by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- I’m learning, too

- The poppet valve

- How it works

- Velocity — Crosman BBs

- Air Venturi Steel BBs

- Hornady Black Diamond BBs

- Cocking effort

- Trigger pull

- Summary

Somebody recently thanked me for admitting I don’t know everything. Guys, if the truth be told, I don’t know more than most of you. Some of what I know is just because I’m old, and other stuff is because I’ve had a lifelong fascination with guns.

I’m learning, too

I learn from this blog just like most of you. A lot of that comes when I research things, but every so often you readers tell me things. That happened in the comments to Part 1 of this report. Reader Kevin told us that he believed those three detents in the V-300’s cocking mechanism were for three different power levels. I immediately went to my pistol and tried it and found he is right! We will see that today.

The poppet valve

Also, another reader named Charles responded to my request to see the special poppet valve. He had a V-350 valve (from a long gun, but the vale is essentially the same) apart when he read my report, so he sent me some pictures to share with you. Let’s look at them first.

Our first look at the V-350 poppet valve.The pistol valve is similar.

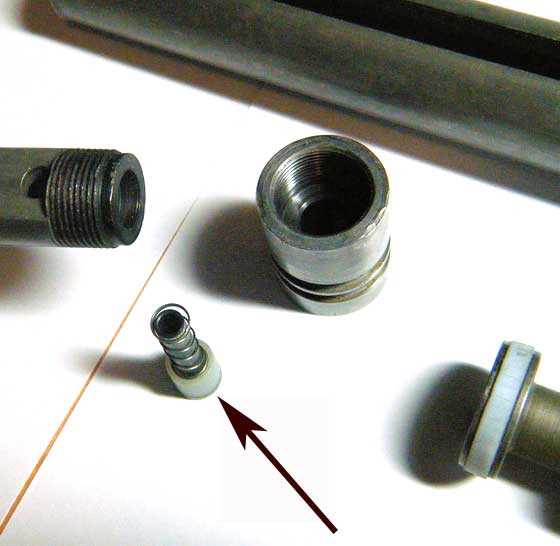

V-350 poppet valve taken apart. The poppet (arrow) is shown clearly.

V-350 poppet valve face. The piston pushes compressed air through the three holes to force the poppet back.

When the valve is inside the rifle, the rubber o-ring seals the compressed air from blowing past the valve body. The yellow felt wiper keeps the o-ring lubricated, as long as the gun is oiled frequently.

This is the assembly of the V-350 piston (right) and the poppet valve assembly outside the gun.

How it works

When the gun fires the piston moves forward compressing air. The piston forces that air through the three small holes in the head of the valve. The compressed air then pushes the poppet back against its spring, allowing air to flow around its head and enter its hollow body (look at the second picture). As the poppet moves, its back end pushes against a BB that is sitting in line with it in the breech of the barrel. That starts the BB moving. When the poppet reaches the end of its travel, the BB continues moving and is now being pushed by all the compressed air that’s flowing through the hollow poppet.

In essence, this valve is very similar to the mechanism (no valve involved) in a Daisy Red Ryder powerplant. It’s just more refined, and I suspect it is also the reason the V-350 is as powerful as it is. My thanks to Charles for these fine photos. Good photography, by the way!

Velocity — Crosman BBs

Okay, let’s now look at the velocity of my pistol with a couple different BBs. I oiled the gun before the test. Since this is a Crosman gun I’ll start with Crosman Copperhead BBs. On high power, which is three clicks, this BB averaged 258 f.p.s. The spread went from 252 to 270 f.p.s., so 18 f.p.s.

On two clicks, which is medium power, the Copperhead BB averaged 171 f.p.s. The low was 170 and the high was 173 f.p.s.

On one click, I had a hard time getting the BB to register on the chronograph. Many shots went through before the chrono “saw” them. With Copperhead BBs on 1 click the average was 54 f.p.s..

Air Venturi Steel BBs

On max power Air Venturi Steel BBs averaged 254 f.p.s. The spread went from 247 to 261 f.p.s., so 14 f.p.s.

On two clicks the same Air Venturi Steel BB averaged 159 f.p.s. They ranged from a low of 139 to a high of 166 f.p.s. The spread was 27 f.p.s.

On one click this BB averaged 49 f.p.s. The spread was 48 to 50 f.p.s. This is almost too slow to chronograph, and I probably fired twice as many BBs that didn’t register as those that did.

Hornady Black Diamond BBs

Hornady Black Diamond BBs averaged 258 f.p.s. on high power. The low was 255 and the high was 261 f.p.s., so a spread of 6 f.p.s.

On two clicks Hornady BBs averaged 159 f.p.s. They ranged from 134 to 180 f.p.s. I don’t know what happened to that string, but the spread was 46 f.p.s. The next result may explain why.

On one click I fired 20 BBs without getting a reading. Several of the BBs hung up in the gun and had to be removed by dumping them out the fill hole. I only got one Black Diamond to register and the velocity was 49 f.p.s. I think Hornady Black Diamond BBs are slightly too big for the V-300 pistol and should be avoided. That also tells me to avoid the even larger H&N Smart Shot lead BBs.

Cocking effort

Cocking the backstrap lever to the first click took 13 lbs. of effort. Click number two took 16 lbs., then, going towards the last click, the effort remained at 16 lbs. for a short while then dropped back to 6 lbs. as the cocking lever went over top dead center and the force was multiplied by the mechanism.

Trigger pull

The single-stage trigger is not adjustable. It breaks with some creep at 5 lbs. 12 oz.

Summary

Yes, there are three cocking stops on the Crosman V-300, but I think only two are useful in the pistol I’m testing. The lowest power is too slow to do much of anything. The BBs bounced off the cardboard backer on my BB trap.

It looks like my pistol is a little tired. That’s understandable, since it is more than a half-century old. I have no desire to open it up for a rebuild, though Charles shows us that it is possible.

Accuracy comes next, and, unless I am surprised by the outcome, this V-300 will quietly retire to my collection.

Yes, the old girl does seem a bit tired. At least she still works. She is still a looker also.

Initially I had thought that the picture showed that the V-350 poppet valve face was cracked. Closer inspection revealed that it was only a scratch fortunately. Definitely not a powerhouse. Hopefully it has accuracy to make it a fun gun to have.

Yeah, its just a nasty scratch on the face. As you can probably tell this little V350 has been through the ringer a few times and has been crudely taken apart by its former owner several times.

It had stop working/cocking properly so i thought it would be a fun little project to attempt to restore it to operating condition.

B.B.,

Well,at least it still shoots. I would be wary of the cocking lever being prone to breakage. Like was said,.. give it another go and then retire it. The provided pictures were a nice addition. The 3 stages are interesting. That must mean that there are 3 sear/latch engagement points. Something like the TX200 has 3 clicks as well, but without the latch rod/sear engaging until the final click (and then some), nothing would happen. That would just be the bear trap mech. working.

That might be an interesting concept for a springer rifle,.. to have multiple sear/latch engagement points = multiple power levels. Then again,.. I am sure you can point to some example where it has already been done.

Good day,.. all,.. Chris

Chris,

I like your idea for a sproinger rifle. I do not know if it has been done previously, but it has been done with a pistol.

/product/beeman-p1-air-pistol?m=555

RR,

I looked pretty hard at that one when just getting back into airguns.

I suppose that a multi-level power springer might be a be a bit of a novelty, but I think that it would serve a purpose for urban and basement shooters. Safe to say too that the higher the fps, the worse the accuracy,… or at least harder to get good groups. Something like 65, 80 and 100% ought to work pretty well.

Chris USA,

Hasn’t this been done before? It was the Whiscombe that had that feature of adjustable power levels.

Siraniko

Siraniko,

I just went back and did a quick re-read of the Whiscombe. It appears the different models required either 2 or 3 pulls of an under lever, depending on model. However, none would fire until the final pull was complete. It was for sure the epitome of an adjustable rifle. Barrel and air port swaps,.. and barrel vibration tuning.

I was thinking of something much more simple. In my thinking, the piston latch rod would have to pass through, (or over), the trigger sear and have multiple engagement points. The only thing that would be affected would be the stroke. 1 click to utilize 60% of the stroke. 2 for 80% and 3 for 100%,.. as an example.

Chris

Chris USA,

Thinking about it, I think the sear will have to catch on the piston body instead of the central shaft. You will end up with a slightly longer main body I imagine. Maybe that’s why this thing will end up as a giant version of the Webley Premier with the barrel on top and the piston below with the air doing a 180 degree turn. Might make a nice engineering project if I were one.

I wonder how our Russian friend Duskwight is doing with his Duskcombe?

Siraniko

Siraniko,

However it would be accomplished,.. it is fun to think about.

“Duskcombe”,… I like that! 😉 I often wonder the same thing. From what I remember,.. I was always enthralled with each new installment/update. Hopefully the “Duskcombe” project continues.

Chris

I found a diagram/parts list for the V-300, it was a bit hard to read so I tried to clean it up a little.

http://www.crankshaftcoalition.com/wiki/images/e/e5/CROSMAN_V300_PISTOL_PARTS_DIAGRAM_A1.jpg

Forgot to add, the diagram came from here: http://cinedux.com/. There are a lot of interesting things to see regarding airguns from days gone by.

Cobalt,

Thanks for the link. It has been some time since I have been to Trev’s site.

After our own Tom Gaylord, Trevor Adams has become a favorite airgun writer, His perspective as someone from a half world and a generation away offers an insight into airguns and airgunning that is different than most.

B.B.,

Not so sure I did you a favor.

Wouldn’t be surprised to learn that you were cussing me when shooting at 3 different power levels and recording each and every one of those velocities just to create this blog entry. 😉

Kevin,

Yeah — that dawned on me when I stared the test! 😉

B.B.

B.B.,

This is an interesting and cool looking pistol and for me a compelling report for which I thank you. I’ve seen these every now and then online, and have always been curious about them. Thanks to you I know more about them, by golly, I am STILL interested by them! :^)

After your first installment, which had me wondering why you described the grips, which look a lot like the ambi grips on my Crosman 150, as being “very ergonomic (for right-handed shooters)”. For other lefties here, I found a pic of this from the rear through an online search which shows a shallow curved thumb rest on the left grip.

I am still very interested to see how this does for accuracy. I am a lefty-only for long guns, but with air handguns I am ambidextrous for single-hand shooting. I cannot get comfortable shooting righty with a two-hand grip, however.

Michael

B.B. I just read the owners manual on the Crosman website and would like to pass on what I read. The 1st click of the cocking lever is to cock the action and to stop the lever in case it slips. Second click is for low power and third click is maximum power. It doesn’t say anything about 3 power levels, just low and maximum. Mike F.

Mike,

Welcome to the blog.

That makes a lot of sense! The first click really isn’t useful anyway. So, just low and high power? I can work with that.

Thanks,

B.B.

Mike,

It’s people like you and all the others that take part in this blog that make it the great resource for all. Thank you for your research and comments!

Bruce

BB,

A thought occurred to me yesterday. Do you think the o ring will swell any from absorbing the oil like some of the old o rings will swell from absorbing CO2? Maybe after sitting for a bit with oil in it, the old girl might get at least some of her old zip back.

RR,

No, o-rings don’t swell from oil. The reason they swell is they absorb gas under pressure and it gets inside small holes in the o-ring material and expands. Oil doesn’t do that.

B.B.

GrandpaDan,…

“Got your ears on”? ( that’s CB “lingo” for the younger crowd) What’s a CB???,…. Ok,… we will skip all of that,… 😉

At any rate,.. GrandpaDan,… be sure to give us all an update if you get to shoot that new .22 Maximus any this weekend.

Chris

.22 Maximus update for anyone interested,…

Nice day to shoot. Lower humidity and temps.. Held off till later to avoid sun reflection of the house. Scope picture was much nicer. Perfect in fact.

I decided to go for 40 yards with the Maximus. I did 7 of 10 shots in 3/4″ and the 3 that were off,.. I knew they were off before they hit. So,.. 3/4″ at 40 is on par with the 30 shots in 1″ at 50.

Next up was the .25 M-rod at 100. 2 1/2″ seems to be what,.. I’m/it,.. is capable of on a consistent basis.

Back to the Maximus at 50 on a 15 oz. tin can. 8/8,.. until the 8th blew it off a 3′ pole and out of sight. Back to the 40 and tin can. 2/2,.. of course.

Just some FYI for anyone pondering the Maximus from a very average shooter.

Chris

Chris U

Sounds like a normal fun day of air gun shooting to me.

The weather’s nice as can be here too. Been shooting since around 11:30 this morning. Just stopped for a break and me and the daughters just did some 4 wheel’n. But back to shoot’n now. 🙂

Chris

Always interested in your shooting results. I would say that was very good shooting with both the Maximus, and the Marauder. 3/4″ at 40 yrds seems very good, how far out were the 3? Was that you, or just flyers. Maybe flyers are relevant to PCPs? 2 1/2″ at 100 yrds seems excellent for the .25 cal. also. I don’t think you are an average shooter either…just saying. Your results with the Maximus are encouraging for us guys looking for a TOOL, right GrandpaDan?

Geo,

Thanks for the kind words. I an assure you that I am average and that my results are more typical of home shooter. The 3 shots were all 3/8″ away from the group and randomly placed. BB calls it “calling a pull”. It just means that that pretty well know where the pellet will land based on what you saw in the sight picture (the very second) the shot broke. PCP’s are just easier to do it with because they shoot much smoother. I should mention that 30 in 1″ and the 7/10 were all with the rear shouldered and no rear rest. Just the front was rested. Something rested front and rear will be more indicative of what the gun will do, as the shooter has been largely removed from the equation.

It just takes some time and practice and after awhile it will be instinctual when it happens. The 100 yard shots were all just what they were. No pulls called.

I still find it amazing that you can shoot groups like that with the Maximus. You make me want one more than ever now 🙂 Keep the reports coming, I love’em. Tell me more about the scope you are using and the pellet of choice. Seems that others have said the Maximus is not a picky eater.

Geo,

The scope is a UTG 3-12×44 mildot w/AO on the side and lighted option. One of their lower cost ones. Full size though. I prefer the mildot with the 1/2 mil dash but that is on the etched glass reticles only,.. I believe. I tried at least 10 pellets. The JSB 15.89’s did the best. But you are right,.. it does not seem real picky. I will keep you posted, but that is the type of results that it does without me doing a whole lot or trying very hard at all. It is just a simple and easy shooter.