by Tom Gaylord

Writing as B.B. Pelletier

Diana 35 pellet rifle.

This report covers:

- Disassembly

- Trigger pin

- Mainspring and guide out

- Dry inside

- Out comes the piston

- Cleanup

- Assembly and lubrication

- Mainspring

- Gettin’ it back together

- Assembling the trigger

- Done

- The difference

- How does it work?

- Summary

Today we do something that’s been on my mind for months. This Diana 35 was part of a deal I made with reader, Carel, from the Netherlands. I bought it because I wanted to turn a larger Diana into a sweet-shooting rifle like reader, Michael’s, Winchester 427/Diana 27 that turned out so nice. The Diana 35 is larger than the model 27 and I thought it was quite similar in the powerplant, which would allow me to tune it the same. It turned out there are significant differences between the two rifles that I discovered as I did the work for today’s blog. We are now going to disassemble, clean, and lubricate a Diana 35.

Disassembly

The first steps in disassembly are identical to the model 27. Remove the barreled action from the stock and put the rifle into a mainspring compressor. Two pins hold the mainspring in the spring tube — the same as the model 27, and, just like the 27, the rear pin was so loose that it fell out of the gun after it came out of the stock. Just the front pin held things together. This is where things got different.

Trigger pin

The trigger on the 35 is an assembly held on the spring tube by a cross pin that passes through flanges on the spring tube and flanges in the trigger group housing. The 27 has nothing like that. This pin has to be removed to get the larger ball bearing trigger cage and the piston out of the spring tube.

But the trigger has a stout return spring to be dealt with. When the crosspin comes out this spring takes off like a shot with a departing “ping.” The trigger unit can then be lowered from the spring tube and you’ll find this return spring on the floor over by the kitchen sink.

The cross pin (yellow arrow) holds the trigger assembly to the spring tube. It’s under a lot of tension from the trigger return spring (blue arrow). The cross pin has to come out for disassembly. Don’t worry about the return spring — it self-disassembles!

The Diana 35 trigger is an assembly that comes out as a unit.

Now there was clearance in the spring tube for the other parts to slide out. Tension was put on the trigger cages inside the tube and the second powerplant crosspin fell out on its own. Then it was just a matter of backing off the tension of the mainspring compressor and the mainspring pushed everything out of the spring tube.

I had to use a short metal pusher (blue arrow) to press against the trigger cages because, unlike the 27 trigger, the 35 trigger cages are about a half inch inside the spring tube when the rifle is together. On the 27 the black inner ball bearing cage is outside the spring tube when the powerplant is together and can’t be pressed by the mainspring compressor directly.

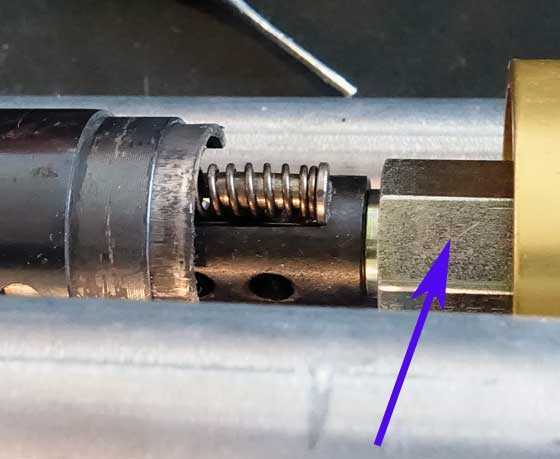

A metal pusher (blue arrow) connects the mainspring compressor to the inner black ball bearing cage of the 35. This photo also shows the spring that pushes the two cages apart. There is a short spring guide inside this one.

This is a Diana 27 that’s still assembled but the end cap is off. You can see the black inner ball bearing cage that the mainspring compressor presses against.

The Diana 27 has the same two bearing cages with a spring pushing them apart, but there is no spring guide for this weaker spring. The arrow points to the place where the trigger blocks the silver bearing cage.

There are the two bearing cages, the bearings and the spring that pushes them apart with its guide. The difference between the 35 and 27 triggers is the strength of the coiled spring, the guide and the diameter of the silver outer cage.

Mainspring and guide out

Once the trigger cages are out the mainspring its spring guide comes out of the rifle. Was it broken like BB thought? Was it bent/canted?

NO! It’s straight as an arrow and fully serviceable, if not as powerful as a new spring. I could not have had better luck!

The mainspring is still serviceable. I see some partially collapsed coils on the both sides, but the spring is still straight. It will go back in the rifle.

Dry inside

The spring guide fits very tight inside the spring, which is a good thing. But there is no lubrication! This powerplant is bone dry! I think this might be the first time this powerplant has been apart, because there is varnish from old oil on some of the parts, and no fresh lubrication. That’s a Diana factory trait from this era.

Out comes the piston

To get the piston out the barrel has to be separated from the spring tube. I noticed as I did this that the pivot washers were lubricated with oil. They should have some grease in there and moly is recommended, but from the 1950s to the ’70s, oil was how it was done.

Once the barrel was off the gun the cocking link came out of the piston and the piston slid out of the spring tube easily. At first it looked corroded, but that was just dirt that wiped off with a rag. The piston was clean and just discolored from assembly

The piston was bright after a wipedown. The discoloration is a result of heat during manufacture. The leather seal is in good shape.

Cleanup

The disassembly took about 30 minutes, including the pictures. Now it was time to clean all the parts. For the most part, all that was needed was to be wiped with a clean rag. But the inside of the compression chamber took a little more than that. I sprayed Gun Scrubber inside and then wiped it dry with paper towels wrapped around a long dowel. That got most of the dirt. I thought there was some lead smashed against the end of the compression chamber, but after a good cleaning it looked fine.

But the outside of the spring tube had some heavy active rust spots. These I sprayed with Ballistol and then scraped with a flat screwdriver blade. When all the bubbly rust was gone I went over everything with 0000 steel wool and Ballistol and the metal emerged smooth again. There was some loss of blue and some pits.

All the cleaning took about 30 minutes. It was time for assembly.

Assembly and lubrication

Assembly and lubrication took about three hours. I will describe the tight spots as we go. First the piston was lubed with moly grease around the front by the seal and around the rear. The piston then dropped back into the spring tube almost by itself.

The barrel and spring tube went together at this time, so the cocking link could be joined to the piston. I lubed both pivot washers, inside and out, and also the pivot bolt before sliding it back through the holes. Now the mainspring could be put back in the gun.

Mainspring

I lubed the mainspring with Tune in a Tube grease, which was my goal back in February, when this project was first dreamed up. I lube the front half of the spring, then stick it inside the spring tube and lube the back half. That way my hands don’t get too greasy.

I lube half the spring then stick it inside the powerplant and lube the other half.

Gettin’ it back together

Once the mainspring is back in the rifle, the ball bearing trigger cages go back inside. This was my first major challenge. The 35 trigger cages are under more spring pressure pushing them apart, and they have to be installed in the rifle so the crosspins that hold them inside the spring tube will align. Don’t forget that spring guide for the two bearing cages that makes the assembly even harder. All of that took me half an hour to figure out. And I could have used a third arm!

Once everything was inside the gun I inserted the front crosspin. I didn’t bother with the rear one because it would just keep falling out on its own. Now it was time to install the trigger assembly. Remember that stiff trigger return spring that tried to escape?

Assembling the trigger

The trigger is a unit, so no problem there, but the flanges and holes in the trigger unit have to align with the flanges and holes on the spring tube. Problem!

I fiddled and fussed for 45 minutes trying to get those holes to align with that powerful return spring pressing everything out of the way. Then the lightbulb went off and I got a small clamp. It isn’t easy to clamp to a spring tube, but it is possible and I almost got the unit on before the return spring decided to take another trip. Oh, well!

Then I installed the unit without the spring, which was easy and tried to manually compress the spring into place, which wasn’t. In all I spent more time doing this one thing than any other part of the entire process.

Done

In all it took me about 4 fours, start to finish, to work on this airgun. This is one I recommend you don’t try as your first project. Do a couple 27s before tackling one of these.

The difference

Let me show you the big difference in the Diana 35. Aside from the more powerful mainspring it all comes together at the rear of the spring tube.

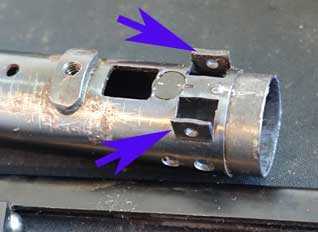

The Diana spring tube is thicker-walled and has two flanges (arrows) to which the trigger assembly attaches. The tube is longer in the rear so the ball bearing cages for the trigger sit deeper inside the spring tube.

Now the barreled action goes back into the stock. The rifle is assembled.

How does it work?

We will need to test how this rifle works, but for now I wanted just to see if everything had gone together as it should. So I cocked it and loaded a pellet. The trigger is now lubricated so I expected it to work a little smoother, but it’s too soon to tell.

The rifle fires with very little vibration. There’s still a noticeable forward jump, but the powerplant is quiet and smooth. And it still cocks with very little effort. Like I said, I will test it for you, including an accuracy test that stretches back to 25 yards.

Summary

Right now I am cautiously optimistic. This Diana 35 behaves very well. It’s not as smooth as Michael’s rifle, but I don’t think it’s lost very much power, either.

We shall see.

Very clear photos, I wonder why such a strong return spring is required.

Not a job I would attempt so I admire your perseverance.

I have heard many a gunsmith comment that they are loathe to

tackle that ball bearing trigger.

On a slightly different note, I just took delivery of a new HW 75 and it’s absolutely gorgeous. Does anyone have tips on how to care for the exterior finish though? When it arrived, there were some small oil spots. I have some G96 gun oil. Will that do or will I need to pick up a different product for the air pistol?

Chanman819,

I am certain that BB will recommend Ballistol. I use it on all of my airguns.

/product/ballistol-lube-non-aerosol-4oz?a=5141

Chanman819,

Ballistol is the best oil for rust prevention, rust removal and general lubrication. Many armies around the world use it for their automatic weapons.

I never owned an HW 75, but I had an HW 45 (Beeman P2) for many years and like the rest of my airguns I wiped it down with Ballistol.

B.B.

B.B.

So you did nothing to the leather piston seal? No soaking in neetsfoot and stand on its butt for 24 hours?

Maybe it is just the photos, but this girl looks like she needs a reblueing? Probably diminish it’s value?

Even if you don’t do it, how would you do it if you did?

-Y

Yogi,

I didn’t notice that but you’re right, there are some bare areas. Some are the spots where I removed some rust.

Overall when she is together most of the bad areas are hidden, so I think I will leave her as is.

B.B.

B.B.,

Quite the adventure. Way to persevere! Luckily the spring did not vaporize into some unseen vortex,.. never to be seen again. I had a spring once get away and found it (on top) of the kitchen cabinets. Having a keen sense of hearing at the time of “launch” is critical to the search and recovery mission. 😉

Good Day to you and to all,…….. Chris

Chris,

Vaporize into a vortex if you’re lucky. It might take out a sofa cushion or drawer face! :^)

Michael

BB,

Thank you for another look “behind the curtain”. Removing the mystery of how these work encourages myself and others to help repair and maintain these old gals. I have never been afraid to “go inside” something to see how it works, but having a good idea what to expect makes things so much easier. Also, your documenting this makes for an awesome reference.

Off topic.

Anyone have an idea what the front and rear sight for a FWB 124 are worth? Have an extra set and might consider selling them.

Jonah,

They are priceless, as in you can name your price. The plastic rear sight has broken over the years and many are needed.

$100 would not be too much for a good set.

B.B.

Had no idea they were that costly. If I can make it to the airgun show on June 22, I take one set with me.

Jonah,

They aren’t that costly. They are that valuable. Shooters who only use scopes will probably not be interested in your sights at any price. But a guy who wants a 100 percent gun and lacks the sights will drool over a set.

I’m saying your market is very restricted, but when you find a buyer you can get your price.

Remember there are going to be free tables for people who bring a few airguns to sell. You might want to place it there, though you are responsible for watching it.

B.B.

Your issues with that spring reminds me of the clips on an old Marksman 1010.We always called them “Jesus” clips because when you were unhooking them they would fly past your head at great speed, heading for parts unknown and you would say”Jesus”!

Rk

Yep that’s we called them too. 🙂

Thanks for the Diana 35 tear-down B.B.! I always love seeing what is inside.

Diana must have had a special assembly jig for the ball bearing cage as they would not accept so much time to assemble a rifle. Might be worth a bit of effort to make up some sort of block/tool to make this easy in the future.

Talking about making tools, I attached an 18″ magnetic strip to a 4 foot dowel – it works great for searching for those metal parts that “ping” out of sight and hide under the bench.

Like your idea of greasing half the main spring, inserting it part way and then greasing the remainder before installing it fully. It is one of those obvious things that I wonder why I didn’t think of it – while cleaning the grease off my hands LOL!

Happy Friday!

Hank

Hank,

I don’t know how Diana assembled the ball bearing trigger cages, but I find tacky grease does the trick, with TIAT leading the pack.

B.B.

BB:

A suggestion if I may: If you use copper wool (or brass wool) on rust it won’t remove the blueing. Copper wool is harder than the rust, but softer than the steel upon which resides the blueing. Also, the tougher rust spots can be scraped with a pre-1982 penny. New pennies have a alloy core in them, but before 1982 pennies were all copper. Once again, the copper penny is harder than the rust, but softer than the steel the gun is made of.

I find it effective to douse things with Ballisol, let it soak over night, then use the copper wool / copper penny on the rust while re-applying more Ballistol as neeeded. Wipe it off, see how it’s looking, put some more clean Ballistol on it and work on it some more.

While cleaning the rust off in this way doesn’t damage the existing blueing, the blueing is sometimes rather thin on older guns, so your may still want to try a few applications of cold blue either way, but it is a lot more optional than using steel wool and a screwdriver to scrape off rust. BTW, I get best results from Brownell’s Oxpho-Blue cold blue cream.

Hope you find this of use!

Motorman

St. Louis, MO (Go Blues!!)

Motorman,

Those are great suggestions.

B.B.

Motorman

If your suggestions work for me this ranks with the best of reader tips in the last several years!

Deck

I should apologize. When I went down to my shop and looked at the package it said, “Bronze Wool” not copper wool. I have “medium” grade. I was still correct about the copper penny, although I suspect it’s actually a copper alloy of some kind.

I’ve not always had the financial resources to purchase the highest grade condition airguns, so I buy what I can afford and then rebuild and clean them up as best I can. The result might not be pristine, but they certainly look much better. I found a Diana 27 that required a tetanus shot after you picked it up. After some work with the bronze wool / copper penny and several coats of Oxpho-Blue, it’s actually not so bad!

Best of luck with this!

Motorman

St. Louis, MO

Motorman

Thanks! Got it.

Deck

Larry

Yep Go Blues for sure. They finally done it.

Hi BB,

This pearl of wisdom reminds me of your approach and the value that you bring to your readers. Found this in the engineering school where I work, put up by students enrolled in a project class.

Rillburgher,

There you go! 😉

B.B.

Love it! =>

Rillburgher

Ain’t that the truth. I like experimenting if you don’t know that already.

I like that!

I have a friend who’s a historian and writer. Along those same lines, he likes to say, “Logical assumption is the opposite of research,” LOL. There is no substitute for having correct and complete information on hand.

“Don’t worry about the return spring — it self-disassembles!”

Thanks, B.B. I needed a good laugh today! =>

Thedavemyster,

I chuckled aloud at that one myself.

Michael

Hey ALL,

I hope somebody goes to the Midwest Airgun Show in Ohio tomorrow. Better yet if they report what they saw!

Not all of us live nearby and it is always nice to see what you are missing…

-Yogi

Hey B.B., I have one general comment on airguns: all of us who own and shoot airguns are ambassadors for the sport; and how we use them is watched by others; hence, we should use them well.

For years, our neighborhood has been mostly military and very gun friendly, to both firearms and airguns. However, there has been a recent rash of shootings of neighborhood pets, mostly cats; some were shot with firearms, and some with airguns. There are more young families with kids in the neighborhood now; and one of them called the sheriff about a guy discharging a firearm, and their complaint was from the point-of-view of public safety. Also, some neighbors wondered how pets were shot with a .22 and no one heard any noise. Another neighbor who knows a bit about guns passed the word around to others that there are powerful airguns called PCPs that are nearly silent.

Hence, our once-fun-friendly neighborhood has become decidedly gun-unfriendly; further, people here now see airguns as “something one buys to stealthily kill their neighbor’s pet.” The sad thing is all this bad publicity for our sport was caused by only a couple of bad apples (one dishonorably discharged from the Armed Forces).

The moral of this story is: we should use our airguns wisely in order to preserve our sport for the future.

OK; I’ll get off my soapbox now, and wish a blessed weekend to all,

dave

Dave

You are absalutly right about using our air guns responsibly. Or any other type of gun or whatever. Like even cars and such.

And I feel sorry for you and others that have to deal with that. It’s a shame it comes to that all the time.

And that’s exactly why I live in the country in a unincorporated area. Search that and see what it means. Again that is a real bummer. Now there’s another thing that makes me mad.

And I hope those people ain’t making up stories just to get things stirred up. I have seen similar things in the past. And it sure makes the other accusing people feel funny when they find out they got caught lying.

I would like to hear more updates if you hear anything else.

“And that’s exactly why I live in the country in a unincorporated area.”

Gunfun1, you nailed it here; we are looking to move, within the next couple of months, to an area like the one you’re in; it will make for a happier life.

Dave,

I do and it is very nice. Best wishes on finding an ideal spot. A garage facing the range (or) an enclosed breezeway like GF1 has would be on my wish list of features. I must go outside and set up where I am at. There is some pretty nice yard sheds that could be outfitted with elec./heat/air conditioning.

What do the ladies call that?,………. a “She Shed”! 😉

Chris

““She Shed”!”

Chris, hahaha! Thanks; I needed a good laugh!

But you have good points here; each time we look at a place, my wife looks at the inside to see if the kitchen is nice, or if the closets are big enough to suit her. I only look at the outside, thinking, “Where can I set up an airgun range that cannot be seen from the road or from either side?”

Thankfully, once you get out into the country, into the unincorporated areas (as GF1 pointed out) there are many good places that fit the bill. =>

Dave,

They do exist. Someplace for the Urban housewife to escape the 5 rug-rats that have been tormenting her all day.

On GF1,…. when he moved there awhile back,… I pictured in my mind a conversation between him and the Mrs. when first looking at the property,……….

Mrs. GF1: “…….. honey,…. this place needs painted inside and out, the roof needs replaced, the windows are shot, the carpet is trashed, the kitchen is outdated,…. I don’t like it!”

GF1: “………. BUT HONEY!!!!!!!,…… it has an enclosed breezeway that I can shoot in all year around! Please Honey! Pleeeeeese! I’ll do anything you want!” 🙂

A man has to know his priorities! 😉

Chris

Chris

It actually didn’t go quite like that.

Read my comment below to Dave.

Maybe this is a hint. We just went looking the other day for a dirt bike for the wife. She had a Enduro when she was a kid if you remember what they were. Basically a dirt bike with head lights, tail lights and turn signals. Nothing big probably just a 125. And of course you know I’ll have to ride it to make sure it’s ok. 🙂

GF1,

Hey,…. I can imagine,… can’t I? I can however see that type of conversation happening amongst a couple with a serious air gunner in the family. Glad you are happy and can shoot so much at will.

Chris

Chris

I have to say air guns, 4 wheel’n and fishing and the kids and the wife out here having fun is what’s making me hold out till retirement.

If I could quit working today I would. I just got way to many things I want to do rather than be at work. 🙂

Gunfun1, my first motorcycle was a Yamaha 175cc endure; thanks for bringing up those memories! =>

Dave

Cool my first was a Yamaha 125 enduro then later on I got a Suzuki RM 125. The RM was a rocket. That is the bike I use to Moto cross and scramble track race. Yep that was some fun stuff. Nothing like when those old 2 strikes hit the powerband. 🙂

Dave

Read my comment to you below.

But yes much happier.

Thedavemyster,

I certainly don’t condone the elimination of someone’s pet of any kind with lethal force or even non-lethal force such as airsoft guns. However, pet owners have responsibilities to keep their pets within their property boundaries and typically on leashes or strict control when outside their property limits. Feral cats and dogs are a huge problem to wildlife as well as pets. Pets permitted by their owners to run wild are typically contributors to the problem.

As with most issues there are two sides that need to clean up their acts.

I hope the neighborhood gets together and resolves all of the factors in this case. If someone has factual evidence of wrong doing it should be reported to the Sheriff/law enforcement.

shootski

Shootski

And that’s the truth too. The pet owners should be responsible. And that is exactly how you end up with wild dogs and cats.

The problem starts somewhere.

Shootski,

In our area, you can only have 3 cats or 3 dogs; if you wish to have more than that, then you have to have 5 acres of land (in which case you can have horses, too), or 3 acres if it is zoned “Agricultural.”

Dogs have to stay on the owner’s property, or be on a leash if they are being walked; outside cats can wander, but if they cause property damage (like come in your yard and rip a screen on your back porch), Animal Control will trap them and take them away.

Feral cats, if their ears are tipped (to show they have been Trapped, Neutered, & Released), are allowed to roam the neighborhood to keep down the rat population; but if they get reported as a nuisance, Animal Control will trap them and take them away.

Local Sheriffs are very active and responsive in our area; so there’s really no need to take the law into your own hands and shoot someone’s pet.

My basic point is this: whenever there’s a school shooting, there is more pressure to ban firearms; and whenever someone uses an airgun to shoot someone’s pet, it just ups the pressure to put more restrictions on airguns; the better we behave, the better we make our sport look.

*shrugs* Maybe I’m just getting too old. =>

Thank you,

dave

Dave

Nope not to old.

Just more wiser

How many times do we talk before someone listens.

Amen.=>

Dave

Yep.

Shootski,

I am afraid I have to disagree with some (just some — I agree with most) of what you wrote above.

“There are two sides that need to clean up their acts” presents, I feel, a false equivalency. A pet owner whose animal gets out is not the kind of vile, concentrated evil that is a “person” who would shoot a domesticated pet owned by a neighbor.

Yes, dog and cat owners should keep their pets indoors, leashed, or in their yards (with tall-to-buried fencing). But my mother’s cat was shot by a neighbor with an air rifle while the cat was lying down in my mom’s yard, next to her front stoop. Would it be O.K. to shoot a neighbor’s dog while it is lying down in its owner’s backyard?

In its first year my next door neighbor’s dog briefly had a habit of bolting out the front door whenever one of the little kids would go outside. Would it have been O.K. for me to pop it with my Sheridan Blue Streak the moment it reached the street? Of course not.

Anyone sick, twisted, and sadistic enough to derive pleasure from harming a domesticated animal needs to be removed from the streets before he starts his serial-killing spree.

Michael

Michael

Laying down in the back yard is one thing.

Thank goodness we have law enforcement and laws in place.

I’m sure they will get it straightened out before us law abiding citizens do.

Right.

Michael,

Post hoc ergo propter hoc “after this, therefore because of this”

That is your fallacy in your reply to me. At no point did I state an equivalency. I very simply stated:

As with most issues there are two sides that need to clean up their acts.

“A pet owner whose animal gets out is not the kind of vile, concentrated evil that is a “person” who would shoot a domesticated pet owned by a neighbor.”. Tell that to a person who loves birds and is forced to watch a neighbors cat that “gets out” all the time with one of the beloved birds in its mouth Stone Cold Dead not because it was hungry but because it was bored and reverted to the instinctual Hunter but a hunter with no taste for its kill. A reason to shoot said cat? Of course not. But certainly a reason to confront the cat owner with warning that the owner of the cat and the cat will be dealt with according to the laws governing in the location.

At no point did I state anything about condoning the killing of anyone’s pet! And, even stated that.

You may chose to disagree with me anytime; I served twenty two years to help allow you to retain that right. But please read carefully what I wrote and then think thrice before responding with a Logic Fallacy of the first order.

I don’t disagree with your sick killer premise! See, and truly feel, the discussions by your fellow readers below and learn. My point is that airguns and firearms don’t jump up and kill things; people do!

And they do it for many different reasons typically not easily determined. Studies are a dime a dozen; if they were so accurate we would be able to predict who is possessed by the Devil and seek to help them come to the Light. May God grant us the path to the wisdom or the medical skill needed some day.

shootski

Shootski,

My Latin teacher Dr. Duffy always translated it to “After this, therefore, because of that,” but the distinction between the two is not so much of translation as it is of modern English grammar and its treatment of the translation, if I am making sense.

Part of my first Masters, in Literature/English, is in Rhetoric, so forgive my, well, I’m sure there will be something. Additionally, I taught Post Hoc fallacies (and Ad Hominem, non sequitur, petitio principii, ignoratio elenchi, and a bunch of other Latin phrases) and argumentation for thirty years to college freshman and sophomores.

First, I might have been guilty of a fallacy. (Not sure. I’ve been up for just over twenty-four hours, and my brain is tired.) I wonder, however. You made an implicit equivalency that both those who shoot neighbors’ pets and the neighbors who leave them unattended are guilty of something. I would argue that the disparity between the degrees of guilt are much like the difference between shooting a bullet and merely throwing it, night and day (Ref.: Larry Miller). How is that fallacious?

And even if it is fallacious (but again, my doubts), are you certain you wish to characterize it as a Post Hoc fallacy? After what therefore because of what, exactly? Instead of an informational fallacy, shouldn’t you instead accuse me of a formative one? Not the substance of my argument but rather the way in which I made it?

Finally, the introduction to your entire post is, to translate the aforementioned ignoratio elenchi, a red herring. My remarks were about the despicable, immoral, slimy, subhuman pet-killer (now THAT’S some Ad Hominen!) being not in the least less execrable because the pet was not indoors or even on the precise private property of its owner. Shouldn’t one address the matter at hand, not some shiny object with nothing to do with the real issue under discussion? Gah! One could argue that by responding to the red herring, I have fallen for “it.” And of course, in so doing, one risks presenting other red herrings.

I see I have committed the fallacy of Tu Quoque, the most infantile of them all. I will apologize for that, too. ;^)

Oh, I have it, what I should apologize for! Above you might have excellent points and even a reasonable defense of your IDing my comment as starting with a Post Hoc fallacy. I confess I do not know as I am too tired to read beyond your first few lines. I do promise to try to remember to read them tomorrow, however.

Bonum Nochte,

Michael

Hah! I must be very tired indeed. I wrote “finally” at the start of my third-to-last paragraph.

Michael

Dave

Maybe you should tell your neighbors to read today’s blog. Maybe they can get some useful info on the subject. Maybe they might learn something.

“Maybe they might learn something.”

Gunfun1, good point; I’ll keep you updated…till we move; my wife is convinced that your way (living out in the country) is the way to go; she wants to move to a less-congested and more gun-friendly, area.

I say “Amen” to that. =>

Dave

Up above Chris made a comment about how me and my wife’s conversation went when we went to look at the house.

Luckily for me and the kids my wife was a country girl. So it wasn’t to hard for the whole family to say yes when we went to see it.

They love it. It’s quiet. Plus both of my girls are Tom boys as well as my wife. They can shoot and ride the 4 wheelers with the best of the boys if you know what I mean. Heck my oldest daughter moved out on her own about a year ago (21 years old). She and her fiancé come over every weekend just to shoot and ride and they fish over in the pond at times. She goes dad don’t worry we will come out to see ya. It ain’t no fun in the city like it is in the country. I’m taking it as she misses old dad. 🙂

I hope you find what your looking for.

Gunfun1,

No FAIR! I’m a sentimental Irishman, and you just squeezed a couple out of the ol’ tear ducts.

Happy Father’s Day!

Michael

Thanks Michael and likewise.

Gunfun1, luckily for me, my wife is also a country girl, who grew up hunting and shooting in the backwoods; hence, SHE is the one looking for a spot in the country for us. =>

Dave

That’s good. I’m betting you all will end up in a nice place.

You will have to give a update when you find the place your looking for. I will be waiting to hear.

Dave,

Try and find a house on a piece of land that borders, on at least two sides, a refuge, State Park, Forest Service land, BLM or other ground that someone can’t sell to developers. Otherwise you will be forced to keep moving as my family did a number of times. In the city you need to be versed in all the current rules, laws and ordinances that cover your activity, talk to your neighbors about your activity in advance and invite them to join you to see first hand your concern for safety, risk management/abatement and the why you shoot…then you need to build your range and ensure your noise stays within your property boundaries. I used a “She Shed” with anecohic baffles surrounding my gunport and also surrounding my target but; keeps most sound contained and makes setup easy…sold that place and am looking for a place that I can dig a 100M range underground with perhaps a plastic or concrete drainage pipe and collector boxes for most of it.

I DON’T WANT TO EVER MOVE AGAIN!

shootski

Shootski,

From what I see in Ohio,… the older farmers do not have anyone to pass “the farm” onto. (other career’s are more lucrative and easier) Aging,… and maybe a bit short of money in their elder years,…. selling 5 acre lots of road frontage can be a pretty lucrative option to quick cash. They still have the back 500 acres of farm land,… which in most cases has been leased for years already to big outfits.

The country side near the very small town that I grew up in is testament to that. A few are popping up near-ish here now.

Your underground 100M range sounds very interesting.

Chris

Chris

If this makes any sense to you the country is getting farther away from town where I live.

Those big 1000 acre farms have turned into I guess what they call them is country subdivisions. Sad is all I can say.

That’s one thing about where I’m at. The farmer won’t sell out to the money hungry’s out there.

It’s like two different places. The highway is like the Wall. All I can say is I don’t want to live on the other side.

GF1,

It is not a matter of selling out to a developer,… it is the once farmer that is the one gaining (directly) for whatever reason by breaking up his road frontage in 3-5 acre lots. 5-10,000 ((per)) acre easy. Direct sell to the home owner.

If being 60-70-80 and in the same shoe’s,… I can not say that I would not do the same. Selective logging is pretty big too with those that have good wooded acres. It does serve a purpose and does help the woods develop further,…. but it generally leaves the woods a wreck from heavy equipment and cut limbs.

Chris

Chris

The farmer that owns all the land behind me won’t even sell like that.

The only reason I was able to buy from him is I had good references and he actually knew my dad and his farm which I didn’t know till after he sold to me.

He told me about my bird dog watching for the neighborhood farms if you will when I was a kid. I got recommended and actually watched a couple of his dogs when he went on vacation. Is that karma or what. Or should I say God doing what he does.

Guess it all depends on what the situation is. But this old farmer guy is a character. Always enjoy talking to him. And he is as stubborn as a ox.

I have a feeling that’s what I’m going to be like in another 30 years to if I make it that far. And why not.

Gunfun1,

If you’re too close to either river, in 30 years it’ll all be flood plain. :^( I have a brother-in-law in Ballwin, and they have a flooded backyard half the summer these days. As recently as ten years ago, he says, it would be two or three days a summer. Ten years before that one day every couple years on average.

Michael

Michael

Now that could be true.

Chris

So they don’t have anyone to pass the farm onto.

So tell me what will happen some years from now.

Hope your aways away from that.

Shootski,

Now that I have retired and would have more time to use it and justify it, my wife and I have mused about buying a small piece of remote property and install an indoor range made up of shipping containers end-to-end and a narrow outdoor range beside it.

Now that I know what to call it, a “She-Shack,” I might have a better chance of talking her into it!

Michael

Come on ya all.

You haven’t seen the insurance commercial about the lady’s she shack.

I don’t watch TV and know that commercial.

Gunfun1,

I’ve seen the ones with “Get a new maid?” “I’m not a maid!” “.. . Not the maid we want but the maid we got.” (I love it. Somebody remembered the old Sec. Def. Donald Rumsfeld line, “We go to war not with the army we want but the army we have.”) Other than that, I haven’t seen any other insurance commercials. Oh wait, the Dennis Quaid ones, yes.

Michael

Michael

It’s ok you haven’t seen any. They all ain’t worth seeing anyway.

= :^)

Michael,

Chris USA actually introduced the She Shed concept to the thread. I just used it since my wife called mine My Shoot Shack. I also have a 24’x 4′ x7′ Kayak Kennel ;^)

I think if I build my 100 meter underground range I’ll call it my Shooting BORE!

shootski

Shootski,

Wouldn’t it be very boring to hit the same target all the time with no need to compensate for wind and other external factors? 🙂

Excellent to work up zero and other ballistic factors prior to taking to the field though.

Siraniko

Siraniko,

You would think so wouldn’t you!

Actually I do a great deal of 10 meter position shooting in .177 and don’t need any wind to make it any harder than it already is. I also work up a large amount of different ammo for my DAQ Big Bores and various firearms since new bullets are always coming out with different shapes, bearing surfaces, form factors and weights. The wind is something to add to a good baseline after all the “boring” work is done. I’m actually never bored shooting anyplace but the 100 meter personal range with positive ventilation, heat and A/C in My compound has always been in the back of my mind.

Shootski

Heh, heh. I’m glad I took one last look before turning off my machine.

My roommate in school lost his keys one drunken night and had to sleep in our landlord’s kayak kennel until I came home the next morning from my girlfriend’s. I hadn’t heard that term until just now, but that’s what it was. I think the landlord was using the kayak that weekend, probably. Lucky for Ross.

Shootski,

Here is a site that makes products like you mention. Not sure how many companies of that type are about the U.S., so I thought I would mention it. The water and beam products are made very nearby. They can custom design and build units.

https://www.prestressservices.com/united-precast/

A buried set up is an interesting concept. More sound proof I suppose, but water management would be more an issue. Can’t be seen from the air. Good. Setting units on top of level ground and then even burying/mounding dirt on that would seem sufficient and easier. Either way,… very impressive.

Best wishes on getting it built someday.

Chris

ChrisUSA,

That’s the stuff! The company you provided the link for looks very well integrated and professional. My wife and I have been looking for land for a home/ family compound in Utah, Wyoming, Idaho and Montana for the past month or so and have another month scheduled before we return home. The idea of above ground is certainly a possibility if for some reason: rock, perk, frost heave depth and excavation isn’t feasable. A D9,10 or 11 Cat should be available in the search area and any of those will make quick work of digging a trench with space for the BORE and end boxes along with the backfilling. I learned about excavation liners and dewatering from my dad so I’m not too worried about water intrusion. My biggest concern is about cooling/heating costs which is dealt with nicely by putting it all underground. LED lighting certainly makes a huge difference in operating cost and I might even be able to use geothermal to provide hydronic heating. The idea has always been to use a tubular precast concrete tube for most all of the 100 meters because of its inherent strength and lower cost but those rectangular sections on the linked sight could provide for two or even three shooting lanes easily…hmmm. Note to self: Check $$$$ ∆! The end boxes have always been envisioned as the storage shooting bench, target system control area and at the other end the longest target/backstop media area. I’m certain I’ll need to put enhancements together incrementally since it will be funded out of cash flow after the initial build.

I just wish we had decided on getting serious about getting out of the Eastern USA sooner!

shootski

Shootski,

Good. Glad I was able to offer something. Since you are looking out West,… there should be something out that way. I do not know how far shipping cost becomes impractical. At least it gives you ideas of the product line and maybe something you can find closer. Underground = lower heat and A/C cost does make good sense.

Chris

Dave,

You almost certainly have a future serial killer in your neighborhood. I would put the likelihood at over 90 percent if two or more offenders are responsible. If it is one offender, then it is a 99.9 percent chance.

I know that is a heckuva statement to make, but take it from someone who because of a former profession has read thousands, perhaps tens of thousands, of pages of scholarly writing on the subject of serial killers. Psychologists, criminologists, profilers, homicide detectives and experts of associated disciplines agree on precious little, but one thing almost all concur is that the expression of sexual sadism through escalating (in number, scope and cruelty) violence against domesticated animals is an entirely reliable predictor. It is pervasive enough in the development among serial murderers and rare enough in people who are not serial murderers (99.99 percent of us) that it is considered a near certainty that a serial animal torturer-killer will, if given enough time, means and opportunity, become a serial killer of human beings.

I hope the local authorities in your area have quietly briefed the Bureau. If a perpetrator of animal killing sprees is caught early enough, the system can try to stockpile charges and convictions such that with a knowledgeable sentencing judge, consecutive maximum sentences can add up to many years in prison, during which, one hopes, the offender will commit repeat offenses which can then be used to stack up more and more consecutive sentences (or at least parole denials) to be stretched into a lifelong incarceration. This is often how extremely dangerous people such as Susan Atkins, Richard Speck and, one hopes, Leslie Van Houten, never are freed to further prey on society.

Michael

Michael

To much assumptions.

Start over and see where the problem is. You done went to far.

But then again maybe that’s what happens. The jury or the Lawyer blows up the situation.

Man don’t get me on the jury. We will be there for weeks and weeks and weeks. Sorry for all that want to get it over with and go home.

And yes I have served in some federal cases with jury duty. And do they really want a true answer. Really do they.

Gunfun1,

I’m not assuming anything. I am going on what Dave described. He was writing casually and informally, but if the situation in his neighborhood is accurately described, the factual data applies, and the statistics are precise and, as the British might say, spot on. This is social science, but it is established and settled knowledge. It is correct and factual, not a matter of opinion.

And one cannot extrapolate too far on a subject such as this or take it too seriously. To use Quint’s sales pitch to the civic leaders of Amity Island as a metaphor, a serial-killer-in-training is a “bad fish. Not like goin’ down to the pond an’ chasing bluegills and tommycots.” We are not talking about some bratty, wayward teenager with too much spare time and who needs to be straightened out. Sociopaths have brains so badly broken they can’t be fixed, and trying to do so is too dangerous to the public safety even to be entertained. No, a serial animal torturer-killer is almost certain to become a serial murderer if, as I wrote, he is given enough time, means and opportunity to do so. Period.

Ask any experienced homicide detective, abnormal psych PhD. or federal agent. I have spoken with dozens of such folks over the past thirty years, and their heads nod up and down. Then they share anecdotes that support this truth. Read up on the subject. Journal article after journal article describes the same phenomenon with little variance and cites study after study. The data is there.

And of course providing due process as defined by the Fifth and Fourteenth Amendments of the Constitution and subsequent case law goes without saying. Incidentally, as an absolutist when it comes to due process, to my frustration I have found I cannot survive voir dire as a potential jurist. I am excluded practically on sight as apparently I am a bit known in these parts for my championing jury nullification when it proves necessary to correct judicial error. :^)

Michael

Michael

From reading more of what Dave wrote it sounds like you might be right.

Michael,

Dishonorably-Discharged-Boy (DDB) has killed two pet cats, one with an air rifle and one with a .22.

He would have been arrested, but the woman whose cats he killed was pressured by her husband not to press charges; the husband has terminal cancer, and is afraid that DDB would cause issues for his wife after he passes away. DDB also lied to Animal Control saying cats were damaging his boat cover, and he wanted them trapped. Animal Control talked with the Sheriff’s Department, and, even though the woman did not press charges, DDB has been warned by both of them; he is “on their radar.”

As a result of all that, things have been quiet lately.

But I still want to do the Gunfun1 thing and move to the country. =>

Thank you,

dave

Dave,

The DD speaks volumes. The military can tell a rotten apple out of an otherwise healthy bushel pretty quickly. They know what to look for and can usually flush the effluent without too many complications. Every drill instructor in the Service can just smell it and see it in a recruit’s eyes. If somehow one squeaks through Basic without messing up, as I have heard it from one retired drill Sergeant — a student of mine who had more to teach me than vice-versa I’m sure — his Sergeant will probably put a “code” on his records for everyone else to see. Different symbols for different types such as malingerers, pathological liars, thieves, bad-tempered, violent-tempered, dangerously stupid, domestic abuser, substance user and so on. These little curious, unofficial notations follow bad news all the way to the brig.

Michael

Dave,

This fellow sounds exactly like everything above. Everybody should indeed be very careful around him and not provoke him. At his relatively advanced age, he could be pretty close to getting there if he is not already.

I know this sounds ridiculously cloak-and-dagger, but his last C.O., perhaps a local detective, and definitely the local Sheriff and the Animal Control officer should each send a brief letter to the closest FBI field office with his full name, address, and phone number (all available information through open sources), and the following description: Young adult male, dishonorably discharged from [military branch and year], shot and killed neighbor’s two cats, but complaint not made and no charges filed. Across the top of each letter should be in bold all-caps print: ATTENTION: PET TORTURER AND KILLER. Ideally they should all be addressed to the same Special Agent. The Sheriff (not his office or a deputy) should direct this and would be able to choose the right Special Agent. Probably the best way for all of this to happen would be for him to call the Special Agent directly.

It all seems silly, but again, this is a bad fish, not some bluegill or tommycot (whatever a tommycot is — Robert Shaw did a lot of line-improvising).

Michael

Well . . . a long vacant former Skeet & Trap club 15 miles from my front door and 50 miles from downtown Chicago. Buildings have been removed but all of the berms are still there. 34 acres. Heavily wooded perimeter and curving gravel drive. Agriculture zoning. The initial listing was for 1.5 million, but that was five years ago. I’ll bet they’d take a third or even perhaps much less for it now. :^)

Michael

Winter (no leaves).

Michael

Still way to many houses around for me.

Gunfun1,

The woods entirely around the open area are so thick and deep one cannot hear the highway or county road that go by it. There is absolutely no visibility through it, either. And the angled berms are all around. One could from any position in the open area shoot a .50 Barrett in any direction and be in no danger of hitting anyone or anything in civilization.

A county forest preserve on one boundary, a protected, historic, natural creek on another boundary, a state-protected wetlands/fen on another boundary, and a county pet rescue shelter on the remaining boundary. So, no development can happen adjacent to it, and there is no retail, industrial, or residential zoning on any land next to it.

But I’m not going to buy it. Not really in the market, except for daydreaming.

Michael

GF1,

Also, read what I wrote below in response to Shootski.

As for its remoteness, it feels like it is 150 miles from the nearest subdivision, not 150 yards.

The woods and berms are so numerous and staggered (by design of the previous sportsmans club that owned it), one could open up a “Naturist” resort on the property, and no neighbor would ever see so much as a bare shin!

Michael

Michael

Maybe but the picture you showed with the trees when they were leave covered looks like the surrounding houses are pretty close to me. And alot of them.

What I wonder is if them subdivisions were around when the shooting range was active. You know the more people in a area will some how be more of a chance for complaints.

I don’t want any neighbor’s for at the least 1 mile. Now maybe air guns that are quiet you could get away with closer distances. But I like shooting firearms also at times. Just me. The less chance of someone poking their nose around the better the way I see it.

Good points. True, when it was a going club, those subdivisions weren’t there.

Michael

Thanks. I kind of thought that.

Bet it was a fun place when it was going. Kind of a shame it didn’t survive.

I look up old dragstrips that have vanished over time. And of course wondering exactly why. Kind of a bummer actually.

There was a stock car track in the out skirts of a nearby small town. It had been there for many years and there were no houses in the area near the track. Then the developers came in and built sup-divisions and then the people buying the homes complained to the township about the noise. It’s like people who buy a home near a railroad track, what do they think is going to happen? They should move the track because it’s too close to the house…idiots!

Geo

Dead on. Bummer how it works that way.

Michael,

Make certain that you don’t become responsible for the potential lead remediation that might be lurking in those berms and shooting zones.

If you can do get an environmental assessment and a clean soil and water Bonded Garanty/Waranty Deed stipulated as a condition of the purchase. If it is a quitclaimed Deed RUN do NOT walk away from this piece of land.

Could be a fantastic deal but complete required Due Diligence is absolutely necessary.

Best of luck!

shootski

Shootski,

Take a look at what I wrote responding to Gunfun1 above.

I’m not seriously thinking of buying it. I did drive in last week and took a walk around around though. It is gorgeous.

It must have the bones of a deep water well on the premises, but the septic system has to have been sealed off and a new owner would probably have to pay for city sewer/water connection. Electric is right there, as is land telephone and high speed internet. It is a five minute drive to an Interstate and a ten minute drive to the commuter rail system for the Chicago area.

Some gravel back-fill has been done very recently in places, and someone has done commercial/agricultural grass cutting every couple weeks, from the look of it. There is a small (about a half acre?) spring-fed low-lying patch that could probably be dug into a tiny fishing hole.

Michael

Happy Father’s Day to B.B. (the Godfather of Airguns) and all other Dads. =>

Thedavemyster,

A happy Father’s Day to you and all the other Dads and Dads to be too!

Siraniko

Thank you! That is much appreciated! =>

Siraniko

It’s funny you say that. Dad’s and Dad’s to be.

This is what my oldest daughter told me this morning. And her fiancé was standing there also. She goes happy Father’s day Dad. And happy Father’s day Diago. That’s her fiancé.

So yep I’ll be a first time Grandpa soon. How about that for a Father’s day surprise. I’m happy. 🙂

Gunfun1,

Congratulations are in order then to all of you!

Siraniko

Siraniko

Thanks.

Ambassadors of Airguns

Hey brothers & sisters (as I hope there are many women who are airgunners and read this blog),

I didn’t mean to start any kind of controversy among us with my [previous] story; all I meant to point out is that anyone who owns and shoots an airgun is an ambassador for the sport; and, even though it isn’t fair, the entire sport may be judged by how each and any one of us uses our airgun.

Long ago, a pastor told me, “Now that you’ve publicly said you’re a Christian, people will scrutinize you…and judge all of Christianity by your actions.”

Me: “That’s not fair; I’m just a big sinner, saved by grace.”

Him: “That’s just that way human nature is.”

For example, look at Corrie Ten Boom; she made a speech about forgiveness, and a couple minutes later, the Nazi guard from the camp where her sister died asked her for her personal forgiveness:

http://www.familylifeeducation.org/gilliland/procgroup/CorrieTenBoom.htm

She was surely “on the spot;” everyone was watching to see what she would do; I’d like to think I could have done what she did, but she did what she could (shook his hand) and God did the rest (allowed her to forgive him). In much the same way, any of us could find ourselves on the spot.

Whenever we airgunners are out in public (even if we don’t have our airgun with us but we’re a known airgunner), people will judge our sport by what we do and say; so we should present it in the best light possible.

Anyway, once again, I wish a blessed Father’s Day to all Dads, and also to all the Moms who have lost their husband and have to be both Mom and Dad to their kids…more power to you for all you do!

Peace & Blessings,

dave

Dave

I’m glad you brought it up. All very good discussions this weekend.

TheDavemyster,

I read the linked piece and it once again caused tears to well up in my eyes even though I had read it before in Guidepost.

Wish that we could all have such strength of Christian and other faiths will for forgiveness.

Dave may you be doubly blessed for your Witness to God!

shootski

Happy Father’s Day!

Dad’s! As Father and a Grand Father I salute you all for the very important job you all do for our society’s health and well-being!

shootski

Amen! =>

Happy Father’s day to all the Father’s out there.

And thank you all that said happy Father’s day on the blog today.

And I thought I would repost Siraniko’s comment above and mine. Got to brag a little here.

“A happy Father’s Day to you and all the other Dads and Dads to be too!

Siraniko”

And here’s my reply.

“Siraniko

It’s funny you say that. Dad’s and Dad’s to be.

This is what my oldest daughter told me this morning. And her fiancé was standing there also. She goes happy Father’s day Dad. And happy Father’s day Diago. That’s her fiancé.

So yep I’ll be a first time Grandpa soon. How about that for a Father’s day surprise. I’m happy. 🙂

Congratulations! =>

Dave

Thanks

And you know girl or boy they will learn to shoot. 🙂

Let’s see if I can wait 6 more years for that time to come. That’s the problem now.

“And you know girl or boy they will learn to shoot.”

Awesome! =>

Dave

Yes it is. 🙂

Gunfun1,

Congratulations! Here’s wishing you (a) healthy grandchild(ren) you never know could be more than one!

Your ONLY mission is to spoil them with LOVE!

shootski

Shootski

Thanks

And we have had twins on my mom’s side of the family so you never know. I was actually thinking about that earlier.

And right definitely going to put the spoiling on in all ways. 🙂

HAPPY FATHERS DAY! To all of my fellow airgun bloggers.

Yes, happy Fathers day to all!

Gerald