by Tom Gaylord

Writing as B.B. Pelletier

Today’s report is a guest blog from reader Ian McKee who writes as 45 Bravo. He’s going to tell us about the Crosman Mark I pistol he recently acquired and what he did to fix the leak it came with.

If you’d like to write a guest post for this blog, please email me.

Over to you, Ian.

Crosman Mark I and II reseal

by Ian McKee

Writing as 45Bravo

This report covers:

- Just kidding!

- Four major changes over the years

- I got this one cheap

- It’s mine!

- Bringing it back to life

- BB’s end cap

- Resealing both caps

- How did it go?

- Outer barrel removal

- Wrong o-rings

Back in December 2018, and January 2019, B.B. reviewed a classic Crosman Mark I pistol in .22 caliber.

There were many comments about how it worked internally, and how the power adjuster worked, so today I thought I would give you a little peek inside the gun.

Here is your peek of a disassembled pistol. This is actually a Mark II I photographed some time back. The parts of the two pistols are identical except for those pertaining to the caliber.

Thank you, that concludes today’s blog.

Just kidding!

I could not do that to you. Here is a synopsis to refresh your memory.

The Crosman Mark I and Mark II (.22 and .177 calibers, respectively) pistols are airgun versions of the classic Ruger Mark I and Mark II .22 rimfire pistols. They share the same grip angle, sight profile, and overall profile of the iconic Ruger rimfire pistol.

Ruger’s Mark I pistol.

All Crosman Mark air pistols retained an adjustable trigger throughout their production run, which was 1966 to 1986, but had other changes in their design over the years.

Four major changes over the years

The flip-style piercing cap was changed to a button-style piercing cap, similar to what’s found on the Smith & Wesson 78/79-series air pistols.

The metal bolt guide that was secured in the frame by a screw on either side below the rear sight was changed to a plastic bolt guide that is retained by 1 screw that’s hidden under the rear sight blade.

The power-adjusting screw that was located under the barrel was eliminated.

And to hold the grips they changed from using screws with countersunk heads to screws with flat heads, as shown.

There are two different grip screw head profiles and grips that match them.

If you use the countersunk screws on grips made for flat-head screws, you will crack them, and it is not easy to find replacements.

There were some other minor changes over the years, but these were the big ones.

I have been a big fan of these pistols over the years, and have owned and resealed more of these than I have of the Smith & Wesson 78/79G series. In my opinion, the adjustable triggers of the Crosman guns are better than the adjustable triggers of the S&W guns. The engineer that designed these air pistols later had a hand in the design of the Smith & Wesson guns.

I got this one cheap

I saw this pistol online with a $50 or best offer price tag, and no photo. These two things together usually tell me to run away and let someone else take the chance.

I got to thinking I could always use it for parts, so I took the bait and contacted the seller. I found out he lived not too far away, and decided on a face-to-face look at the pistol.

He sent some fuzzy photos by text, that didn’t help my feelings about the deal.

In the ad he said the gun had leaks. When I finally saw it, it was one of the roughest Mark Is I have ever seen. It had been repainted several times, and at some point, someone had covered the bare spots with a permanent marker to make it all black again.

Right side.

Left side.

I put a CO2 cartridge in it and it vented all of the gas out of the piercing cap while I shot it a few times. [Editor’s note: Doing this in front of the seller is a big negotiating tip, because it emphasizes the fact that his gun doesn’t work!]

From this short examination I knew 3 things:

1. This was an early model Crosman Mark I in good mechanical condition.

2. All of the parts were there.

3. It did NOT leak out of the barrel, when it vented the gas.

It’s mine!

I made a ridiculously low offer, and he accepted. When I got it back home and on the bench, I started by cleaning off the permanent marker with alcohol.

I knew it was an older model, but did not realize how old, as in serial number 000659! There is not even a date code.

This is an early Mark I.

I now own one of the first ones made and also one of the last ones made.

Bringing it back to life

I put a second CO2 cartridge in it to check it out on the bench. It vented the gas in about 30 seconds and it all came from the piercing cap. That told me the valve seal was still good.

I shot it over the chrono as it was venting. The gun was cold from the CO2 cool-down, but it still registered 485 f.p.s.

Most times the leak is because the tiny o-ring in the piercing cap deteriorates. The piercing pin moves up and down in the older models by a lever. You flip the lever one way to pierce the CO2 cartridge, then return to its normal position to let the CO2 into the gun.

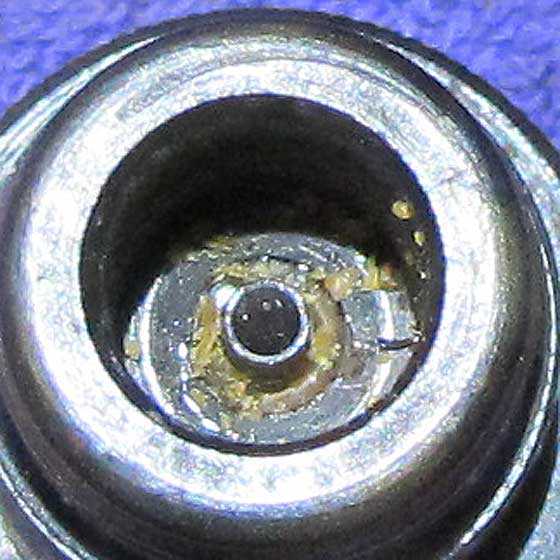

Some online disassembly guides say you have to remove the snap ring at the bottom of the cap and then drive out a roll pin. That is the hard way. The easy way is to use a 3/8-inch wide (9.5mm) screwdriver blade in the slot inside the piercing cap. Use it to unscrew the cover that contains the 006-sized o-ring.

This cover is threaded and acts as a screw to hold the small o-ring in place. It looks in the photo like the piercing pin will prevent unscrewing it, but the end of the pin is actually below the screw slots. Remove this cover. In a moment I will describe and show a newer style end cap that has some different parts and comes apart differently.

With the cover off, use a dental pick to remove the old o-ring. It is probably hardened and will break into fragments when you pick at it. It may not even look like an o-ring, but it is tight around the base of the piercing pin.

Once all the small pieces are out of the cap and the o-ring groove is clean, lightly lubricate the new o-ring with your choice of lube, center the new o-ring over the piercing pin, and push it into its recess. Then screw the cover back into place over the o-ring.

The screwdriver fits into the slots on either side and unscrews the cover. The tip of the piercing pin is below the slots. The cap looks brassy in this photo but it is really steel.

This picture with a different angle shows how the o-ring sits at the base of the piercing pin.

Check the large o-ring that seals the end cap to the pistol. Is it still pliable? It can look okay and yet be brittle and useless. If it is okay, lubricate it. Then insert a new cartridge and test it, listening for leaks.

[EDITOR’S NOTE: When I looked at my Mark II end cap from a very late pistol I discovered it was made differently inside. I contacted Ian and he provided the following information.]

BB’s newer end cap

BB was following this article and rebuilding an end cap of his own. His is much newer (made in 1977) and has a slightly different design. I disassembled a newer end cap like BB’s for you to see. Instead of the threaded plate that holds the tiny o-ring, there is a star washer inside the cap. Believe it or not, that star washer is not held inside the cap by anything other than its own fingers. Use a small dental pick or something similar to get under it and pull it out of the cap.

Turn the cap over and tap it sharply on the wooden bench and the plate that looks like a screw but isn’t falls out. The o-ring can then be seen around the base of the piercing pin.

Like the other cap you need a sharp pick like a dental pick to get the small o-ring out, as the space is small.

This is the newer Mark I and II end cap.

Reach under there with a small strong hook or a hooked dental pick and pick the star washer out of the cap.

The newer end cap apart. The cover with the screw slots has no threads and should come right out of the end cap, once the star washer is out.

BB followed my instructions and has disassembled his cap. Now he is picking out the tiny petrified o-ring around the base of the piercing pin.

Resealing both caps

After the o-ring groove is clean, lubricate and install a new 006 o-ring. If you have an old cap, screw the threaded plate back on top of the small o-ring. If it’s a newer cap insert the plate that looks like a screw, then insert the star washer and press down on it with a screw driver that has interchangeable bits. But leave the bit out of the driver. You want to press down on the edges of the star washer, but not touch the piercing pin in the center.

How did it go?

My new/old pistol has now been holding gas for a month. When I test-fired it, I noticed it was significantly louder than my other Mark I pistols, and it only had 1 cocking power level, none of the other ones I had ever handled or worked on had just 1 setting. I had to see what was going on inside.

I ran it across my chrono, at room temperature, it registered 545fps with Crosman Premier 14.3gr. domes, this thing was smoking!

Outer barrel removal

Using a pair of needle-nosed pliers, or snap-ring pliers, turn the front barrel nut counter-clockwise and the outer barrel will back out, as it is under spring pressure from the hammer spring/power adjuster. It just slides off the inner barrel.

The piston barrel sleeve is held on the barrel by a nut at the muzzle.

Some previous owner had inserted a 5mm thick brass spacer to add extra preload to the hammer spring. That’s where the extra power was coming from.

In the photo below, the power adjuster can be seen, and the hammer and cocking knobs. The power adjusting screw just increases the preload of the hammer spring.

Notice the hammer spring has a extension that goes through a tiny hole in the cocking knob rod to keep the knobs from rotating. It’s shown in the detailed photo below.

Mark I hammer assembly.

Mark I hammer spring detail.

After reassembling the hammer without the extra part the pistol is back to where it should be at 478fps, and 2 cocking power settings.

Wrong o-rings

What happens when you use o-rings that are not resistant to co2 gas? They swell much larger than their normal size.

This is a normal-sized end cap o-ring. You can barely see it!

When the o-ring absorbs CO2 gas it enlarged like this! It took over an hour for this o-ring to return to normal size. This makes the end cap difficult to remove when you want to replace the CO2 cartridge.

I am sure the other o-rings inside are the same as this one, but they are captive, and should not be a problem, so I am going to order a seal kit, and get to know it for a few weeks. Then I want to repaint and reseal the pistol.

Are there any suggestions for a good durable paint, that can be applied by someone with less than average painting experience?

And, of course I will document the rest of the rebuild for everyone.

Ian

Nice knolling in the first pic!

Ian,

Aluma-Hyde II from Brownell’s. It takes a week to fully cure, but it is easy to use and works great.

I liked that first picture myself.

Thank you, I will look into that paint.

That photo was the first Crosman I had fully taken apart.

I was following online photos. And had seen one like it.

I laid my parts out just like the one I had seen online, and took the photo.

Mostly to record the parts placement, and to use as a checklist to be sure I didn’t lose any small parts.

It’s easy to forget about the small ball and spring that is a detent on the bolt.

Ian.

Ian,

I forgot to mention, the reason it has such a long cure time is it is an epoxy based paint. It is pretty tuff stuff. I used it when I was rebuilding the old Mossberg target scopes and recently used it on my Crosman 101. I like it.

Thanks for a great writeup. This is probably the best of the Crosman vintage pistols. I resealed both my MK1 and MK 2 a couple of years ago along with my S&W 78G and 79G’s. Crosman 116 on the bench now being cleaned up to finish resealing.

Thank-you all for an interesting article. As inquiring minds would like to know for current and future use, can anyone suggest a source for Co2 rated o-rings metric and English, as even the local big box hardware stores do not seem to carry them.

Waldorf1,

I bought two sets — SAE and metric — from Grainger. That’s how I came to have a 006 ring for the cap. If my rings were made of the right material I could have also put on the large cap o-ring, but Buna is a material that absorbs CO2 gas. So I ordered two sets of Mark I seals from Ebay for $10. When I return from the SHOT show I will finish the job.

B.B.

B.B.,

So what is the ideal material that O-rings for CO2 airguns be made from?

Siraniko

Siraniko,

I don’t really know, but I just bought some made of urethane that a lot of folks say is good.

I do know not to use Buna.

B.B.

Siraniko,

B.B. has already forgotten a resource I have repeatedly supplied him and the Blog Readership:

https://www.theoringstore.com/store/index.php?main_page=page_3

This is a very through index of O-Ring/materials level of resistance. CO2 (Carbon Dioxide) is listed twice.

It also debunks the MYTH about Buna and CO2! Many Stores sell other “stuff” and call it Buna or Buna N; most of the trash comes from the usual country(ies) of origin!

They are a very reputable company and have EVERYTHING O-Ring!plus educational material like the linked resource!

I’ll add this to help the doubters understand the problem of just specifying Buna:

Definition of buna. : any of several rubbers made by polymerization or copolymerization of butadiene.

You want Buna-N nitrile

There are other materials thatwill do the job as 45Bravo indicates they are more expensive and harder to work with…”choose your poison!”

Shootski

I agree with Shootski, a good quality Buna-N nitrile O-Ring should work fine for airguns in general, including those using CO2.

Personally, I prefer Viton o-rings, perhaps because it was the material we used almost exclusively at work. This compound is more expensive but not excessively so, and it is more resistant to certain oils. It also works better at high temperatures, but this irrelevant for our applications.

FWIW, Henry

Henry_TX,

I also use Viton® O-Rings to replace bolt probe O-Rings because I find it seems to handle the abrasion better. I choose to use Viton® on fill QD fittings (Foster®) because of the potential of excess heat if the fill rate is too fast from 4,500psi sources.

shootski

Shootski,

I do appreciate that you share resources and experience (wisdom) so often.

Thanks

Dan

GrandpaDan,

Denada (think nothing of it!)

Just think of all the knowledge I have gained from B.B. over the years starting with the Airgun Letter, Airgun Reviews, and the original Forum Tom and Edith did such a great job on! Once PA “discovered” the Baron and Baroness of Airguns and this Forum was created I have been lurking and only recently started contributing once I retired from my last full time career. So I OWE my shooting and Airgun communities to give back a little of what I have learned from so many others and the little I have learned on my own along the way of these fun sports.

You are most welcome!

shootski

From personal experience, I suggest mil spec urethane o rings.

They are not affected by co2.

It is what Mac1 airguns uses when he builds his LD pistols.

The down side to 90durometer o rings is they are harder to get on, and make them seal the first time.

You can warm them with a blow dryer to make them softer for a few minutes to put them on the part you need.

Nicely done. If you know all the o-ring sizes, you could order them from McMaster-Carr and have about 100 of each for what a rebuild kit will cost. Viton 70 or 90 durometer have worked well for me.

I’ve had success.with Rustoleum epoxy spray paint on vintage Crosman guns. Like Ridgerunner says, the drying time is long unless you can bake the finish.

Ian,

Thanks for posting this guest blog. B.B. needs the relief.

I remember shooting the Ruger .22 when I was in college. ROTC had a range set-up in the basement of one of the buildings. After a frustrating week, it was nice to go down there and shoot 2 boxes of ammo.

Have a nice weekend all,

-Yogi

Everyone,

Just post your comments. The error page will come up but if you return to the blog page again you’ll see that your comment has posted.

IT is working on the problems.

B.B.

Ian,

I enjoy disassembling and fixing things (even if they are not “broken” LOL) so I spent quite a bit of time looking over the first picture.

Nice report Ian, interesting read – thanks for sharing!

Minus 10 F outside… think I will stay indoors and find something to “fix”.

Hank

Minus 10, I used to live in Colorado, and Wisconsin, sometimes, I think I kinda miss those temps.

Then I snap back to reality….

If something is working well, I tend to leave it alone.

But I have been known to deep cleans things when I am bored.

I have a early Crosman 1008 on my bench at the moment.

Yes it is leaking.

And a Crosman 761xl next in line for some TLC..

Ian,

…”But I have been known to deep cleans things when I am bored” – me to, altho I usually tell my wife that I am doing “routine maintenance”. LOL!

I had a beat-up Kelly given to me a while ago – today’s project is the straighten the barrel and make a rear sight for it.

Hank

Hey Hank,

My kind of weather as long as there is lots of SNOW on the ground and trees! Under Armor makes tactical IR Cold Gear; the way it works is nothing short of a miracle!

Thin, breaths, layers (all three) well and doesn’t STINK like some of the other stuff out there! I just got their Belaclava to replace a poly one that someone decided they “needed” more than the owner!

Get out there! -10C is warm or even -10F is just coolish!

shootski

Shootski,

I like winter but not as much as when I was younger 🙂

This morning it took the tires about a 1/2 mile to remember what “round” was LOL!

Yesterday’s view out my front door…

Hank

Hank

Vana2,

That looks like some very light powder…nice! Are you certain you need a snow blower Hank? Looks like a little fanning with a folded paper fan would blow that stuff to the next Province.

shootski

Shootski,

Yes, light powder. In fact I cleared off the decks and vehicles with the leaf-blower (my own private blizzard LOL!).

As I mentioned to Dave – my driveway is 175 feet long, that and my snowblower would be upset with me if I didn’t take it for a walk!

Hank

Shootski,

I like winter but not as much as when I was younger 🙂 This morning it took the tires about a 1/2 mile to remember what “round” was LOL!

Yesterday’s view out my front door and more forecast for tomorrow, glad that I have a good snowblower!

Hank

Hank,

That looks really beautiful…probably more so if you are over 1000 miles south, and will not be the one manning the snowblower! =)~

Perhaps you might try what I do: hire the teenagers from next door; then drink some coffee…and watch them while they do the stuff. =>

Cheers!

Dave

Dave,

Before moving to a smaller house, Mom and Dad (80’s) could not find kids that wanted any work. Not like when I was kid. We were savvy on getting paid for something, somewhere, from someone! Need that shed painted, yard mowed (every week?), etc., etc.? Door knocking was still a valid practice for a kid back then.

Chris

Chris,

Seems kids have little interest beyond their phones and the only way to get their attention is to send them a text message.

Like you said, we could always find a way to make some money. Had my own lawn cutting business with my own lawnmower. Allowances were earned by doing chores – no such thing as freebees.

Best was that twice a year there was a special garbage day that people could get rid of junk – I used to grab all the lawn mowers and bikes I could fix them up and sell them to get enough cash to buy my guns and ammunition.

Yup, different now Chris.

Hank

Dave,

Don’t think that that would work – my driveway is 175 feet long!

Hank

Shootski,

I am pretty sure that you are one of “the bad guys” in the linked video chasing after Arnold in True Lies (opening scene). With the outfits,… I just can not figure out which one you are. 😉

https://www.youtube.com/watch?v=VdCTYYBpqGk

Nobody in their right mind can like snow that much!!!!

🙂 Chris

Chris USA,

They all got SHOT!

“Nobody in their right mind can like snow that much!!!!” Who can say if I am in my Right mind?

Do you remember how Ahhnold arrived at that party? I own a GoreTex Expedition Dry Suit from Kokatat too!

As far as which one of the guys in Snowflage I wouldn’t use an MP-5! I much prefer the Anshutz 1827 Fortner from: http://www.altiusguns.com/product.php?product_id=21125 Much better to stop, take aim, put one in Ahhnold’s ear; then it is to spray and pray with an MP-5 (regardless of how much fun as it is to hose down targets with one) and get shot with a pistol! They used what looked like downhill (Alpine) skis; much better to use Nordic Skate Skis. Like the Salomon Carbon Skate S Lab, RED https://gearwest.com/salomon-s-lab-carbon-skate-red/ 980 grams! I just got to add to my ski Quiver for the warmer days. Looks like the snow was pretty wet and temperatures were around freezing during Ahhnold’s chase scene.

I NEVER got shot and hope I never will…Purple Hearts are respected by me unless displayed/worn by John Kerry!

shootski

Shootski,

LOL! 🙂 Yes, perhaps I could have picked a better movie for reference. 🙁 It was just the first one that popped in my head for an action ski scene.

I am beyond impressed with your breakdown of scene conditions, equipment used and firearms used. Without a doubt, you know your stuff!

As for holes,…. try to leave this life with only the ones the good Lord gave ya’ when ya’ came into it!

Chris

Dura Coat from Brownells is a 2-part epoxy paint that cures extremely hard and is resistant to chemicals. It is my go to paint for airguns and even firearms that might need a different color or camo coating. The one drawback is that it is best sprayed and applied with an airbrush. That is not a huge hurdle or cost to overcome if you will repaint more than one airgun. Let me know if you have questions about using DuraCoat.

Thanks, I was hoping you would add input.

I no longer have an airbrush setup, when my daughter attended Kansas City Art Institute she needed one for a project so I gave her mine. It was never to be seen again…..

I guess it’s time for me to invest in another one.

Do you just need an airbrush? Those are cheap. I use my shop air compressor with an extra regulator that will accurately regulate the pressure between 10-20psi. I think I spent $75 total for everything except the compressor.

I had a paasche airbrush and compressor set.

But like I said, it went to school….

I have been pricing them online for the last few months, but haven’t had the need to buy one yet.

45 BRAVO,

If you used that Paasche Airbrush with a paint cup or even a bottle you are not a noob to painting stuff!

I enjoyed reading and looking at your excellent guest blog!

shootski

Shootski

Thank you, I enjoy writing them.

The last time I used an airbrush was in the 80’s.

And yes with the cup, never used a bottle.

It’s been so long, I would rate my availability back at below average.

Ian

Interesting that you mention airbrushes, I was just looking at them.

My brother has a Paasche and likes it. I have an old Thayer Chandler (sp?) airbrush for painting lures and jigs but I am looking for something with more capacity for spraying varnishes.

You might want to check out this video on inexpensive airbrushes… https://www.youtube.com/watch?v=ZyEAG614AQE

Thank you for the link to the video.

For as often as I would use it, it definitely would not to be a high end one.

Ian.

45 Bravo/ Ian,

great blog article and good photos. Tom Slocum is a big Crosman airgun collector and repair guy. Every airgun show I’ve gone to on the East Coast, I’ve run into him. He once graciously gave me a ball bearing used in the detent of a Crosman pistol safety that had traveled to another dimension in space and time during a repair I had done. I’m sure BB knows of him, too. Anyway, now we have two sources of information should anyone need it.

Fred formerly of the DPRoNJ now happily in GA

Fred,

We really need to do better about getting together at the next NC show.

Hey all,

Stephen Archer has been showcasing a bunch of the new models that will be at this year’s Shot Show. It is going to be very difficult to keep my grubby little paws off of my bank account.

https://hardairmagazine.com/

R.R. and Readership,

He also does a nice short piece on the how and what of the future of B.C.’s and is projected work after retirement with his LabRadar! It really shows you why the optical, magnetic, and single point RADAR Chronographs are not that great of a deal if you are into PRECISION! Yes they cost a lot money but so will the cost of trying to get the right pellet/Slug/Fire Arm/Airgun/crossbow/bow/Spit Wad shooter set up right!

shootski

Shootski,

That is Bob Sterne from GTA doing the Technical Tips.

Hard Air Magazine is my second favorite airgun information source.

As for the LabRadar, if someone was to give me one I would greatly appreciate it. As for buying one, I will stick with my Caldwell for now.

R.R.,

My bad! Bob Sterne IS doing some really good work for the Airgun Community! I hope his HoneyDo List isn’t overwhelming in retirement! And he has a lot of Round Toits!

shootski

LOL! I am sure he will be able to squeeze in some time for his readership.

Bob is very thorough, and explains everything with easy to read graphs.

But there is too much math some times..

Math should not have numbers AND letters…

Ian

ROTFWL! You should hang out with Hector some. His math has a lot of letters in it. If he isn’t doing that math thing with all those letters in it, he is talking about FT.

RidgeRunner,

What else is long range accuracy but weaponized math?

Siraniko

Siraniko,

You are indeed correct, however Ian and I were taking a less serious view of things.

Sometimes all of the math makes our heads hurt and gets in the way of having fun.

RidgeRunner,

I usually throw in that remark to kids who don’t think algebra and geometry have any use outside the classroom.

Siraniko

Siraniko,

Brilliant!!!! 🙂

If someone had put math (advanced math) into that context early on,… I might have done, (read: applied myself), better. I like math, always have.

I would imagine that you could put together some very quick (shooting related) demonstrations and examples to “set the hook” into a youngster.

A simple protractor and explaining angles would be a good first step I think.

Chris

Siraniko,

Good point. Trig can be of use also.

My college math professor and I were discussing the upcoming advanced math classes and he said as usual, you will use it every day in your life as a police officer.

At the time my major was criminal justice, we got into discussing ballistics , and he asked me to figure out the drop of a 30-06 bullet at 1000 yards. (he was a hunter)

I Gave the ballistic coefficient, weight at what velocity, and what temp, and what altitude, and what humidity.

I thought about it for a few seconds, wrote my answer, he figured by pencil for a minute.

Our answers were a 14 inch difference in drop.

He asked how I did that in my head, and had a problem with algebra.

My answer was short and simple.

Experience.

I had shot a high power match a month before and knew the answer before I started.

He said that was cheating.

I explained once you have done it a few times, and you know your ranges and bullet trajectory.

You can visualize it.

R.R.,

I dug out this from the Way Back Machine from B.E. Spencer:

http://home.insightbb.com/~bspen/math.html

I don’t know if Bob is still with us, but he was an interesting character for sure!

I have a feeling you are gonna enjoy his approach to math!

shootski

Shootski,

That is awesome. When I have more brain cells to devote to such I will read through it again.

45Bravo,

If it had not been for an eighth grade math teacher I would have probably never managed to be placed in the Academic Track in high school! He taught me PEMDAS:

https://www.google.com/search?q=pemdas+equation&oq=PEMDAS&aqs=chrome.1.0l3.11641j0j7&client=tablet-android-lenovo&sourceid=chrome-mobile&ie=UTF-8

after that math was easy until I hit differential equations and it was a farmer’s son that got me through that! Seems that DiffEQ was invented for farmers to figure out water, land area, fertilizer, hours of Sunshine and seed required = crop yield! Who knew!!!!

shootski

45Bravo,

Thank you for the guest blog today. Excellent pictures and explanations. I do not have any CO2 airguns but still find the information informative. I only have one pistol which is an old Crosman 130 in pieces. I have been thinking of attempting a rebuild of it now that I have done my Crosman 147 multi-pump rebuild.

Looking forward to your future blogs on resealing this old pistol.

Geo

Ian,

This is a very nice report, and I think people who already own, or in the future acquire, one of these guns will be looking this over for years to come; thanks for a great job! =>

Take care,

dave

not a bad little pistol being he cheated the guy out of it

he got a good deal on it by cheating the guy

Mildot52,

I hope your comments are meant tongue-in-cheek!

“I got this one cheap

I saw this pistol online with a $50 or best offer price tag, and no photo. These two things together usually tell me to run away and let someone else take the chance.”

To my way of thinking, since that was all the value the seller put on the pistol it is not the task of a well informed buyer to educate! Obviously no other informed buyer was interested enough to take a risk on making an offer. 45Bravo took the RISK, which was substantial, and made an acceptable offer.

My Apologies if that is how you actually look at the deal too!

shootski

Mildot52,

There is a saying in real estate that, “The market determines the price.” I can ask $5000 for my Gamo Hunter but if after being on the market for a while all I get is one guy with a $100 bill in hand, I have the option of accepting or continuing to wait for the guy with $5000 in hand. If I have no other offers and I accept the $100, was I cheated? Hardly. I’m free to reject the offer. I may have misjudged the market.

There are a LOT of variables that go into a sale; my technical or mechanical skill, the price that I paid (or didn’t pay) for an item, how much I really value an item, and so on.

In my rural upbringing, we would have said that, “They struck a bargain.” Both parties had a say and came to an agreement.

For the record, I would not have bought a CO2 gun without testing it. In my view the buyer did due diligence, then made an offer.

Dan

Grandpa Dan,

Without saying more,.. I will say,… 🙂

Well said. “Grandpa Dan” has some golden knowledge,.. as well we all should hope to possess. Skewed deal or not,.. a deal is deal as long as everyone is forwards in negotiations. Sly, savvy and well informed/educated run a very close second though! 😉

Chris

I understand totally but what I have noticed is the type of guys that cut prices down always want top dollar for their hardware then complain what low ball offers they get

Mildot52,

I so agree. Pricing is such a crap-shoot. Somebody paid big money for a particular airgun and I have one like it, or at least think that I do. So I put it up for sale asking a “little” more than the previous selling price. Not greedy, ya’ know, just looking for a nice payday. And all I get are crickets. Bad call? Who knows? Sometimes things just work and sometimes not.

Some years ago a friend, Sam, put his very nice older brick home in a good section of town on the market. The Realtor, Fred, was a friend who helped research comps and come to an asking price. Fred knew of another Realtor who had a client looking for just such a home. Fred contacted his colleague who brought his clients to see the house. They paid full asking price on the spot. House was sold in four hours!

Sam was sure that he had been “Low-Balled” by Fred. Not so, Sam got top dollar for his house. It was just that at that moment everything lined up, house on market, clients looking, clients had money available, Fred was aware and was generous to pass along the tip to a colleague.

When I’m looking to buy, I NEVER offer asking price at first. I always as if the seller would consider an offer. If one doesn’t ask, one never hears, “Yes.”

About 56 years ago I saw a lovely blond lady at a college Christmas dance. In spite of the fact that I couldn’t dance, I asked her to dance. I heard “Yes.” Best question ever. 😀

Dan

GrandpaDan,

Just gotta ask, is that lovely blond lady now Mrs. GrandpaDan?

Indeed the never asked question never gets answered, always wise to ask.

Mike

Mike in Atl,

Yes, she is my wife, 54 years and counting. Happily, she put up with my clumsiness on the dance floor.

Four daughters, nine Grandchildren, (two Princesses and seven Pirates).

So very blessed.

Dan

I didn’t get to make the first move on my wife.

I was riding my motorcycle, and she pulled me over at a red light.

Been married 25 years.

Ian.

Ian,

🙂 So? No ticket? Or,… are you that much of a “natural charmer”? 😉

On that,… a fellow lady worker told of a story of her getting pulled over. She broke down (crying, etc. ?) and told the officer that he should just take her “straight to jail”,.. because it would surely be better than what her husband would do to her if he found out she got a ticket. (not in actuality) He let her go. She is a bit of a “ditz”,… but she pulled that caper off! 😉

Chris

No, No ticket, just a ring, a year later.

Ian,

That is usually the way I do it.

GrandpaDan

Wow, so very happy for you.

You are more than very blessed.

Mike

What I didn’t say, was it was first listed for $60 plus shipping.

With no photo.

A week later, it was listed again, $50 or best offer.

I offered $25, he was happy, and I so was I

He said he had gotten it in a trade, with several other guns, and he doesn’t like messing with co2 pistols.

He is an airgunner, and has several of them for sale in various price ranges, and states of functionality.

The reason I called it a ridiculously low offer is places online ask more than that just for the early style piercing cap.

Ian

then you will try to sell it for $200 and complain people are offering you $75

Nope, this one is staying home.

Right next to my Gunpower stealth. Serial number 667.

And no matter how you slice it a functional Crosman Mark pistol in good condition has a street price of about $125.

With the factory box and paperwork, maybe $175.

Over the years I have given away probably 4 or 5 mark 1’s to friends to get them into vintage airguns.

For a deal to happen, both people have to say yes.

If you don’t like their price, make an offer.

If the offer is too low, you tell them “thank you for the offer, but at this time I will have to decline.”

in negotiating being rude and complaining will not help you.

And in a small community like Airgunners, word gets around fast.

45Bravo,

Fine job on the guest blog today and I see that you are getting lots of replies! Always a good thing. 🙂

They also sell “home” powder coat kits. You do need an old kitchen oven to use though as they say it will ruin a house oven from the fumes. The stuff is nearly indestructible and the most common paint on many things these days. All sorts of powder mixes and colors. Even “copper vein” and “wrinkle” finishes as well as many more variations. I have done a bit of it at a previous job on a larger scale. 100% of the switchgear steel we get at work that is painted is powder coated. We are talking tons worth.

Clear and gold zinc plate are more options, as well as anodizing.

Chris

I thought about powder coating.

I have a friend in Louisiana who does that, but he isn’t an Airgunner, and don’t know if he would take the proper care of keeping the powder out of the important places.

I do know another guy who is an Airgunner and he is thinking of investing in a commercial setup.

He just hasn’t made the leap.

I guess with something as small as pistols you could use a toaster oven to bake it.

45Bravo,

There is special heat resistant tapes and silicone plugs and caps to prevent powder from getting where you do not want it. The parts must be hung from a steel or copper wire, a ground wire attached (even on the hook is fine), spray the powder,……. and then transfer to the baking oven (to be hung) from the same hooks/wires. They can not lay on anything while baking. If concerned, you try to put the wires where the “hook marks” will not be seen on the end product.

That is the basics of it. Probably not worth it. You can do things as big as car rims with a home oven set up,… so if you think might you might want to do other things, then it might be worth exploring further.

Chris

Chris USA,

Question, what is the temperature range and the time that you need to hold the bake at? I’m wondering if my ski waxing Hot Box can get hot enough for Powder Coating?

shootski

Shootski,

350-400F as I recall. About 20 minutes. Cool down depends on mass of item. Some ovens are batch, while others are a continuous movement. Tight spots can be tuff. (Faraday effect). Open, flat areas are best. A car rim would be fine,… a gun barrel too. 2-4 mil baked is about average. Even .5 will cover, but may look a bit like over spray from not having enough powder to “flow/melt” together.

Anything I have ever read says to use a dedicated home oven,… something that will never bake food again. Why? Not sure, but it does put off fumes. If in a garage,… opening the garage door would suffice. I think any spilled powder might continue to bake and give off fumes and poison food,.. I think.

Chris

Chris USA,

Thanks for that temperature info! I would need to upgrade my heat source as well as insulation. I’m only going up to 60°C/140°F.

More questions!

Would higher voltage, say a 2800 volt power supply, be better for the Faraday Effect? Obviously really low amperages?

Waxes are bad at outgassing so I use a big ventilator in my waxspace.

shootski

Shootski,

As for voltages and amperage’s,.. I do not know. I believe,.. we turned down the voltage = less + charged particles to attract to the – grounded item. Instead of being attracted to the item (and repelled),… the powder would just “flow” in place in a tight spot. Easy to get too heavy.

You seem well funded,… so I imagine that you can get an oven something akin to a large gun safe. That should do anything you want. Of course,… the better gun/powder set ups have more knobs to adjust stuff.

Sorry I can not be of a more scientific support source of information.

Chris

Chris USA,

This is beginning to sound like a better way for me to go is find a reputable shop and get a professional to do the deed. I have a spouse who is fantastic…up to the point I start bringing in more gear for something new! She shoots, skis, and kayaks; so she has no problem with that space but a powder coating space may be TOO MUCH!

Both of us are lucky to have pensions from two careers each as well as being able to wait until 70 to draw SSA retirement. We have watched friends suffer through the 2008 recession and the aftermath with badly depleted nesteggs! We made some early hard choices along the way and got a lucky roll of the dice in the long run as a result.

shootski

Shootski,

You should have no trouble finding someone to do any work you want done. Wet coat is out and any body that knows anything requires powder coat as a paint requirement,… thus,.. there are many well established companies as well as start ups that would be willing to do your bidding.

Of all the switch gear bidding that we do,… powder coat is specified 100% of the time anymore. Proper washing and rinsing is key to good adhesion. Chemical etching and impingement and such. It will flash rust very quickly if done right. Sandblasting is another prep method.

Typically,… a 50# box is dumped into a “pot”. It is pressurized and the powder is forced out by air. Color changes can be a hassle on a line.

Please keep us posted as to any further advances into the hobby. Baked powder coat is as slick as ice. Well,… not that I can tell you anything about slick, snow or ice!

🙂 LOL! Chris

Shootski Chris can probably tell us more on this.

From what I have seen the 2 times I watched stuff being powder coated, the thin powder gets EVERYWHERE.

It’s fine like talcum powder, or like fingerprint powder police use.

The shop I was in was sweeping it up, and I asked why not vacuum it.

He said most vacs, don’t catch the fine particles of the coating.

Your wife may be tolerant, but maybe not that tolerant.

Ian..

Bravo,

Yes, they can be messy. The cheaper home set ups put out far less powder (which is good for a beginner) compared to the industrial set ups. As I recall, you could screw the plastic jar right on the gun, making color swaps a breeze. A Shop Vac with extra filters (as opposed to no filters) should do just fine.

A spare 220 V outlet, an old oven, a cheaper hobby set up and you are good to go. It is pretty hard to mess up. The one guy I worked for started out that way. Now he has a big outfit.

Approach it as a hobby. And,.. just like (this) hobby,… you will spend more than you think, down the road! 😉

Chris

Shootski,

Also, on a heavy, thick item,…preheating the item is required/recommended. It may coat, but the mass will slow the bake/melt process because it is not heated through. A longer bake would work too,… but that can discolor the paint color.

One fellow was rebuilding a 30’s something Chrysler/Dodge something or other. Not only did he do the misc. parts and frame,… he also did the body panels.

Chris

45Bravo,

I thought I knew my MK 1& 2 fairly well until I read the part about the grip screws. My MK 2 has countersunk heads and my MK 1 did originally. When I got a replacement set of grips for the MK 1, they were for flat head screws, but I never noticed. So I do have countersunk screws in the flat head holes thanks to your writeup.

Now, where am I going to find the proper flat head screws? Countersunk screws part number is 10A055, the flat head are part number 10-055. Ain’t this fun? Got any ideas of where to get the proper screws. I hate to drill and tap the grip just to use proper type screws. That won’t ruin the value to me because at 79 years old, I’ll never sell the gun. It would be the kid’s problem someday in the future.

But if I can find the proper screws, I’ll do that first.

Jonah,

Call the folks at Crosman parts: https://support.crosman.com/hc/en-us Ask for the parts department. You have the part numbers and that is the only way to order on the telephone. I haven’t ordered parts in a few years but it was once US $4.00 for shipping and handling. They also had free shipping n Tuesdays. Maybe someone has ordered from Crosman Parts more recently and has better information. Another source is from Tim at:

http://www.mac1airgunshop.com. he is a Mark 1/2 expert and builds the LD version.

shootski

In addition to the ones listed above, you could contact mike baker at baker airguns, he sells parts for the vintage Crosman guns.

You need the part number for him to check, but you already have that.

Most owners would not notice changes like the grips screws, having owned or taken apart only 1 or 2 of the guns.

But after you do 15 or 20 of them, you start noticing the little things…

Most of the pistols have bolt knobs that were cast, but some were steel and knurled with a checkering pattern where you grabbed them..

The rear barrel nut, by the loading tray, most were just knurled with straight lines as seen in the photos of the pistol above.

Some were knurled with a checkering pattern like the bolt.

I have seen the front barrel nut on a few that had a slightly different profile at the muzzle side than the normal one.

But I have run across pistols that were unmolested by their owners, that did not have the checkering patterns on both parts on the same gun.

I think Crosman contracted the parts from an outside supplier when their stock of the regular parts ran low.

I can’t prove that, but just my opinion.

If someone that was a serious collector of these guns, who wanted to get every variation known, they could go crazy tracking down the guns with these minor changes.

Ian

You are so right about all the different parts one may find in some of the vintage guns. I really enjoy working on the vintage guns. Used to find non-working guns all the time. Now, it seems harder to find much. Just hope people are not throwing the old one away.

Thanks for all your information. I keep copies of any article I find on repairing the old guns.

Jonah

Ian,

Thanks for sharing a nice ‘old school’ design. Not much plastic, and higher quality hard parts, fully worth rebuilding affordably at home with this sort of info.

With modern ammo, does it print nice groups? Big fan of this style airgun, Crosman 600, and SW 79/78g. I have a Sheridan EB c02 in 5mm. Brass barrel. I guess I was a dummy for paying $60. for it 30 years ago, but when I mod it, I will put an SSG on it, get some more shots and quiet it down a bit. I havent checked lately, it may still work just fine. Not as many bells and whistles as a mag fed full auto airsoft or bb gun, but

it’s a cannon compared to modern replicas.

Rob

Rob,

“With modern ammo, does it print nice groups?”

The trigger is great on most of them (I’m not your typical Trigger Nazi, Lol) and the valves on CO2 are great as is…mostly. So…

Does one inch groups at fifty yards qualify as nice groups? The barrel is the key to that kind of accuracy with one of these and you can replace the barrel with a Lothar Walther sourced 10″, 12″, or even a 14″ replacement! Much more length and you need to work on the valve and maybe use a 13cu. in. hangy tank to convert to PCP!

shootski

Rob, you can never go wrong buying a well made airgun.

The trigger man not be the best, but unlike modern air pistols. The gun is all metal.

I love the brass Benjamin’s.

I had a 252 that used 8 gram co2 cartridges, I sold it at the Texas airgun show a couple of years ago.

I haven’t found “the pellet” for this one, but they do tend to shoot the Crosman premier pellets well, and Jsb.

One mark 1 I bought had several pellets stuck in the barrel.

WHen I disassembled it, I noticed the barrel was 180 degrees out of there it should be, the transfer port hole was pointing up, not down, when I pushed the pellets out. The first one was an old Crosman “flying ashcan” and the rest were modern domes.

No telling how long it had been in there.

Externally the pistol had seen a lot of use, internally, it was in excellent condition.

If you get a Mark I or Mark II, and want to quiet it down, there are a couple of companies that make after marker suppressors for them, they just replace the muzzle barrel nut, and hold the outer barrel shroud in place.

No permanent modifications. And look great, it is in .22 caliber, but works on the .177 MkII guns as well.

Ian..

Great article and timely as I have both a Mark 1 and 2 in need of new seals.

Grantb , do they leak out of the piercing cap, or the frame and muzzle?

If it’s the cap, do what is here.

If it’s the frame/muzzle, there is 1 o-ring around the valve that can go bad, but not too often, and there is a small nylon insert in the poppet valve that does go bad.

If that went bad, it can be repaired but is beyond the abilities of most of us without specialized equipment.

But replacements are available online.

We will cover that when we reseal this one.

The Mark 2 is leaking from the cap. This should be an easy fix. The Mark 1 is leaking from the muzzle so there is likely a more serious problem. I ordered new seals and will try both repair jobs myself. There is something on my Y chromosome that makes me try to fix things even if I don’t have the right tools or know what I am doing. The last episode was with a BSA Scorpion air pistol with a decomposed piston seal. After

a frustrating Sunday afternoon, I packaged all the parts and sent them to my favourite airgunsmith. It now shoots like new. Slowly, I am learning that some things are best left to experts – but I am not quite 100% there yet.

I used to be that way, then I figured out something.

X= an unknown quantity.

Spurt= a drip under pressure.

Definition: Expert is an unknown drip under pressure.

Seriously though.

I came to figure If someone else can do it without special tools, I can do it also.

The hardest part is getting the valve out, it takes some prying, putting a small piece of wood across the front trigger guard area to act as a fulcrum to pry the valve part out is a trick I have learned.

Also if it has been in there for a really long time it may have some funk built up. A blow dryer to heat the area helps.

Tip: always take the grips off when working on the gun. They are hard to find for sale alone.

And wood sets run about $65 online.

Mr. Ian, if you see this, it seemed like the most appropriate place to ask. On B.B.’s advice, I purchased a couple of Crosman Mark I and IIs to start learning pistol target shooting with my daughter. One of the end caps needs resealed and I’m following your wonderful reseal instructions. My question for you is that the little screw thing inside the end cap seems to be rusted in there and I can’t seem to coax it out. Any other ways to get to the smaller seal in the end cap? I have a pistol with the lever. Thanks.

Off topic (although in fairness, it is a single shot pistol styled after a firearm) but I’ve added a couple of comments comparing the Sig Super Target to the FAS 6004.

/blog/2019/11/sigair-super-target-part-4/

I can’t tell you how it actually shoots yet …

iain

I have handled a 6004 but not shot one.

I did like the feel, and the way it hung.

( I am very big on the FEEL of a gun. ) if you don’t like the way it feels, you won’t shoot it much.

It is on my short list, but have not had the chance to pick one up at a reasonable price.

Ian.

Iain – UK,

I took a close look at you additional comments on the SIG AIR Super Target Blog Part-4. I really liked the details brought out by superimposing the two airguns!

I’ll say this up from great observations a few of which are exactly what I also found down to the valve housing lip and the blob of grease!

shootski

I’ll also add a few more my observations to Part 4.

45Bravo,

Nice report, I have always liked these pistols I will now keep and eye out for one. Thanks for the information on fixing them, that gives me more comfort in getting one that needs a little work.

Here is a picture of my Benjamin 132 pistol I just made some new grips for. I made some earlier out of oak and then realized they did not match the walnut pump handle lol, senior moment I guess. I made the new ones with a lot of wood so I could fit them to my hand. So far so good. Next will come the shooting to see the real results. At first I was just going to keep it in the box because it was like new. Then I started shooting it and enjoy it so the finish will go pretty quick. Even with a few shots the finish is wearing quickly. It seems to have a nickel finish under a black paint finish. I will know more as it wears off.

Don

Does anyone know the size o ring that goes on the outside of the threaded cap? It would be the larger size. I believe it’s part #150-054

Also does anyone know the exact sizes of the O ring mentioned (006)? I am shopping online to try and hunt it down locally and am not too familiar with what 006 means. I believe I found a pack of 100 on amazon that shows 70A durameter as a comment above mentioned if that’s the right one.. https://www.amazon.com/gp/product/B000FMYQBC/ref=ox_sc_act_title_1?smid=ATVPDKIKX0DER&psc=1

Looking for this “normal sized end cap” size

I have one of these that I took apart as it was leaking from the barrel. I started scraping what I assumed was a hardened gasket from the pin part of the brass parts. I realized that it seems to be some kind of graphite seal. How do I repair this/ replace that seal? Does the pin screw out or is it press fitted in? I don’t want to snap it off trying to remove it. Could I use something like rear window defrost repair kit (as I believe I’ve read its graphite based) to fill the void?

wazzappenning,

I will leave the technical advice on Crosman Mark pistols to reader 45Bravo.

BB

Can you take a photo of the parts you are referring to, and them attach it to this series of comments?

This

This a press fit seal. It is not graphite. There is a bit of technique from what I understand to get the size of the seal right and then press it in properly. Most folks buy a replacement and them send their old one back which then gets recycled and sold to the next customer. I have purchased these from a fellow named Mike Baker, along with other vintage Crosman parts. You simply need to find an exploded diagram and tell him the parts you need. I can find it for you later this evening.

Thank you for that. The seat it goes against in the other half on top of the vise seems to have corroded or formed small cracks which may be where the air was escaping. Im guessing the press fit seal slams against the other half when you fire

My original plan was to possibly smooth that out and maybe glue a piece of leather to the press seal side but not sure if that’s durable enough. If replacement parts aren’t too expensive it might be easier than trying to home machine repair parts.

Looks like you need the Valve Stem Assembly (Part 10-087) If the brass Valve Body (Part 10-025) is cracked, get that too. The parts should not be too expensive. See the picture below.

Here is what a “new” Valve Stem should look like:

Ok thanks I’ll get a hold of him and check pricing.