Benjamin 397 with curly maple stock and Williams peep sight.

Part 1

Part 2

Part 3

Part 4

Part 5

Part 6

Part 7

Part 8

Part 9

Part 10

Part 11

This report covers:

- Different

- Oh, oh!

- Discussion

- Off your high horse!

- Making the sear smooth

- Summary

Today we are going to look at the trigger of the new Benjamin 397. This will be interesting for all of us.

Different

I took the buttstock off the rifle and saw the modular trigger. Well, that looks different. Let’s see.

The new Benjamin 397 trigger is a modular unit.

To remove the trigger assembly remove the threaded bushing in the front of the unit — that’s what the single stock screw attaches to. It has flats for this. Also remove both small Phillips screws on either side of the rear of the tube that houses the trigger. In the picture above look straight up from the trigger blade to see the screw on the right side of the rifle.

To do this job right take off the tension by opening the pump handle. If you don’t the valve body will push back when the bushing and the two side screws are removed.

I have opened the pump arm. This takes the tension off the firing valve that puts tension on the hammer and hammer spring. If I had done this first, the threaded bushing would have come out easily.

Oh, oh!

Now we come to the moment I have been dreading. This unit is split down the middle. In the old days the nasty engineers would put tiny ball bearings under spring pressure so they would release at the worst possible moment as you were separating the cases halves. After that you never knew where to put them,assuming you ever found the ball bearings again. But those guys all retired and were replaced by more sensible guys who apparently don’t care whether you are looking inside. Let’s look.

The round coil of the sear spring fits over the pin just below it and the leg of the spring rests against the safety, putting tension on it.

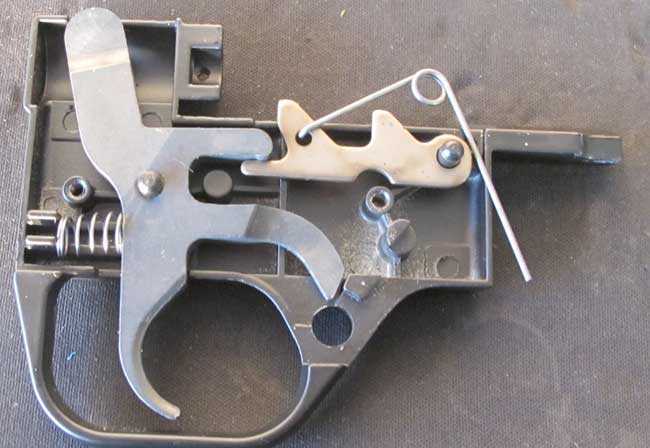

Here is the thousand-word picture. This shows almost everything about how this trigger operates. For example, you can see that the sear spring also puts tension on the trigger blade. Why do we need that coiled spring behind the trigger? You can also see that when the safety is pushed in from the left, the fat leg gets in the way of the trigger and blocks it.

Discussion

At this point I see that by removing the coiled spring that pushes against the trigger blade I will knock off a couple pounds of trigger pull. I don’t need to test it to know that.

But what about the sear? What does it look like? Let’s see.

The sear looks like it was punched out or cut by an EDM (electronic discharge machine).

Off your high horse!

People will see that picture of the sear and immediately mount their steed to tilt at the windmill. Relax, guys — it works! Yes, when you see it enlarged 20 times it looks rough. But the way it functions, it is really no problemo. Contact is only made on the lower half of the part in the picture. That’s what gets in the way of the ridges on the hammer, preventing it from going forward until pulling the trigger lowers this sear out of the way.

Polishing a sear like this is like chrome-plating the inside of your car wheels. It doesn’t make them roll better and no one will ever see.

Making the sear smooth

However, since I have the opportunity, I will polish the sear lightly. On the internet I have read where guys say they need to “grind” on the sear. Not on this one, you don’t. This is no doubt a piece of 1018 or 1020 low-carbon steel that was cut and shaped and then tumbled. Maybe someone touched it to a wheel before heat-treating.

The heat treatment is extremely thin. Grinding or filing will cut through to the soft, un-hardenable steel below and then you have a problem. But judicious use of an Arkansas stone will just flatten the high spots and make it smooth-ER. Go slow, use magnification and remember — this isn’t the real problem. The bigger problem is that coiled spring that we eliminated.

Summary

I have another surprise on tap that I will tell you about next time when we look at the Benjamin 397 Regent Grade again.

B.B.

Triggers are like plumbing. Something better left to the professionals.

-Y

Yogi,

I wish I had a nickle (or a good kick in the head) for every time I forgot the truth in the plumbing part of that simile.

Half

B.B.,

Seems like a straight forward job of removing the spring and maybe bending the return spring just a little. I doubt that itty-bitty spring you mentioned on the safety will affect the trigger much. Especially as that you didn’t show it.

Siraniko

PS: At the thousand word picture of the trigger. Last sentence: “When (What) you don’t see here is a tiny coiled spring in the other half of the trigger box that presses against the small end of the safety.”

Siraniko,

That sentence wasn’t supposed to remain in. I took it out. Thanks,

BB

BB,

Nice to have a peek inside. Maybe lessen the coil spring instead of removing it? It must serve some purpose. As for the V spring, I bent mine on the Maximus. I traced the legs on paper to have a reference start point. It worked very well. The spring was still V shaped, just less of an angle. I was careful not to just bend/arc one leg.

Shim washers at the trigger blade pivot may reduce any side to side slop,… if present.

Chris

BB,

The round tipped arm on top of the trigger, does this engage a slot in the bottom of the bolt, preventing it from opening when the trigger is pulled?

For those on the high horses, the sear contact point is on the smooth rounded end on the right, not the rough top flat that BB is showing in that picture.

Needs fixing.

Making the sear smooth

… Maybe someone touched it to a wheel before (before) heat-treating. (twice)

RR,

That round-tipped arm prevents you from decocking the rifle witout firing it. Some say to cut it off, but I didn’t.

I got rid of the repeated before. I don’t understand the rest of your comment.

BB

BB,

In your picture of the top of the sear, the actual contact point is the rounded smooth edge on the right. I think that is what you are referring to not understanding in my comment.

My bad. Looking at the picture more carefully I do notice that the “flat” surface is indeed the contact of the sear. That is indeed pretty rough. A touch of moly grease may not help, but it will not hurt.

Thanks for this BB!

How is the trigger now that you removed the spring? Lighter? Is it loose or wobbly at all?

The trigger assembly looks dry – any grease or oil at all?

…You realize that now I’m going to HAVE to disassemble mine just to see eh? 🙂

Hank

Hank,

Take a stab at why that coil spring is there. It obliviously supplies added trigger pull resistance,… but does it do anything else?

Chris

Chris

Don’t think I will have time today (I’m busy with the garden) but I did put the box of springs out on the work bench 🙂

Hank

Hank,

Tomorrow I tell all. 🙂

BB

Can’t wait 🙂

BB

Should I take stab at why that small coil spring is there or wait for tomorrow.

I can’t resist.

All I’ll say for now on this paticular gun the coil spring is there for a reason after the sear releases.

Its function is very similar to how the Semi Auto Marauder coil spring behind the bolt works. And I’m not talking about the striker spring on the SAM.

Oh and there is no way that was cut with a EDM. We had them at the other shop I worked at. We cut out the dove tail shave and form tools with them for the Acme Gridly screw machines. The EDM’s will make very nice precise smooth cuts. After all that’s what the shave and form tools do. They make the shape of the finished part coming off the Screw Machines making the production parts out of bar stock metal.

I don’t know if I missed any comment about the Olympics here but the USA won a Gold Medal in air rifle competition on Sunday. Will Shaner from U of KY brought home the Gold. Apologies if this was already commented on in the last two days. Now I’m trying to find out what or whose rifle he used.

Fred formerly of the Demokratik Peeples Republik of NJ now happily in hot GA

Fred

Maybe a Walther LG400

Deck

Thanks, Deck. So far, none of the main stream media articles commented on his equipment nor did “Teamusa dot org”.

Coverage is noticeably absent.

Deck

B.B.,

I took the stock off of my fairly recent wood stock 392. I did not take the trigger case apart but it looks identical from the outside. I am be interested in how your trigger tune goes. I did notice that the two sides of the case were pulling apart under the bushing that holds the stock on. Some kind of metal clip to hold them together seems needed.

We had friends over last week. I wanted to show them my low pressure pellet gun. It did not go so well. I gave a safety lesson on how the gun functioned and how to load and fire it. I said to keep the barrel in the safe position until ready to fire.

On the first shot the gun went off as she was cocking the hammer. I do not know if the hammer slipped out of her fingers or she hit the trigger or the sear slipped. Luckily part of the safety lesson was not to trust the trigger and the gun was pointed safely at the target. After the second attempt did the same thing. She had had enough. We thought we heard the pellet hit the target on the first try. I said I thought that was an echo. They were adamant that they heard the pellet hit the target. On the second shot I had to agree. So all shooting stopped for that day. I have shot a few thousand rounds out of this gun and never had it go off like that. It just shows testing with one person does not mean much. I don’t think I will worry about the hammer going off for now that can happen on many bolt cocking hammer pellet guns if the bolt slips while cocking or does not catch the sear all the way, but the gun firing while in the safe configuration needs attention. When I set up the latch for the barrel I have a cam that seals the barrel to the valve for an air tight fit. I put a slot in the cam blade to provide about 1.5 inches of space between the barrel and the valve. That was not enough. The picture below shows the barrel in the safe position. Not sure what I will do about that. I tested the gun using my new FX radar velocity meter. The pellet came out of the barrel at around 225 fps. Not good.

So for now the low pressure pellet gun will be confined to controlled conditions. So far all of my improvements have not increased the power or the accuracy of the gun significantly. It reminds me of taking out the x on the target with the first shot with a new gun. It doesn’t get better from there.

The good news is I am still having fun with the gun.

Don

Don

Bummer but good nobody got hurt. Hopefully you find out what is going on. Let us know what you come up with.

BB,

Is the sear engaging the striker in two different places with those two humps? Also, at the point where the trigger bears against the arm of the sear, were those two surfaces smooth and was there any lube. Seems there would be some friction that could come into play at the junction.

Half

Half,

No. The front one is a safety of some sort, I believe. The lower one in the rear is what holds the hammer.

BB