by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- What are firearms?

- What is an explosion?

- What starts the burning?

- Ignition

- Smokeless powder

- The hammer-fired system

- Evolution

- Hidden hammer

- Striker

- On the airguns

- Valve stem

- Summary

Today I want to explore a gray area in airguns. It’s gray because airguns operate differently than firearms, so we will begin our discussion with firearms for better understanding.

What are firearms?

Firearms are devices that launch projectiles by means of a chemical explosion. To start the explosion there needs to be some kind of initiator. In the beginning, when the gunpowder that we call black powder was in use, all it took was a spark or a hot coal to start the explosion.

What is an explosion?

An explosion is a violent expansion of gasses. Pop a balloon and it explodes. Anything that burns can explode under the right circumstances — even dust. The flour that bread is made from can explode so violently that it can kill people and even level huge buildings.

An explosion requires the right conditions. A handful of black powder placed on a tree stump and set afire will burn in a flash but will not usually explode. Confine the same powder to a vessel that restricts the expansion of gas, though, and the explosion will be quick and powerful.

What starts the burning?

If we are talking about black powder, heat starts it burning. Even a small spark can ignite it and, once the burning begins, it spreads to the neighboring particles of powder at a speed of 8,000 to 11,000 f.p.s. HOWEVER — if the black powder IS NOT packed tight and there is air space in-between the powder granules (but the powder is inside a container) the speed of ignition increases, often producing so much pressure that it blows the container apart!

Smokeless powder, on the other hand, burns very slowly when it’s loose and in the open, but extremely fast when confined. It actually burns much faster than black powder when it is tightly confined.

Now let’s look at a video demonstration of the relative burn rates for smokeless powder and black powder when both are burned in the open.

Ignition

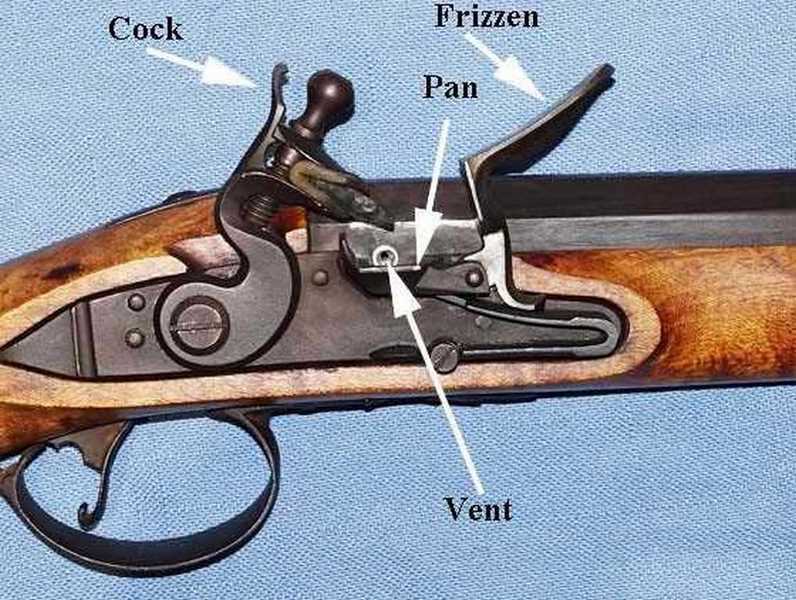

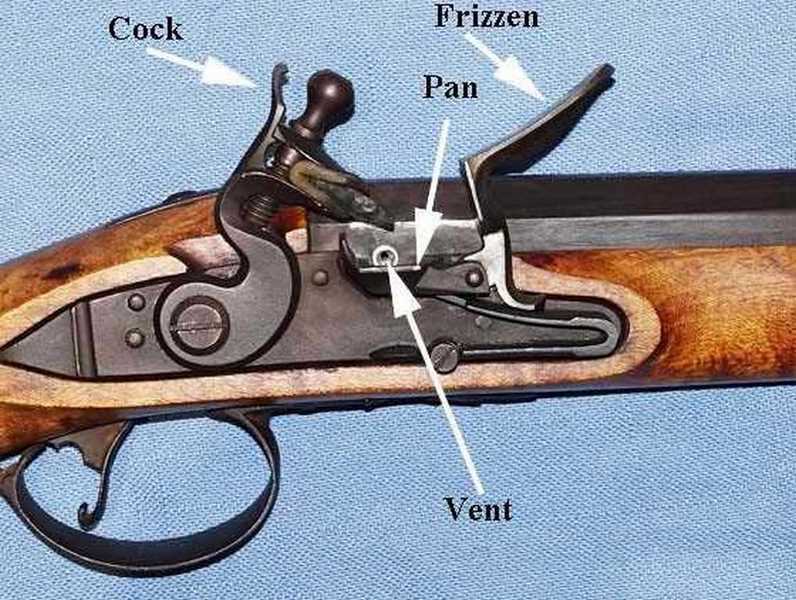

Black powder can be ignited by just a spark. That’s what makes the flintlock possible. The piece that held the flint was called the cock in the beginning, because people thought it looking like a rooster with something in its mouth, as it “pecked” at the frizzen. As time passed, the term hammer crept into the vernacular and both cock and hammer were used until the end of the flintlock era, around 1830-45.

The cock, or hammer, has fallen against the hardened steel frizzen, both pushing it back out of the way and striking sparks from it with the flint. Some of the sparks fall down into the pan where the priming powder is and they set it off. Part of the fire from that small explosion moves through the vent hole into the main powder charge at the rear of the barrel.

In the early 19th century (CA 1807) mankind learned how to create sufficient heat to ignite black powder by means of a secondary explosion that was set off by concussive pressure. The percussion system was born.

To create the percussion that ignited the explosive material required the hammer that had held the flint to be turned into a hammer that could smash. Instead of a touch hole, a nipple with a hole in it provided the anvil that the percussion cap sat on.

The nipple is the anvil that the hammer smashes the percussion cap against. The hole directs the fire from the cap’s explosion down onto the powder charge in the barrel.

Smokeless powder

Percussion caps were not hot enough to set off smokeless powder reliably, plus the nipple they used allowed gas to escape. Smokeless powder burns too slowly to explode when there is any possibility for the gas pressure to escape, so a new system of ignition had to be invented — the primer. The primer worked in conjunction with an enclosed copper cartridge case (later brass) to contain the gas pressure, allowing it to increase to explosive levels.

The hammer-fired system

I have told you all of this to make the point that the first smokeless powder cartridges were ignited by a hammer that looked very similar to the percussion hammer. But this new hammer either contained a firing pin to smash the primer directly, or it may have hit a separate firing pin that then hit the primer.

Early hammers, like the one on this 1916 Webley Mark VI revolver, show how focused the designers were on crushing the primer! Nothing prevents this hammer from directly crushing a primer.

This 1867 Peabody rifle, the forerunner of the Peabody Martini, has a heavy hammer that’s powered by a strong leaf spring. The firing pin (arrow), however, is separate and spring-loaded to stay away from the primer until the hammer drops.

Evolution

As time passed hammers became less obvious, though they still performed the same function. On the M1911 Colt pistol the hammer is still visible, if smaller, and the firing pin is still spring-loaded to keep it away from the primer.

The M1911 hammer is smaller but still functions the same, and the firing pin (arrow) is still spring-loaded for safety.

Hidden hammer

It is possible to hide the hammer inside the gun. You don’t see a hammer on the M1 Garand, the M1 Carbine or the M16, yet all three rifles have one hidden inside their actions. These hammers might not look exactly like external hammers, but their functions are identical.

M1 Garand trigger group. The hammer is cocked.

The hammer is fired.

Striker

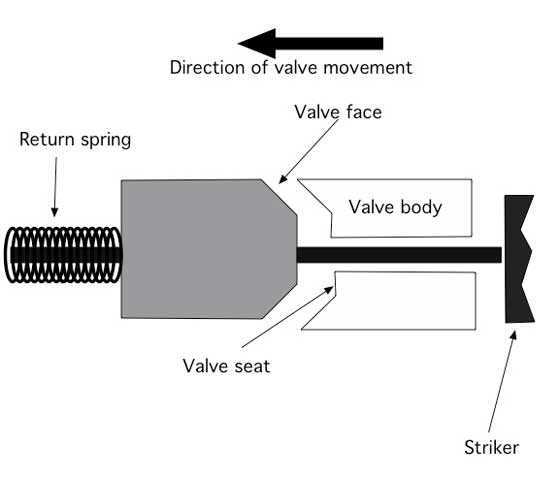

What, then, is a striker? It’s a firing pin that has a spring on the other side. The spring doesn’t keep the pin away from the primers, it pushes it towards them. It STRIKES them without being pushed by a hammer. When a striker gun is cocked, the striker (firing pin) is caught by the sear and when released it’s pushed forward by the striker spring to hit and crush the primer in the cartridge.

I could show you a gun with a striker, but you wouldn’t see anything. The striker/firing pin is buried deep inside the action.

On the airguns

I could also give a list of the advantages of each type of mechanism, and there are some for each, but that’s not what this report is about. Now that you know the difference between hammers and strikers, let’s talk about how these terms apply to airguns. Airguns don’t have primers, so what does a hammer or striker do?

Valve stem

In pneumatic and gas-powered airguns, the valve stem performs a function similar to a primer, but it’s not identical. A firearm primer first explodes, and the heat from that ignites the gunpowder. That’s two separate actions. In an airgun, the valve stem opens the valve to exhaust pressurized air or gas. That’s just one action. What, then, should we call the “thing” that hits/strikes the valve stem to knock it open?

The knock-open valve needs something to hit its stem. I call it a striker here, but if I called it a hammer it would do the same thing.

On some airguns the answer seems easy. If it looks like a hammer and does what a hammer does, it’s a hammer. I have no problem with that.

This Umarex Colt Single Action airgun hammer sure looks like a hammer to me!

But AirForce Airguns calls the cylindrical thingy that slides back and strikes the valve cap on their smallbore rifles a striker. And it doesn’t actually hit the valve cap. It hits the bolt and the impulse of the hit travels through the Delrin bolt and impacts the valve cap. Does that make the bolt a firing pin? Hardly.

This old AirForce striker is made from Delrin and slides over the barrel to impact the bolt. This one is probably obsolete, but it should be similar to what’s used today.

Summary

Today’s report doesn’t prove anything. It’s just a discussion of what a hammer is and what a striker is. It makes sense as long as the discussion stays with firearms. When it crosses over to airguns the definitions get blurry in a hurry, as we have seen today.

Because a valve stem does not do exactly the same thing that a primer does, the definition of the thing that actuates it is also not clear. Call it a hammer and I don’t think you’re wrong. Call it a striker and you are just as correct.

B.B.

Were/are firing pins made from a super hardened metal?

-Y

Yogi,

That material is important, but I don’t think it’s “super hardened.” I think toughness is important, but I’m not sure hardness is.

B.B.

Yogi,

“Super hardened” metal is a brittle as glass and can shatter because it is not ductile (can’t bend or absorb a blow) so it would not be suitable for a firing pin.

Carbon steel has three (usual) states: annealed (maximum softness/deductible); hardened (maximum hardness/brittle); and tempered (reduced hardness/tougher) that are imparted on the metal by how it is heated and cooled. The heating and cooling cause changes in the “grain” of the metal which control its properties.

Generally speaking, heating a piece of carbon steel to bright red/dull orange and letting it cool slowly will anneal it. Cooling the metal quickly by dunking it in water or oil will harden it. A hardened piece of carbon steel can be heated to a specific temperature (you can see this by the color on the metal as it is being heated) and dunked to reduce the hardness to the level required for the application.

The trick is to choose the correct level of hardness/toughness that the part is “tough” enough that it doesn’t deform or wear during normal use but not be too brittle either.

Hope this helps.

Hank

Hank

This may sound crazy but I remember that from 8th grade shop class in school.

Have you ever spliced a band saw blade back together when it breaks. The band saw at the other place I worked had a small grinding wheel to square the blade up and a annealer on it to soften the weld. Oh and the welder was built in too.

That was a good band saw. The place I work at now has a nice heavy duty band saw. But no way to reweld it on the band saw like the other band saw at the other place I worked. They was throwing the blade away if it broke. I started welding it with the mig welder and annealing it with the oxy accetalene torch. I actually got a $100 award for that idea. I’m sure I saved them a bunch by not having to buy new blades all the time.

Oh and that’s usually what we do if we grind off the rounded edges on our Allen wrenches. We dip them in oil to harden them. Other wise when they heat up from grinding material off that softens them. If you don’t quench them after you grind them they will twist like a pretzel when you use them the next time.

GF1,

You brought back memories. When I was in trade school (1967), we had a vertical band saw that we had to learn how to weld the blade back together. It was built into that saw too. It always worked well and wasn’t difficult to do once you learned how to do it. We used lots of machines at the school that were WWII surplus. Many lathes and mills and surface grinders. I made a spindle for a watch maker’s lathe once and had to cut a fine 40 pitch thread on an engine lathe as well as a keyway slot. We could do some real fine precise work on those old lathes. Every third or fourth year the instructor would designate a week where all the machines had to be scrapped down to bare metal and repainted. We had to learn how to sharpen the end of a file to do all the scrapping. Those old machines looked line new when we were done. The school was initially built to instruct veterans job skills but then it was opened up to the public, but men only when I went there. Later they opened it up to women and ex-cons and the school went down hill from there. I went there for two years and loved it though. Companies would come to the school and solicit prospective candidates. I was recruited by a job shop and paid top wages right out of the gate, $3/hour.

Geo

Geo

And more memories.

I started the machine shop I use to work at about 4 years out of high school. It was a bit more than $5.00 a hour back then. That was 82.

All I know is the machine shop biusness has been good to me. I have never got laid off and money has always increased over the years.

Everybody talked it was good back when I got into. And surprisingly it has been. For sure frustrations throughout time with mostly management. But I endured. 🙂

GF1,

It was my father who taught me about working with tools and metal… He started me young, I had to stand on a stool to be able to use our Atlas lathe!

Yup, I’ve spliced bandsaw blades that I’ve broken (more often than I would want to admit LOL!). I frequently rip 8-10 inch diameter, 8 foot logs into quarters to make bow staves – if you catch a knot on the table or the log twists it is easy to put a serious kink in the blade. I use pieces from a broken blade to replace damaged sections.

Welding is best but silver-soldering works fine as well – you have to scarf the ends of the blade to get a good joint. I made a clamping jig to hold the blade in alignment. As you say, saves lots of money.

You can do a lot with a good bandsaw in the shop. I just upgraded mine to a Rikon 10-326 which has twice power and capacity of my other bandsaw. Couple of days ago I was cutting 9 inch high slices off of green maple (for another stock project) without any problem.

Hank

Hank

Sounds like a nice saw. For all the nice woodwork you do on stocks it doesn’t surprise me you would have a nice band saw.

And yep my dad taught me more about machining than I learned in school that’s for sure. But I have to say machine shop and mechanical drafting was for sure my favorite subjects in school. Oh and math of all things.

B.B.,

Thank you for clearing up the confusion in my head. The two terms were interchangeable after all!

The video also brought to my attention the space requirement of using a muzzle loader. I cannot imagine the added amount of difficulty in reloading within a confined space which is probably why carbines were developed in the first place.

Siraniko

Siraniko,

Yes, you do need a bit of room to reload your muzzle loader, but they are fun, fun, fun to shoot! I’ve shot my .50 caliber Hawken style percussion rifle in many black powder matches; these matches are slow-paced and very enjoyable; they are less about winning, and more about celebrating a certain period of history while having a good time. =>

Take care,

dave

Thedavemyster,

With that many variables? Winning a match seems more heavily weighted to luck rather than expertise!

Siraniko

Siraniko

Or taking time and know what your doing. Just like us finding the right pellet for our air guns and getting the sights and such set up right.

It’s all about time.

BB

Nice report. And that’s pretty well how I have always thought about the strikers and hammer’s too.

B.B., I love these historical reports; I always learn something new; thank you! =>

BB

I did not know about the rooster holding something in its mouth. Good example how common words we use everyday came into being (like cock, cocking).

Also a much needed warning for reloaders about the perils of loosely packed black powder in muzzle loaders and cap and ball wheel guns. Oh and gas escaping through vent holes and percussion anvils.

Deck

Mr. Gaylord:

Hammer fired vs. striker fired is the M9 vs. M17 question.

Learned on the old and venerable 1911A1 transitioned to the new M9, and now the army has gone and adopted the new new M17. What gives?

In 25 years kids will look at our hammer fired pistols like kids from the 1950’s looked at 1750 continental army flint lock pistols.

What’s next? Caseless battery powered electro pistols? 🙂 🙂

I’ll leave those to the next generation of pistol coaches and instructors.

Respectfully

William Schooley

I just received my latest air gun catalog from Pyramid Air. (Thank you) for still sending out hard copies. I enjoy looking through them and always look forwards to B.B.’s articles which are always great. I see many guns that I have forgot about, or, are new and have not yet seen.

Missing this issue was the several pages of pellets that I have always found to be (very useful). It is nice to look at all the options when presented in a very concise manner. I call to bring it back.

The P.A. site is nice,… real nice,… but it does take quite a bit of time to look at all of the pellet options.

Chris

As an after thought,…. that same list that (was) in the catalog would be a good addition the on-line site. Just another quick reference/search tool.

Chris

Once you pull up a pellet page you click on a spot and it can break down your search in different categories. Like weight or brand or shape of the pellet. And more that I don’t remember right now without looking.

I use that alot when I’m looking for certian things.

GF1,

Yes, “refine search” and “sort by”. I use it. It is nice to look at (all) pellets at a quick glance within just a few printed pages though.

Chris

Chris

Yep one way or the other.

Dang. 58 this summer, and I just learned why you “cock” a rifle. The hammer looked like a rooster. Now about another hobby of mine, building and flying airplanes. It’s called a “joystick” for all of the reasons any teen boy might think of–move it around and things get fun, lol

Bejezus

I fly RC planes too. Fun stuff.

What do you fly. Electric or fuel?

In rc, I’ve got three diesels, some nitro, and a dozen electric, in full scale, a 140, a Sonex, a Hornet, and getting a little stick time in a hang glider tug call a Dragonfly. Also learned to hang glid last year. Flying, riding bikes, building, all this stuff seems to cross over into a lot of other hobbies.

Bejezus

Some diesels too. That’s cool. I remember one guy at the flying field I belonged to years ago had some diesels. I remember they swung some pretty big size props for thier size. It was fun watching those planes fly. He had one in a clipped wing cub. It was very realistic when it flew.

And all I got right now is a 36″ flat foamy Sukhoi electric that weighs just a bit over a pound. It got a out runner motor and swings 10×3 prop. I fly the 3D acrobatic flying with it.

But yep use to do nitro and pylon racing as well as some acrobatic flying with a Extra 300 that swung a 24″ prop and the pylon 1/2a’s to the Quicky 500’s. And everything inbetween. Oh and still have 3 small helicopters. Fun stuff.

B.B.,

I also have just learning why we “cock” a rifle or pistol/revolver (last evening I heard a report that included saying one culprit was using a wheel gun; I don’t hear that often.

Today is an educational experience, as always.

~ken