by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- Balls

- Patched balls

- Results of patching

- Conical lead bullets

- Pellet head

- An experiment

- Pellet skirt

- Summary

Before I begin, I am enroute today to the Sig factory, here in America. They are bringing in a number of writers to show us their airguns and see their factory. I will take lots of pictures and tell you all about it when I return.

But I will not be able to attend to the blog the way that I normally do. I ask those readers who have been here awhile to help the new readers, just like you always do. I will be back in my office in Texas on Friday and things will hopefully return to normal.

Today I will finish the discussion of bullet-to-barrel fit and alignment. I will begin with bullets and then transition to pellets.

Balls

I will start with lead bullets, because they are fundamental to the fit discussion. Before around 1850, the word bullet meant a round ball. Conical bullets did exist before that time but they were very specialized and hadn’t come into the limelight yet.

Fitting a round ball to a rifled barrel can mean fitting the naked ball to the rifling and ramming the ball down the bore to the powder charge. This effort invariably deformed the bullet from the friction of the rifling. The ball had to be pushed aggressively. The ramrod was iron to take the force of repeated blows, and the top of the soft lead bullet mushroomed flat from being struck. But mutilated noses don’t affect accuracy much, so the rifled ball was far more accurate than a ball fired from a smoothbore. The only problem was it took much longer to load such a bullet, and, as the bore became progressively fouled, the inside of the barrel got so dirty that it had to be cleaned before another bullet could be loaded. All of this slowed down the rifle in operation, making it a secondary weapon on the battlefield.

Patched balls

The patch was invented sometime after the year 1700. A ball (bullet) that was much smaller than the bore was covered with a leather, parchment or fabric patch that tightened the fit within the bore. The patch engaged the rifling, spinning the ball that was inside, yet the patch came off the ball easily when it exited the muzzle. The meant much faster loading, plus patches could be reduced in thickness as the bore fouled, giving more shots before the weapon had to be cleaned. As time passed, riflemen who were not in combat learned to clean the bore as they shot, making it possible to shoot patched balls indefinitely.

The thickness of the patch was the big issue, rather than the diameter of the ball, since the patch was a sabot (container) for the ball in the bore. That continues even today. Muzzleloading shooters must learn which patch material works best with which ball size in their rifle. And, when they can’t get the size balls they like to use, they can always substitute a smaller ball with a thicker patch.

Results of patching

Patch material, alone, can tighten a 5-shot group from 10 inches to 2 inches at 50 yards. So a muzzleloading enthusiast will find a certain ball they like — be it a swaged ball they buy commercially or one that they cast, and then they will try to lay in a lifetime supply of the right patch material. I discussed this to some length when I showed you Part 3 of the Nelson Lewis combination gun. I never finished my testing of that gun because, as some of you might recall, I blew up the gun. It was later repaired and I did shoot it again, but I thought I had better not subject a fine old collectible to constant use like that.

I did switch over to a modern .32 caliber muzzleloader, but that was to test swaged bullets against round balls. I never did enough shooting with that gun to get the patch material finalized, and it looked like the swaged balls were going to be much more accurate. But that was another test I never finished. Let me tell you about one I did finish and what results I had

When I was in the Army at Ft. Knox in the 1970s, I shot an original Green River muzzleloader that was probably made around 1850. It was too short to call a plains rifle and had a barrel that was too fat to call a hunting rifle. What I think I had was a target rifle whose muzzle had been damaged and about a foot of barrel had been cut off. The barrel was only about 28 inches long on this .45 caliber rifle. It weighed about 9 pounds as it was and probably 12-13 pounds before the barrel was shortened. The rifling inside barrel was heavily worn from the patches over the 125 years of its life, but there was still enough rifling to do the job. Cloth patches wear out a soft steel rifle barrel much faster than naked lead because they contain abrasive particles!

I fiddled with that rifle for a year, testing different cast balls and patches until I finally found the right combination. At 50 yards I could put five balls into an inch. The charge was somewhere around 50 grains of FFg powder, plus a grain of powder loaded inside the drum that held the nipple, to enhance ignition. It took me about 2 minutes to load the rifle each time, but when the hammer fell, I knew exactly where the bullet was going. I had found an ideal (patched) bullet-to-barrel fit. I had to sell that rifle to pay bills when my first wife divorced me, and I wasn’t a picture-taker in those days, so all that’s left is the story.

Conical lead bullets

I could go on ad nauseum with stories about conical bullets, because shooting has been my life for more than half a century. But why don’t I just cut to the chase and show you what it looks like when you get the right bullet fit.

Ten .45-caliber bullets ripped through the target at 15 yards. Group measures 2.271-inches between centers.

That’s not such a bad group, is it? I bet you would be happy to shoot one like it. Oh, maybe it’s not up to the standards of all our readers, but most of you would be happy. So, the question on everyone’s mind is — what gun did that? Was it a tuned 1911? Or perhaps an S&W model 25 with target hammer, target trigger and target sights? Not even close.

The gun that shot that target was a battered World War I Webley Mark VI revolver whose cylinder has been shaved to allow the use of American .45 ACP cartridges — as long as they are on moon clips! Yep, it’s a 1916 war bunny that’s been fooled with!

But the bullets I shot were SIZED 0.455-inches, to match the larger 0.455 caliber Webley bore. Ain’t it nice when the stuff I tell you really works?

Yep — this tired old Webley Mark VI that was made in 1916 and then modified to accept .45 ACP cartridges in moon clips shot that target. And the BULLETS FIT THE BORE!

There will be whole lot more on this Webley in the future, so this isn’t your last look by a long shot.

Nuff said! Let’s turn to pellets. This won’t take long.

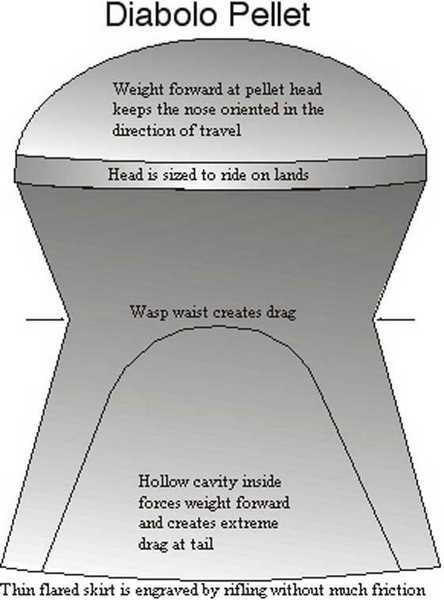

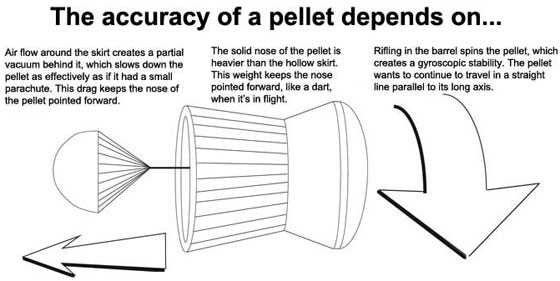

Pellet head

The size of the pellet head determines whether the pellet rides the bore straight or on a slight angle to the axis of the bore. A pellet whose head is too small will be slightly cocked in the bore and will exit that way. The spin from the rifling and the drag from the skirt in the air will straighten the pellet in flight once it leaves the muzzle, but there may also be a slight bit of instability (wobble) introduced at that time.

An experiment

Those who are curious might try this. Throw a throwing dart at a dartboard tail-first. You will see the dart swap ends in flight and hit the board point-first. This will happen in as little as 7 feet 9.25-inches of flight! The dart is weighted and aerodynamically designed with a high-drag tail to always fly point-first. Diabolo pellets work the same way.

But no dart champion ever threw a dart that way in a match they wanted to win! They hold the dart carefully the same way every time and their arm moves in the same way each time for consistency. And so it must be in a pellet rifle for the best accuracy. The pellet head is what guides the pellet as it leaves the muzzle, so the size is critical.

The diabolo pellet is designed to fly nose-forward.

Pellet skirt

The pellet’s skirt seals the back of the bore so all the air (or gas, in the case of a CO2 gun) pushes on the pellet. Pneumatic guns are extremely gentle to pellets and do not deform the soft lead skirts at firing. There may be 3,000 psi inside their reservoirs, but the valve releases the air slowly at a much lower pressure. So, when shooting pneumatics and especially PCPs, look for pellets with larger skirts.

Spring guns generate a much smaller amount of compressed air, but they do it so violently that they blow the pellet skirt into the walls of the barrel. The power of the spring gun will determine whether this is something you have to consider, but with powerful springers, it always is. A skirt that’s blown out too much will affect the pellet in flight, reducing its accuracy potential.

Summary

Bullet/pellet fit and alignment to the bore is very important to its performance. In this short series I have shown how this works, but I have left many avenues unexplained.

This 3-part series has been very short and to the point. Some of you may not understand everything — especially today. Ask your questions and we will go from there.

B.B.,

That was a great job by you, as usual; I learned some new things about diablo pellets!

And that war bunny Webley is very cool; I look forward to seeing more about it in the future; thanks.

take care & God bless,

dave

Dave,

Thank you. I am off to Sig this morning!

B.B.

BB

Sounds like a exciting day to me. Like a field trip when I was in school. Use to love that.

One of my favorite field trips was to the Corvette plant when it was in St.Louis Mo. It was the last year it was open before it was shut down. Or machine shop class teacher took us. He was probably my favorite teacher throughout school. Probably was my biggest reason for going to school everyday. 🙂

I was wrong on the year.

The Corvette production line closed in 1981. I graduated in 79. So it must of been that year or the year before because that was the only 2 years I had that shop teacher.

Anyway it was a fun trip.

So, based on all this, one could develop a computer program that would ask if the rifle or pistol was single or multi pump pneumatic, PCP, CO2, or springer. If, as an example, the rifle was a springer the program would ask the nominal FPS of which it was capable. Let’s say that was 1,000 FPS. The program would then consider all the available pellets with skirts of sufficient thickness not to be blown out by that much springer-induced sudden pressure rise. If you could then supply the springer’s bore diameter, the program could narrow it down to all the pellets with sufficiently thick skirts that also have that matching head diameter. Thus, it should be able to fairly accurately predict what the best pellet would be for any given air gun, thus eliminating all the traditional guess-and-by-golly, random testing of handfuls of different pellets to figure out, more or less, which was the most accurate for a particular gun.

That could save thousands of dollars of pellets in the market on an annual basis and really screw up a lot of fun backyard testing to determine the most accurate pellet in your new rifle or pistol!

Motorman

St. Louis, MO

Motorman,

I sort of do that already. That’s why you see the same pellets used in tests so often.

B.B.

BB,

I have always drooled after an unmodified Webley, so much so that when they brought out the bb gun it was all I could do to not get one. Now that I am an old geezer I have learned I can live without that. Now I just drool.

B.B.

Enjoy the factory tour. Just make sure that they give you freebies! I can hardly wait for a report on their new break barrel.

I have enjoyed today’s history lesson. Perhaps when you are looking for a blog topic, you could do a report on the weapons of the Civil War? It seems things were really changing right around that time. I know the Prussian Army sent observers over to monitor all the changes.

-Y

Yogi,

The Civil War! Now there was a time. The North needed weapons and pushed factories for as much as they could produce. At the end of the war General Ripley, the chief or Ordnance, had a million muzzleloaders on his hands and the world had changed to cartridge breechloaders. The Army went into a prolonged development program that produced the Trapdoor Springfield, and more importantly, the 45/70 cartridge!

B.B.

B.B.,

Hmm…a future article involving the Webley Mark VI? You already did a standard three part report on the BB version: /blog/2014/12/webley-mark-vi-bb-revolver-part-3/ Going to do a part 4 using the firearm then transition back to the pistol for part 5?

Siraniko

Great post B.B!

I especially appreciate the graphics to go along with the explanation. Do you keep a “doping” book of general pellet data — identifying which pellets you have had success with in a particular brand of gun, or PCP vs. springer, etc?

Have fun at SIG. That’s a trip I would enjoy.

Jim M.

Jim,

i keep such a book for some guns, but not for all.

B.B.

B.B.,

I have observed that these days many “jumbo” weight pellets of diabolo shape carry much of their mass in the hollowed tail, to the degree that there is very little hollowed portion at all. I wonder if that has an effect on accuracy. The desirable shuttlecock drag has to be reduced by this. I would think such pellets might be more likely to keyhole than others with a hollow tail that is more voluminous.

Michael

Don’t know if anyone is interested. I am. I like semi-auto guns well and full auto but you know how that goes. And been waiting for the release of this gun. It’s not available yet but at least it’s happening so far now.

And even a surprise. It’s the same price as it’s kin. I figured they would ask a higher price for the folding stock. But nope. The same price. Hope it stays that way.

Wish it was available now. I would be getting it with the PA sale going on. But here it is.

/product/hatsan-sortie-tact-semi-auto-pcp-air-pistol-synthetic?m=4584

GF1

Been considering the Galatian Tact Auto, Semi-Auto rifle myself. Just noticed it today But I think I’ll wait for some reviews first.

Bob

I saw the Galatian tact also. Cool gun and not to bad on price compared to some other brand pcp semi-auto’s.

I myself want the Sortie-tact because it’s a shorter and light gun. Right under 5 pounds if I remember right. And that’s with the folding stock on it too.

And it’s mostly going to be for plinking. So not too worried that it’s lower powered than the Galatian. But both cool guns.

B.B,,

First off, safe travels to you!

I forgot to mention how much you nailed it on the patched round ball discussion.

Back in September of 1995, my wife got me this Traditions .50 caliber “Hawken” replica.

I spent a lot of time trying different patches and everything from 50 to 80 grain powder charges.

(note: the barrel is rifled 1 turn in 66″; hence, it is at its best with patched round balls)

With Hornady swaged .490″ balls and a 0.015″ patch over 70 grains of Pyrodex,

it will put a ball on the “X” of a cross made of electrical tape at 50 yards…on the 2nd shot.

The first shot will always be 2″ high; hence, you either have to fire a fouling shot, or,

if you are at a match that does not allow that, you have to use a 0.020″ patch to get that 1st shot on target.

If you go a few grains either way, accuracy drops off dramatically.

But the best thing about this rifle is that, once the barrel is fouled,

it will shoot consistently enough to shoot a 20-shot match without any cleaning between shots.

Well, actually, that’s the 2nd best thing; the best thing is it was a gift from my wife.

And I’m sure all y’all know, if your wife buys you a gun, be it airgun or firearm,

you had best shoot it a whole bunch to keep her happy so she might buy you another one!

(Trust me, it works; I’ve got 5 wife-bought guns so far =>)

Happy shooting to all,

dave

Dave,

Here is what is over my fireplace.

Hewn that’s the word I was looking for.

Awesome! Is that a vintage BSA underlever?

1906 Lincoln Jeffries Model BSA. It is the Queen of my “collection”.

RR

And likewise as to what I said to Dave.

Cool gun and picture.

Dave

Cool gun. And picture.

Thank you!

There is a story to that gun: my wife’s grand dad had an actual Hawken that was given to him by the Indian trapper that taught him how to hunt and trap. One day, my wife and I were in a sporting good store, and I saw a Hawken replica on the wall, and I wondered what caliber it was. My wife’s like, “That’s a .50 caliber.” So, I asked the salesman, and he said, “It’s a .50 caliber, pal.” Then I asked my wife, “How did you know?” Her: “I only saw one every day of my life growing up.” =>

So, after watching “Jeremiah Johnson” like 50 times, I decided I needed to get a .50 caliber Hawken.

My wife bought me this one for Christmas (1995), but gave it to me in September, since deer season started December 19th, and, as she put it, “You have a LOT to learn about shooting black powder.”

She was correct, but after much work, I got my first deer on 19 DEC 1995 with that rifle from my wife; hence, it hangs in the place of honor. =D

Dave

And now a cool story. 🙂

Ain’t it amazing how the mind can remember.

R.R.

Is that your BSA? 1906 right? You should do a guest blog on it! Those are some nice logs, are they hand worked ? Looks like adze marks on them. Very nice!!

Carl

Carl,

Yes, that is my 1906 BSA in the place of honor. The logs are indeed hand hewn.

R.R., those logs are way cool; and ditto what Carl said, a guest blog on your BSA would be well-received! =>