by Tom Gaylord

Writing as B.B. Pelletier

The Beeman R8 looks like a baby R1.

Part 1

Part 2

Part 3

Part 4

Part 5

This report covers:

- Don’t over-lubricate

- Rail Lock mainspring compressor

- Degreasing

- Lube the piston seal

- Clean the mainspring

- Finish the assembly

- What is it like now?

- Velocity test

- Discussion

Last Friday’s report set us up for today. I was discussing “tuning” airguns before knowing how they performed. I didn’t do that with this rifle, but that discussion loosened up a lot of minds, and I got many suggestions of what to do with the R8. I wanted to disassemble it and remove most of the “special” grease I had applied, and then Gene Salvino of the Pyramyd AIR tech department and I had a long conversation about what was happening with that rifle.

Don’t over-lubricate

Gene said it is very possible to put too much of that grease into a lower-powered spring gun. He said if you do that you’ll get exactly the result I got with the R8 — a reduction of several hundred feet per second in the velocity.

He didn’t say this, but here is what I am guessing happens with this grease. At room temperature and when it is just sitting out loose it is tacky, but no more so than many other greases. But put it under the pressure of an airgun piston moving fast and the grease stiffens up. Other tacky greases don’t change under pressure, but this grease is a special blend and that is why it is so good at what it does — which is reduce vibration in a spring gun. That’s just my guess — not a known fact. But it explains why the gun behaved like it did when I used too much.

I won’t document the teardown a second time, because it’s there in Part 5. But I will note some things that were different this time.

Rail Lock mainspring compressor

I like the Air Venturi Rail Lock Mainspring Compressor a lot! It is so small and allows so much access to the spring tube of the gun where work needs to be done. This time I installed it and had the rifle apart in minutes. Let me just tell you about the threads on the end cap to illustrate how easy it is to use. I expected to be able to feel when the spring tube threads released the end cap, because it was still under a lot of tension from the mainspring, but I could not feel the release. That tells me the compressor is under complete control at all times.

The Rail Lock compressor installs quickly and easily on this Weihrauch spring tube.

This time I tightened the screws in the rear of the compressor and noted that the white Nylon tip did not walk around the end cap as it came out from the gun. There was some walking when the end cap went back in, until the threads were engaged, but it was simple and easy to control. At no time did I lose control of what was happening.

Thus far I have only tested the Rail Lock compressor on a Weihrauch rifle that has a threaded end cap. There are many more types of spring guns to disassemble, so the compressor report is just getting started.

Degreasing

Once the rifle was apart I began degreasing everything. I cleaned the inside of the spring tube with a long dowel that had some paper towel on the end, held by a rubber band. This towel was saturated with isopropyl alcohol. There wasn’t much grease inside the tube, but it took a LOT of scrubbing to remove! This grease is sticky!

After cleaning the inside of the tube I dried it with another bit of paper towel. This job took the longest of all, because that grease was holding onto the honing scratches inside the tube.

Following that I cleaned the piston — inside and out. That was a simple wiping job. I also want to show you the piston seal, because several of you asked about it last time.

According to Gene Salvino, this much of their special grease on the piston and mainspring will really slow down the action of a weaker spring gun if the piston seal is too tight. If it’s not too tight a little of their grease works well, but I didn’t know whether it was too tight or not, so I assumed it was. I removed all the grease from the piston, inside and out, and about half from the spring.

This is a parachute piston seal. When the seal goes forward and compresses air, air gets in the groove and presses the sides of the seal against the compression tube wall.

Please don’t examine the picture of the piston seal above and think you see imperfections. I examined it thoroughly, both last time and this time, and it is in perfect condition. I’ve seen enough bad piston seals to spot one.

Oh, I did clean out the groove in the seal after that picture was taken. It took a stout paper clip and lots of paper towel.

Lube the piston seal

Okay, Gene’s next tip for me was to lightly lubricate the piston seal with 85W-140 gear oil. Don’t use anything else! The synthetic gear oil is too runny for this job. It doesn’t take much! I used just 2 drops. This is a special treatment that’s only for those piston seals that are too tight.

Use two drops of this gear oil on the clean piston seal.

It took 20 seconds for one drop of this gear oil to run like this. It is viscous!

I spread the 2 drops evenly around the piston seal that is larger than the piston body behind it. The seal touches the wall of the compression chamber; the piston body never does.

I also used a second 2 drops of gear oil around the enlarged rear skirt of the piston. The spring guide is supposed to keep the piston body from ever touching the inner walls of the spring tube, but a little oil back there doesn’t hurt.

Clean the mainspring

The mainspring was already coated with the special grease. All I did was remove about half of it, or maybe a little more.

I wiped about half the grease off the mainspring.

This is what the cleaner spring looked like when it was back inside the gun.

Finish the assembly

The remainder of the assembly went well, except for one thing. As I was grabbing the end cap to turn it in the threads I rubbed my index finger against the side of the trigger slot and sliced it open. Oh, well. They say the job’s not done until you leave some DNA inside!

What is it like now?

With a lot (3/4?) of the grease gone from the rifle I wondered what it would shoot like. Would there be some spring buzz? Nope! It is just as smooth and quiet as before. So Gene got that part right, at least.

Velocity test

Now let’s see where the velocity is.

Hobbys

Before………………..After

Avg…..Spread………..Avg……Spread

402…….64……………416…….47

I didn’t finish the test. Obviously the rifle did not change significantly. Man, was I disappointed! I felt certain I’d have dramatic results to show you today. I even replaced the breech seal, though in truth the seal that was in the rifle looked fine.

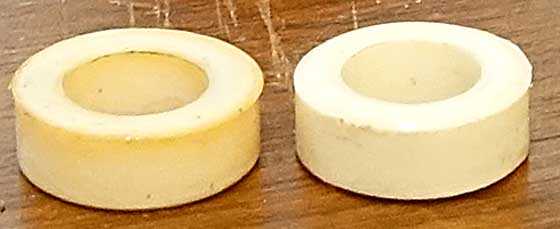

The breech seal that was in the rifle is standing proud of the breech. It appears to be good.

The seal that was in the rifle is on the left. You can see a little flaring at the top, but it looks pretty good next to the new seal on the right.

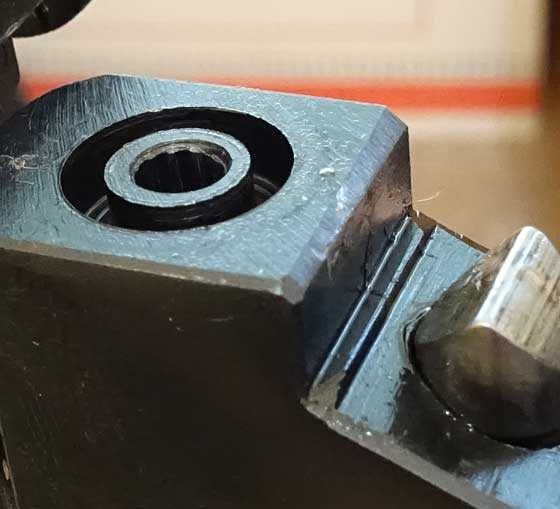

This is the groove the breech seal sits in. As you can see, the depth is not suitable for a o-ring.

“

Discussion

After the “test” I called Gene Salvino and had a long talk. We came to the conclusion that either the piston seal that I think is okay really isn’t or the mainspring is tired, or both. I have tuned a couple hundred spring guns in my life. Gene does that many every year. He is much better acquainted with the details of the work I am doing.

He is sending me a new seal and spring. I will install the new seal first, followed by the new spring, if necessary. That way we will know which one was the culprit.

I can think of one other possibility. The honing I see in the compression chamber does not seem to be done correctly. The scratches run perpendicular to the movement of the piston, where they should be a series of crosshatch scratches that run on an angle approximately 45 degrees to the piston’s axis. It is possible that the bore of the compression chamber was enlarged by aggressive honing and doesn’t allow the piston to compress all the air that’s inside. I hope that’s not the case.

This series started as a look at an historic airgun, but has turned into an advanced tutorial on tuning a spring-piston air rifle. I don’t enjoy reporting negative results, but things like this do happen and you need to know that if you ever plan to tune airguns.

B.B.

The statement, “We learn more from failure than success” sure is true here.

I understand that some HW 50’s had a bracket solder problem that distorted the receiver.

Could compression chamber honing be from mounting sand paper on a dowl and not raising and lowering it as it was turned?

If the piston is not compressing all the air, wouldn’t the piston head hit the transfer port?

This will be a 10 Parter yet!

-Yogi

Hi BB, I’ve always loved the HW50 and have done a few but never owned one, I have an HW85K I have just refurbished and several more HW’s. I have to say that I believe you are overlubing the rifle, I use moly paste’s on a highly polished cylinder with a smear of moly suspension around the piston seal, I also replace the guide tube with a delrin one, a British made Titan spring shortened to suit (no preload, no compressor needed) and the result is 11.3 ft lbs with Crosman premiers, glass smooth to cock, no dieselling, and little recoil.

I cannot put into words how much these improvements make, these are a different gun with the work done, one you can’t put down till that last pellet in the tin’s gone.

Mr Clive Hill,

Thank you for your tips. I agree that a well-tuned spring gun can be a joy.

B.B.

Nice article. I think that “extreme pressure” in the grease refers to the pressure exerted on the grease, like when 2 gears mesh. I do not think that would apply spring compression. As for the seal,.. assuming that is made of a fairly pliable material, I would think that it could handle a (range) of ID’s, within limits. Perhaps it is hardened somewhat?

It will be interesting to see what a new seal does,.. and then possibly the new spring. I would be tempted to re-hone, but that would be a bit of a pain on a long tube application. No doubt that one of those extensions with the 2 set screws to secure the tool would need to be used.

As a final thought, you no doubt have caught the dialogue between Cobalt327 and myself on taking the 499 from 255 fps to 415 fps. In the process of putting in a Red Ryder spring, which is all the tune really is,….. I also modified the Red Ryder piston seal a bit. For one, I had to plug the hole that was for the air tube. But,.. the other thing I did was to shave that inner lip of the seal with a new razor blade. That basically involved cutting that inner edge of the sealing lip at about a 45 degree angle,.. leaving about 1/2 mm of front surface on the lip so as not to disturb the factory sealing edge. The 2 seals are very similar in that area. The whole idea there was to improve the flexibility of that lip.

That may be a last resort remedy to a possibly over sized tube.

Good luck. That is all I have for you on any thoughts.

Good Day all,….. Chris

Chris,

One of those long extensions is exactly what I used when I honed my 1906 BSA. I used one of those bits with all the squares of sand paper glued to it to hone the tube with and a wire bristle bit to clean up the end of the compression tube some. My tube was in pretty bad shape where it was shot repeatedly without any apparent lubrication. You can still see the impression of the screw head that was holding on the leather piston seal in the end of the tube. Also, where the cocking lever was pushing the end of the piston up against the compression tube there was a lot of gouging. Fortunately it was not too bad inside the actual compression chamber.

BB,

I would think that you could feel whether the piston seal is making good contact with the compression chamber wall. You might try a plug in the transfer port to see if you get compression when you push the piston forward.

It could be the piston seal has stiffened with age and is not parachuting out as it should, but do you not have to compress the seal slightly to insert it? It could be honed beyond the seal’s limits I guess. That would really be a shame.

A tired spring? Well, I no longer have the umph I used to have, that is for sure. Were not the older Weihrauch springs a bit of an issue, or was that with the old Dianas?

Just some of my thoughts.

B.B. Pelletier,

If this grease slows down the power that much I am not unhappy with its results in mine. Previously where the rifles shot with a snap it is down to a thud. Accuracy seems to have improved and overall feels better. I know it is not the exact same grease you are using but it is a close relative being used in the automotive industry to reduce/eliminate vibration in shocks.

Siraniko

“… has turned into an advanced tutorial on tuning a spring-piston air rifle.”

B.B., from a reader’s perspective, that’s not a bad thing at all; I know it’s more work for you, but it will provide great lessons for your readership on advanced tuning techniques, especially those who are new to spring piston rifles. Hence, speak on, professor, we are listening. =D

B.B.

Awesome report. I know the Kentucky Derby is over but I am betting the piston seal is the problem, not the spring. We shall see. That spring compressor looks to be a home run.

Ken

Hi B.B.

Just jumping in here, off topic….

You have always steered me to the right airgun choices… I love my Daisy 953 (which I just found was discontinued) and Beeman P17. Both very accurate… even for me. I am looking to purchase a multi pump pneumatic. My first airgun was a Daisy 880 from the 70’s, when they were built with more steel… I still have it, but needs repairing… I am considering the Daisy 901, Crosman 2100 and the Crosman P1377 (may use with removable buttstock…) Could you comment on which has the best build quality and which is the most accurate of these three. Just using for plinking and target practice. As always, thanks for your help.

Jeff,

Build quality among your choices isn’t the term I would choose. All of them are built for manufacture and have used shapes and materials that have been selected to keep costs down.

The 2100 is the most accurate of the three, in my opinion. The 2240 is the easiest to work on. I don’t have any experience with the 901.

B.B.

B.B., you did me 1377 instead of 2240, right? Also, wouldn’t I be correct in assuming the 1377 would be much easier to pump than the 2100? Seems like the pump up pistols were easier if I remember right.

Doc.

Doc,

Sorry, I got confused. I think the 1377 is harder to pump all the way because it is a pistol. But I could be wrong.

B.B.

B.B.,

the 1377 could very well be harder to pump. I was just thinking I read once where you said it was easier than the rifle due to a smaller piston? I had a 1377, but that was so many years ago. I thought it was easy to pump, but I may have forgotten. Any 1377 owners care to chime in?

Doc

Doc

I never had a 2100 so can’t compare the 1377 pumping to it.

But to m the 1377’s are not that hard to pump.

GunFun,

I have owned a 2200 and 1377. I currently own a 2100. I thought my 1377 was easier than the others. It never got real hard to pump, even when pumping 10 times.

Doc.

Doc

Yep same here on the 1377’s.

BB

Very good report today.

And will mention this. Cross hatching the cylinder bore will in a sense tight up the bore diameter some. Not alot but it will help a bit. Kind of like how knurling something does.

But I think you got a good game plan for the gun from what I read today.

GF1,

Someone else suggested that I re-hone the cylinder. His name is Robert E. Lee. He is a former world champion flat track racer ( Google the Little General in the ’60s and ’70s) who still works on motorcycles.

I am reluctant to hone the tube anymore, but Robert also suggested plating it if the new seal doesn’t work out. That is a possibility.

The current seal fits the bore loose, so let’s hope that’s what it is. Remember, the rifle was 100 f.p.s. faster when I started this report, so somebody else knew how to do better than I have thus far.

B.B.

BB

You know what. I think we may be missing something else here.

You know how when we all get our new spring gun and we chrony it and save the velocity numbers and such. Then we shoot about a 1000 shots through it when we think we got it broke in some. Then chrony again and notice the gun did pick up on velocity compared to those numbers we wrote down when we first got the gun and the velocity spread decreased also.

Well from what I have seen on the spring guns I took apart and tuned. And mind you some of them I took apart and put back together several times. Well I learned real quick that each time the gun came apart and went back together it needed some shooting time to stabilize itself again.

Some guns picked up alot after shooting them. Some picked up a little. And occasionally they didn’t change at all.

So maybe you just need to shoot the gun more as it is right now. See if it speeds up. If not come back to it and tear into it again. I know from what I done it takes me a few weeks upto a month sometimes when I mess with spring guns. But on the other hand some come right in.

Gf1,

Yes, I’ve seen that too. But never 200 f.p.s. If I was within 50 f.p.s. of where I think I should be I’d shoot it in.

B.B.

BB

You sure there wasn’t a spacer on the spring to preload it heavier. Maybe you misplaced that when you took it apart?

GF1,

Positive.

B.B.

GF1,

It’s time! PA is having the sale you have been waiting for! You had better strike while the iron is hot! 😉

RR

You didn’t read what I wrote at the end of yesterday’s blog I guess.

Weirauch is not included in the sale. I tryed to order yesterday.

It is at the other store.

Perhaps you should contact PA and tell them you can buy an HW30S elsewhere for $279 and would they be willing to match that price.

RR

I’ll just wait for PA to have another sale. Like the 10% off and free shipping over $150. They usually include Weirauch in them sales. Normally it’s Air Arms and AirForce guns and some others that aren’t included.

I think I’ll go ahead and stock up on some pellets with this sale. Pellets did accept this sale that PA is having now when I tryed yesterday to see.

RR

I was wrong. It’s only certian pellets with this sale also.

GF1,

LOL! It reminds me of the sales they have at Belk and such. Everything is on sale but what people want to buy.

I would call PA with the offer I mentioned. Who knows, they might go for it. If not, you take your money elsewhere. I will not buy Crosman or Gamo sproingers because they have lousy triggers. Yes, I can fix them but buying their junk only encourages them to make more junk. If PA will not sell something at a competitive price, they can keep it on inventory. I bought my Webley Tomahawk AND a Hawke 2-7 x 32 IR AO etched glass scope for $130 when PA was selling the Tomahawk alone for $280. They had the scope for $110. Big difference. It also did not take any longer to get here.

Right now I am wanting to buy H&N Field Target pellets. PA no longer carries them. Someone else has them in 3 different calibers. Guess who is going to get my money.

RR

Read down below. Pyramyd AIR added the HW30S to the sale.

Yes I ordered. Yes I’m a happy camper right now. 🙂

And here check out this Pyramyd AIR link. Its got a bunch of different HN feild target pellets. Scroll down the page and see if one of them is what you want. Let me know.

/search-results-ext?Ntt=Hn+feild+target+pellwts&sid=1375A617A415&N=0&Ntk=primary&q=Hn+feild+target+pellwts&cx=002970863286801882398:jlcminxfwdw&cof=FORID:11;NB:1&saSearch

GF1,

Good for you!

Those are the Field Target Trophy pellets, not the Field Target pellets. They are actually longer and lighter.

http://www.airgunsofarizona.com/ammo/pellets/h-n-field-target-pellets/

With the Webley, I am going to try not to lose power if I can. I am going to remove small lengths of the spring and check the results as I go. If I need to lose a little power to gentle the firing cycle some, So be it. At least I have plenty to work with and it is already surprisingly accurate.

RR

Your not going to believe this. I had terrible accuracy with the pellets you gave the link to. A tin of them came with a gun I got a long time back. Kept them to try in different guns. No matter what gun I tryed them in the JSB’s always done better.

GF1,

That is why we have to try different pellets in different guns. These work great in my Webley/Hatsan Tomahawk. I was sitting on the porch Sunday evening and plinking at my 3/4″ spinner at 25 yards and was hitting it most of the time. If I recall correctly it is grouping about 1/2″-3/4″ at that range.

My Gamo CFX really liked the H&N FTT in 4.52mm head. It would shoot sub dime groups at 25 yards all day with them, but if I used the 4.51mm head the groups would open to about 1″. By the way, my Tomahawk does not care for either of the FTTs, though it does seem to like the Baracudas. I think it prefers a slightly longer pellet. I cannot remember if I tried the RWS Superdomes in it. I will have to give them a try.

RR

Yep true about trying different pellets in different guns.

Man there sure are alot of different pellets out there to try. 😉

RR,

OBE. They added it.

B.B.

BB,

OBE?

RR,

Overcome By Events. In other words, the world moved on.

B.B.

OK. I’m up to speed now.

BB,

Speaking of spring compressors, I know your usage of this one has been limited so far, but how does using this one compare to the Square D/Sun Optics spring compressor? I am also very curious as to how well it will fit on a weaver/picatinny rail.

Another question about the older spring compressor, it is obvious that you would need to remove a scope to use the new AV spring compressor, but is it necessary to do such with the older spring compressor?

RR,

The B-Square/ Sun Optics compressor still works on rifle that don’t have 11mm/Weaver scope grooves, and there are many of those among the vintage guns. Also, some Benjamin Trails have their scope bases too far forward to reach with this one. So there is a place for both types. But for convenience, this is the one I’ll choose.

B.B.

This is somewhat related to today’s topic.

I was shooting my Webley/Hatsan Tomahawk some yesterday and I noticed that I am still getting enough dieseling from it to have a wisp of smoke come from the muzzle and breech. I have over three hundred pellets through it so far. I am beginning to suspect that during assembly the piston seal may have been slightly damaged and is allowing some lubricant migration from the rear of the compression chamber. I guess I can use this as an excuse for a tear down and inspection. 😉

Another note about the Tomahawk is the Quatro trigger. I do not know if it is better than the Rekord, however it is far and above better than any trigger on any sproinger made by Gamo or Crosman. Straight from the box mine has about 1/8″ of light first stage before coming up against the 2nd stage which has a wonderfully crisp break.

I think this Tomahawk has a lot of potential if I can get a few minor issues worked out.

RR

The Hatsan spring guns I had with the Quattro trigger were pretty good. And Crosman does need to learn to make a good spring gun trigger. I don’t care for them triggers at all.

GF1,

Gamo is not any better. Really this is a nice trigger on a really nice looking air rifle. If I can calm the firing cycle down a bit more this will be a real winner.

RR

Oh but you will be able to get the shot cycle smoother on your gun. But how low in velocity do you want to go is the question.

I can only wish I had the knowledge and expertise of this post for my M1 Garand. The plot thickens. Over the weekend, while sorting brass, I found a pierced primer from the last session. I understand that this is a hazardous situation, so my experiments will come to an end, and I will send it back to the gunsmith. The picture now is like this. There seem to be overpressure problems based on the way my reloaded cases are ejecting forwards, the horizontal stringing of the groups, and the pierced primer. But, my reload is the lightest one possible for the standard 150 gr. bullet and my powder. Besides, the gas system is adjusted for minimum volume in the gas tube which should mean the least gas. And, I had a malfunction with surplus ammo which the gun was tested with successfully. Even the pierced primer is a puzzler because if I had too much pressure why was there just one in 48 rounds while the others were fine?

If pressure is not causing the problem what else could it be? Surely the op rod spring has not broken again? What other parts in the rifle can interfere with the timing of the bolt? I not only don’t know the answer, but I can’t even imagine what it is. What comes back from the gunsmith will definitely be interesting, but unfortunately circumstances prevent me from getting it back until late in the summer. Aaargh.

Matt61

Matt61

Bummer about not having your gun for a while.

But look on the bright side. When you get it back it should rock and roll this time. I’m sure your gunsmith will find something out.

I think low powered springers are the hardest ones to tune well. There is so little spring power to begin with that just a small reduction will show up in velocity.

My first guess is that your piston seal it too tight. If you have a good fitting guide, I don’t think I would use any tar type of lube at all. That high pressure oil might be all the spring needs.

David Enoch

Weihrauch went through a spate of incorrectly brazed end plugs at about this era, sometimes with fissure but most often with lost volume from a channel around the inside that should have been filled, also check to see if Mr Gloopy Grease the tuning man didn’t have some half heard concepts regarding transfer port size, I’ve seen many a good rifle ruined by a 4mm drill bit

Dom,

I just checked. The port has not been drilled out. Can’t tell about the end plug brazing yet.

B.B.

No, it’s actually incredibly hard to tell, though one of those automotive bore scopes would be great for it, the bottom should be machined totally flat, if the brazing has missed then there will be a 45 degree bevel on the edge of the plug, though this can be partially filled.

Its an old girl, quite possibly a few critical pounds have gone from the spring

GunFun1,

Watch the HW 30S. I think it’s about to go on sale.

B.B.

BB

Thanks for the heads up. I’m for sure watching.

BB

The HW30s is listed on the Pyramyd AIR 20% off birthday page now.

Just ordered. Thanks a bunch. 🙂

BB,

I will put forth a theory as to how you lost so much velocity once you took apart and cleaned the piston. I’m guessing when you first removed the piston, the circular groove in the front end of the parachute piston seal was packed full of greasy crud. If it was really packed tight, then removing that crud decreased the pressure the seal exerts on the compression chamber. You did say the fit was on the loose side once you put it back in. Given all the other factors you have given that is the only thing I could think of that explains the large velocity loss. I think that is also a very good reason to replace the piston seal, as long as you have the means to fit the new one properly.

David H.

David

Thinking about what you just said about the gunky grease stuck in the front of the seal and making it push out makes good sense. That may be very well why it feels loose in the cylinder now. Which could allow air to blow by and loose power.

Curious to see what happens with this gun.

David,

I haven’t got a better theory. Different, maybe, but no better.

B.B.

BB,

Since you say the piston seal fits loosely now, you might check with Jim Maccari before doing anything drastic to the tube. He offers some HW 25mm seals that are slightly larger than factory:

https://www.airrifleheadquarters.com/catalog/item/251485/1381148.htm

He might be willing so see whether he can find at least one that is larger than average.

I recently acquired a virtually mint R8 together with a mint R10 .177 after years of searching (courtesy of John Chippis). I also just picked up JM kits for them and my HW55, but I want to baseline their current performance before going any further.

Lance

Lance,

Thank you for that. It would have been something to consider, but on Monday you will see that the factory seal (a new one) fixed the rifle.

B.B.