by Tom Gaylord

Writing as B.B. Pelletier

Daisy Number 12 model 29 single shot BB gun.

This report covers:

- Taking the gun apart

- BB gun spring compressor

- Help!

- No air tube

- What does this mean?

- BB gun technology

- What to do?

- Summary

Today I tear into my Daisy Number 12 model 29 single shot BB gun to see what’s wrong with it. If you recall, I was testing this gun last August when it stopped shooting altogether. I was testing it for velocity when it simply stopped shooting a BB out the barrel, so I removed the single shot tube and extracted bits of what I knew were leather.

This stuff came out of the Daisy Number 12 model 29. It’s leather that has rotted and come apart.

When I saw that junk I knew what had happened. The leather piston seal, which in a Daisy BB gun is called a plunger seal, had rotted and was coming apart. It had to be fixed, before the gun could work again.

Taking the gun apart

I frankly did not know how a Daisy Number 12 model 29 came apart — except for one detail. Most Daisys have a spring anchor that holds the rear of the plunger assembly (in a BB gun the piston, spring guide and mainspring are assembled together and are called the plunger assembly) inside the rolled sheet steel body of the gun. For the guns that are like vintage Red Ryders, something has to press the mainspring forward to take pressure off the plunger anchor. I could see that this gun had a spring anchor that also served as the rear sight, so I assumed it was made that way.

Most folded metal BB guns have a spring anchor that looks like this (arrow).

On some older guns like this one, the anchor also serves as the rear sight.

BB gun spring compressor

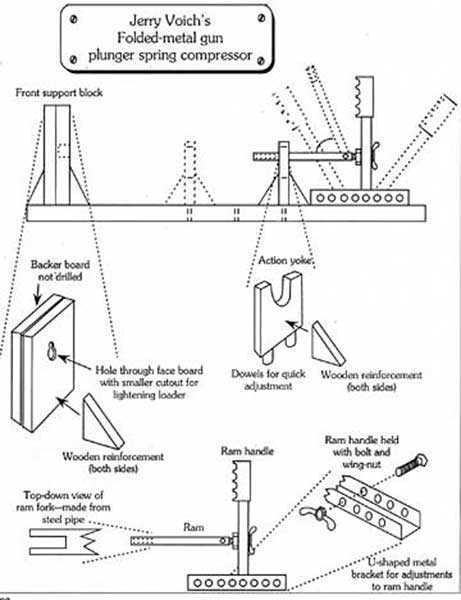

Many years ago the late Jerry Voich wrote a guest article for The Airgun Letter about disassembling folded metal BB guns. In his article he gave the plans for a spring compressor that allowed the worker to take tension off the spring anchor to remove it from the gun.

Help!

I could never build a contraption like that, but my neighbor, Denny, volunteered to. He built it to a point and then we tried to use it, but we had no success. Apparently the Number 12 gun doesn’t work that way.

Denny got to this point with the spring compressor before we discovered that the Number 12 doesn’t disassemble in the normal way. It will still work for most BB guns.

As we were fiddling around and trying to understand the mechanism, we pulled the spring anchor out without a compressor. It wasn’t that hard.

The anchor (upper right) came out easily. And there is the plunger assembly. The arrows show how the lever contacts and pulls back the plunger against the mainspring. A shiny wear mark on the plunger plate that can just be seen in this photo (left of the upper arrow) confirms this.

When the plunger came out of the gun, the damage to the seal was very clear. The leather had decomposed and was missing on one side. But that wasn’t all I saw. This plunger does not have the central air tube I was expecting to see.

This photo shows how the plunger seal is disintegrating. It also shows a little of how the seal is held to the plunger tube. I think there has to be a cross-pin under all that gunk that holds the plunger head to the sheetmetal body. Notice there is no air tube on the end of the plunger head.

No air tube

This plunger lacks the central air tube that starts the BB on its journey down the shot tube. Compare it to a modern Red Ryder plunger

This modern Red Ryder plunger head shows the long air tube I have mentioned.

What does this mean?

What this means is the Number 12 model 29 does not function like many BB guns. There is no initial push by the air tube before the compressed air blast hits the BB, sending it on its way. This piston in this gun acts more like a pellet rifle piston, in that it simply compresses air for the shot.

BB gun technology

Daisy had perfected welding thin steel steel several years before this gun was made. For many years welding was impossible because the thin sheet steel of the tube evaporated in the heat. Daisy used to solder a patch on the underside of the outer tube to seal the seam and make the compression chamber airtight.

In the outer tube of this gun they put a sharp stepped crimp that holds a steel plate on the inside. That plate is the end of the compression chamber, made airtight by the weld. The single shot tube on the other side of the plate has a short tube that sticks through the plate and acts as an air transfer port — just like on a pellet rifle. Instead of the long air tube giving a starting push to the BB, it sits in the rear of the shot tube (the breech) until air pressure alone forces it to move! I have seen the inside of many folded metal BB guns, but this is the first time I have seen this design.

Here you can clearly see the weld on the seam of the folded metal. Daisy perfected this process (welding thin sheet steel is difficult because the metal wants to evaporate from the heat) several years before this gun was produced. That sharp step is actually a crimp that holds the plate that forms the end of the compression chamber inside the folded metal tube.

The rear of the shot tube has a short tube that sticks through the steel plate inside the folded metal outer tube and into the compression chamber. The leather washer around the base of the shot tube helps to seal the air on that end. It’s deteriorated, as well, and must be replaced.

What to do?

I have to make a new leather seal for the plunger. There is no hope of finding another seal 90 years after the gun was made. I am pretty sure the head of the plunger is held to the sheetmetal body by a cross-pin — just like you see on the Red Rider plunger.

I also have to make a leather washer for the rear of the shot tube. At least that will be easier.

The inside of both the compression chamber and the place that holds the shot tube have to be cleaned before assembly of the parts.

These steps are much easier to describe than they will be to do. The thickness of the leather parts has to be close to the original if the gun is to work as designed.

Summary

There is a lot of work to be done! I have to source the leather and then shape and trim it and hope that it works when I’m finished. I guess I won’t be finished until it does work! Stay tuned.

BB-

Don’t mean to jump off topic right off the bat but just had to comment on the new product line being offered by Pyramydair! Glad to see the FX line of airguns being available thru my favorite airgun seller. They only show the new Dreamline series as of now but that is a great start! They show first shipment in by next week.

Bruce

Bruce,

Most interesting! I imagine if they are offering one FX model, the rest should follow? If so, I would have thought that they would have made some sort of announcement/advertisement by now. I do hope so.

Chris

Bruce,

Yes, they will start to carry the entire FX line.

B.B.

Bruce,

That’s OK. There will finally be a bit more price competition on this side of the pond with FX. I have already noticed a slight price reduction with the competitors.

Bruce

Outstanding! That made my day.

B.B.,

Glad you got enough gumption to take the old gal apart. I think I will wait for one more Part in the series before taking my model H apart. Mine has some plates soldered on the bottom of the folded sheet steel to hold it together; I am pretty sure they are original. Those plates are comming loose and will need to be re-soldered. The only weld on my gun is to hold the sight/spring anchor in place. I think I am the dummy that welded it back in the 1960’s, so I will need to cut it loose. That makes me think the spring anchor will come right out and I won’t need a spring compressor either.

My old buddy gave me the gun last year and said it was his grandfather’s. I think the basic design of the Model H and Model 12 will be very similar.

If the sheet steel needs to hold air where yours is welded I my have some issues. I may resort to brazing or a silver solder. I am thinking brazing may be better. Or use my friends tig welder, but that is thin steel.

Thanks for diving in.

Don

Don,

Your gun has the patch that was used before Daisy learned to weld the tube. The patch is soft-soldered.

B.B.

Don,

You should be able to re-flow the solder on the patch with a propane torch.

Clean the area as best you can (remove any oxidation and then degrease), apply some flux and clamp the patch in place (use a wood spacer in between the clamp and the patch). Reflow by heating the tube and feed in a bit of solder if required.

Wouldn’t braze or weld as those processes use high temperatures and are a “one-try all or nothing” deal. With soft-solder you can remove, reposition and reflow the patch as needed.

I would suggest clamping the length tube in a wood jig so that it can’t spring open during the reflow.

Good luck Don!

Hank

B.B.,

I’m still trying to wrap my head around the BB power plant. Does the missing air tube make a difference in velocity imparted upon the BB? Wouldn’t the BB get more velocity by the increased pressure behind it instead of getting a head start going down the barrel?

Siraniko

Siraniko,

That’s what I wondered, as well. If I can repair it well I guess we will find out.

B.B.

Tom,

Good to hear I’m not alone in wondering. Maybe because of the size of the power plant and the limited range it is expected to be used is what kept the air tube out of the design.

Siraniko

B.B.,

I just noticed that there are two Part 1 links. one leads to Part 1 and the other leads to Part 2 though.

Siraniko

Siraniko,

Fixed it. Thanks.

B.B.

BB,

I do so enjoy it when you go inside and fix things. I myself enjoy doing such. Also, when you do it I get to come along and see what and how it is done without having to figure it out all on my own.

I would rather you make the mistakes and tell me how to avoid doing such than make the mistakes on my own. 😉

RR,

If you like mistakes you are backing the right horse. I’m rather good at making them. 😉

B.B.

BB,

LOL! I understand. Sometimes I do learn what not to do. 😉

B.B.,

Very interesting. Very similar to the 499 when I put in the Red Ryder spring. Upon tear down, I used 2 bamboo BBQ skewers. They contacted the back of the spring. Push, pull anchor. The new RR spring was longer and assy. was a bit more challenging. This is what Cobalt posted here sometime ago.

http://www.crankshaftcoalition.com/wiki/images/1/1b/DAISY_SPRING_COMPRESOR.jpg

The piston end is similar with a cross pin, but no air tube. I used a TX200 seal from a Vortek 12 fpe kit to replace the hard, white, nylon? piston seal.

I wonder if the spring is compressed/set some or if this is something close to the original length. You will have to apply some pressure to the back of the spring coil to get the anchor back in, but from how it came apart, not much pressure will be needed. Cut coat hangers, no longer than needed, would be ideal and better than skewers.

From the picture (with the cocking lever), your wood press should have worked. The back end is identical to the 499. It is tight up in there, but pressure to the spring is what is needed. Cobalt used a 13/16″ OD washer to put behind the spring (permanent install) so more area was available to apply pressure to. I had mine back together before learning that, I think. At any rate, mine is no washer.

Looking forwards to more.

Good Day to you and to all,…… Chris

B.B.,

I see now that the TX seal was used in conjunction (with) the nylon seal. The TX seal slipped over the latch rod and sits behind the nylon piston. A washer behind that and the spring sits against the washer. Sorry for any confusion.

If similar to the 499, which it appears to be,… this may be a quick fix and there will no need to make a leather seal.

Also, the Vortek site has new seals that replace leather ones. I was just on the site. Check it out as something may work or you can get an idea of trying something new/different.

Chris

B.B.,

Is a synthetic replacement of the leather seal something you would even consider? Or, is that considered taboo with a vintage air gun?

My suggestion has nothing to do with power increase or anything of the such. Just a simple, quick fix. Yes, it would be “rigged”, mis-matched parts, non-period,… but if something like a TX seal can be placed behind the piston head (regardless of piston head condition) in a secure manner and it works fine, why not?

Chris

Chris,

I doubt there is a synthetic seal for a BB gun as old as this. I have no problem using them, but I know from testing that they are no better, except they don’t need as much lubrication.

B.B.

“This plunger lacks the central air tube that starts the BB on its journey down the shot tube.”

B.B., that being the case, even once you make a new seal, are you expecting lower than normal (current) BB gun velocity due to the lack of that initial push?

If that’s perfected welding, they need to go back. That’s allot of porosity, does it matter how it is on the inside?

Have a nice day!

R

1stblue,

It’s airtight and has been for over 90 years of use.

B.B.

Is the central air tube not more relevant to a repeater – I don’t know how the magazines worked on BB guns? The BB to be fired falls through a hole in the side of the barrel, initial movement of the piston physically pushes it into the barrel and seals the feed hole?

Iain

Dave,

If I get the length of the seal right I expect to get close to the original velocity, which I would guess is over 300 f.p.s. The problem is, this gun was made at a time when lead BBs were still very common. I don’t know if it was made for lead or steel, so I will test with both.

B.B.

Cool; I’ll be watching this with great interest; thank you. =>

lain,

You know, you are probably right! A single shot probably doesn’t really need one.

B.B.

BB

When I rebuilt my 1894 10 years ago I was a little confused as to why there was an air tube there.

If you remember back then I also discovered that there was a reduction in the diameter of the air passage over the years also. The smallest being the second edition of the 1894 with the composite wood stock and deactivated loading gate. I had some others that spanned the years to compare.

Break barrels have nothing like that and I eventually figured it out. It prevents a second bb, and possibly more, from popping up from the feeding block passage and possibly flying out the barrel behind the first bb. Also it prevents air pressure from pushing the next BB back down the feeding block into the tube mag resulting in a power drop, but not much I guess.

Without the air tube the rifle may act like a short burst spring assisted syphon fed full auto. ( Now that gives me some ideas for HPA but it’s already been done, you tube. )

Bob M

Iain,

I had not given that any thought previously. I thank you for your two pence worth. 😉

Off subject. Crosman Mark II.

Well sometimes you walk through the barn yard and never step in any you know what. Took a $53 plus shipping chance on e-bay on a Crosman Mark II with out the piercing assembly. I have two S&W 79Gs , a 78G and a Crosman Mark I so figured I could just use the piercing assembly off one of them when I want to shoot the Mark II. The gun sealed up when CO2 added, but after five shots had slow leak through valve. Put a few drops of transmission stop leak in gun, new CO2 cartridge and fired it four times then left it for three hours. Went out to shop and the Mark 2 was still holding CO2 with no sign of a leak. Thanks Tom for that information. Don’t know if the transmission stop leak did it or not. Anyway, gun is shooting at 406 fps with wadcutter pellets. All four of the sight screws were frozen tight along with the power adjust screw. Kroil loosened all but one windage screw. Had to apply heat from heat gun and the last screw came free. Have no idea how long the seals will last, but having a hard time fixing what ain’t broke. If I stumble across a piercing assembly for a decent price, might buy it, but can get along fine if I don’t find one.

Jonah,

My experience has been those seals should last for years now. Don’t you love it when something like that works? 😉

B.B.

Everyone,

Just a random question here. Just wondering if a .22 LR firearm barrel with micro-groove rifling could be used for an air rifle. Twist rate is 1:16 and length the usual 18″. The breech would be cut off leaving just the start of the rifling, so no chance of a rimfire cartridge ever fitting it again. How well would .22 pellets fit that? Would having a firearm marking stamped on the barrel be an issue for airgun use?

Clicky,

To me, you are inventing something. You have already said that you will disable the barrel from ever accepting .22 LR again. I see no issue. As for PB .22 size and air gun .22,.. I can not answer. B.B. and others seem to know that info.. I would think that it could be easily looked up on line (projectile OD). Barrel ID might be a bit harder to find. My 2 cents.

Chris

Online results get some interesting experiments using nailgun blanks & muzzle loaded airgun pellets. It looks promising, but I’m still not totally convinced

And I’m always inventing something! Woke up this morning thinking I ought to try making my own thixotropic foaming agent, then fill the space between a barrel shroud & barrel with that. The combination would act as a harmonic damping system, provided the shroud weighs enough. Or maybe the shroud would be better off anchored to the stock?

Clicky,

The “foamed” shroud sounds good to me. Makes sense.

I did make a reactive target that uses nail gun blanks. Very nice. It is incapable of firing a projectile. Basically, the pellet hits a disc that drives a firing pin that strikes the nail gun cartridge. Spring loaded and reusable.

Chris

Chris,

Maybe a soda barrel stuffed inside a 1/2″ tube and a stack of these things: https://www.ebay.com/itm/4-SORBOTHANE-VIBRATION-ISOLATION-RINGS-1-2in-DIA-1-8in-HT-1-8in-Hole-12-7×3-2mm/371956202819?hash=item569a513d43:g:sVAAAOSwZ4dZH8UJ:rk:5:pf:0

Or just find the same material in a larger size, for a more serious build

Clicky,

Like I said before,…. cross-over tech. used for new technology. I like it.

Chris

Clicky,

Also,.. I think it comes down to (what) is powering the projectile, regardless of what that projectile travels (in) on its way out of the muzzle. Powder powered would be a firearm. Explosive vapors (might be) another. Air, and only air, I think would be air gun associated/categorized.

Chris

Clicky,

Your pellets will not fit the barrel well, B.B. talks about the difference here only the other way around.

/blog/2007/08/bullets-and-pellets-what-gives/

Mike

Ok, looks like BB has the answer without even doing anything!

Wonder if Taofledermaus knows why he couldn’t get on target doing that nailgun blank trick?

Now, if I wanted to really get weird and buy Daystate .22 bullets, maybe it’s not such a bad idea. But I want to keep using standard pellets. So no

Clicky,

The nail gun blank video I saw was quite eye opening. The std. 22 only dented steel where a nail gun fired pellet blew straight through steel. I never would have guessed that. The accuracy on the nail gun fired pellet was (completely) crap though. I forget the fps comparison’s,… if there was any.

Chris

Chris,

They’re getting up towards 3000fps with those experiments. But if the pellets are smaller than the bore, what they ought to be using are subsonic .22 short bullets loaded in front of the highest power grade blanks

Clicky,

Here is the one part look at Pellet adaptors in firearms /blog/2016/12/pellet-adaptors-in-firearms-part-1/

Which lead to this 3 part blog on firearm pellet adapters /blog/2017/02/firearm-pellet-adaptor-part-3/

Kinda cool,

Mike

Mike,

Well, I was kinda hoping that was a barrel liner & conversion cartridge for a .30 or bigger

Interesting sort of oddities out there, though

Clicky

I’m surprised BB hasn’t said anything yet.

A .22 rimfire bullet is a different diameter than a .22 pellet.

A .22 pellet probably won’t be accurate out of a .22 rimfire barrel. It will fit too loose. It will probably shoot out of it. And you could probably make the pellet shoot real fast and make lots of power. But I bet you will be lucky to hit a 5 gallon bucket at 50 yards with it.

GF1,

That’s what happened to Taofledermaus, on youtube. He tried to test that idea for accuracy and couldn’t make it work. But he might not have known about the size issue. I think he was shooting at 50 yards, and the result was more like a 50′ spread!

Clicky

I didn’t read through all the comments and see that it was already brought up about what I’m talking about.

And now your talking about designing this air gun with a rimfire barrel.

My question to you is. What have you designed and actually built already. It’s easy to talk about making something. But actually doing it and succeeding is another.

Just curious. Maybe I might just be surprised by the answer.

GF1,

I know that all too well! I have started more unfinished projects than I care to remember. And all my best ideas are the ones that I never tried out

I didn’t really think of the rimfire barrel as designing so much as just improvising. This project ought to be able to use any barrel, in any caliber. I just want to start out with a .22

I think this isn’t really a designed sort of thing, it’s more like an engineering art project. There’s been no math involved so far! That’s usually a bad sign, right?

Today, I cut a few parts of the fork down into pieces that are a little closer to being useful, but so far it’s still just a basket case. Turns out that the inner tube is sized so it doesn’t touch the main tube. It was designed to ride on the lower seal and a bushing that snaps into a groove around the tube. So it really looks perfect as a piston skirt. I’m turning that around and using the bushing for the tail. Whatever I come up with for the seal, or another

No barrel, no frame, no piston seal. And a few critical interfacing parts need to be custom built, but those are all easy. Just a bunch of cylinders less than 3″ dia. Though one of those has to wait until a barrel shows up…

Clicky

So when it’s all said and done. What do you want the gun to do.

GF1,

Primarily to find out if a burst disk will aid a spring piston powerplant

And to learn a few things about port design for myself

It’s certainly not for hunting, or match competition!

But it would be nice if the thing shoots straight, as I like target shooting. Or maybe it’s long-range plinking?

But this burst disk idea is why I came here in the 1st place. I was just curious if anyone had already done that, and it seems like maybe that’s out there somewhere, but just not that I see as yet

Clicky

I don’t recall the burst disc being used that way on a air gun.

Why don’t you just use a break barrel gun you have or get a cheap one. Then do some machine work on the transfer port to accept a burst disc.

Then make a bunch of burst discs and shoot and see if you get the same or better or worse groups and velocity with that gun as it was before the burst disc mod and after the mod.

That will tell if your idea was a success or not. In other words don’t throw in other varibles of design until you know the burst disc idea is proven.

GF1,

Well, I just hadn’t thought of doing it that way until after I got started. So now I am planning on doing exactly that, but it has to wait a bit until other things are paid for

And I really don’t want to give up just yet on the bike fork, so long as it doesn’t get in the way of anything else. If it doesn’t work, then I want to know first hand how that goes

Clicky

Nobody said you had to give up on the bike fork idea with the project.

I was just trying to come up with a idea to speed up your process so we could see the results of the burst disc idea.

I would like to see the results actually. I have thoughts on what could happen. But as they say you never know till you try.

Yep the paid for thing. Just do what you can when you can is how it is.

GF1,

Nobody but me, perhaps! There is one advantage to a scratch-build. Fewer alterations needed

For what I was planning, an existing gun would need to be cut clean in half just flush to the piston where it comes to a stop in it’s forward position. Then a ring could be permanently attached to the spring tube to allow changing out inserts that would act as the transfer port & also carry the barrel. I was planning on inserting the barrel into a socket with standard o-rings for the breech seal. That solves the issue of how to have the barrel set into position at any arbitrary distance from the piston. Having the barrel pivot or tilt would drastically complicate the design. You could perhaps think of it as a forward-acting bolt action? Except it would travel farther than usual & be able to lockup at any position. The locking action would actually be a clamping system that would hold the transfer port insert in place, along with any burst disk assembly

There’s nothing in what I was thinking of doing that wouldn’t work using a store bought rifle for parts. It’s just the pivot block and cocking linkage wouldn’t be used. And that would solve a variety of little details. I suppose I could skip using my idea for a ball-bearing sear based on a QR air-fitting….

A chronograph is just a bit out of budget still, so I’ll have to use other means of measurement

Which reminds me, back a long time ago people used to shoot into logs hung from strings, and measured the amount of movement. That and the weight of the log could give a good indication of impact force

I would be surprised if B.B. hasn’t used one of these setups!

So until something better comes along, that’s probably what I might try

Clicky

My way of thinking has always been simple but effective.

Why not just drill out the transfer port to a bigger diameter and put threads in it. Then you could just make up some burst discs that would thread in. Then have the opening vent to the center instead of out the side like conventional burst discs.

But that’s my idea. Not yours. 🙂

I say get going on it. Let’s see what happens.

Clicky,

A rimfire barrel is much larger than a pellet barrel in the same caliber. It works but not that well.

B.B.

BB,

Yeah, just read your previous report on that matter. Spent the morning looking at Marlin 60 barrels & wondering just how close that would be, thanks!

Clicky,

Crosman Parts sell .22 barrels sized for pellets in various lengths and they are not all that expensive.

The Patent Art you posted shows, in my opinion, exactly how you DO NOT design a Transfer Port! EVEN though it is strait throughput It has sharp transitions at both inlet and outlet; makes for very turbulent flow which kills Airgun power. Think tuned inlets on carbs and tuned headers to get some quick guidance for good flow design.

Good luck with you build(s) and planning!

shootski

Shootski,

The patent was not for the transfer port, so that’s not surprising. If the port itself should be patented, then it would be right but everything else would be wrong! I wouldn’t place a lot of faith in the slope of the piston skirts leading edge in that. Until B.B. takes the piston apart to show the rest of us how the NP2 technology really works, I wont know for certain

Thanks for that parts tip, didn’t think Crosman was doing that for non-warranty work

I see that Pyramyd has barrels in their parts area. Diana Stormrider barrel is $35, that’s not too out of budget. It is about one full tank of gas though

Clicky

Crosman will sell you parts if you have a part number.

It’s that easy. Well if they still make the parts. Which in most instances they do.

I have put guns together by using Crosman parts. That’s one of the reasons I like Crosman so much.

GF1,

I just read their support page. No online sales, got to call their customer service at 800-724-7486, but I would need a part number

So I was just doing a trial run on the Benji rifles. Interesting what they had in 2013, 1st gen NP platform

Really would like to know if the bore & stroke stayed the same between NP & NP2. Like as in, what does it take to buy a NP2 gas ram & piston assembly, and swap that into the older NP guns? Well, besides how the sear works

Clicky

Yep Crosman wants part numbers if you call. If you don’t you might as well not even call them.

GF1,

Reminds me of all the times I want a car part for something that never had that part. Like when I took out the ECU & TBI on a mid-80’s Horizon, welded-up an intake using the exhaust from a jap bike, then was able to install a set of Honda Civic side draft carbs. All I wanted was a late 70’s Dodge voltage regulator to run the Horizons alternator, and a 5lb fuel pressure regulator. They always start by asking me what car it’s for, and I always start in on a really long story while the clerk looks sideways for help…

Clicky

Reminds me of when I was buildng race engines from the 70’s to the mid 2000’s.

If you can’t get what you want you got to make it.

And those Horizons was cool. And I had one of those 86 turbo Lebarons back in the mid 90’s. Had a bunch of stuff done to it. Was one of the first front wheel drive cars at the local dragstrip beating the the rear wheel drive V-8’s at the time. And I drove it 60 miles round trip back and forth to work and getting around 28 mpg.

Heck I remember welding up a bracket to mount a alternator on the back of a drive shaft by the rear yoke on a old 72 Nova I had. Then we welded a pully to the yoke. After all we had the battery mounted over the right rear tire to aid in traction and weight transfer.

You know why we did that? That was to get the alternator off the engine to free up engine horse power and put it at the rear for weight transfer. That car also had a electric fuel pump and water pump and no power steering. The crankshaft didn’t have any thing on it but the harmonic balancer.

And we done many more things back then on the old muscle cars that I ain’t going to spend time here about.

Let’s just get your transfer port burst disc air gun done. That’s what I want to see when you get it done.

GF1,

My unfinished Horizon project had a 2.4 out of a PT Cruiser sitting in it on temp mounts, counter balancer replaced with homade windage tray. Megasquirt in the glovebox. My power steering rack had the fluid drained and the ports connected to each other to keep squirrels out

Plans were to install an OBX geared locker, replace the hatch glass with a louvered screen & install a plexi firewall where the rear seatback was. Then move the radiator back into the rear, along with the battery, windshield washer, fuse block and anything else that could move. An underfloor vacuum system would provide air for the radiator. I had a 30-HP USN compartment exhaust fan I was going to try wedging in there, along with a vertical shaft Briggs V-twin. That probly would have required a box built over the rear seat. The brakes would have been twin masters with adjustable balance bar, and I wanted to add a 2nd set of lines to each wheel so I could have a pump keep the brake fluid circulating through a heat exchanger. Front struts were to have the upper mounts replaced with a pivoting linkage that would change the camber via steering input. The springs were to be replaced with a air over hydraulic system like what Cruat was doing, except I never really figured out how they did theirs. For initial use, I was going to add a spring-loaded cable tiedown to the wheels that would act like a pre-tensioner & thereby make the stock springs act stiffer. The heavier springs would be behind the drivers seat. (yes, lots of pulleys) I already tested that and it worked perfectly, maybe even too much, as I had to back that off a bit to stop sliding in corners. I usually was on three wheels around hard corners with all the Horizons I’ve owned, until I tried out that cable suspension. But it did make the car totally different, less smooth. I think more horsepower to pull out of corners would have helped that. Guess I’m more of a Clubsport enthusiast than a drag or bracket racer

Clicky

You remember the Dodge SRT 4.

I had 2 of those I bought new as well as a PT GT Cruiser.

Had them all built. But the last was the 05 black SRT4. It had a stroker kit and was a 3 litre. Had adjustable cam gears and a number 3 Crane intake cam and a naturally aspirated exausht cam from a standard PT Cruiser. Had the bottle on it too but used it as a super cooler with a Snow Booster methanol injection in the intercooler pipe before the intercooler.

It was making 500 hp and 525 ftp of torque. And the neat thing was I could watch my temperature gauge drop as I was making a quarter mile run. The intake manifold was ice cold still by time I got to the pits. And yes I had Stage 2 injectors and computer in it among other things done to it. It ran 11.65’s at a 130 mph in the 1/4 mile. Was doing a 105 mph in the 1/8 mile. Oh and I was using only a .030″ nitrous jet. It would get 30 runs on a 10 pound bottle and get 32 mpg on the highway.

Nothing like machines. See what you got me doing again. 🙂

Oh and forgot I did SCCA Solo1 road racing in the 90’s also. Had a 90 1LE Camaro I bought new back then. Mine was a rare one too. It was RS version and came with a Muncie getrag 5 spd instead of the Borg Warner 5 spd. 5th gear was 1:1 instead of overdrive and it came factory with a 3.73 posi. It was a very good running car. And also had a 540 stroked 72 Cutlass with 50 series stickys all the way around and different sway bars and 2″ drop springs. Yep it ran it’s butt off too. 🙂

GF1,

11 second SRT4, very nice!

What do you think of the Hellcat-powered Trackhawk? That and the Toyota ’86’ are the only cars on my wishlist

Clicky

Read my reply again about the SRT I added some stuff about road racing.

And yes I like the Hellcat alot.

Oh and by the way. I got a 2016 Turbocharged Chevy Sonic I drive everyday to work that I got stuff done to. And just got to ask. How old do you think I am?

GF1,

51

Clicky

Kind thought you was going to say something like that.

I’m 57 years young. 🙂

And not being rude. Would like to know. How old are you? I don’t want to guess. I know I’ll mess up on that.

Clicky

A little closer after you edited your comment.

So how old are you?

GF1,

That was for myself

B.B.,

Too bad. I was about to ask if it would be possible to convert an air rifle into a CB cap shooter! ;^)

Michael

Clicky,

The .22LR barrel is a not so good idea as the .22LR is .223. The pellets will be way too loose in there. You can get airgun barrels pretty cheap to play with.

As for foam in the shroud to dampen harmonics, it will indeed do such. This will also take up the volume that is being used to provide expansion room for the redirected muzzle blast.

There are several schools of thought concerning the control of barrel harmonics. One school likes the barrel kept under linear tension. One will have a bushing on the muzzle of the barrel to keep it aligned in the shroud and help reduce vibration such as in the Marauder.

I myself am a free floater with the possible addition of an adjustable/movable barrel weight/sleeve for tuning. The barrel is going to want to move, so I let it.

I am certain there are other schools of thought concerning this. Any and all insights are welcome.

RR,

Linear tension for barrel control is a new one on me. I’ll keep that in mind for future experiments, but I would add a damping system in the middle

I think what I was first thinking of testing would be more like that forward bushing Marauder, except the bushing would then be held in a Sorbothane cushion like an engine mount, otherwise the barrel might try bending & oscillate in the middle like a guitar string

I’ve been more inclined to the idea of not having a suppressor, just a really good muzzle brake. In case anyone was wondering why it seems like I forgot to leave room for one of those. So I tend to think more in terms of a damped shroud that is either full length or just like your tuning weight system, right at the muzzle. There was an older comment about adding a 2nd air-cushion inside a gas ram that would act as a bounce-back. That plus an active braking system to lock the piston & hold it for a second so as to create a vacuum pulse inside the barrel is how I would attempt to control the sound level of muzzle blast

There’s no reason why a damped weight couldn’t be clamped in place, the same as a typical tuning weight. And that would also allow putting all of the control weight into a more focused point where it would have the greatest effect

Every time I hear the term ‘free floating barrel’, I wonder how to really make that work. It just seems to me that somehow the barrel should be divorce mounted from the gun and work more like the primary gun on a modern battle tank. The goal would be to balance a full shot glass on the barrel & fire a round without spilling a drop no matter how much recoil, spring/rifling twist torque or vibration is acting on the shooter

Maybe I could try out a ball joint on my test rig? That would be a 1″ ball with the entire transfer port inside that, and a damped suspension holding the barrel. I just might be a free floater too, you know!

I suppose a centerfire person might want to try a roller bearing attaching the bolt block to their stock, with a damped suspension at the fore end. Maybe the barrel weight would be re-located to the stocks fore end to control the recoil motion?

Clicky

Check out how the FWB 300 and Diana 54 Air King work.

I think that will give you a idea about barrel or action floating.

I had both and they are smooth shooters.

GF1,

I’d like to try out one of those Air King’s, sounds very interesting. And my project gun is already going to be based on a rail, in fact I was already thinking about having it recoil in the same manner. My garden cart can have a set of guide rails screwed down to the plywood deck. Those will be spaced just loosely enough that the gun will easily set down in between. No stops fore & aft. If it wants to go flying off the cart & fall to the ground, then I’ll add some friction. First few shots will have a tether

This free recoiling method is taken from what I know about my R1’s best kept secret. Only with the R1, the recoil movement was a lot shorter, about 1/16″

1st 7 years I had my R1, I thought the sloppy looking gap in the stock right at the rear of the metal work looked bad, plus it seemed like because the action was moving back into that gap it was working all the stock screws loose. So in 2001, I made some shims to prevent that. I made one large shim to go in the back, and a pair of small shims to go one on each side right at the front of the spring tube. That fixed the stock screw issue, so I just kept it that way

Then I spent the next 5 years trying to figure out why my R1 wasn’t as accurate as it used to be. Thought it was either the pellets or I was getting sloppy

Then one day after putting in a Maccari spring kit, I lost one of the front shims during the tuning period. So I decided to go without the shims until I could make some nicer ones

So of course, I thought the black tar was the only reason the R1 was back to it’s best form. A few weeks later, I put some new shims in, and that’s when I finally figured out what was going on

Anyway, I might want to copy the FWB cylinder seal for my current project. The front of my spring tube is going to be wide open each time I remove the burst disk assembly. And I’m already going to copy the Air King’s recoil method

Clicky

So when you lost that washer I’m guessing you figured out why the hold of a gun matters on some guns.

That’s why some people can shoot guns better than others. It don’t mean you need the artillery hold. It means some people can hold a gun more naturally than others and let the gun do some of the work.

And that is a complicated thing to explain. But the FWB 300 and Air King help with that answer. Sort of.

Plus more to it then that. Once you build a gun that can repeat itself very easily and give it to a person and they can’t get it to group good. Then what does that mean?

The person behind the trigger has to know what they are doing too. There is a feel you get once you shoot a particular gun long enough. Some just take more time than others.

If you don’t figure that out. No matter how good of gun you got you won’t shoot it good.

GF1,

I took long enough on it

And there was something about having had that R1 so long that’s not easy to explain to anyone. The feel of carefully placing 200 rounds, one at a time, on a slow afternoon was like some kind of zen space

Clicky

Call it what you want.

Yes some people can get there easier than others.

Some can even do it without thinking. The more you do the more natural it is.

If you have to think how to hold or what to do then that means you ain’t got the feel yet.

GF1,

I guess so. I always had a warmup period on each day I went out for serious shooting. I would usually wind up thinking about what I was doing wrong, then try to stop thinking so much. Usually 50 rounds and a short rest break, do some yoga or something. That’s when my day would really get going, then hours later I would realize time had passed and I would be late for something

Clicky

Your just to much.

Hours have past. But you make me laugh.

In a good way. 🙂

Clicky

Oh and remember when we was talking about that I used different o-rings as the piston seal.

That was the FWB 300 I messed with too. I took the cast iron ring off and replaced it with a o-ring. Or as I said before the right fitting o-ring.

And I found out something else about that gun. The inner barrel actually floats a bit in the outer barrel. I know this sounds crazy but a few drops of super glue tightened up the inner to outer barrel.

That gun also has a heavier single Maccari spring. My buddy that can’t shoot a spring gun to save his life has shot it out at 50 yards and says it’s the most accurate springer he has ever shot and couldn’t believe how easy it groups.

So to me it sounds like your trying to design the best spring gun in the world is what I’m seeing the more we talk.

GF1,

Darn, I didn’t want to say anything until it was working yet! Bad luck!

Clicky

Well there you go.

It’s not about luck at all. it’s about knowing how to make it happen after you come up with a idea.

It may take time. But designing is only part of it. And having other people around to help is a good thing. But you may find that doing it your way may be the only way.

Clicky maybe this burst disc springer will be the one project you fininsh.

Good luck or bad.

GF1,

Well there’s been a few good ideas coming from here that I hadn’t thought of

Like maybe I should look into building gas rams? I don’t think I would ever have considered that until this week

Clicky

Do you or someone you know have a way to make stuff?

Machine shop equipment is what I’m talking about.

Just me, and not a lot of money for it. I have a 6″ Harbor Freight lathe that I wore out, used to have a 101 with extras, and a good size benchtop milling machine. I have a oxy-acetylene welding rig with tips down to 0000. Just recently welded up a stovepipe with that little tip. Chasing rust is not a good time for anyone else to be around me! I have some very simple 2D drafting software – DeltaCAD, which I use for layout work. I was always in the drafting classes during high school, but mainly so I wouldn’t have to take one more boring class, but 3D CAD is just a bit more than what I’m good with. I put together the last 5 computers I owned. I have a plastic welder, but still haven’t gotten the hang of that yet, maybe I just need to pick the right size project for that guns ability. Got an all-metal Kenmore sewing machine, DeWalt hotglue gun, Weller soldering station. So I can do what it takes. I’ve completely torn down motorcycle transmissions, about 3 or 4 times and completely rebuilt a couple engines. Partially rebuilt a few more. I’ve made a few prototype carburetors, designed & built some venturis for gold dredges, one of which was a 5″ that worked better than the storebought it replaced. And all the little projects I couldn’t possibly remember

Clicky

Sounds cool. I did drafting and shop classes through school too. Was my favorite time in school.

And you know what. Something just occured to me. Where so yo buy your material from when you need it for a project?

All through time I have been able to tell them what I want at work and they will get it then take the money out of my paycheck. Never had a issue getting the material I need.

Do you order it from somewhere or just keep stuff to make it out of later?

GF1,

It’s a little bit of everything, I guess. When I throw something out and it has straight sections of steel I could use for something else, I cut it up and stash the parts. But other things, like LED drivers & star boards, I buy off Digikey or Ebay

The ceiling fixture right above me at this moment has a custom conversion I did a year ago. That is using a 12-volt Cree XHP70 in 3000nM color spectrum, driven with a 350mA chinese LED driver that runs directly off of the 110AC. It’s putting out about as much light as a 40 watt halogen, but only uses 3 watts. The fixture feels cold to the touch, even after being left on all day. So no cooling fan required when under-driving a LED like that one. I think if that LED had water-cooling, it’s supposed to be able to put out 1200 lumens without getting overstressed

Sometimes, I just sketch ideas for things but never build them. I used to have a box of paper, but it was stolen out of the storage I was using at my parents place. So I’m not sure just how many thousands of ideas were lost. But I always keep thinking of new stuff, so I guess if I wasn’t building any of those things, it was time to move on

Anyways, there’s a few too many times I just don’t have the materials or tools. So I just work out as much of the idea as I can in my head, then move on to other things

Clicky

One of my buddies likes electric stuff. He comes up with some cool stuff.

And bummer the papers got stole.

I’m not all into that design and build stuff anymore. I dealt with it at work all through the years.

I’m just into relaxing and enjoying what I have now. Done picked the crop if ya know what I mean. Time to kick back and enjoy is what I’m about now.

Bob M,

I haven’t seen a Pinto come stock with a variable venturi. Aftermarket?

And that 3-stage industry standard is exactly what I was trying to improve on. The individual circuits have a lot of overlap throughout the pressure & flow range range. Fuel injection is much easier to deal with at the technical level

So what I did was design a fuel circuit that drops off faster. Like if you were to consider the standard circuits as a type of wide-band design, my circuits are very narrow band. Then I simply run 20 copies of the circuit, all in parallel to each other. The trick is that the circuits can be shut off one at a time in sequence via a control rod attached to the slide

You’ve seen on most small engines, the slide style carbs usually have a metering rod hung off the slide, running down through a jet. Imagine that same thing is now a slide valve that does not allow any airflow past itself. The bore which this valve drops down through has 20 cross-passages, each one of those is the main delivery port of each circuit, all of which then runs into a single emulsion tube. That emulsion tube then is run back up to the slide where it dumps into the airflow in standard fashion. Now, each circuit has a fuel metering jet, an air metering jet, and an adjusting screw to control the flow, just like an idle mix screw. On my carb, the 20 mixture screws are all arranged in a vertical row, the top screw is the last one you would adjust as that one is only used at WOT. The bottom screw is the idle mix, as it corresponds to an airflow rate that is only seen at idle speeds. Each screw going up will add to all previous circuit adjustments. The only real issue I had was that the float bowl wound up not being high enough for the top screw & way too high for the bottom one. I needed to rethink that one and shelved it. But the nice thing about it was how intuitive the adjustments were. There’s no jumping around to all sides of the carb, trying to remember what each screw is for. Adjusting is done from idle, then slowly increasing engine speed until you reach WOT. The slide is operated by vacuum diaphragm, so this is a CV carb

A slide carb can have a barrel shaped slide, or a rectangular shaped slide, like what you saw in that Pinto. There was also another design that’s very rare these days. It had a pivoting flap to change the venturi size. I can’t recall the name of that one, but I did see one at a bracket race once back in the 80’s. Haven’t seen that carb design since. All I remember for sure is it’s logo had an american eagle with a banner

Clicky

I do believe that’s why sequential fuel injection has came about.

Very tunable. Of course do to electronics also.

Remember our conversation about electronic valve dampening. Yep also in fuel performance.

GF1,

Being retired & content is actually a bit hard to imagine. My mind doesn’t stop, so I’d probly have to be dead before I stop thinking of things that haven’t been done yet

One of the few things I actually built, that were kinda interesting. It’s a CV joint with articulating linkages. It maintains true constant velocity and is able to swing the output shaft a full 180°. Years after I built that, I found a very old patent from the late 1800’s that was basically the same exact idea

I could just use that to make a steampunk oscillating room fan, or something. But I keep forgetting I have the thing kicking around. That CV joint was part of what was stolen, too. All my layout sketches, proposed applications, detailed descriptions of how it functions & templates for this prototype

Clicky

As long as it makes you happy with what you do.

Clicky

While rebuilding a carburetor I concluded that having three stages of fuel flow had to be pretty inefficient. Idle, mid-range and full throttle and in my mind put together a sliding block fixed venturi carb that would always be working at full efficiency. The sliding block would allow for increased demand by extending the opening.

Needless to say it went out of my mind just as fast as it came in. Then one day, years later, my ex asked me to see if I could fix her Pinto. Low and behold under the air cleaner was a sliding block variable venturi carburetor. Gotta’ watch out for those mind readers !

They just made the sliding block part of the venturi and called it variable. Same idea different application.

GF1,

Something I haven’t done yet, but would still like to, is re-build a CV slide carb to have servo-driven metering jets. I’ve seen a few examples of software controlled carbs, and I suppose you could even include the infamous ‘feedback carb’ of the 80’s. Holly used to sell a little black box that would allow setting a constant rate duty-cycle to the solenoid inside a ‘feedback’ type OEM carb. Just about any Arduino or R-pi can do the same with one hand tied behind their backs. It just needs a high-current driver circuit added, and setting up a potentiometer input to select a % of PWM to send out over one of the output pins. That’s the sort of thing I have been doing with microcontrollers. So not really very advanced coding just yet!

But with a better carb than those ‘feedback’ types, which has the ability to set a much wider range of A/F ratios at the main jet, combined with a wideband O2 sensor and maybe some other signal inputs, I think something interesting can still be done for a modern carb. The basic prototype is to simply remove the slide needle & run that upside down from a port in the bottom of the float bowl. Then a servo on the bottom of the bowl would control the needle position. A more advanced design would add another servo valve to act as a cold starting auxiliary fuel circuit. The ECU shouldn’t be much bigger than 20mm square by 80mm long, with heat sink

That will never be as good in terms of best fuel efficiency or power, as having a fuel injector right at the intake port, but the total system weight, complexity & cost can be very competitive vs fuel injection on vehicles where size & weight matter. Motorcycles and race Karts

Clicky

Don’t know what this has to do with air guns.

But GM did that to the Quadra jet spread bore 4 barrels in the 80’s. They even went as far as turning them into 2 barrel carbs by eliminating the back two barrels. That’s when they was trying to make the V-8’S economic.

And do some searching. Holly and Edelbrock has made 4 barrel fuel injected throttle bodies that bolt on to a standard 4 barrel intake. They come with their own ecu that is programmable.

Anyway back to air guns.

GF1,

Sorry if I’m off topic. It’s just that for myself, air guns are just one more puzzle

I guess what I’m trying to get at is that I need to do whatever it takes to learn more coding skills, in order to actually make a soft-nitro piston that works

Clicky

Maybe your over thinking it. Have you ever thought that before.

Simple but effective remember.

Once you start adding more to a process the more potential for problems to arise. What I mean by that is more things that can fail. Yes there is reliable products. But something can fail at anytime.

As others have said. KISS

GF1,

Yup, I’m always reminding myself to not overthink. Lifelong bad habit based on thinking instead of doing

But coding is it’s own thing, and I’ve just barely gotten going with using that sort of tool

Clicky,

A free floating barrel is not in contact with anything other than the action. In powder burners the action is typically glass bedded in the stock for a tight fit and the barrel has no contact with the stock. This allows the barrel to flex, etc. as it will with each shot without interference from an outside source.

The barrel IS going to flex, vibrate, expand, etc., so you let it. You will most likely desire a more rigid barrel, especially if you want long range consistency, hence the “bull” barrel. Fluting helps to lighten this type barrel without losing rigidity.

My Rapid Air Weapons HM1000X Sporter is an example of an air rifle with a free floating barrel. It is also a very accurate air rifle at long ranges, most especially when I get into the zone.

RR,

I don’t want to change a good shooting platform without any respect for it’s heritage & ability

But I do still like the idea of having a barrel that wont tip up under recoil. As for all the inherent barrel activity, I’m ok with that, it will just be inside a region which remains centered on target

I do keep thinking about more rigid barrels. Something with carbon fiber trusses taking the place of milled flutes

Clicky,

Many of the new RAWs have a machined down barrel covered with a carbon fiber sleeve to provide stiffness AND reduce weight. Other air rifles are coming on the market with such also.

As for the Limbsaver, It would be easy to add multiples if you so desired, but the idea is to move it back and forth until you find the proper location where it properly dampens the harmonics. It is my intention to pick up one of these for my HM1000X and see what it does.

Do not get me wrong. I do not want to discourage you from tinkering around. There is no telling what you might come up with that will revolutionize the airgun world. More often than not it has been the guy in the garage that comes up with something new.

RR,

If I were making my own barrel damper, I would want to buy any other designs I could find, to use as design references. Wouldn’t want to spend a lot of time doing something that didn’t work as well as that $12 part!

But once you find a point on the barrel that works best, you still need to find the best amount of damping material, depending on choice of material. And you would want to find the best amount of weight for that material to react against. It could simply be how much of the stuff is used, as the damping material itself has some amount of mass per unit of volume

I’ve seen archery damping systems from Limbsaver years ago. They were talking about damping out several frequencies at the same time, which may have something to do with the different size rings on that doodad. So my version may be flawed from the start. And the tip of each of those rings might need to have it’s own individual adjustable weight

Clicky,

Quite honestly, I do not know. I have never conducted experiments with harmonic dampening. What I know about it I have learned here from the Bearded One. He has done blogs on his Whiscombe. At least one of them concerns the adjustable harmonics.

RR,

Has He measured the vibration in a barrel?

I’ve been thinking about different ways to do that. Phonograph needle was one. But I think maybe something like a engine knock sensor attached to the barrel. That’s a piezo electric microphone in a sense. The knock sensor would generate a voltage that is in synch with whatever the barrel does. Using a storage oscilloscope to record the resulting waveform will allow looking at the shot cycle and determine exactly what frequencies there were & identify which frequency has the greatest amplitude

The weight of the knock sensor will alter the barrel harmonics of course, so it’s not a perfect idea. But it might give a better idea of what’s happening. That’s why my 1st idea was to use a phonograph needle that just touches the barrel. But I’m not sure if the needle can move far enough. Maybe if it’s set at the rear, then move it forward until it’s signal starts clipping?

I think this sort of thing should have already been done in a lab somewhere out there, so whatever techniques were found useful to do this, that would be nice to know about

Having a record of what’s actually happening will make adjusting a harmonic damping weight go a little bit easier. Sorta like how having a chronograph would help pick an appropriate pellet weight

Guess I could’ve used the search for just 1 minute 1st!

There are very small accellerometers that can be attached to the barrel which will add very little extra weight. They can be connected with thin light weight teflon-coated wire like what you would find inside cheap headphones

That takes care of how to get some barrel data. Piezo electric crystals might still be what makes this work, but the choice of sensor is better than what I had thought. Cellphones have some very small sensors that might work, not sure about maximum impulse force. But breaking one of those wont cost much

Clicky,

Somewhere I have seen a (very) slow motion video that shows the extent of whipping that occurs with a powerful powder burner rifle. It looked like Jell-O. I would do a search, but it is a work day. 🙁

Chris

Clicky,

Hector Medina has been working on this issue some. Read this.

https://www.ctcustomairguns.com/hectors-airgun-blog/truly-taming-the-harmonics-in-spring-piston-airguns

RR,

Thanks for that link! What Hector is showing is exactly what I am talking about

Also interesting that he’s demonstrating a scope mount that has a damping method designed in, so I’d like to know more about that mount

Another very interesting point he raises is that he was previously tuning his barrel so that the pellet exits the muzzle while the barrel is at it’s maximum excursion of harmonics-induced vibration. The critical thing to keep in mind here is that the barrel is moving the slowest only while at it’s pausing before reversing directions. So, the barrel will be moving the fastest when it crosses the point in space where it would normally be when it’s in it’s relaxed state. Trying to tune your barrel to get the pellet to exit at the neutral point will give your pellet a sideways kick

What Garcia is doing, is what I want to do. I just don’t have the tools yet. And the most important thing he says is that what he’s capable of doing is due largely because of the tools used to detect & measure vibration

That sensor is a 3-axis, shown with a adapter they cut to fit it into the scope rings. Digikey has a few hundred different examples of these type sensors. That’s the easy part. I’ll have to ask him what the hardware interface is to that laptop & what software it’s using

Chris,

Thanks, I’ll check the youtube for that. It’s always the 1st stop for research, these days!

Clicky,

The mount he is using is the Diana ZR Mount.

/product/bullseye-zr-1-pc-mount-fits-1-and-30mm-tubes-11mm-dovetail-0-04-droop?a=5495

The original ones were not so great, but have been greatly improved. I just acquired one this weekend. If you check through his site you will find his reviews on them.

RR,

So you got one,… (ZR). What swayed you and what is the intended purpose? What gun? I figure you to be a pretty “hard sell”,… so something made you “flip”. Well? Details,… for those interested. I figured these to be more springer specific. Maybe wrong? I have yet to read Hector’s article by the way,… but I will. I will.

Chris

Chris,

Do read it. I also commented back and forth with him a bit. I think this will greatly help with the uber magnum sproingers. My Tomahawk has a considerable jolt and this should allow me to use my 2-7X32 Hawke on it without killing the poor thing.

Hector has many articles on his blog concerning technical details. He is most definitely a good one to read.

Clicky,

Here is a little doodad that might be of interest to you, and others as well.

https://limbsaver.com/products/sharpshooter-x-ring-barrel-dampener

RR,

That’s my idea, all right. And Limbsaver has been doing this sort of thing long enough that I would recommend testing that doodad before you scoff too loudly at it. Of course, it’s a preset size & weight, so it may not be the best for all setups. I would like it better if there were a way to change it’s mass

Basically the same thing as what I was saying about having a small heavy barrel weight suspended by a material like Sorbothane

The material is an expanded foam, filled with a damping fluid. Sorta like dumping a bunch of liquids that don’t like mixing, into a kettle, then injecting CO2 or nitrogen into that mess while heating it up until it sets into a rigid foam. Making your own allows custom designing the durometer & response rates. Limbsaver has that experience. But they claim standard ammo can perform like match grade, so I’m not so certain about their marketing department

Clicky,

On barrel whip/vibration/oscillation control (less of an issue with airguns),… my understanding is that you want the projectile to leave the barrel at the same time (read: timing) that it is at it’s relaxed point (if it were relaxed). In other words, the projectile exits at 0 point/arc, between whipping back and forth. Regardless of system, weights or rubber dampeners, I think that is the end goal/desired control.

I could be wrong on that and there may be other theories,.. or things that actually happen,…. but that is my (very) basic understanding of the matter.

I think that shrouds are primarily for sound suppression, (air flow/report is redirected back into the shroud), though I think that they also stiffen the barrel from a linier standpoint, depending on how the shroud is affixed. Plus, no restriction between the shroud and barrel along the barrel length, would allow the barrel to flex internally, which may be a good thing. Then again, maybe not.

I would prefer an open barrel, with a screw on moderator, if desired, and that is it. I would rather rely on end weights or rubber dampeners to control/modify whip, directly to the barrel mid/end.

The Red Wolfs were/are quite popular in recent shoots and one fellow removed the shroud and shot it that way. I thought that was interesting. Not sure of the results. He must have had some good results at testing prior to the shoot to even consider it though. All in all, the whole topic is interesting.

Chris

Chris,

I’ve heard of that timing theory. Mostly that whatever part of the barrel motion, that you want to stay at that same point for a repeatable exit path off the muzzle. I haven’t seen anything on determining the best, or typical point of the cycle. But I like the idea of having that point be at the neutral position

I probably shouldn’t call a tube-shaped barrel weight a ‘shroud’, seeing as I meant it to be used in a different manner than as a suppressor housing

Removing the shroud from that Red Wolf may have helped increase the exhaust flow of the baffles so as to get even less blowby down the centerline of the suppressor. Or maybe that guy was simply hoping that would be the result. Be easy to check by monitoring for any blast effect in front of the suppressor, with or without the shroud. Could just shoot across a table top covered in dry flour

And, why don’t the suppressors use reed valves to prevent exhausting out the boreline after the pellet has passed?

Clicky,

Reed valves? Not bad! 🙂 Dude,… you are way above me on brain activity,… that is for sure! I was laid off for about a year and I can tell you that after about 3 weeks,… my brain was doing much like yours. Some people never stop,…. others,… it takes a few to get going.

Do yourself a favor and follow through on what you start. This an excellent place to bounce ideas,.. but it is a bit hard to get (focused feedback) with so much bouncing around. Not easy,.. I understand,… once inspired,….but you got to move forward at some point.

I am afraid that you and I are much more alike, than different. 😉

Chris

Chris,

Cool. Just keep in mind that thinking in a design-focused manner is a practiced artform, not easy to do while distracted by mundane routines. But if you do too much of that, it’s like the Arnold Schwarzenegger effect: once you do the body building thing long enough, you wind up becoming a state governor who while inspecting storm damage, just has to pick up random items to see how they curl

And I’ve been wondering why suppressors don’t use reed valves since the early 80’s. Besides can expansion acting like a speaker diaphragm, how else does the muzzle blast still manage to be so large out the end? If a large portion went inside the can, it ought to stay there until it bleeds off slowly

And if you look at what special forces use, you’ll find that they have spent a lot of effort to delay the gas exhaust. I think I’ve seen valves tested, but usually it’s a steel wool or felt packing in the rear of the can that absorbs energy. All airgun suppressor designs are meant to be easy to stamp out quickly, as the cost of production is important to running a business. But for custom builders, those limitations do not need to apply

Oh, and I build motorcycle mufflers for the fun of it. I have some ideas to test out that nobody else has done yet. Can’t explain here

Regarding the air tube, Iain – UK has it right- the air tube is necessary to make the Daisy BB gun a repeater. Without the air tube there’s no pressure loss between the air tube OD and abutment seal ID and no losses through the holes in the shot tube for the BB retainer spring and the loading port cover in early Daisy BB guns or no losses through the view port/loaded chamber indicator in the abutment of the current Daisy BB guns. And without those losses you have a much more efficient powerplant- and that’s why the Daisy 499B can easily shoot a BB 420 fps using a Red Ryder spring when the exact same spring in the repeater Red Ryder makes 270 fps on a good day.

On repairing the No. 12 Model 29, if the piston/compression chamber is 7/8″ a 499B piston will fit (or even a piston for the Daisy 400-series lever action pellet guns from the ’70s). But chances are it’s 13/16″ and I know of no synthetic Daisy pistons that size that are made without the hole for an air tube.

Good luck.

FWIW, the 499B abutment, piston and shot tube fit into a new production Red Ryder. I mocked up a 105B Buck just to see- it did 380 fps with a well-used spring.

Cobalt,

Good to hear from you! 🙂 If anyone knew about lever bb gun parts swaps,.. I figured that it would be you.

Chris

Hi Chris! We’re off on another 499-based tangent at the GTA thread, stop by if you get the chance.

Take care, Mark

Hey Everybody!

Some time back I was one of the first on here to begin singing the praises of Tune-In-A-Tube and how it can work wonders on cranky sproingers. Now even Pyramyd AIR is carrying it. The only issue is, what do you do when the syringe is empty? Most will likely buy another syringe full. Why not refill it? Well, some have no clue where to find the red grease to do such. I found it a while back, but have just got a round tuit this weekend. I now have a lifetime supply of it that I picked up at my local Lowe’s store for $6.

New guy here .. Speaking of the 499; has anyone ever thought how cool it would be to have a single shot BB pistol using the same barrel (a bit shorter) as the 499? Same drop the BB down the muzzle operation. My 499 is almost as accurate as a good pellet rifle at 9-10 yards. it would be a supremely simple design, and really easy to use. Could be a single stroke pneumatic, or even CO2.

Why would I want this? Why not!

CSA,

Welcome to the blog.

I have been pitching a 499 pistol to the industry for many years. Now that I have the ear of the Gamo Sales VP, it could happen. Gamo owns Daisy.

B.B.

B.B. .. thanks for the reply! I’m new here, but have been into Airguns for many years. Keep up the lobbying with Gamo .. I really think it would be a cool pistol, and likely fairly inexpensive. My 499 amazes me every time I shoot it. When I got it, it wasn’t available to the general public; I had to special order it from Daisy. Glad I did though, because it’s a joy to shoot. My most recent purchase from Pyramid is a Weinrauch HW75, and so far I’m thoroughly enjoying it. Keep up the good work:)

CSA,

Welcome too. I have a 499 and like you, it is amazing every time I shoot it at 24′. I did put a Red Ryder spring in mine and it boosted the fps another 150. It is even more accurate, like that was possible. Of course that varies from day to day,…. but it is for sure not worse.

A pistol would be a real blast, but I am not much of a pistol guy. Now,… an adult sized 499 would really have my interest and would probably sell like hot cakes, given the 499’s reputation. Upsize the whole thing,… not just the stock. And, put a RR spring in it while they are at it. I love it.

Chris

An adult version of the 499 would be great .. I agree! Daisy .. are you listening? Hint .. even if it’s a low volume item, and more expensive to manufacture, we’d pay for it ; )

CSA,

An adult sized (re-stocked, same action) is a no-brainer. Upsizing (everything) might/would require re-tooling. For starters,… adjustable LOP with butt plates (stacks) is also a no brainer. I have said many times in the past,… but knowing what I do now,… a 499 would be a kid’s first bb gun/rifle.

Chris

Chris USA .. I also have a Chief A.J. Red Ryder with an adult sized stock and metal cocking lever. Probably 10-11years old. Not the same tube as the 499 by any means, but fun to shoot nonetheless. And … unique!