part one 🙂

The 124 has been my go-to rifle for close to 35 years and it was the need to replace the piston seal that brought me to this blog. Hoping to learn something new.

Happy Friday all!

Same here Vana.

I enjoy the extended adventures that really dig in and deliver new knowledge.

B.B.

The gun did not sell at Findlay because all the interested buyers were at home reading your blog!

Next gun show, I want to give you a list of guns I am interested in(plus the cash for them) and $50/gun if you find a nice one at a good price for me……..unlike RR, I will pay you up front.

I am only half kidding…Have a nice weekend everybody.

-Yogi

Unlike RR?! I hope that is the half you are kidding about.

BB

There is no such thing as writing too much about the FWB 124. All your blogs on the 124 have been read and reread several times. Looking forward to this series.

Why not write a book on the FWB 124 like you did for the R1. A lot of us would buy it.

My first 124 was stolen many years ago, but I replaced it as soon as insurance paid me for it. Bought it from Beeman before 1980. When the first was stolen, the 124 sights were in my parts bin(lost the rear sight screws along the way) but still have two sets of open sights for the 124. The replaced 124 has a 4-16x scope installed. Every once in a while, I remove the scope and reinstall the front sight and my Williams receiver sight. Don’t shoot the 124 as much these days, but every once in a while I put the PCP’s up and pull out the 124 for the fun of shooting the 124.

The 124 was my first top end airgun along with my Sheridan Blue Streak that was also stolen with the 124. But now, I have two Sheridan Silver Streaks and one Blue streak along with the so called Benjamin Sheridan C9B. I can’t bring myself to really put the Benjamin Sheridan in the same boat as a Racine Sheridan. All though, the Benjamin Sheridan does shoot as well as the original Sheridan. At least mine does.

BB,

Picking up on Jonah’s point, you’ve been teasing us with promises of a new R1 book that was supposed to be ready about this time if memory serves. Any updates on that? I’m such a cheapskate that I keep resisting the urge to spend a couple hundred bucks to get a used copy of your original book!

halfstep, I’ve heard about mink oil in my recent education about leather care. No question that it softens leather and may bring it back to life in a sense. But the word is that it deteriorates the structure of leather like neatsfoot oil, and over time will turn it to mush and disintegrate it. This is given as a reason why leather artifacts from the Civil War is non-existence. So, it seems that the moisturizing of leather puts us in a bind by also destroying it. I wonder if Ballistol would do any good since it is supposed to be a universal preservative for everything.

Gunfun1, is Mad Max’s Ford Falcon the same as the Ford Gran Torino from the Clint Eastwood film? I had not heard of the Torino before this film, but as Clint says, “Why is everyone after my car?… You don’t know half of it.”

ChrisUSA, the one-inch criteria applies only to the individual. B.B. said that his pistol guru Lt. Col. Bonsall could hold a two inch group offhand at 25 yards with an issue 1911. Ain’t no way I can do that. If you’re talking about matching other people’s performance we’re dealing with competition. I haven’t found that particularly helpful as it tends to distract me. But being able to hand the stress of competition is definitely a virtue.

Matt61

Matt61

Nope the Gran Torino body like Clint Eastwoods car is like the picture of the 73 Gran Torino I posted yesterday. Well that is if I’m remembering Clint’s Torino correctly.

The Mad Max car is more like the body style of a 70 Torino. Matter of fact the 70 Ford Falon and 70 Torino used the same body style. But here’s the catch. The Mad Max Ford Falcon was a 73 but had the body style of a 70 Falcon or Torino. That’s what happened to most Australian cars of that time era. There current model year cars were like the American cars that were produced a few years earlier.

Matt61

Well I searched Clint Eastwood woods movie Torino car.

It was a 72 which was different than the Gran Torino and also different than the Torino or Falcon body style that year And also the 73 body style Falcon that the Mad Max car was made from.

I didn’t realize how much Ford mixed up the their names for years back then. But then again GM did the same on the Australian cars. Well also the Canadian cars. I’m thinking Ford might of did the same for Canadian cars.

Matt61,

Well,… I suppose that it is competition then. See what the best of the best can do with my same equipment and try to achieve that. No stressing here though,… just do the best I can do, stack as many of the odds in my favor, strive to improve and try to have some fun along the way.

Chris

Matt61,

Thanks for the info. Always seem to end up learning on this sight rather than managing to teach. I Like It !!

I have had good luck with “Sno Seal” on leather boots. I just use shoe polish on my Gortex duty boots.

Mike

not to change the topic but does anyone know who does repair a hill air pump ??????

thanks

dirty harry,

Pyramyd AIR fixes them.

B.B.

Check this out. I think the Shoebox pcp compressor has some serious competition now. And it doesn’t even need electric to run the compressor. Only a first stage shop compressor that can supply 5 scfm and 60-90 psi.

If I didn’t have a Shoebox already I would be getting one of these for sure. Oh and check out the video on the page of this link. A very nicely done video I might add.

/product/air-venturi-power-booster-4500-psi-unit?a=7367

GF1,

Yes,… wow! That will be a game changer in a big way. Nice video too, as you stated. Now,.. you know me,.. I want to rip the cover off and see how the darn thing works!!!! 🙂 Thanks!

Chris U

You know that could be dangerous when two minds think alike. 😉

My exact thoughts. Rip that cover off and see how it works.

🙂

GF1,

This sounds right up your alley since you rebuild valves. Someone posted a booster awhile back that was fed with a low pressure compressor. If the booster is auto cycled/driven by air, then the booster is doing a 5:1 ratio of work for example or maybe even more ratio. An air driven motor – driven compressor is my bet.

Chris U

Yep my same exact thoughts too.

Now will you stop reading my mind please. 🙂

GF1,

Think die grinder,… 120 psi powered, air driven, small bit, a.k.a. (compressor) on end, 15,000 rpm.

Other option would be an air cycled valve to cycle a 10:1 ratio piston. 10 to the low side and 1 to the high side.

One would be faster and noisier and the other would be slower, but quieter. I do wonder what the sound level/cycle is like? Thump, thump, thump or a high pitched Whirrrrrr?

Chris U

No way to know that till we get the cover off that darn thing.

Now this will be a good product for BB to review. And hopefully very soon.

Just think about it. If someone had a low pressure air tank in the back of their truck . Say a 50 gallon or bigger. Wonder if it would work the pump and how many fills you could get from the new Air Venturi booster pump. And I just randomly picked 50 gallons. It might need to be alot bigger. If it would work you would only need to fill that low pressure tank before you go out to shoot. We use to take one of them small tanks with us to the dragstrip to fill our cheater slicks back up for the drive home after lowering our tire pressure to hook the cars up at the track.

And heck a gas powered low pressure compressor could be used to operate the Air Venturi booster pump. So you could fill up all day long at the shooting range or out on a weekend hunt or something.

I like it. I just may sell my Shoebox and get one of these once I hear more about them. And of course to see if they actually hold up.

GF1,

Yup on the review. IMO, the “Cobalt 499 Magnum Tune” too. After all, we are talking about an “iconic” air gun here with the 499. Woah!,.. what’s this?,.. a couple of tinkerers made the “best” even better? That is not to mention it was done with parts that are already in their inventory. Mmmmm?

Out’a here,… Chris

Chris U

Yep amazing things can happen with a little thought.

As it’s been said before. Would be nice if the manufacturers would catch on and get some kind of skunk works going on. That’s what helped the car dealership’s sell their muscle cars back in the day. They had their own people at the dealership working on special packages for the cars to perform better. That was a very big deal back in the 60’s and 70’s. Matter of fact if you weren’t developing new things for the cars they were selling. They probably was loosing biusness and people were going where the reputation for fast cars were being produced at.

So yep when something gets improved on it makes me happy.

For those who have not jumped on the bandwagon and bought an air compressor to fill your PCPs and tanks, Pyramyd AIR and Air Venturi have another offering for you if you have a decent shop compressor.

/product/air-venturi-power-booster-4500-psi-unit?a=7367

It would most definitely seem we are entering a new age for airgunning.

RR

Did you forget to read the blog before you posted? That’s the link I posted above about the pump and me and Chris was talking about. ??? :0

GF1,

I just found that Crosman has posted the parts list on the Maximus. They have also come up with a new version with a threaded barrel muzzle and no front sight for the euro group with silencers. If the price is good I may order one of each type of barrel. If these are available I may need to order a new Crosman 1322 to build for one of these barrels.

With all the work Cobalt and Chris U have been doing I will be following along with my new Daisy 499. I have already taken it apart even though I was trying not to. It needed a rubber butt pad and a little work on the trigger before I could enjoy shooting it. Its a lot of fun.

The new compressor looks like a real game changer. One may be on my list soon. I was thinking it may be more like a hydraulic ram pump?

I have also been trying to get my Marauder with the hammer forged barrel under 1 MOA at 46 yards. So far I haven’t quite got there. It is consistently between .52 and .75 inches c.c. at 46 yards. The wind is still not cooperating with me.

Things are changing rapidly in the air gun world right now. A great time to be here.

Don

Benji,

So are you going to do the 499 hyper tune or just shoot as is? I would shoot as is and get a RR plunger assy. ordered and laying around and then can soup it up at some point in the future. See what that sweet shooter will do as stock first.

Chris U,

Yep that was my original plan. The stock was so slippery and the trigger pull so long that it kept slipping off my shoulder. Once I got started I put a rubber butt plate on it and could not resist shortening up the trigger pull.

My 499 is shooting sub 1/4 inch groups at 5 yds. When I go to 10 yards it really opens up, That may be the wind? It can be dead calm until I set up to shoot and then here comes the wind.

I plan on ordering some parts from Crosman and Daisy on Monday. I will order a RR plunger assembly. If they are not all bought out!!

Don

Don,

Good deal. Feel free to ask any questions when you get to that point. 100% of the credit has to go to Cobalt though. He did a good job of posting support links too. The 4/6, 4/10 and 4/24 blog comments had some good info./links. Have fun and enjoy. Nice shooting on the M-rod by the way! 🙂

You got a bolt on butt pad for a 499???? Long armed me is very interested!

Chris U,

I found the butt pad at an air soft store close by; most butt pads go from 25 to 50 bucks, that seemed like a lot for a bb gun. This one was setting under the counter with quite a few others most fit the AR snap on type. The one I got only adds about 3/4 inch to the stock and only has one screw in the middle. It is slightly smaller than the stock. It was 11 bucks so I gave it a try. There is no name on it. I am sure there are better ways to add some length to the stock. I works for me for now.

A wood spacer could be made fairly easy, especially for someone like Vana. I have seen this done to some stocks before and they looked ok. If you can’t hide it make it stand out! I would square off the stock first, that would make it much easier.

Benji,

Thanks for the tip. I like about 15 1/2″ of pull. I use the Limb Savers on the TX and LGU and they add 1″ and fit like a glove. Large on the TX and Med. on the LGU. I think I checked the chart and even the small would be too big for the 499. They are not cheap either.

No,.. Vana2 would never mess with a measly spacer/stock extender. He would make up a custom shaped laminated maple and walnut stock! Probably some rosewood inlays too! 😉

That dude is a wood wizard.

Hi Don and Chris (I hope Don sees this)

The photo linked to below is an AK47 butt pad made by COI, bought off Amazon for ~$9.00 delivered. I laid it on the end of a 499 to show the fit.

http://www.crankshaftcoalition.com/wiki/images/4/42/499_w-_butt_pad.jpg

I started a thread about butt pads for the wide frame Daisy here:

http://www.rimfirecentral.com/forums/showthread.php?t=860721&highlight=daisy+model+96

A few good ideas were brought up; one was using the flip flop method. I don’t care for the slip-on pads I’ve seen so far so I opted for the screw-on, but it’ll take some reshaping of the end of the stock unless I just screwed it on and called it good enough. Haa As if!

Don

That’s good to know they have the barrels available now. I will probably do me up another 1377 with a Maximus barrel to. Just to see if it’s better than the Discovery barrels I have used in the past.

And I forgot what caliber your Marauder is. But that’s pretty good for 46 yards.

GF1,

Not sure the barrels are available but the part number is out. They should be available. It will be interesting to see what the cost is.

I have been using the 2260 barrels with good luck I think they are the same inside as the Discovery barrels but I don’t know. The 2260 barrels were only $15 last time I ordered a couple.

My Marauder is 22 cal. After much fussing I finally got ok groups with the original barrel. This new one has been much better right from the start. I just haven’t made it a priority to complete the tuning and I have one more pellet to try. I have been using the JSB Diabolo Jumbo .22 Cal 15.89 grains. Once I get this pellet optimized I will try the same pellet in 18.13 grains.

It takes me a long time and a lot of pellets after I set up the chrony and start turning knobs on the Marauder to find the sweet spot. All for a few tenths of an inch. And like gold mining the chance to find that perfect combination that will hit the same hole every time. I know it wont happen but I think that is what keeps me trying.

Are you getting better accuracy from your Maximus than from your Discovery? I keep hearing wild claims on the accuracy of the Maximus barrels.

Don

Don

Ok that’s what caliber I thought you said it was. And yes I know exactly what you mean about trying to get the tune just right on a gun. Sometimes as easy as can be and others a real pain in the butt. Glad your getting some where with it though.

And yes straight up my Maximus shoots better than the Discovery’s I had. I thought at first I got lucky and got a good one. But I hear alot of good about the Maximus accuracy from other people. So seems they must be pretty good.

Oops! I scanned through, but missed it. Oh well. It is of such an impact that it should be reemphasized. 😉

I am actually glad I bought the compressor before they brought this out as this would require me to buy a larger shop compressor.

As far as the Shoebox goes, that was never a consideration for me. I could have picked up a used one a while back, but to me they were way overpriced. For less than a new one I picked up my AV compressor.

Like you guys were talking about, Rick Eustler had a sequence a while back where he used an HPA booster pump on a scuba tank to fill to higher pressures.

https://www.youtube.com/watch?v=9VM_s5uFCec

RR

I’m sure you probably didn’t look at the Shoe box website since it was never in your mind to get one.

But did you know this. Here check it out. All the Shoe box compressor’s aren’t as expensive as the ones PA sells. They sell the high cost top of the line one. My Shoe box compressor I got was one of the first ones when they came out. Matter of fact I believe it was the only one out there available at the time. I believe it was originally developed for the paint ball shooters. But anyway mine was $540 when I bought it. You can still get the base model to this day from Shoe box for like a hundred more dollars. So the base model in my eyes is still very good competition for the new Air Venturi booster pump.

But here check out the link. This is the base model Shoe box that is still available.

http://www.shoeboxcompressor.com/order/compressors/shoebox-max-4500-psi-compressor.html

GF1,

It was in my mind to get one for several years previously. They have come WAAAAAAAY down in price recently. I can recall checking out their website about a year ago and they were wanting a good bit over a grand for their cheapest booster. I met the owner in 2012 at the Roanoke show and they were priced waaay up there then. Now they are priced where they should have been in the first place.

How you bought yours at the price you did, I don’t know. What I do know is I was not about to contribute to such blatant overpricing.

RR

What does that matter if you met him. I talked to him way back when he first started making them and that don’t matter right now.

The original ones were cheaper than the model I got back then. Mine was the second generation that came out. The first ones had a chain drive instead of the belt drive. Then the next models you could get the belt drive and hardened piston rods. That’s what mine was.

The one I have is almost 6 years old. So far the only thing that I had to do to it is a new drive belt. And the first stage cylinder was leaking. And guess what. Called them and told them what was wrong. He sent me a whole new main block and both cylinders. And that was a few years after I got it. Haven’t had anymore problems with it since that. And I need to mention that probably happened from me over lubricating. And yes I only lube the rods if they feel real dry if I rub my fingers on them and don’t see no oil shine on my finger.

So yes you are wrong. They were that cheap and even cheaper when they first came out. And I give them good regards that they had one of the first small compact HPA compressor’s available to the general public.

And again. Not to put down the new Air Venturi booster pump. Definitely a cool product. Especially that no electricity is needed.

As it was said here already. Definitely a good time to be a air gunner.

GF1,

Maybe I am wrong. It would not be the first time. All I know is my memory does not recall seeing or hearing of a price anywhere near what I would have considered reasonable. That is the only reason I never bought one. It sure would have been nice to have when I was filling Lloyd’s Benjamin Rogue with a Hill pump.

RR

Same with my Mrod going to 3500 psi. I’m sure I would of had to take a few breaks if I was hand pumping it.

And now it makes me wonder if other people think the only Shoe box available is the high dollar one. I would have to say if the high dollar Shoe box was the only model available I would probably bought the big Air Venturi pump like you got instead. Only for the fact that the first stage air supply is built into the compressor.

But now it with the new Air Venturi booster pump it would be possibly it over the base Shoe box. But first I need to see how the Air Venturi booster pump holds up. As I mentioned above. We’ll see. I may just get one yet. 🙂

The thing about the new booster pump is it requires a serious shop compressor to feed it. If you already have such, then I think this is going to be a winner. For me, I would have to buy a shop compressor for either the Shoebox or the AV booster. Either way I would have to shuck out bucks that start approaching the price of the AV compressor, so I went that route. With these .357 air rifles, you need lots of air.

RR

Yep on the bigger caliber pcp’s.

And the cost of a shop compressor that can supply 5 scfm at 70 psi or so starts going up. So yep the Air Venturi booster pump and the bigger shop compressor is getting pretty close to the cost of the bigger Air Venturi self contained pump like you have.

The base Shoe box doesn’t need the bigger shop compressor. So it should be cheaper on that part. Not counting if someone already has the right shop compressor.

So probably another point would be if you want to have the extra electric use from the Shoe box verses the Air Venturi booster pump that don’t need electric. That could make the difference out in the feild. Like I mentioned above. The Air Venturi booster pump and a gas powered big shop compressor could be important for some people. And on the other hand the Shoe box and the small shop compressor could probably run off a 12 volt power converter from a car battery or a gas powered generator out in the feild.

Guess it’s all about weighing out what would work for where and how you would use them.

And again it’s cool that we have all this available now days.

GF1,

It really is awesome that we have the opportunity to discuss the merits of various air systems when not too long ago we either used a hand pump, became real good friends with the owner of the local dive shop or mortgaged the house to purchase our own compressor.

RR

Well that’s the truth.

Now maybe Evonix or Umarex will get their nose wet and heat up the competition with a even lower priced version of the different pumps we was talking about. I do hope so.

GF1,

I do not know if those guys will market a cheaper hand pump, but they are now coming to market and can be found if you look around. Here is one.

https://www.youtube.com/watch?v=KngSr69mCtA&t=37s

B.B.

Sounds like your eye is getting better and will be back to 20-20 that is great news. Hope all is well with the family.

I don’t think you can get too deep into the nitty-gritty of air guns for most of us on the blog, especially when it comes to the classics.

Thanks for all the effort, I don’t see how you have the time.

Don

Hi B.B., el al,

I discovered your blog sometime last year and decided that I would read up from the very beginning instead of just reading the current blog. Well, It’s taken most of the year and been quite a trip!

I’ve had airguns since about 1977 when my first purchase from ARH was a Webley Premier Mark II which I still have and shoot. After reading all the material I could dig up by Robert Law I decided I would jump in whole hog and get the top of the line FWB 127 with the custom stock and all the special tuning for it. That rifle now belongs to my brother and still shoots great.

After that I got another German made rifle from ARH but I don’t remember the make. It has since disappeared though could very well be in the possession of one of my relatives. I then got a FWB 127 with a serial number of 10169 and the Beeman San Anselmo address.

My brother has the 124 because he was able to get it repaired at a time when I was unable to. Of course the 127 eventually needed a new piston seal so I determined to learn how to fix these myself. I foolishly thought I could use my Rockwell Jawhorse as a spring compressor so story short, I also now have to replace the trigger. I’m going pretty slow but I did get a new spring replacement kit and trigger and, of course, an appropriate spring compressor.

I’m still left with one question: Is there REALLY any difference in a 124 and a 127 except the barrel?

Thanks.

Larry from Algona

Larry from Algona,

Welcome to the blog.

I think the barrel is the only difference between the 124 and 127. That’s the way most manufacturers do it.

B.B.

Thought as much. Thanks for the confirmation.

Larry from Algona

Jim H., you’re correct. I was wondering about the deterioration of plastic in drinking bottles. Nothing to apologize for. I was just wondering if it was another example of the process you described. I don’t know either. 🙂

Gunfun1, that is funny that the futuristic Mad Max car was based on what was an outdated American model at the time. But it looks sporty enough to me.

ChrisUSA, competition without stress is the key. I’ve been delving into psychoanalysis recently and trying to apply it to shooting. The superego is supposed to be the part of the mind responsible for order. It is the part that makes us sort pellets. The id is supposed to be all the primitive drives of aggression and desire. So, this would be the origin of competition, at least the part about destroying the foe. The ego is supposed to be the part that keeps the other two in balance so that you don’t become a Nazi or a religious fanatic with too much superego or an immature person or even a psychopath with an overactive id. But I’ve come across another term called the “superconscious.” This part is not dedicated just to the creation of rules. It has actual capabilities that go far beyond the norm which we cannot normally access. It has been theorized that at some level we remember everything that has ever happened to us, and this presumably is also where people gain the strength to lift cars. Maybe this is what Jason Lesczak used to defeat the French favorites in the 4×100 swimming final in Beijing. They said what he accomplished was equivalent to lifting a car. So, perhaps this is also the domain of the Jaws of the Subconscious, that element that never sleeps, never makes a mistake, and always lands unerringly on target when it is accessed. Chomp.

Agh, I completed another epic range day yesterday. The stage was set for something dramatic with perfect weather that was sunny and cool and an array of new gear by me. In the restroom I caught a glimpse of myself in a full-length mirror. There I was with paratrooper jump boots, Russian camouflage pants, my new magazine pouches for my 1911 and CZ 75 and pouches for my revolver speedloaders. It looked pretty cool, I must say. I felt just like our blog reader from some years ago who was parading around his bedroom in full tactical gear, right before he aimed his Gamo CFX at the mirror and inadvertently fired a pellet.

There were definitely bright spots. My magazine pouches really enhanced the shooting. It occurs to me that one thing that firearms have that airguns do not is large cartridges that allow you to load magazines and throw bolts with authority. My protege told me that he really enjoyed the process of loading rounds into my Saiga magazines. My Bianchi and De Santis magazine pouches worked well and allowed me to practice tactical reloading. They also got me thinking about Lara Croft Tomb Raider as played by Angela Jolie. She presses the magazine wells of her guns onto a device on her belt and the magazines load automatically, but I can’t imagine how that would work.

But the paratrooper boots were the stars of the show. My bogus high school rifle team coach said that combat boots give you stability, and I hadn’t felt much of a difference. But he turns out to be right. The handgun groups improved significantly. The sight picture was steadier. The sights never strayed that far off target, and they came back much easier. I guess the reason is akin to why the martial arts put so much emphasis on stance. The feet are your point of contact with the ground, and any imbalance there will get magnified going upward just like a slight movement of a tree trunk will cause the branches to wave wildly.

Using the boots, I also attempted to shoot kneeling for the first time in decades. I was able to do it which says something since the position was impossible in athletic shoes. But it was not particularly comfortable. And that is even after hedging my bets further with deluxe gardening knee pads. My toes and knees were okay, but there was a general discomfort in the lower leg from bearing all that weight, and I was not in any kind of natural point of aim. At 50 yards, I actually did okay with a group that wasn’t recognizably different from my rested group with the Lee-Enfield. But at 100 yards my kneeling groups fell apart for both the Lee-Enfield and the M1; they were even worse than my offhand. Being in an unsteady kneeling position is worse than a steady offhand, apparently.

But all this was thrown into the shade by my M1 jamming again. It was like the horror film where the psycho voice on the phone says, “I know where you were last summer.” I had a jam about every clip. In one instance, the bolt somehow closed on the round, but the firing pin did not set it off. And then I wasn’t able to open the bolt. The gun had to suffer the indignity of getting whacked with a rubber hammer on the charging handle to open it. I had another jam where the bolt came forward prematurely and rammed the cartridge into the magazine well, pushing the bullet back into the case, and then one where the bolt closed on the bullet with the body of the case sticking out. I was sort of holding out hope that the jams were associated with my reloads since surplus ammo had a 100% reliability record. But when that jammed, I truly felt the sword in the bowels. Inconceivable that this is happening again!

I briefly imagined a deathbed scene where I give a speech something like this: “Son, I just wanted to give you this message. Stay away from the guns (cough, hack, gasp). They’ll break your heart and take your money. Avoid the siren’s call and do something else. (Croak.)” But then I had a terrifying thought. The M1 groups showed extreme horizontal stringing. At 100 yards, I put about 40 rounds into a group that was maybe 8 inches wide but only 1.5 inches tall. Going back to the notes of my gunsmith who installed my adjustable gas system, he says that horizontal stringing is the sign of too much gas. Could it be that the gas system is at fault after all and not the rifle? The terrifying part is that this means that I might actually have to modify the gas system myself. True the system is designed to do that, but it still counts as modifying the gun which I am loathe to do. Anyway, it looks like I have no other option. I need to adjust the gun, and if that doesn’t work, back it will go to the gunsmith.

Matt61

Matt61

Why did it jam again???

And why horizontal groups?

Why not vertical?

And been meaning to ask. You didn’t send your 1077 out on it’s last trip did you? You still got it?

Matt61,

Wow,… I am amazed at your ,… heck,.. I do not even know what to call it. While not as knowledgeable as you on such a diverse range of topics, I do believe that there is the “jaws of consciousness”,… or “being in the zone” as I prefer to call it. No thought, just pure perfect action/execution.

As for the firearm issue,.. I say,.. “just get in there”. You might just surprise yourself! You seem to have knowledge above what many people have,.. maybe even a gunsmith.

Michael—-The original waterman pen company once made a pen with a one hundred year warranty. They called it the hundred year pen. In order to distinguish it from there other , similar pens, they used a clear end piece ( about 1/2″ long). The transparent plastic that they used began to break up, after about 20-25 years. I had 10 of these pens in my collection. They were in a cabinet along with many other pens. They were untouched for about 5 years. One day, i noticed cracks ( crazing) in the clear ends. When i picked them up, they fell apart. they had self destructed! If the FW trigger is made out of a similar plastic, it does not matter how light the trigger pull is. Even if you dont shoot the rifle, age alone might cause it to self destruct. —–Ed

How about that.

Maybe back then they was worried about the future of the Earth.

Maybe those engineer’s were paid to be quiet. Or more than likely fired or let go when the new wave of engineer’s started making plastic. Yep now it lasts and never goes away. Or does it.?

Hah! Thanks, Ed. I have an old Waterman (without the clear end piece) that must be 80+. Not a daily driver, but a terrific performer still. Only had to replace the rubber ink bladder in the early 90’s. They warranted the wrong 100-year pen!

-Jan

I’m pretty sure the trigger on my FWB 127 broke because I was just being stupid. 🙂

Jan— The end piece had no effect on the writing performance of the pen. All of the top quality pen manufacturers put out fine writing instruments, even in their mid range quality pens. Remember, this was before the age of the disposable ” widget “. People expected the things that they bought to last for many lifetimes. That is why BB and many of our fellow airgun collectors desire and value steel and wood vintage air guns compared to modern pot metal and plastic guns.——Ed—— PS– also pens, cars, motor bikes, and other “widgets” too numerous to mention.

LarryMo— Can you tell us how the trigger broke? Were there any signs of stress cracks or fatigue at the broken ends ? If you still have the broken trigger, can you send photos, or better, send it to BB for a forensic analysis . One final question—what happened to Curley ? —–Ed

Your last question brought me up short for a few seconds before it hit, then I had a good laugh. There were no signs of stress that I noticed prior to the break. Of course, not being forewarned of this phenomena, I wouldn’t have given it the magnifying glass going over it should have had. As I mentioned, I was trying to use a JAWHORSE as a spring compressor – which worked quite well when I released the pressure on disassembly. I got a new spring kit from Maccari and then, when trying to reassemble, the rifle slipped out of the vice and the trigger was pretty much sheared off. Any other damage, like lost parts was kept to a minimum due to the spring housing coming to rest against my gut, which bore the bruise for a couple of weeks. Like I said, my stupidity.

I’m not up to taking pictures right now maybe also related to stupidity. First since I refuse to follow the herd and get a smart phone my old cameras are designed to use microsoft software. Second, I am using Ubuntu Linux as my OS and have been getting strange results on my few attempts at posting pictures.

I think it’s safe to say that the trigger was not ready to break this early in its life.

Larry from Algona

You’re not kidding about those replacement sights going for a premium and it’s not just the Feinwerkbau. I have misplace *cough cough* the iron sights for my RWS350 Magnum. I spent about three hours in the woods last weekend since spring squirrel season just opened and figured out that the monster 6-18X50 Meopta scope is more of a hindrance than a help when hunting. I love it to death when I’m shooting paper at 50 yards but adjusting and readjusting it in the woods is extremely difficult. Plus just getting on target with a bushytail playing hide and seek in a leafy tree is a horror. I was actually just looking along the barrel trying to shoot instead of using the scope. Long story short Umarex wants $48.67 for the front sight and $39.95 for the rear which seems backwards to me. In fact I think I can just use the front sight from my old RWS34 but still WTF?!?! $88 before shipping for some factory open sights? Is there some aftermarket sight I could use or something else anyone would recommend? Maybe I’ll just put a red dot on it or something…

I bought my first “real” air rifle in 1979 from ARH. My FWB 124D is still treasured , and was re-built by Pomona Airguns. New spring , piston seal , and tune. It works like new ! I replaced the scope with a Hawke Vantage 4X16 , and love shooting it. Accuracy very close to my Air Arms TX200. The AA TX200 SHOULD be more accurate , but at 25 yards , I do not see a lot of difference. Both are too nice to hunt with , so the Umarex Octane in .177 is my tool. Besides , if I drop the Octane , so what ? A Benjamin Marauder in .22 is on the horizon , but still like my springers. When my pal bought the Beeman R1 when it first came out I quickly noticed that it was heavier , twice the cocking weight , and little accuracy difference ,if at all. Still , the FWB124D is my love.. I only wish I had bought the super fancy version that ARH had , FX120 ? Anyone know ?

Readyfisher,

I know about that custom 124. It has a deep forearm so the cocking slot can be short. Been looking for one for years. I’ve only seen one.

B.B.