by Tom Gaylord

Writing as B.B. Pelletier

Michael’s Winchester 427 is a Diana model 27 by another name. The rifle pictured is my Hy Score 807/Diana 27

This report covers:

- Reader MarklinJHawkland

- The blind pin

- Sheared the screw

- The lesson

- Cleaning the spring tube

- Other cleaning

- The assembly

- Summary

I’m tuning and overhauling reader Michael’s .22 caliber Diana 27, which is actually a Winchester 427. In Part one I disassembled it and in Part two I showed you how the ball bearing trigger works. In Part three I talked about removing the old piston seal that had a screw that was stuck. I have a lot more to say about that today.

Reader MarklinJHawkland

This is the reader who solved the puzzle. I knew there is a pin in the head of the piston, because when I disassembled the rifle someone had tapped that pin in far enough for me to see it. Unfortunately it was probably that and not the rust that had jammed the screw in place.

And BB Pelletier added insult to injury by trying to drift this pin on through the piston! I figured I was just unable to see the other side of the pin on the head of the piston, because who in their right mind would ever use a blind pin to secure a screw?

The blind pin

A blind pin only goes into something halfway. Think of it like a nail. You can’t push it all the way through because it doesn’t go all the way through, so there is no way to push it back out from the other side. I never thought anyone would use such a thing on a part that is meant to be disassembled periodically.

Well, Diana of the 1970s did! I don’t think it’s there to secure the screw; I think Diana used the blind pin to fasten the piston head to the sheet metal piston body. And, when it is tapped in farther, it impacts the screw threads from one side, jamming them, in place. Then, add 40 years of rust to the problem and that screw isn’t going anywhere!

This is the head of the original pistol in Michael’s rifle. That blind pin shouldn’t be tapped in like this.

Was the pin jammed in that way at the factory? I don’t want to think that it was, but when I opened the gun the parts looked like they had never been apart, yet the pin was definitely driven into the piston head. And my tapping it even more with a pin punch certainly didn’t help. Probably somebody had the gun open years ago, tapped the pin in and then couldn’t get the piston seal screw loose and just left it that way.

Sheared the screw

I spent about an hour trying to coax the screw free with the impact driver. All the while I was pouring Kroil penetrating oil on the screw head in the hopes that some would get down into the threads.

Anyway, the piston seal screw was jammed so tight that the impact driver finally sheared it off at the piston head. I knew something had to be done quickly. I ordered a new Diana 27 piston with the seal attached from T. W. Chambers & Co. in the UK. I also ordered a second piston seal set for the piston with the sheared screw. The order went in on December 22 and both items arrived at my mailbox on January 3. That’s great service!

The impact driver eventually sheared the shank of the pistol seal screw, leaving a good stub for removal.

The old piston seal assembly has 4 pieces — the seal, the inner spacer that keeps the soft leather from collapsing in on itself, a fiber spacer that was behind the seal and the screw that held the seal assembly to the piston body. Notice how crushed the spacer that goes behind the piston seal is (bottom right). It should be flat.

The new seal assembly appears very similar to the original, except for the color of the parts.

The new piston looks like new old stock from Diana, which it may be. I can’t detect any difference in manufacture. It may look corroded in the picture but that is just patina. There isn’t a spec of rust anywhere.

This is how the blind pin is supposed to look. This seal could be disassembled. The leather piston seal has already been soaking in oil for 12 hours.

My plan is to use the new piston and seal to finish the tuneup on Michael’s rifle. I hope to eventually repair his old piston and keep it for a spare, and I will write that up when it happens. You never know when another Diana 27 will come along!

The lesson

Learn from this! If you are working on a Diana 27 or any air rifle that has a pin through the piston head, determine whether it is a through pin (some are) or a blind pin like this one. Don’t tap a blind pin in or you will jam the screw that holds the seal. I think the screw was jammed more from the pin impacting it than from the rust.

Cleaning the spring tube

All the parts that go back into the gun must be cleaned, but the spring tube is the most critical, because that’s where the rifle’s power is generated. We want to remove all the rust and leave as smooth a surface as possible on the inside surface.

I had “marinated” the spring tube inside and out for about 10 days with lots of Ballistol, which removes rust. It looked horrible inside, but I knew that was the Ballistol making the rust bubble up to the surface.

This shot of the inside of the spring tube, looking through the cocking slot, looks horrible, but I knew that was just the crud the Ballistol had lifted off the metal.

To clean the inside of the spring tube I used a shotgun cleaning rod with a tip that was looped. I shoved 0000 steel wool through the loop. Then I chucked the rod in my drill and turned it as fast as it would turn. Running the rod in and out of the spring tube for two minutes loosened everything!

A large shotgun cleaning rod spun by an electric drill is perfect for cleaning the inside of the 27 spring tube.

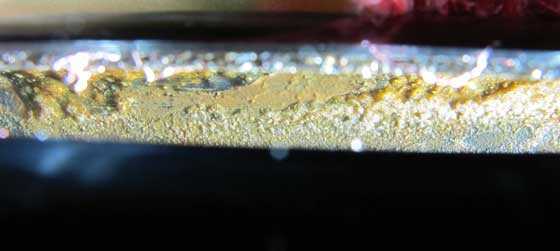

The steel wool and Ballistol made short work of the rust. After cleaning I ran in some rags followed by paper towels to get everything out. What was left won’t show very well, as it is a smooth blued steel surface.

What you are looking at, the bright part, is the same place you saw in the photo above. It is the inside surface of the spring tube and is now perfectly smooth and free from rust. You can see that the bluing (yes, the inside of the spring tube is blued) has been removed by the piston moving back and forth and that is the only wear that’s there. The factory cross-hatching is still sharp, though you can’t see it in this picture!

Other cleaning

The surface of all the the metal parts was cleaned with steel wool and Ballistol. Since I had coated every external surface with the stuff while waiting for the parts to arrive, the rust came off immediately.

The smaller internal parts were also given the steel wool and Ballistol treatment. This took very little time, because most parts weren’t rusted that bad.

The assembly

I’m not going to assemble the rifle in this report, but I wanted you to know that Michael bought a new mainspring for his rifle. The combination of that new spring, the fresh breech seal I made and a new piston seal will put the power this 1970 rifle back to like new.

Summary

I will assemble the rifle next. In that report I will show how to assemble the ball bearing trigger that can be a little tricky. Then I will chronograph the rifle and see what the tune has done for it. I haven’t decided whether I’ll test the rifle for accuracy or not. We shall see.

BB

Please do the test for rifle for accuracy. After all this work and teaching it would be nice to see the three cent piece next to twenty five yard group. How are able to remove a blind pin? From the photos it does not look like you could get pliers on it.

SP4449

SP4449,

The pin can be drilled out, or you can drill into it and install an Easy Out to try to pull it out.

B.B.

SP4449,

Don’t expect to see the trime in an accuracy report of this rifle. They are good for plinking but not that accurate.

B.B.

At least a minute of beer can accuracy test? What these nice vintage springers accel at

New seal and spring will take a few shots to settle.

Are you pre compressing the spring? Keep up the good reading BB.

B.B.,

My, my,…. quite the adventure! Glad things are on track now. Nice job on the clean up. Oddly, the can of Ballistol does not mention rust remover, though I know that you have mentioned in the past of using it that way. Do give it a 10m or 25 yard (informal) quick accuracy test when your done.

Good Day to one and all,……….. Chris

Chris,

Ballistol doesn’t mention being medicine, either, but in some parts of the world it is.

B.B.

Ballistol as a medicine??? …a laxative?

B.B.,

To my nose Ballistol smells like anise seed. Perhaps one of its ingredients is anise seed oil, but that is just a guess,

For those who don’t know, anise seed is the flavor of licorice and is used in a number of liqueurs as a flavoring.

Michael

I had to dust off my old bartending days books. The list of anise flavored cordials includes Absinthe (the hallucinogen stories are false, and I doubt it is made from Wormwood anymore, either), Anisette, Ouzo, Galliano (the liqueur), Sambuca, and supposedly Jägermeister (although to me that tastes more like cough syrup).

Many of the above, but most famously Absinthe, are capable of producing the “ouzo effect.” Put a shot in a medium or large sized glass (never with ice), and then pour two or three ounces of water (preferably ice-cold and poured from high above the glass). The combination will develop a light green cloudy effect sometimes referred to as “The Green Fairy.” It does produce “Oohs” and “Ahhs” from onlookers.

Your resident former mixologist,

Michael

Michael,

Is Sambuca the cordial that traditionally has whole coffee beans dropped into it?

Half

Half,

Yep, that’s the one. It can also be drunk like Irish whiskey, a shot in a strong cup of coffee. I guess one could call it an Italian Coffee instead of an Irish Coffee.

Michael

Michael,

A shot of whiskey in coffee just ruins them both. Amaretto goes in coffee, it even brings its own caffeine. Irish coffee must be invented by the same guy that thought it would be a good idea to squeeze lime juice into a perfectly good Rum and Coke. LOL

Half

Rum and Coke with Rose’s Lime Juice (or just regular fresh squeezed lime juice) on ice is a “Cuba Libre,” Ernest Hemingway’s favorite drink.

Seriously, make a cup of hot strong coffee with sweetener and add one shot of Jamesons, and it is incredible. Also, if you are stopped up, that takes care of it. ‘Nuff said.

Michael

Michael,

The first (and only) time I ordered one, I did it because I knew it was Hemingway’s drink, so it must be good, right. I was a big fan of Rum And Coke already at the time, so I went for it. Just a very efficient way to screw up an otherwise tasty drink. IMO ;-P

Half

Michael,

Order a Cuba Libre on the Costa de la Luz in Andelucia, Espania you will get a gin & cola! Really surprised my wife and I the first time; it starts off bitter in the mouth and ends with a sweet finish.

shootski

BB,

You cannot convince me that you do not want to shoot this air rifle any more than is absolutely necessary but to confirm that it is working properly.

Now if Michael would like to write an extensive accuracy report, well then I believe we should indeed give him the opportunity.

RidgeRunner,

“Extensive accuracy report” would not be necessary as the low power of this model limits it to 10 meters, so four or five targets would suffice. But seeing it do its thing rested at 10 yards or ten meters would be interesting. My indoor range is unavailable at the moment, and the weather outside if frightful here, but if B.B. were to . . .

Besides, a report of my shooting the rifle would be a report of how accurate it is in the hands of a weak-eyed, shaky-handed amateur. :^)

Michael

Michael,

LOL! That sounds about like me!

B.B.

Nice work! Is the Diana 27 older than the Diana 50? A friend of mine has a Diana 50 he wants me to work on.

I love Ballistol, but had no idea that it could remove rust like that, live and learn.

-Y

PS you have to do an accuracy test at 25 yards or else, why bother?

Yogi,

You busted me! I was just running it up the flagpole to see who saluted. 😉

B.B.

B.B.,

I am now exceptionally happy! I was hoping my “Well, gee, 10 meters or so would be OK” might get the accuracy testing going.

And you know how much you enjoy shooting Diana Model 27s. Shooting them is like eating peanuts. You can’t eat just one peanut, and you can’t shoot a 27 just once. ;^)

Michael

Michael,

From shooting my grandson’s new HW30 the other day, l most certainly understand.

Yogi,

There are two different breeds of Diana/”Original”/Winchester 450/Hy-Score/Gecado Model 50s. They are all tap-loading under-levers, but the later ones are hard-cocking, slightly harsh shooting medium-powered air rifles.

The earlier ones are lighter-cocking (but not exactly light as the lever is short), sweet-shooting, low-powered air rifles. All of them are very large and heavy. That are common in Europe but uncommon in the U.S.

Manufactured from 1952-1987, with 1965 being a year of significant design changes. Earlier models have the three-ball-bearing trigger.

Michael

Sorry I meant a Diana 35. I have not seen it, just described as old in the 70’s.

-Y

The blind pin

” I never thought anyone would use such a thing on a part that is meant to be disassembled periodically.”

Me neither, B.B.

Even back in the 70s, how much money could they be saving by using a blind pin instead of a through pin that could be easily pushed out for dis-assembly?

Still, you did get it sorted out, and it all makes for an interesting report.

Hoping the New Year is still going well for you,

dave

Dave,

Agreed, doesn’t make sense they would use a blind pin just to hold things together. Bet that the pin is soft iron and it’s purpose is to lock the screw in place.

Hank

Something here reminded me of the Falke rebuild I reported on almost 8 years ago (/blog/2011/02/it’s-not-my-falke-part-3/).

I was also converting THAT gun to a synthetic seal, as the original was pretty much trashed. When I tried to get the old seal off I found exactly the same issues with the stuck screw and the blind pin. On that one I drilled out the pin and removed the screw… and found that the pin held the piston rod to the piston, not the piston head to the piston.

I suspect this was the same way.

Just went through this exact same drill myself with my 427. Even though the leather seal was in reasonable shape I wanted to convert to a synthetic (just “because”, ya know), which meant I needed to get that leather seal off.

Screw stuck, screw snapped.

But in my case a had a quick and easy solution: chuck the piston up in a lathe, drill it out, and tap it with a 10-24 thread. I made a synthetic seal adapter out of some mild steel stock, and installed a Gamo/Crosman seal for a 25mm tube.

BTW – the specs for the adapter – .175″ high, .61″ diameter at the big end, and the sides cut at a 16-degree angle from the spring tube (which is 74 degrees from the face of the adapter).

Before this it pushed CP’s at about 480fps. After all that it now pushes them at… about 480fps!

Of course, though, it’s now doing it with a SYNTHETIC SEAL… which makes all the difference!!!

Vince,

Thank you for explaining the significant difference between a leather seal and a synthetic seal. Now everybody knows. 😉

B.B.

Vfblovesnancy,

Excellent solution!

Interesting that the velocity of the old leather seal and the new synthetic seal is the same – says a lot for the practically of a leather seal for moderate power guns.

Cheers,

Hank

Yup, this was pretty much already known. But now, at least, some future dude will not have the stuck-screw-in-the-piston dilemma to deal with.

But also: I am a serious cheapskate. The seal I used was a used seal – an old Apex seal that I got from Maccarri about a dozen years ago and had spent some time in a Gamo Shadow. But it was still a snug fit, so I used it. I had also honed the cylinder, so hopefully it will “bed in” a bit and improve as time goes on.

I would have to say if I ran into this blind pin situation and got the pin out. I would have to go ahead and drill through to make it a through hole to make it easier to disassemble the next time around.

And yes I would like to see the shooting results. And something else comes to mind that I never thought of doing after tuning up a gun is see if it ends up liking a different pellet then what it liked before the tune. Maybe that barrel will like a different pellet with the new velocity. Or maybe not.

Gunfun1,

Even with same spec replacement spring, piston and seal, we know that nothing is exactly the same microscopically. So the harmonics change. If the harmonics change, the “favorite pellet” might change too.

Good observation.

Michael

Michael

Probably more to it than harmonics too.

Only one way to know. Test it’s favorite pellet and some others and shoot and see.

Maybe we can have a surprise from your springer in the future. 🙂

It really likes AA fields. Here is a pair of ruined 5 shot groups.

GF1,

I haven’t got my stock for the Onix Sport pistol yet ( I know it is in America now) but because the weather this weekend was so good, with calm winds and warm temps, I went ahead with the 30 yard testing. I set up a vice and workbench in my yard and fired from there. It’s not as rigid as the setup I use in the basement so I had to mount a rifle scope on it so I could hold it steady on the aimpoint. The vise did most of the work, I just had to add enough force to keep it on target. 4 X 32 Winchester scope, BTW.

Out of 28 pellets I had 14 that shot under 1″ at 30 yards and 4 more that put 9 out of 10 in under a inch.

Here’s some pics.

Half,

Wow,…. I never would have guessed that a pistol would do sub 1″ at 30 yards. I am very happy for you. That is a fine shooter you have there.

Chris

Chris,

BB has pointed out that the Chinese are capable of producing accurate barrels. Honestly, until now, I thought he was being kind or that he was using a lower standard than he might for a U S, German, or British manufacturer. I see now that he meant just what he said. I’m plain tickled with it, so far. I think it’s gonna be a very nice carbine. Hope the stock arrives soon!

Half

Half,

Chinese? All of the literatura I see online es en Espanol.

Michael

Michael,

Here you on the Espanol. Only real problem with the gun that I see.

This is another Snowpeak gun, made in China and branded Air Venturi, Diana, Nova, or whatever you, as the marketer, want put on the side. This particular gun is sold as the Zasdar PP700 SA, The Air Max Precision MK II, The Onix Sport, the Artemis PP700S-A and others, I’m sure. My Onix doesn’t have any markings designating where it was made, but the packaging it’s boxed in clearly says “Made In China”. It also has “Spain” and a long series of numbers and letters. I guess it’s made for the Spanish market, it is full power and fully adjustable, and perhaps they don’t require that the gun itself be marked. I bought mine from a Spanish retailer, not a US importer. I think a company that we all know and love should look into importing them, though. It is a lot more gun than the Diana stormrider or the chaser, IMO, and I own both of those.

Half

It really likes AA Fields. Here’s two 5 shot groups that broke my heart. they’re still pretty sweet for a pistol in this price range.

Halfstep

Looks like it’s a shooter to me.

What distance was the AA .195 group at?

GF1,

Both of those 5 shot groups were at a measured 30 yards from the muzzle.They finished up at .667″ for the 4.51mm and .710″ for the 4.52mm, for 10 shots.

I plan to shoot with the stock, but I’ll only be sharing the results I get from sand bags. What I end up with off hand will remain my little secret /shame.

I want to mention that, just before it got too dark to see last night, I did a quick drop assessment on Chair Gun with JSB Exacts at 66 yards and managed to hit a 2″ square 2 out of 5 times, positioned as a diamond set 66 yards away. Had to estimate the hold over( around 10 1/2 inches) with a $29, 4 power, duplex reticle scope. I have the diamond suspended from a heavy wire screwed into the end of a railroad tie on the track that runs behind my house. I also have a 1′ disc and a 1 1/2 ” disc that I was unable to hit. They are about 1/4″ thick aluminum and the light coloring was the only reason I could still see them in that low light.

Was gonna try again today in the daylight but the winds are high and on and off rain all day.

Half

Halfstep

Yep that’s what I mean with the stock when you get it. You holding the gun and bench resting it. No vice involved.

And yep I like low light scope shooting. I like when there is a full moon and clear out. I throw out a aluminum can and aim for the shine with the scope. That’s fun shooting. Haven’t done that in a while.

Here’s the results charted out. The last 2 rows are the 30 yard results

Here’s the results charted out. The last 2 rows are the 30 yard results

Halfstep

Yep it seems to be happy shooting pretty well all the pellets it gets.

I still want to see what you get out of it with the shoulder stock and some of the better grouping pellets. And you shooting it at 30 yards. Not a vice.

B.B.,

The before and after photos of the inside of the compression tube provide quite the contrast. Wow.

Would you take a photo or two of the application of Tune-in-a-Tube lubricant to the spring and any other parts? I bought some Almagard 3752 and would like to apply it to two or thee twangy break-barrels (one $60 Gamo in particular). Seeing where to apply it and how much to use would be instructive.

I noticed the irregular-shaped, recessed area around the blind pin in the photo of the new assembly. I presume that is from the manufacturing process, but am curious what it suggests regarding that process. Does it hint that the pin was installed in a sheet of steel and then pressed and adhered to a hole made in the cap? There is no corresponding area on the old one. Forgive me, but little mysteries like that sometimes interest me, and we happen to have a remarkable resource of metal workers, mechanics, machinists and metallurgists here to chime in.

Again, thanks very much for doing this.

Michael

Michael,

I will show the application of Tune in an Tube in the assembly. The mainspring and trigger assembly are the two places where it will be used.

That mark on the piston is from the press that pushed in the pin. The pin was put into the hole then a hydraulic (probably) press rammed it home and made the mark.

B.B.

B.B.,

O.K. The press pushing the pin into the hole makes perfect sense.

Today a dab of Loctite Red (Blue?) on the screw would be appropriate, no? Applying heat with a soldering iron might then allow a tuner to open it up someday, decades after the air rifle was manufactured. The Loctite might reduce rusting on the threads, too.

Hey Diana: When you make an air rifle that can last many generations and then some, make it so that it can be rebuilt down the line! :^)

Michael

BB

Ok that’s what I wondered. So it’s a interference fit. Not a precise fit.

In other words the pin is pretty well oversized for the hole.

To me they assembled the gun like it wasn’t ever going to need to be taken apart for the life of the gun.

So could a leather seal last longer if there would of been some sort of instructions from the manufacturers to do to the guns throughout time. And I guess that’s if that manual actually got handed down to the next owner of the gun.

Maybe there would be more leather seals alive today. As well as internal parts of the guns.

GF1,

Way back when all seals were leather. Probably everybody knew how to take care of them.

My BSA did not have a manual, but the manual did state to oil frequently.

RR

Another good tip lost in time I suppose. Most probably know. But then again. Maybe not.

GF1,

Lost in the mists of time with the coming of synthetic seals. Very similar to the old cartridge designations such as 45-70. Most know that the 45 refers to the caliber of the projectile, but many do not know that the 70 refers to the number of drams of black powder the casing holds.

RR,

Change drams to grains and you’ve got it! 🙂

B.B.

RR

What I wonder is if the old owner manuals told of how often to oil the leather seals. And how much and what type of oil to use.

I know there is info nowdays as to how often and how much and what kind to use. But I would like to know what the manufacturers said back then. That is if they even said anything.

GF1,

They did tell you to oil the seal, though I don’t remember a lot of specificity. I don’t even think they told you how to do it.

Anybody have a manual?

B.B.

BB

I just find it interesting to read owner manuals.

For the most part they have good info. But some aren’t very helpful.

But yep it’s just something I have had on my mind about what the manuals said to do back then.

GF1,

I do not know of others, but the manual for my BSA said to put two or three drops of light oil in the loading port every 50 shots or so. This not only lubricated the piston seal, but also provided the airtight seal for the loading drum.

RR

Every 50 or so. That seems like a lot. But I guess it’s got to stay moist to seal right and not deteriorate.

I guess them leather seal guns probably smoke faintly every shot. Haven’t owned a gun with a leather seal so don’t know.

But if so I imagine that could be a hint as to when to oil them. If the smoke goes add a few drops?

GF1,

I myself think that is overdoing it, but if you think of the times and what was going on, maybe not. This air rifle was a competition air rifle used by shooting clubs in the pubs and at ranges in the UK at the time. These were very expensive and a dozen or so working stiffs would get together and pool their money to buy one or maybe two. Each would take turns shooting it in a competition. It might get quite a few pellets through it to see who was going to buy the next round.

RR

Yep your probably right. And I’m sure they wanted the guns to last. Especially if they were that expensive back then.

Does your gun smoke when you shoot it?

GF1,

No, it doesn’t. It is pretty low powered. It pushes 8-9 grain pellets at around 600 FPS. You do not need much power to punch a hole in paper at 10 yards. In the pubs they were shooting bell targets at 7 yards.

RR

So I wonder how we would of done if we was in one of those pubs back then shoot’n.

I bet that was some fun stuff. Reminds me of playing pool in the local beverage establishments when I was a kid. But how could you not like shooting guns in a drinking place. You know how that would go over now days.

GF1,

Yeah, right.

Now I do have to admit that airgun shooting is permitted off of the back porch of my local beverage establishment. There is a rule that no shooting is allowed after beverages have been consumed though. 😉

RR

Ain’t it crazy how times change.

That’s cool you can shoot there now days. But I bet they was drinking back in the day when they was ring’n the bells with those parlor guns. Was a lot safer then someone getting out their six shooter’s back then. And I wonder how often that really happened with the six shooter’s.

GF1,

Not near as often as they make it out to be in the movies, etc.

What most people forget was that most of the men were war veterans and most of them carried firearms. You were careful how you treated others because they might put a hole in you.

Those sod busters were not so easy to kill either. Like I said most of them were vets. They also fed their families with their rifles. Somehow I do not think a young punk with a 6 shooter is going to stand much chance against a war vet with a 44-40 rifle.

RR

The putting a hole in you was the big thing.

Respect is what I say. That makes all the difference in the world.

Hello B.B.,

Thanks for the shout out. I’ve only been inside a few Diana’s of this design but in each case the pin was pressed into the threads of the seal retaining screw blocking it from coming out. I always assumed it was to keep the screw from backing out. If it’s not designed for that it sure does a brilliant job of it anyway 🙂

My method has been to soak the whole front of the piston in Ballistol as long as I could. Then with a screwdriver just work the screw back and forth. In my experience I can rock it back and forth (maybe 20-30 degrees of play) which I think taps the pin from within until it eventually pops the pin out enough to get some good pliers on it. Pull it out a little bit which clears the threads and allows the screw to come out easily. I’ve never seen the pin come out very far. Maybe an eighth of an inch if that.

Speaking of shout outs anyone interested in Diana 27’s should check out Mike Driskill’s amazing posts/photo essays if they haven’t already (hopefully the links are allowed):

https://www.tapatalk.com/groups/americanvintageairguns/diana-27-s-talking-to-the-dolls-t4916.html

https://www.tapatalk.com/groups/thedianawerkcollective/evert-old-diana-threads-t13365.html

FWIW I still feel bad I couldn’t alert you to the situation with these pins earlier. I was unable to login because I forgot my password and kept putting off dealing with it. Finally I remembered it but too late.

Also resetting my password for this blog is broken for me. You might make inquiries. When I get the email to reset the password the “link” in the email is NOT a link. And no amount of copying and pasting what appears to be the link takes me anywhere that helps. And I’ve tried 3 different browsers. I’m pretty decent with web stuff but I was never able to reset my password. And I wonder if others may be having issues too.

Thanks again,

Mark N

Some thoughts…it appears that the pin is simply used to hold the end cap on the piston. If the pin hole had been drilled completely though there would be very little material for the screw threads holding the seal. Judging from the length of the screw I would assume that the screw threads are actually tapped into, maybe through, the end of the piston. Another observation on the new piston is that the pin appears to have been staked below the surface of the end cap for relief. The metal at the bottom of the relieved area does not appear to have been machined.

B.B.

Was there any evidence of thread locker having been used on the original screw? I cannot believe that the pin would have been pressed down onto the screw unless it was never meant to replace the seal.

Geo

I’m thinking the pressed in pin actually shears off some of the threads on the screw. The pin is probably offset to the outer edge of the screw and is only contacting the threads as the pin goes through.

Drilling the hole the pin goes in all the way through as I suggested above would be the way to go. That way when the pin is pressed through out of the way the threads that got tore up by the pin have a place to escape when the screw is being removed. The screw would probably even come out pretty easily.

You could be correct. A spring pin would be the way to go. It would be easily punched out to remove the screw then.

Geo

Yep that’s the way I would of done it.

And I’m guessing by spring pin you mean a roll pin. That’s what we call them at work and use them in alot of similar instances. To me that would of been a better design then the pressed in blind pin.

Yeah, some people mistakenly call a spring pin a roll pin. Actually a roll pin, as you probably know, is just that, a pin made from rolled steel. The spring pin (AKA roll pin) is open in the center and squeezes into the hole tightly. And yes, a spring pin would have been much easier to remove from the blind hole.

Geo,

I could be wrong,.. but it seems that the 70’s brought about a whole host of “cost saving/efficiency” ,…uh?,…err?,…. “innovations”. I think that cars were a good example of that. Maybe the beginning of the age of “disposable consumerism”? Like I said,… I could be wrong. Just a hunch. Nothing to back it up.

Chris

Geo

Either would of been good. Only if they would of drilled the hole all the way through.

B.B.,

Since you have all of those extra parts, maybe this is your next project?

https://www.gunbroker.com/item/795248471

Kevin,

That was evil!

B.B.

B.B.,

I learned from the best.

kevin

Nah. It’s missing the rubber bumper on the buttstock. Walk on by. ;^)

Michael

BB,

I don’t remember you stating the condition of the barrel when you pointed out the rust in the power plant in part 1. Is rifling in good shape?

And speaking of “good shape”, have you fully recovered from your recent surgery?

Half

Half,

The barrel on this rifle is perfect.

B.B.

BB,

Wonder why the rest was so rough?

Half

Half,

It wasn’t rough. Just a little surface rust on the outside. The major rust was inside.

Maybe the owner cleaned and oiled the barrel?

B.B.

B.B.,

Maybe a previous owner would periodically slather the entire air rifle in oil, dunk it in sea water, drain the sea water, let it bake dry in the hot Gulf sun, and then wipe the outside down with a clean cloth.

That would do it!

Michael

Michael,

As horrible as your scenario sounds a much simpler one is more likely. Nice cold 30°f, Sunny blue sky… day grab that gun from behind the back door and go out for some plinking or peering. Hours latter with a big grin on your face your back in the toasty house with a hot toddy steaming in your favorite mug. In the corner propped by the backdoor is your favorite rusty airgun. Cold metal guts covered with condensate!

Oh you guys and gals in warm country think your off clean as a whistle?

Try on this scenario:. Nice Sunny day outside, maybe 79°f and really not all that humid for a change. You grab your trusty gun and are out the door in a flash. You see the Starlings, cock that barrel, hmmm metal feels pretty cool, load a pellet…bang…bang…bang and yet another Starling falls to the master pester! Gettin’ kind’a warm! Sun’s high and a cold one sounds mighty good! Not a Starling to be seen! Back nside, rusty gun back by the door, POP TOP KISH!!! Boy this (enter libation of choice) tastes good, that AC shure feels good after that HOT Sun!

Only real difference is when the condensation collects on all the inards!

shootski

B.B.,

Wouldn’t the clean barrel simply be the result of shooting only pure lead pellets?

Siraniko

Siraniko,

That would be my thought.

B.B.

BB,

When I said rough I really meant rusty.

I’d say you’re correct. I guess all but the laziest or most uninitiated would know to take care of the barrel. That would carry over well from firearms usage, I guess. The power plant isn’t part of the gun when speaking of firearms, so the need for care in an airgun’s secret innards would not be as obvious to a powder gun user.

Half

Half,

You should see the inside (they use more spendy metal and coatings on modern firearms than the old airgun gals were afforded) of all the AR-15 and clones that our firearm only brethren and womenfolk run dry as a bone! If they get to 2500 rounds the action is usually toast.

I looked at close-ups of the gunbroker .22 427 Kevin was beating B.B. up with (above) and suspect that the inside might look a little like Michael’s inside before the Magical hands (wand) of Tom’s touched it . The “furniture” on the Kevin “find” looks like it might smell of Lemon Pledge! Lol!

shootski

Interesting discussion on possible “Made-In-China” airguns coming into Spain; seems Gamo might be facing competition in their home turf. Not surprised; when Mrs. and I were in Madrid 5+ years ago, we found out the city now had its Chinatown. One of my cousins, a Madrid resident, told us Spain had been luring Chinese investors for years with tax breaks and an easy path to Spanish citizenship.

Would love to see the español instructions for those guns, and see if really written in Spanish, or if in “Chinespan” or possibly “Chinglish,” for the North American market. For a good laugh on the subject, this has become FM’s “go to” site: Engrish.com. FM ees bad boy, he like ethnic humor.