by Tom Gaylord, a.k.a. B.B. Pelletier

Part 1

Part 2

Part 3

Part 4

Part 5

Part 6

Part 7

Part 8

Brand new TX200 Mark III. It’s very similar to my TX; but the checkering is different, and the line of the forearm is more scalloped.

This report is getting long and perhaps a little confusing, so let me explain what I’m doing. We’ve been looking at the Air Arms TX200 Mark III underlever air rifle. I used my own TX for the first 6 parts of the report. In Part 7, I introduced a brand new TX that Pyramyd AIR sent for me to test. Many of you were concerned that the rifle had changed somehow over the years since mine was made, and perhaps what’s shipped today isn’t the same rifle…so I agreed to test a new one for you. The first look at that rifle came in Part 7 of the report, and in Part 8 we looked at the velocity.

Today ,I’m going to show you the trigger in detail, describe how to adjust it and explain why I always say the TX trigger is an upgrade of the Rekord trigger that Weihrauch introduced back in the 1950s. To get to the trigger adjustments, the triggerguard must be removed. But today I’m going farther into the gun to show you the entire trigger assembly. That will help me explain how the trigger functions.

The stock needs to come off to get into the rifle, so I did that first. Just remove 2 forearm screws and 2 more triggerguard screws.

Once out of the stock, the action and trigger can be seen clearly.

The trigger unit is inside the spring tube with seemingly no way to come out. The rifle must be partially disassembled to remove the trigger.

Here you see the disassembly bolt (all the way to the lef). Turn it out, and the rifle comes apart. You can also see the 3 trigger adjustment screws. On the trigger blade are screws to adjust the first-stage length and adjust the sear contact area. Behind the trigger blade is an Allen screw that adjusts the trigger pull weight. Behind that is the threaded hole the rear triggerguard screw goes into.

If I were just adjusting the trigger I wouldn’t need to go even this far. Just remove the triggerguard and start by adjusting the trigger return spring tension. I found that was all I needed to do on the test rifle, as the first-stage length and sear contact area were right as they came from the factory. But you can adjust either of them or both.

To take the trigger unit out of the gun, I removed the disassembly bolt. As it turned, I pressed down on the entire barrelled action with the end cap resting on a soft cloth pad. When the bolt was free, the mainspring decompressed less than 2 inches.

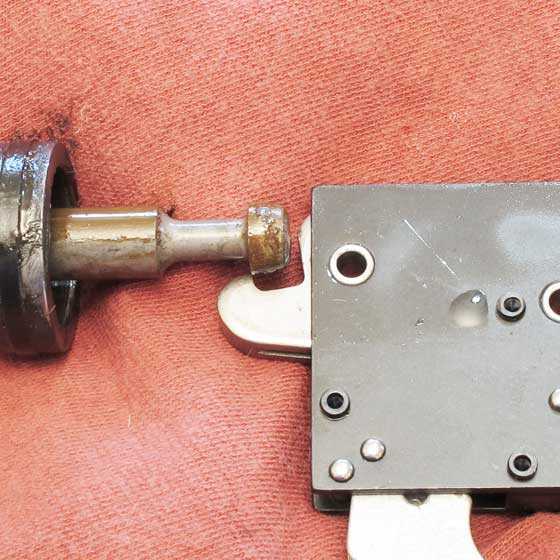

The disassembly bolt is out, and the mainspring has relaxed. The trigger unit moved less than 2 inches. A mainspring compresser was not used.

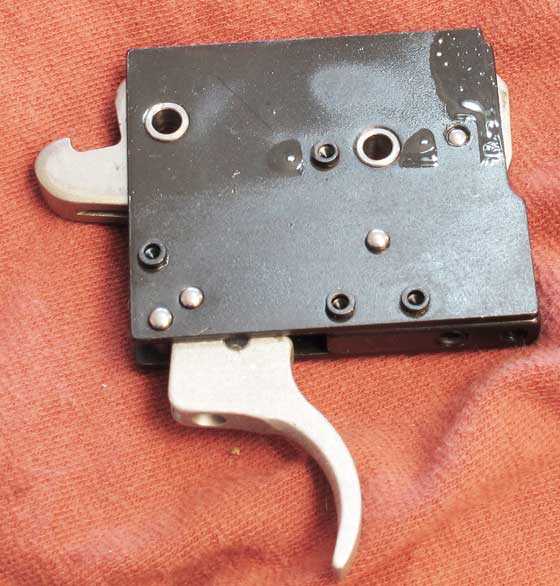

When the trigger unit comes out of the rifle, it’s still pinned to the end cap and spring guide like this. Now, the trigger unit looks familiar to Rekord owners because the 2 pins that hold it to the end cap are visible.

Because I want to show you how this trigger works, I’m going to continue to disassemble the end cap. The 2 pins that hold the trigger unit in the cap are driven out. They are several times harder to remove than Weihrauch trigger pins. This unit is together very tight!

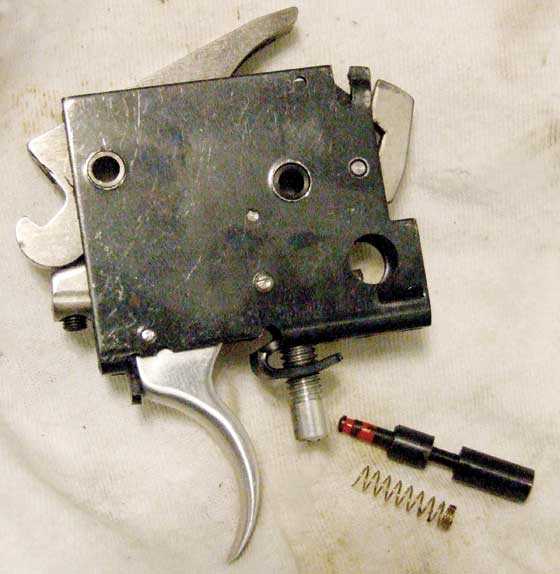

Once the trigger assembly is out, we can see how it differs from the Rekord.

The trigger assembly is similar to the Rekord — but also different. The box is riveted together instead of being a folded sheet metal structure. There’s an additional pin, forward of the trigger blade, and internally there are bearings where the Rekord parts just turn on pins.

A Rekord trigger for comparison. Weihrauch did more with sheet metal stampings.

So far, I’ve shown you the differences but not described how they work. For starters, the Air Arms trigger has adjustments for the first-stage pull and for the sear contact area, as well as for trigger-pull weight. The Rekord has the sear engagement adjustment and the pull weight adjustment but not the first-stage adjustment. But that isn’t what makes the Air Arms trigger better.

What makes the Air Arms trigger better is the presence of bearings instead of just pins. The parts are also more finely fitted, which has to be done during manufacture because there’s no money in the gun for costly hand-fitting. And the trigger isn’t the only place that’s different. The piston is also different.

Circular piston

The TX200 has what I will call a circular piston. All pistons are circular, of course, but most of them are held from rotating by the cocking shoe. Because of that, the piston can have a hook that’s engaged by the trigger when the gun’s cocked. That’s how the Weihrauch rifles that use the Rekord trigger are made. But what if the piston was free to rotate on its axis?

TX200 piston has bearing surfaces front and rear.

Detail of the rear piston bearing. Also, note how far the piston rod sticks out the rear of the piston. Weihrauch pistons don’t have bearings front and rear, so they tend to vibrate more when fired.

Blog reader RidgeRunner asked how the TX piston was cocked by the sliding compression chamber. The answer is that the chamber pushes the piston back until the trigger catches it. The piston rod is so long that it can be caught by the trigger while the piston is still inside the compression chamber.

When the gun is cocked, the piston rod comes back and pushes the trigger parts into lockup. As they lock up, a hook catches the rear of the piston rod and holds it until the sear releases it.

I have manually cocked the trigger the same way the piston does.

This is what the cocked trigger looks like with my hand out of the way.

And this is how the trigger holds on to the piston, no matter how it turns inside the gun.

The ability of the piston to turn on its long axis while being supported front and rear by bearings adds smoothness to the powerplant without sacrificing power. A centrally located air transfer port that’s centered on the piston boosts the air scavenging efficiency and therefore the available power. The TX200 Mark III is giving all the power it can from a powerplant that’s still smooth and easily cocked.

How is the trigger after adjustment?

Before I adjusted the trigger, it released crisply at 1 lb., 12 oz., which is 28 oz. All I adjusted was the trigger return spring tension and now the trigger breaks cleanly at 12 ounces. So the adjustment dropped one entire pound. And, yet, the sear still has the same contact area, so it’s just as safe as before.

A good tuner can adjust a Rekord just as light, but the sear contact area won’t be as great as it is at 3 lbs. The Air Arms trigger allows for this adjustment without sacrificing any safety. That’s what I meant by the TX trigger being more finely adjustable that a Rekord.

By the way, the work done here, including taking the pictures, took a total of 30 minutes.

Hello B.b. and Fellow Airgun Enthusiasts

Thanks for the clear, and concise comparison of the TX200 trigger to Weihrauch’s Record trigger. I had no problem understanding your explanations, and with the inclusion of excellent pictures, the similarities and differences come across crystal clear. I like the trigger action on my Weihrauch’s as they came from the factory, and have not had need to adjust them on any of my guns. However, I had often wondered what the big screw behind the trigger blade actually adjusted. I must say the outward appearance of both triggers is quite similar, evan to the placement of the pins that hold them in place. If I may ask, what does the tiny screw at the front of the Record trigger adjust? I have been advised it would be in my best interest not to fool with it. Thanks again for this blog. Required reading for any airgun enthusiast.

Ciao

Titus

Titus

The big exposed screw on the Rekord is the trigger pull weight. HW installs this screw then bends the end of the tab to jam up the threads so it won’t move. It has to be unbent to make adjustments. It’s a pain .

The little screw in front is going to change sear engagement and where the stages are.

It is best to leave both alone unless you really have to change things.

First stage travel can be changed by bending the tab in front of the trigger . It changes how far the trigger can move forward . Again, not easy to fool with.

The triggers on all of my HWs have a different feel, and it is not worth trying to get them all the same.

twotalon

Thanks BB! The piston is also shaped as I envisioned to maintain alignment. The bearing surfaces are a nice touch and really quite simple. I was over engineering them.

If I recall correctly, you showed the trigger internals for either the Rekord or TX in a previous blog. What should I search for?

RR,

I have difficulty finding it, but here is something:

/blog/2008/11/hw55-tyrolean-part-6-adjusting-the-trigger/

/blog/2012/03/air-arms-tx200-mk-iii-air-rifle-part-1/

B.B.

Sweet!

And thanks for standing in the gap.

Great blog. I love it when you take guns apart so that we can see and understand how all the parts come together and work. Some one told me that the TX main spring is different from regular main springs. Is that true? And if so, can you show us what the main spring looks like??

Thanks

Pete

Pete,

A TX mainspring looks no different than any other. There are custom springs for the TX that look different. Maccari made some. But the spring on this rifle looks normal.

B.B.

B.B.

I really enjoy your blog, B.B., and your work on the Air Arms TX200 is well done. It is always interesting to read other shooters opinions about things, and yours are very close to my own.

Eddie 🙂

Howdy Mr. BB, Ms. Edith & the Gang. To all of you who are Vets, thanx for your service. Ms. Edith, hope you’re back upta crusin’ speed. Mr. BB, thanx sir. Shoot/ride safe.

Beaz

Beaz,

Thanks for asking. I’m feeling much better today and am back to warp speed 🙂

Edith

Atta girl. Always liked Dark Helmet in Space Balls & Ludicrous Speed.

Wasn’t it Lord Helmet instead of Dark Helmet? Yes, that was surprisingly funny for such a goofy film.

I didn’t even know that Edith was sick but glad she is feeling better.

Matt61

Howdy Matty6, yup, Lord Dark Helmet (Lord Darth Vader). Shoot/ride safe.

Beaz

B.B.,

I was searching the PA blog for accuracy test of the Diana 48 and cannot find one. Did you ever do one? I like to compare it to your TX200’s accuracy. You said a few times that the Diana 48 is one of your favorite airgun and is one of the top airguns to own.

Joe

Joe,

I don’t see one. A 48 can shoot 10 shots into an inch or better at 50 yards, when it’s on.

I would get the 48 in .22 caliber for the power potential. And it is one of the easiest rifles to cock for the power it delivers.

B.B.

That explains the relative ease of cocking my B30. I was surprised since that gun has some power.

Matt61

BB,

I am not sure if my question is for this particular part of TX200 review, or it’s rather for TX200 in general, but the question I have is: can TX200 and Pro Sport be safely de-cocked?

I mean, if I am about to make a shot (meaning safety is off), and for some reason I can’t take a shot, can I de-cock it. I think it’s a bad idea to leave spring cocked in the rifle for longer than 10 mins. Or I am wrong here?

Ariel,

There is no harm leaving a spring gun cocked for just 10 minutes. You need to read my mainspring failure test where I left springs cocked for a whole month.

/blog/2006/5/how-long-does-a-mainspring-last-part-2/

/blog/2006/5/how-long-does-a-mainspring-last-part-1/

And, yes, it is possible to uncock both rifles, but it’s a little tricky. You have to hold the cocking lever and pull the trigger, then release the compression chamber with the catch while riding the cocking lever down.

B.B.

BB,

Will you make a small addition to the next part of the review and show us how to de-cock it properly?

I hope it’s not to much to ask…?

Thanks in advance,

Ariel

Ariel,

Sure, I can do that.

B.B.

B.B.

How does the TX200HC compares to the TX200 in terms of accuracy? Better, worst or depends?

Also did anyone ever tried to bring the power of the TX200 down? If so, did it affects accuracy?

Joe

Joe,

The Hunting Carbine is just as accurate as the regular TX. And I have tested 12 foot-pound TX 200s. They were no more accurate than the full-powered versions and a little harder to cock, because of the shorter lever throw.

B.B.

B.B.,

Thanks, but I believe it only if I see accuracy test results of the TX200HC from you.

Hey Joe,

The difference between the HC and the MKIII is the length of the shroud and the cocking lever. The HC is louder because of less baffling and harder to cock because of the shorter lever. Otherwise they are identical.

Now if BB wants to test one and prove it, I too am all for it.

The first picture showing the trigger assembly on the end of the receiver really shows how nicely finished the steel on the TX200 is.

Well, I’ve always been convinced about the accuracy of the TX200, but I’m always ready to hear about this classic.

FredDPRofNJ, that’s a surprise that your ammo was ruined by water. I thought the bullets were seated airtight. But perhaps the problem was the length of time they were immersed. When you pull the bullets does that mean your brass is wasted along with the primers?

CowBoyStar Dad, that is pretty good to try out the sniper equipment. For the 1911, you might want to try a lighter bullet. Even a 185 gr. makes a big difference compared to the military issue of 230 gr. Nice of your boys to hit the gong at 300m. That’s my longest shot to do date, done with the Savage 10FP in .223. I held about 1 foot high without changing the zero and was ecstatic when I hit.

Matt61

I would have thought the same thing. What was interesting was the powder was dry and except for one round, the powder was not clumped as one would expect from having gotten wet. But the primers did not detonate! Maybe I had a bad batch?

Fred DPRoNJ

Fred, Matt,

The brass should still be good, but it really doesn’t take much moisture to mess up primers. Nail lacquer is the cheaper alternative to buying sealant, but either way it doesn’t take much since it wicks itself around the joint.

/Dave

/Dave,

thanks for that information. Yep, I know the brass, bullets and even the powder is good (I used what we old fire protection loss control consultants call the SAFT – Standard Ashtray Field Test).

Fred DPRoNJ

B.B.

As usual, your pictures are worth a thousand words. I have a TX200HC and a few Weihrauch breakbarrels. Seeing the way the piston is designed in the TX it is easy for me to understand why the firing cycle is so much smoother. I also see why tuners need to button the stock Weihrauch pistons to get them to the same level of smoothness. I also didn’t know the AA trigger units used bearings. They certainly do the trick. I don’t own a trigger gage, but I believe I have the trigger on my TX200HC down to about 12-14 oz. also. Great blog today.

David H

Hello to all. I have a question. I would like to purchase a Mendoza RM 10. Problem is PA doesn’t sell them or anyone else as far as I can tell. There was a place in Arizona that carried them up until a few months ago. Is Mendoza no longer selling their products in the U.S.? I own a Bronco but would like to have the RM10 because it is (as far as I can tell) more or less the .22 caliber version of the Bronco. Any direction or suggestions would be appreciated. Thanks, Toby.

Toby,

They made the RM 10 in .22? I never heard of that. I had one in .177, but it was the gun we used to create the Bronco. In .22 it would be a real dog, because of the low power.

I think you have to look on the used market. Because the RM 10 wasn’t very popular, you may have to look a long time.

B.B.

BB, Thanks for the info. The place I saw it for sale said it was in .22, but perhaps it was a typo. Anyway, if you think it would be a dog I will take your word for it, your advice in the past has always pointed me in the right direction. Don’t need any “dogs” in my collection and I won’t waste my time looking for this one. My short list just got shorter. Thanks! Toby

B.B. this is off subject, but concerning the closure of the of the Doe Run lead smelter [in Herculaneum, Missouri], ammo prices are expected to jump (last smelter plant in the USA?). In your opinion, Will this effect pellets much? Or does it take so little to make pellets, maybe they won’t be affected like powder ammo. I know there are already lots of lead free pellets, or at least they are easier to buy in my area than powder burning lead free ammo (not including shotgun shells as steel shot is everywhere). Thanks, Bradly

Bradly,

It will affect everything. Politicians don’t realize how ubiquitous lead is. Of course industry will now buy lead from foreign sources, allowing them to control the market.

In a few years when people see how stupid this was, perhaps the tide will turn and we will rediscover lead in the U.S.

B.B.

B.B., I agree! I only hope our sport doesn’t take much of a hit. So little lead in most pellets. Who knows, you can making want to buy a BB pistol anyway, this may be an excuse! Thank You, Brad

How many pellets are manufactured in the US?

Maybe Crosman… But I’d bet 75% of the tins I own are European production (RWS, Gamo, Beeman/H&N) and a few tins of Korean Eun Jin.

Wulfraed, I hadn’t even thought of that. Thanks for reminding me! That makes me feel a little better. Thanks, Bradly

Hi. Sorry if I placing my comments on the TX200 Mk111 in the wrong spot but am new on your blog and would like to mention my experiences with the TX regarding pellet choice. After thousands of rounds and experimenting with a wide variety of pellets found that the lighter pellets (8grs) were not highly accurate, with the 10 grs pellets (JSB, AirArms, H&N Match, Beeman Kodiaks and Weihrauch Magnum) with a diameter of 4.52 doing best. Interesting that the diameter is quite important for my TX with the 4.52 performing better than the 4.51. In terms of best placement of a rest – just in front of the trigger guard works best on an elevated wooden (4×4) rest with a carpet covering. Also found that my velocities were comparable to your new TX. I also acquired a 12 lb spring and guide set and have really enjoyed the smooth performance and ease of cocking during long stretches of target shoot. Beautify gun. Very much enjoy it and am very pleased you are doing this series.

Thx Bob

Welcome Bob!

We frequently wander off subject around here, so don’t sweat it. My CFX liked the H&N Field Target Trophies in 4.52 mm and would produce dime size groups at 25 yards with them but the groups would open to quarter size groups with the 4.51 mm. My 46M likes 4.49 mm pellets. Every air gun is different. Some will take just about anything you feed them and some are real finicky.

Bob,

Welcome to the blog! I’m doing the TX 200 because it comes up in all my blogs as a standard reference, as in , “Just as accurate as a TX 200,” or, “A trigger as nice as the TX 200’s.”

I have some plans to do more stuff with this newer model, so the fun isn’t over yet.

As far as comment topics go, our rules are keep it clean and no flaming others, but you can pretty much talk about whatever you want, wherever you like.

B.B.

BB

I just wanted to say maybe that’s another positive point about the TX is the tear down time you said it took you to disassemble.

And the point of the relaxed spring. Easier to disassemble plus. Longer life of the spring and other components because there is no stress on the parts when being stored.

Just like your old TX. Maybe that’s why its still shootn’ good?

BB,

This report is not long or confusing to me and I am enjoying the different parts a lot thanks again!

Bear

Hi Sir

I have to admit that it was your blog that led to buy TX from PA & i wholeheartedly thank you for that. On stripping down my TX i found that the spring rear guide is inserted into the trigger unit (fourth picture) unlike others where the spring guide has a flared end which rest on the trigger block. So my question is this phenomenon common in newly sold TX (FAC version) or is it some kind of tuning done to it? Is there any way of taking out the rear guide as i tried without any success. Thanx a lot

Moulindu

Moulindu,

I am not understanding your question. Can you please restate it for me?

Welcome to the blog.

B.B.

Hi Sir

My TX 200 spring rear guide is similar to the 4th picture of this blog. In other TX’s I have seen that the spring rear guide can be detached from the trigger block, but the spring rear guide in your newer TX MKIII shown in 4th picture cannot be taken out from the trigger housing. IS it refurbished or some kind of modification done to the rear guide to fit into the trigger block? Is there any way of taking out the rear guide. Thanx a lot

Moulindu

Moulindu,

Yes, your rifle has been modified if the spring guide will not come off the trigger unit. There must be a crosspin holding it there, or the base of the guide is tightly fitted and just feels like it won’t come off.

You have to look at the base of the spring guide for how it was attached, because Air Arms never did that.

B.B.

Thanx a lot Sir for your reply. I bought this rifle from PA in the month of Dec 2013,its a left hand walnut model & i opted for unused piece. I am wondering PA shipped a modified/refurbished version. Since both TX MKIII (in your blog & mine) have got same modification, do you think that its performance is better/same compared to the factory version? I am guessing the person behind these modifications will be same. Surely would like to contact him. Sorry for bombarding you with all the questions.

regards moulindu

Moulindu,

Well, I must have misunderstood you again, because Pyramyd AIR will not ship a modified airgun and call it new.

I simply do not understand what you are saying.

B.B.

Hi Sir,

Sorry for such a late response. I am willing to put a standard rear guide to my TX & want to take out the stock fitted one. Tried to pull out the guide but in vain

http://s1352.photobucket.com/user/moulindu/media/IMG_2878_zpsd1c3440e.jpg.html

http://s1352.photobucket.com/user/moulindu/media/IMG_2877_zpsbc692154.jpg.html

Can you please mail me the contact no. of the person who did that modification to your TX as I am thinking of taking the guide out without damaging the trigger block.

Regards Moulindu

Moulindu,

As far as I know, you gun was not modified in any way. That guide is standard.

B.B.