by Tom Gaylord

Writing as B.B. Pelletier

BSA Meteor Mark I.

This report covers:

- Tune in a Tube

- Baseline the Meteor

- A second tune?

- Disassembly

- The compressor

- What did I find?

- The rest of the powerplant

- Offset transfer port

- The pivot point

- What’s next?

Ho ho, hi ho; inside the gun we go! Today’s report brings a lot of topics together on one stage.

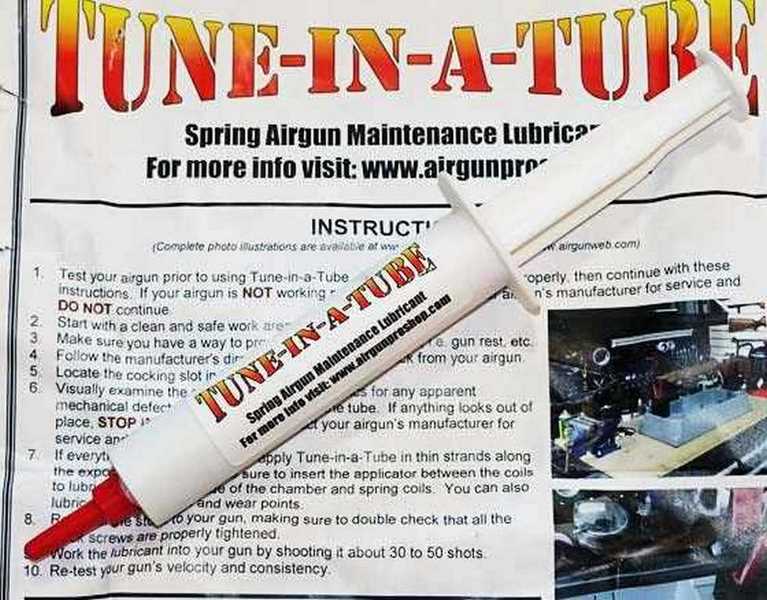

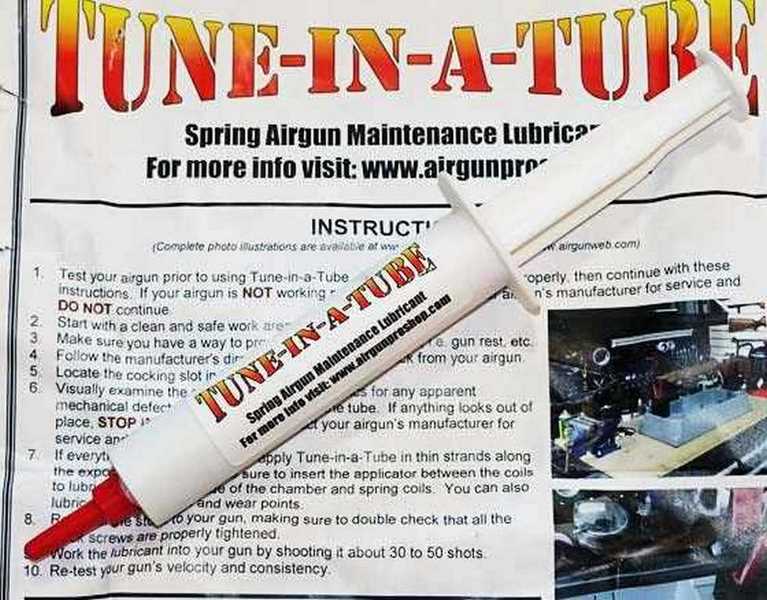

Tune in a Tube

One reason I’m doing this is because reader RidgeRunner has been touting Tune in a Tube — or at least I think he’s one. This is getting confusing, so please bear with me. Tune in a Tube is a tube of viscous grease that comes in an applicator that makes it easy to squirt the grease into the spring gun powerplant. It’s a type of lube tune that is simple and supposewd to be very easy to do. I want to find out if it’s a product that does what it says, because if it is there are quite a few spring guns that could benefit from it.

Tune in a Tube looks simple and straightforward. Let’s hope it works!

Baseline the Meteor

Before I start working on the Meteor Mark 1 though, I thought it would be nice to establish a baseline of performance. I’ve done some of that already. In Part 2 of this report I tested the velocity. We know my rifle is very powerful for a Meteor and that it is also very buzzy. We don’t know anything about the accuracy yet, but as I have said many times, a tune does not affect the accuracy. Maybe it makes a gun more pleasant to shoot, but that’s all.

Today we’ll have a look at the parts of the Mark 1 powerplant, so we know the condition of the gun before I apply the grease. After we look at them I will assemble the gun again and apply Tune in a Tube — following the directions to the letter. I have to tell you that I have already read them and they are both simple and straightforward. The manufacturer doesn’t make any outlandish claims. So far, I am impressed by the product.

Then I will test the rifle after Tune in a Tube has been applied and give you a complete report. Except for accuracy. I won’t test that just yet.

A second tune?

After that I may tear the rifle apart again, clean it and do a more thorough tune; one like I did for the other Meteor in that 9-part series. I must tell you that this Mark 1 is quite a bit different than that Mark IV Super Meteor. We may be comparing apples to oranges. I’l know more after we look inside this gun today.

So that’s the plan. At least to this point. Let’s get started. Oh, and I will be using the new Sun Optics mainspring compressor that I reviewed for you yesterday to take the gun apart. If there is anything noteworthy there, I will mention it.

Disassembly

Before I started I read Part 2 of the Mark IV report. That was most helpful! It cut the time to do the job to a minimum and also saved some embarrassing missteps. The Mark IV and Mark I are different in some ways, but they come apart the same way.

The first step was to install the barreled action in the mainspring compressor. That took 5 minutes of adjustments. Then I was ready to begin.

I will cut to the chase and tell you to read that Part 2 I just linked to, because everything I did to this rifle is in that report. It took me 15 minutes to completely disassemble the rifle — including photography! With this new mainspring compressor the job is a snap, though I will now note some things about the compressor.

The compressor

It would have been better to have been able to use the new pusher block that has the pin, because my plastic pusher block walked around the headstock cup a lot. Also, I do lament the lack of a locating bump in the center of the tailstock to anchor the muzzle. Other than that, the new compressor works beautifully. The bridge bolts work a lot better than the leather belt I have to use with my older B-Square compressor. I’m going to look for some plastic cap nuts for my bolts.

What did I find?

Can you say “dry as a bone?” And rusty! I don’t think this rifle has ever been apart. The mainspring appears to be a stock one and it’s still very straight. There is some wear on the coils from rubbing over the years, but overall it’s in fine condition.

The spring is straight and dry. The trigger parts are dry and gritty.

I was surprised to see that the construction methods of the Mark 1 piston, i.e. folded metal that’s welded top and bottom, are identical to the Mark IV Super Meteor piston I worked on. That one was just broken in several places from a lot of abuse. This one seems to be fine and intact, but dirty and rusty!

This is the top of the piston, where the seal attaches. The spot-weld is visible.

The bottom of the piston may or may not be welded. If it is, it’s a very precise spot-weld. It may just be punched into shape.

The piston body is rusty!

The piston seal is leather and did have a little oil in it when I took the gun apart. It needs a lot more and I think I will oil the rifle through the transfer port after the rifle is assembled — just as I would if I never took it apart.

The piston seal is leather and looks good. It has a little oil, but needs more. A good cleaning is also in store — but after the Tune in a Tube.

The piston head is keyed into the top of the piston. And that’s not an optical illusion. The piston top is really out of round. The head is larger than the piston and that’s all that’s necessary to keep the seal centered in the compression chamber. This is mid-century economical engineering at its best!

The rest of the powerplant

The trigger parts are dirty and gritty and desperately need a cleaning. The mating sear surfaces seem to be shaped well and they seem to be properly case-hardened. I can tell that because they are not overly worn from use. I will NOT stone them! Case-hardening is too easy to remove with a stone — I don’t care how careful you are. Besides — I already told you this trigger is very nice. I will lubricate it with some moly grease, and I’ll also oil all the pivots.

Offset transfer port

I peeked inside the compression chamber to confirm that the walls are smooth, which they are. I also wanted to make sure there wasn’t any excessive dirt or smashed pellets that dropped through the air transfer port. People will sometimes load a .22-caliber pellet rifle with .177 pellets and you’ll find them at the end of the compression chamber, smashed into a wad. Thankfully the chamber was clean and clear. But what’s this? The air transfer port isn’t in the center of the chamber!

I guess I never paid attention to the Mark IV, but the transfer port has to be offset to align with the rear of the barrel. According to airgun tuners, that lowers the rifle’s power potential just a little. Nothing to do about it — I’m just pointing it out.

From the front the offset transfer port is obvious.

The pivot point

Remember that I had to repair the barrel pivot joint on my Mark IV? Well, this one seems fine, even though it’s the same construction. It’s dry, so I will moly it after this first test. For now I’ll just oil it.

The pivot point is plain and has no washers. It needs some moly, but it seems tight. Look at that detent that has popped out!

What’s next?

The rifle is assembled just as it was before. I will oil the pistol seal and the pivot point, but the next big thing will be applying the Tune in an Tube. The next report will be immediately following that, and I will give you velocities to compare as well as my impressions of the smoothness of the shot cycle.

I will definitely tear this rifle down a second time, to clean out all the rust. Yes, I left it all in the gun, except for a little that flaked off when I touched the parts. It felt like fingernails scratching a chalkboard, putting those dirty, rusty parts back in the gun, but how else am I going to test Tune in a Tube fairly?

Yes this is about standard. In terms of airgun and indeed firearm Manufacture in the UK the Meteor was a revolution with its stamped and welded parts. Yours does look like it has had very little use.

Ogilkes,

Thank you for that comment. I guessed it was an early one. I think it is remarkable what those engineers were able to do.

Monday’s blog will be impressive!

B.B.

The BSA Meteor from the first blog 9 part blog report is still safe in mid Missouri. Thanks again Tom for the rifle and a great memory.

Bill,

Welcome to the blog.

Thank you for signing in. Having the owner of the Mark IV that I tested and tuned over the span of nearly a year in 2013/2014 means a lot to both the readers and to me. Although it doesn’t show it on the outside, Otho and I put a lot of sweat equity into that rifle. I hope it lasts you a long time.

B.B.

Bill tried to post this, but it didn’t come through.

The rifle shoots well. I do have one question. Is the trigger a direct sear design? (have not checked the blog) Mike M told me about grinding the sear from the sides to make it narrow, not changing the angle. I have tried this on a Diana 25 and found improvement. I am intrested in your thoughts. Thank you and take care. Bill

Bill,

I would not grind that sear or trigger! They are case-hardened and if ground you can cut through the hard metal. Then the softer metal starts wearing. I know it’s just the sides and not the contacts but I still wouldn’t advise it.

B.B.

B.B.

I can hardly wait. I thought tune in a tube, was lube for EVERYTHING…

Don’t quite understand the point if you are going to moly the trigger sears and pivot linkage??

Confused,

-Yogi

Yogi,

No, Tune in a Tube is only for dampening the mainspring buzz. It’s not for critical lubrication.

I will explain when we get to that report.

B.B.

Further on to that and with respect.

What is the point of reassembling an air rifle without doing a thorough cleans first.

Mr BB, you are doing a comparison between an old MK! BSA Meteor with rusted internals and then same Meteor with this ‘fix all’ stuff in a tube, rust and all.

That is never a correct way of doing this correctly. If there is an improvement, will you be advocating the use of this product as the fix all for the lazy and useless. I hope not.

I would have assumed that a more correct comparison would be a correctly services air rifle against the same air rifle with this magic cure as the lubricating medium, surely.

It seem to me that this product may be promoted as another tube of magic akin to the rubbish available for tired old clapped out automobiles.

What is the fixation with greases minimising ‘buzz’ for spring lube? Whatever happened to moly, have you all lost your way? 🙂

Slow_runner,

The point of B.B.’s exercise is for people with minimal mechanical aptitude or those without a spring compressor. To see if the product works he used his BSA Meteor Mk1 as a test subject. He disassembled it so that he can have a baseline data in how much rust, etc. was in it and re-assembled it so that it would be as if he did not so that he can test how much of a change the Tune-in-a-Tube would make. After documenting this the next phase of the test would be to tear it down again and this time to tune it as he would regularly which means removing all the rust and polishing the internals, burnishing or “linishing” (a term I see often used in British groups) regarding the application of moly to the chamber and proper application of other lubricants as needed before re-assembly and then comparing it to the previous performance with Tune-in-a-Tube only. He did not expect it to work but it did. There is the question though of how long will the improvement from the product would last compared to a proper tune.

Siraniko

Siraniko, I hope that you are incorrect in your assumption of B.B’s intention.

As I understand, B.B has been at this long enough not to give such poor directions to the less mechanically minded; and yet the article does appear to give that impression.

Slow_runner,

The purpose was so I would be testing the product on a gun in the condition it came to me. Of course my disassembly did remove some of the rust and crud, but I was careful not to remove it intentionally.

The point of Tune in a Tube is so an owner can apply it without disassembling his airgun. If it doesn’t do that, then there is no point to the product. If I disassemble the gun, I can use any good viscous grease, and there are plenty of them on the market. But this is the only one that can be applied to a gun without disassembly.

You mention using moly, but for this application moly doesn’t work. Moly is good for reducing friction — not for dampening vibration.

You object to my assembling a dirty gun, but if I didn’t show you the pictures of the insides, how would you have felt about the results?

My other readers understood exactly what I did and why. I’m sorry you don’t.

B.B.

B.B. Thank you for your reply.

I do understand what you did. The why? I am sure that there are other members who are perplexed.

My mention of Moly as a remedy was incomplete and is only one area that may need addressing in respect to ‘twang’.

I read that you have mentioned the obvious of minimising tolerances between piston wall and spring and spring and guide, so enough said there.

“You object to my assembling a dirty gun, but if I didn’t show you the pictures of the insides, how would you have felt about the results?”

I would have thought the same as I do now B.B, knowing that you had opened up and closed a dirty gun or not.

I think that you may be trying to muddy the waters a bit; I do not object to you reassembling a dirty air rifle and proceeding as you did, that is your decision. But to present it as a valid exercise for comparison is not the correct way.

“The point of Tune in a Tube is so an owner can apply it without disassembling his airgun.”

I would have thought that was a conditional statement by Tune in a Tube. They do not advocate such action per se and why would you? As an illustration of what, expediency?

http://www.airgunweb.com/tune-in-a-tube-spring-airgun-maintenance-lubricant/

If the point of Tune in a Tube is so an owner can apply it without disassembling his airgun, especially a secondhand unit, then that is so much poor directive to those who do not know better and maybe insulting to those who do.

The people who I am familiar with, who follow this interest of air rifles and associated pursuits, would never consider continuing to fire a newly acquired used air rifle without first stripping it down to give it a full mechanical inspection, and more especially, to discover what mischief lies inside the receiver. To do otherwise is to invite further problems.

So this lube is applied and the spring ‘twang’ diminishes? Now what about the breach leak, loose pellet, worn bore, poor piston seal, poor spring quality that may also be contributing factors? The cause does not always lie with the spring.

Consider what may lie inside the receiver that could be killing an air gun with every action- Bbs, nails, brads dust, grit etc.

BB,

This should be a real good test for Tune in a Tube now that you know everything inside is in good shape. I can well imagine it was pretty tough to put that air rifle back together without cleaning and lubing it.

Am I correct in my assumption that the detent has a groove that the barrel pivot pin engages to retain it? If so that is some very good engineering. A lot of thought has gone into the manufacture of this little sproinger.

RR,

Yes, the detent has a relief groove cut into it. But it is wide enough for the detent to move, so assembly is easy.

Monday I do the Tune in a Tube!

B.B.

BB,

Looking closely at the picture, I can see the groove in the top of the detent now. As I had stated, a lot of thought was put into the design of this air rifle.

Dry, rusty and still pulling 10ft/lb!, that’s remarkable!, they have such a short compression tube. I wonder if it will lose anything after a clean up, stranger things have happened.

I’m relieved in a way that its got the usual gimcrack pressed steel piston, I thought I was going batty as I never recalled the early models as being engineered much differently to the later ones, though this is an airgunning “truth”.

This tune in a tube reminds me of my own rough and ready method, using a spray can of motorcycle chain grease, they come with an applicator rod so is easy to squirt in and come out thin and then thicken up, I’ve used this a few times with success when I’ve been lazy, though I still maintain that if there’s grease you can see you’ve done it wrong, there’s no substitute for getting the twang out by allowing the natural rotation to occur and decently fitting but low friction guides, poke your nose in a Walther LGV or a TX200 and you’ll find but a smear.

Dom,

I think Ian Hancock used that chain lube on the spring in his Mag 80 Laza kit for the HW 80. That was where I first coined the term “black tar” because that was what that grease reminded me of.

B.B.

Dom,

The chain lube is an interesting idea. They not only typically contain high levels of molly but they are also designed to resist attracting grit and grime from the road.

The offset transfer port is normal for break barrels, and the one manufacturer who tries to engineer their way round it, Diana, makes things significantly worse, Airguntech here in the UK keeps himself quite busy filling the daft (and difficult) dogleg drilling they do and cutting a straight through the transfer port

This finds just over 1fpe with no other modification in .22, allowing a 10mm shorter stroke conversion with a lighter spring…with no loss of power. The ideal scenario would be straight through the centre but I suspect we would end up with a bit of an odd looking break barrel.

Dom,

Isn’t the central transfer port used in the Walther LGU and Air Arms Mk III? Then again they aren’t break barrels. I agree it would be a humpback requiring creative thinking when making the sights for it though.

Siraniko

Yes, there’s a bit more leeway in the design with under levers (and side levers)

It could, doubtless be done with a break barrel, maybe a ribbed barrel, but the hinge would end up dangling lower. The amount of power it robs appears to be pretty minimal anyway

Siraniko,

Yes, the TX 200 Mark III does have a central port and a humpbacked outer appearance.

B.B.

Dom,

I have seen others drill a slanted transfer port so it could be centered.

B.B.

That’s kinda what Diana do, well, a few mm straight, then a slant, then straight again, however its been pretty solidly proven that extending the transfer port distance significantly like this (let alone a bit of chicanery) does more harm than the advantages from taking from the centre of the tube provides. Probably hence every other manufacturer not doing it

Same problem with tobacco pipes.

If the hole in the bowl and the stem dont line up you can feel and hear it.

Belgrath04,

I smoked them years ago. I was always partial to the “free-hand” carved. My best one was a 12.00$ picked out of a basket. 3/4 bent. I always wanted to try a Meerschaum or a Calabash.

You guys ever smoked a corn cob pipe?

Seriously don’t laugh till you try one. My dad smoked pipes and cigars. I did as well in my younger days when I still smoked cigarettes too. A corn cob pipe will give the true flavor and smell of the tobacco.

Corn cob pipes were unique in the older days. Kind of like wood carving and pellet gun shooting. You tryed to make your pipe for the best smoking exsperiance. A different kind of accurate is what I will say.

GF1,

Yup,…. like anything,….. how far do you want to go? There is many finer points to the hobby, the tools and the accessories. Construction, craftsmanship, brand name, history, reputation, pedigree, etc.. To answer your question,….. yes. Having more than one and rotating the “stable” was part of the drill.

Kind of sounds like another hobby that I know of! 🙂

Nice report. Good pics too. It is always fun to see the inside workings of something. The link to Part 2 of the 9 Part was nice to refer back to. Lots of good pics and descriptions there too.

Chris,

I had done such a good job of documenting the teardown of the rifle in that earlier report, that I felt I could better spend the time looking at the parts this time. Except for the triggers, the two rifles are virtually identical in their parts.

B.B.

How is the fit between the spring and spring guide?

Belgrath04,

It’s snug, but not “nailed on” as it would be in a good custom tune.

Given the construction of the Meteor’s parts, I doubt I am going to be able to do a full custom tune on this rifle. I could do one, bit it would mean making a new piston and guide, or modifying the current parts greatly and I don’t want to do either of those things. This little rifle is just too nice as it is.

B.B.

Did HW just make cosmetic changes to the hw80 and call it a Beeman R1? My R1 has no checkering on the forearm and a dovetail groove for a sight under the silencer. It also looks like there’s provision for a rear sight just in front of the barrel joint. I’m wondering if this is an early model of the R1.

Brent

You are almost correct. HW made cosmetic changes to the Beeman R1 and called it the HW80.

From BB’s report:

The R1 is made for Beeman by Weihrauch. The R1 was designed by Robert Beeman, who employed a CAD engineer just for the task of designing the gun. The agreement he made with Weihrauch was that Beeman owned the R1, but Weihrauch was free to market the same action in a European stock under the model name HW80. The 80 in that model name refers to the length of the piston stroke in millimeters. The R1 was a redesign of the HW35, which you now understand has a piston stroke of 35mm. That explains where the tremendous power of the rifle comes from. It’s not the piston diameter, though that is large, and it’s not the mainspring, though it’s also very powerful. It’s the long stroke that generates the awesome power.

/blog/2012/08/the-beeman-r1-supermagnum-air-rifle-18-years-later-part-1/

SL,

I wish they had retained the barrel lock of the HW35 when they designed the R1.

Right now I am trying to learn to handle an uber magnum sproinger, the Webley/Hatsan Tomahawk. I bought it with the intention of playing with it just as BB did with his R1. Once I have shot it for a bit I intend to try different type tunes on it such as a shorter spring, a lighter spring and possibly a gas spring. A new seal will also likely be in the mix, maybe even buttoning the piston. With what I paid for this air rifle, I will not feel bad about tinkering with it.

RR

Even better would have been the barrel lock on the HW55! If you have never seen one, that is beauty in engineering.

Very interesting that you are experimenting with the Webley Tomahawk. I know that you are not one to buy a gun just to leave it laying around. What made you settle on the Tomahawk to tinker with? I have never handled one, and I was hoping to find a report from BB on it, but no dice. I am looking forward to reading the results of your efforts.

The spring gun that I have tinkered with the most is an HW50S (newer model, not the superior older model) that I purchased from a dealer who shall not be named. I was looking for an HW30S, which was out of stock at Pyramyd at the time, so I went with the second string dealer. I ordered the gun, which they said they had in stock and two weeks went by with no gun. Then I called them to see what in the Holy hell was going on, and they admitted that they did not have the gun in stock.

To soothe my seething temper and make amends, they offered me a HW50S for the price of the HW30S. I begrudgingly accepted the deal. To make a short story longer, the gun is accurate and relatively light and very pointable, but it eventually vibrated and buzzed more than a hornet’s nest in a paint shaker.

I installed a Vortek tuning kit from airgun goodguy Tom Gore, and a set of piston buttons from airgun goodguy Jim Maccari. Now the thing is a smooth-shooting pussycat. I should have documented the procedure with photos and chrony results for a guest blog, but I am a lazy inconsiderate jerk, so I didn’t.

The most uber magnum air rifle that I own is the AirArms TX200. It shoots lighter weight lead pellets in the 1000s. The thing is, the danged rifle is fairly easy to cock and not the slightest bit hold-sensitive! Those limey bastards cheated me out of the whole uber magnum experience!

SL,

I covet your 50S. Yes the 55 lock up is nice.

There are several reasons I went with the Tomahawk. One is the Quatro trigger which I have been hearing good things about. Another is the beautiful walnut stock. Also, it is possible to change it to a Vortex gas spring if I desire. The real big reason was the price. At $100 for a brand new one, I would not feel bad about going into it and tinkering around all I want. 🙂

I took my R1 to the range Saturday and the pellets it liked best were Winchester hollow points and CPHP’s. Cheap Chinese guns like expensive pellets and expensive German guns like cheap pellets. Go figure!

Brent,

I understand. That is why I have an ammo can full of .177 and a can full of .22. When a new one comes through the door I pull out the appropriate caliber and start shooting. With my future plans to expand into .25 and big bore, I think I need more cans.

OK everybody,

Next Friday and Saturday is the North Carolina Airgun Show in Hickory, NC.

http://www.tmacsairgunservice.com/page/airgunshow

I, Lloyd Sikes and my son-in-law will be wandering around the tables, shooting at the range and enjoying NC style BBQ on Saturday. It sure would be nice if some of you other guys managed to show up. A good time will be had by all.

B.B.

You are too macho. On one hand you say, just do it, on the other hand you say don’t disassemble an air rifle unless you know how to put it back together again. I have a buggered trigger, one that is apart and I have no idea how to put it back together….have a new trigger on back order.

Maybe you should talk to Jamel again!

-Y

Everybody,

So you all like the vintage HW 50? Here is one going for a good price right now:

http://www.gunbroker.com/item/588072281

It’s been fooled with (somebody mounted a peep sight to it in the past) but it’s still all there.

B.B..

B.B.,

The great enabler strikes again.

The cut-out portion doesn’t look like it was chewed by a rabid beaver. Somebody could put some wood into the defect and match the missing contour.

Wish I could buy it. But with our economy going south and the tariffs and red tape I face on importing it that will just be a dream for now.

Siraniko