by Tom Gaylord

Writing as B.B. Pelletier

This report covers:

- Teardown

- 25 years?

- Krytox!

- Petroleum archaeology!

- Grease to oil

- Spring is fully scragged

- Grease formed plugs and solidified

- Start cleaning

- Removing the barrel

- Surprise!

- Piston out

- And rust!

- Diana peened the blind pin in the piston head!

- Cleaning done, time for the Krytox

- Lubed the mainspring

- Assembly

- The rest of the parts go in

- Finishing assembly

- The verdict

- Did I do it wrong?

- What should I do now?

- Don’tcha wanna know how it works?

- RWS Superpoint

- Air Arms Falcon

- Summary

Today is the day we learn whether Krytox is the miracle lubricant that both fixes and quiets spring-piston airguns. I have been hounded by people for more than a decade to try this stuff, and I had dug my heels in real deep, but then it dawned on me that Gene from Pyramyd AIR had been after me for an equally long time to try Almagard 3752 — the grease that turned out to be Tune in a Tube. We all know how that went!

I promised to become the number one Krytox cheerleader if the stuff really works as advertised — by some airgunners, not by Krytox, themselves. But, I will also be only too happy to poke a hole in the Krytox balloon if it turns out we have been hoodwinked.

To quote the comedian Gallagher, just before he slams the Sledge-O-Matic down on the watermelon, “And, don’tcha wanna know how it works?” I sure do, and my plastic sheet is in place!

Teardown

I must love you readers because I started on this project at 4 a.m. Friday morning! It’s entirely beside the point that my two cats started tag-teaming me at 3:15, so I would get up and feed them, because it was time for them to start their 8-hour morning naps!

25 years?

I estimate that it has been roughly 25 years since I have been inside this particular Diana 27. Oh, I have tuned a number of other Diana 27s in the meantime, most recently Michael’s Winchester 427 that is a Diana 27 in disguise. His rifle turned out so sweet that I was moved to look at mine again.

For 25 years my Hy Score 807/Diana 27 has been the fairest in the land. I thought I had blundered into the sweetest spring gun tune that was possible and I was certainly going to leave it right where it was — until Michael’s rifle came along. Now that I know what smooth really is, I want one, too!

Last Friday that I tested the velocity of my rifle before starting. RWS Superpoints averaged 462 f.p.s. and Air Arms Falcons averaged 452 f.p.s.

Krytox!

I’ve been told for years that Krytox is the finest airgun lubricant and why would anyone use anything else? So, I bit. I went online and ordered up some Krytox, so we could all learn together whether it is the greatest thing since peanut butter or just a schoolboy fantasy.

“Ladies and gennemens: In this corner, costing $44 per ounce — the contender — Krytox. And in this corner, at less than one-quarter the cost — the champeen of the world — TIAT!”

Petroleum archaeology!

Sometime in the 1990s I “tuned” my 27 with Army grease made specifically for the M1 Garand and M14 rifles. It is “Grease Rifle Special White Lubricant FSN 9150-754-0063”. That name allowed the Army to pay $12 for the can instead of the $1.25 everybody else was paying for the same white lithium grease in June of 1961, when my can was produced. How do I know all this? Simple,

1. I used to teach the Army supply system at Fort Knox.

and

2. I still have the can and it’s still half full. There haven’t been that many human wave attacks on my place since I moved to Texas!

So, what do you think lithium grease looks like after a quarter century on the job? After freeing the barreled action from the stock I looked through the cocking slot.

Changed color, hasn’t it? It wasn’t pure white to begun with, but there is definitely more brown in there now.

Grease to oil

Another neat thing about lithium grease is that it breaks down into a thick oil over time. That looks bad when it’s in the wrong places, but it’s good because the rifle is forever lubricating its piston seal. I haven’t oiled the rifle in 25 years — that I can remember. My rememberer isn’t that good these days, so maybe I have. I’m just sayin’.

The end cap has been removed prior to popping out the pins that hold the action together. One pin fell out on its own! There is the grease turned to oil I mentioned.

When I pulled the end cap off to put the action into the mainspring compressor so I could pop out the cross pins, the rear pin fell out. Apparently on this gun the front pin does all the work and the rear pin is held in by the end cap.

Spring is fully scragged

This 27 came apart before Michael’s did, because the mainspring is shorter. His new mainspring pushes the trigger cages out another inch before the tension slacks off. Yet my rifle is just as powerful. These older low-powered spring guns will last for a long time because their springs are under so little strain.

The mainspring in my rifle doesn’t come out of the gun nearly as far as Michael’s new one. I guess a half-century plus of partial compression has tamed it.

Grease formed plugs and solidified

The grease that moved as the rifle was fired stayed loose and useful. The grease that didn’t move solidified and just stayed in place.

That plug of old lithium grease inside the black inner ball cage (arrow) is starting to solidify. It’s been pushed there by the end of the piston rod every time the rifle is cocked.

I found grease ridges on the piston that were quite solid. They had to be scraped off.

The mainspring had retained a lot of grease throughout the years. It is still straight and I will continue to use it because it’s still at full power.

The original (?) mainspring is still straight and strong.

Start cleaning

I was 30 minutes into the project at this point. Only the barrel still needed to be removed so the piston could come out. I started cleaning the parts at this point and I was more scrupulous than normal because of what I was about to do. Cleaning the gun took me three and a half hours. I went through many paper towels, shop rags, cotton swabs and acetone. When I was done each part had to not just have all the grease removed, it also had to be completely dry, so the Krytox could be applied to bare metal.

I went through many times this many paper towels, plus rags, acetone and Q-tip swabs, getting all the old grease off the parts.

Removing the barrel

You have to remove the barrel to disengage the cocking link from the piston. Diana eliminated the cocking shoe and put the connection to the piston at the end of the link. The barrel needs to be free of the action forks to move the link far enough to disengage it from the piston. To remove the pivot bolt, after removing the bolt’s locking screw, break open the barrel. The releases the tension that the detent puts on the base block. After the tension is off the pivot bolt should come out easily.

By breaking the barrel like this the locking detent tension comes off and the pivot bolt turns easily.

Surprise!

When I slid the base block (the squarish block the barrel is pressed into) from the action forks I was surprised to see that I had not lubricated the pivot washers when I was inside last time. I expected to see moly grease there, but both washers and the pivot bolt were dry.

Bone dry! The pivot washers should be lubricated, but they’re not!

Piston out

Now the cocking link can be disengaged from the piston and the piston will slide out of the spring tube. Remember to pull the trigger as you do this, because parts of the trigger stick up inside the tube and will impede the piston’s path.

The piston was awash with aged lithium grease. It took about an hour to clean it thoroughly. The outside was easy. The inside around the piston rod took a lot longer.

The piston was coated with lithium grease.

And rust!

I found patches of patina, otherwise known as rust, on the body of the piston. Apparently this metal is very susceptible to rust and will do it while covered by lithium grease.

I scraped off the rust that would come off. The rest wasn’t really rust, but sheetmetal gone dark. It’s possibly a pre-rust condition but is smooth to the touch and doesn’t want to come off. And even if it does come off, the metal beneath will do the same thing over time.

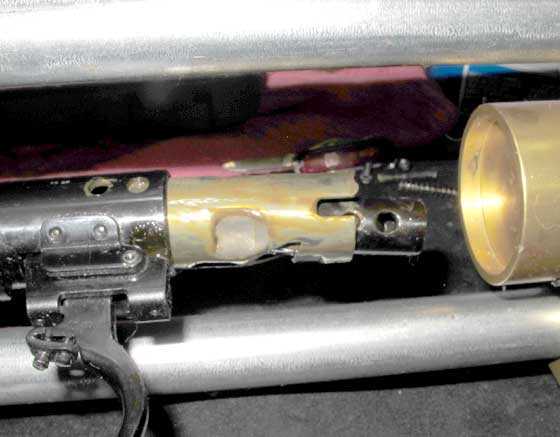

Diana peened the blind pin in the piston head!

Remember the trouble I had getting Michael’s piston seal off? I determined that there was a blind pin that was jamming the screw that held the seal. But was that done at the factory or by an over-eager airgunsmith? I had the perfect opportunity to photograph my piston head that proves that Diana are the ones who drove that pin in deep, peening it in place! This piston seal is not meant to be removed unless that pin is drilled out!

There’s the proof of who peened the blind pin. It was done during manufacture. Tuners need to take this into account when they tune a vintage Diana.

Cleaning done, time for the Krytox

I had been cleaning the gun parts for 3.5 hours by this time. They are all dry, so it was time to lubricate with Krytox and assemble the rifle.

Everything I read said to use Krytox very sparingly. So I did. The most I used was put on the piston head and seal.

This is the piston head, lubricated. As the piston was installed, 95 percent of this was scraped off on the spring tube walls.

I also lubed the rear of the piston with a little Krytox and then pushed it into the spring tube. Remember to pull the trigger to get the piston to enter the tube. The piston slid down the spring tube easily — much easier than ever before.

Lubed the mainspring

When I lubed the mainspring I used a tiny fraction of the grease I would normally apply. Let me show you.

I used this much Krytox on each half of the mainspring. When I was done the coils were shiny but there was very little buildup of Krytox.

Assembly

You lube half of the mainspring and then slide it into the piston that’s inside the spring tube. The half that remains outside the gun is now lubed and slid all the way inside. That pushes the piston to the end of the compression chamber.

I’m sliding the mainspring into the spring tube. The mainspring is lubricated up to where the arrow points. As you can see, this is a thin coat of Krytox, which all the tuners say is the right thing to do.

The rest of the parts go in

After the mainspring is in, the spring guide goes in. It got a thin coat of Krytox on the outside which will get on the inner spring coils as the rifle is cocked and the mainspring is compressed. I also put some at the open end of the hollow guide that the piston rod passes through. That will coat the piston rod when the rifle is cocked.

I then put some Krytox on all surfaces of the end of the cocking link and connected it to the piston. Then I lubed the pivot bolt and washers with Krytox before installing the base block in the action forks and tightening the pivot bolt. I tightened the bolt so the barrel will stay put in any position on a cocked gun. Then I locked the bolt head with the small screw. Now the rifle is ready to receive the two trigger ball cages and cross pins that will hold the action together.

Will Krytox hold the ball bearings in the inner black cage? Yes, it will. Krytox has enough tackiness to hold the balls inside the black cage. Once, during assembly, the black cage fell to the floor and all three balls fell out. But the Krytox stopped them before they rolled too far. For comparison, TIAT probably would have held them inside the cage though the fall.

Krytox is tacky enough to hold the three ball bearings inside the inner cage during assembly.

Finishing assembly

Assembling the trigger parts is the real challenge to assembling a Diana with the ball-bearing trigger. The toughest part is that spring the pushes the inner and outer ball cages apart. It humps up under compression as the cages are being pressed into the spring tube and until the spring tube contains it, it wants to spring out of place. It did that three times during assembly. Fortunately I was familiar with assembling this trigger (from Michael’s gun) and my finger was pressing down on this spring all the time. It made it to the floor twice, but couldn’t go very far.

Finally the rifle was together agin and the two crosspins were in — remembering that the rear pin has no tension on it until the end cap covers it. Then the barreled action went back into the stock and the rifle was whole once more. This job took about 5.5 hours, start to finish, with no distractions. That’s four hours longer than normal, and all of that was due to cleaning.

The verdict

So — what’s the verdict? Does Krytox reduce vibration as well as Tune in a Tube?

Nope!

In fact, Krytox has allowed some high-speed vibration to creep back into my Diana 27 action — vibration that I haven’t felt in 25 years in this air rifle! It isn’t much and if you didn’t know what a smooth gun should feel like you might be fine with it this way.

Am I angry? Was this a wasted effort?

Nope!

I had been told all the good points of Krytox grease for tuning airguns and now I have seen what it actually does — not relative to Tune in a Tube, but to plain white lithium grease that was 25 years old. It’s nowhere close to what TIAT can do, and it’s even less of a vibration damper than the lithium you can buy at any auto store.

Did I do it wrong?

Probably. I’m sure those who favor Krytox will now expound on all the mistakes I made. I used too much. Too little. I didn’t clean good enough. I didn’t cross my eyes as I applied the grease. Something! Probably many things!

What should I do now?

I said at the beginning that I want a quiet air rifle like the one I tuned for Michael. That’s what I want and that’s what I’m going to have. On the other hand, I still have this Krytox and there is at least enough left for three more rifles and probably for four.

So, I will listen to the many critiques of this job and apply them to my next tune with Krytox. Remember — I have three Dianas coming from reader Carel. The Diana 35 won’t get Krytox because I’m trying to stop its buzz and I know Krytox isn’t as good as TIAT for that.

Don’tcha wanna know how it works?

We know Krytox doesn’t dampen vibration, but what does it do to velocity? Let’s see.

RWS Superpoint

I only had 5 Superpoints left, so here are the velocities

Shot………Vel

1………….464

2………….433

3………….413

4………….430

5………….435

The average is 435 — down from 462 at the start of the report.

Air Arms Falcon

Falcons loaded easier but the rifle buzzed a lot more when shooting them.

Shot………Vel

1………….445

2………….447

3………….445

4………….441

5………….441

The average is 444 f.p.s. — down from 452 at the start of the report. Krytox doesn’t increase velocity in my Diana 27, it lowers it. I expect TIAT to lower velocity, as well, so that’s not a problem.

Summary

I tried something that didn’t work for me today. Could I make it work if I kept on trying? Maybe. But I already know what does work, so I’m switching to that next.

I hope you didn’t feed the cats one minute before the usual time. Personally I feed the dog WAAAY after my usual wake up time so she doesn’t have any incentive to wake me up.

The idea that such a thin layer of grease would dampen vibration is bizarre to me. No wonder you waited a decade before trying it.

B.B.,

From what I understand Krytox is excellent as far as lubricity is concerned. How tight was the tolerance between the spring and the piston body? If there is some space between you probably should shim with either a beer can or a plastic milk bottle depending on how big is the gap. That might remove the vibration. Then again you just simply apply TIAT without taking it apart. 🙂

Siraniko

PS: Section The rest of the parts go in. First paragraph, first sentence: “After the mainspring is in, the spring guide goes it (in).”

Siraniko,

Fixed it. Thanks.

There is a gap in the parts. Yes, I could have reduced it with shims, but I didn’t have to do that with Michael’s rifle and I don’t want to do it here, either.

B.B.

I think this is the point with krytox. You have to be mechanically sound or the spring will still vibrate. Covering up a loose tolerance with grease is only masking a defect.

I use it and will continue to do so. The benefits outweigh the trouble of shimming things.

B.B.,

Thank you for the extra effort required to investigate this. The advocates of the Krytox now need to tear theirs down, use some TIAT and then report back. 😉

Good Day to you and to all,……… Chris

BB,

Whew! I am glad that did not work. What was I going to do with my lifetime supply of TIAT?

RR,

I know what I’m going to do with mine! 😉

B.B.

BB, another excellent report, from which we all learned something. After many years in the Engineering field I realized that a failed experiment is the one that didn’t teach you something. I am sure that Krytox is a great lubricant for some applications, it seems to be particularly effective to reduce friction and works well at high temperatures where most greases fail. That being said, it is just not what we need to reduce vibrations. Lesson learned.

Thanks again,

Henry

Thanks for the report B.B.!!

In addition to the typical cans/tubes of gear grease I have a good supply of the “special stuff” – clear silicone grease, white lithium grease, black moly grease (in several flavors) and red TIAT grease… been wondering if Krytox would be added to the list. Now we know. =)

…And now, for some reason, I have this incredible urge to disassemble a springer or two.

Happy Monday all!!

Hank

B.B.

Very nice detailed report. Was the piston seal still in good condition? If you were to replace the seal, would that require the whole piston assembly to be replaced? I was thinking that possibly the peened locking pin could be drilled and tapped so that a screw and nut could be inserted with a small bushing slightly larger than the pin. Then the nut would act as a puller to remove the locking pin. Just a thought.

Could you now disassemble just enough to get the spring back out and put the TIAT on it to eliminate the vibration? At least you shouldn’t have to do any cleaning which was so labor intensive. The Krytox may be a very good lubricant on the other moving parts and trigger assembly. Does the Krytox have any anti-rust properties?

I found that grease alone has poor anti-rust properties and does not prevent rust from forming on my table saw. Using CRC SP-400 anti-corrosion spray prevents rust from forming on the table indefinitely and is much easier to remove when I want to use my table saw.

Geo

George,

The piston seal is in great condition. I plan to remove the Krytox before relubing, but this time I’m not going to be fanatical about it. And once the mainspring is out of the gun all the hard work has been done, so removing the piston isn’t much more work.

Nice thought on the blind pin. It would probably work.

B.B.

BB,

Very nice tuning article on a vintage airgun close to my heart. I upgraded from a Crosman 760 multipump to a Hyscore 807 in the 1970’s and boy did the barn pigeons regret it.

I caution the use of fluorocarbon lubricants in the chamber or barrel of a spring piston gun. Peak chamber temperatures (above 800C) can easily exceed the breakdown point of Krytox lubricants.

Fluorocarbon ethers are fantastic inert lubricants until they start to decompose above 400 C. The decomposition products are extremely toxic as they include hydrofluoric acid and carbonyl fluoride. Read the safety data sheet. The downhill ski wax companies had to issue warnings about avoiding overheating fluorowaxes when melting.

I personally don’t use pellets lubricated with fluorocarbon additives-particularly indoors.

Here’s a link to a Krytox grease SDS:

https://3eonline.com/ImageServer/NewPdf/ae0b2241-ebc2-4d1f-99a3-17b165ddb42a/b02a0b11-3a4e-418d-a039-a1b0e65a77a8.pdf

piper,

Hydrofluoric acid!!! Yikes! I had no idea! Isn’t that the most corrosive acid there is?

B.B.

Yes HF is a very corrosive acid and particularly dangerous to humans as it attacks bone. There are other health concerns about fluoroether compounds even if they aren’t thermally decomposed. As we all know, airguns are excellent aerosol generators. Any fluid we put in the barrel or chamber is partially aerosolized creating huge numbers of micron-sized mist particles. We should think twice about what we inhale in indoor ranges.

I don’t have any problems with using fluorocarbon greases on the pivot assemblies of my springers, the lubricity is great. I stick to using ballistol for barrel cleaning and paraffin or organic waxes for pellet lubrication, which I rarely use. I don’t have scientific evidence that those compounds are truly safe for indoor use but the combustion products on dieseling are more mundane.

Caveat Emptor: I’m not an industrial hygienist

Piper,

Thank you. I will probably cease tuning with Krytox as a result of this.

B.B.

B.B.,

I was impressed that the lithium grease remained slathered on everything the way it did. Are you concerned the piston might corrode more rapidly now that there is no film/barrier on it?

TIAT remains the undisputed heavyweight champion of springer air gun tuning grease. I am surprised the Krytox didn’t make the action quicker. I incorrectly expected it to do that but fail to reduce much vibration. I chuckled aloud when I read, “I didn’t cross my eyes as I applied the grease.” I’ll bet you also forgot to burn Tibetan incense and walk to the workbench backwards, LOL.

But I think we know what to expect after you finish this job on your Diana 27. It will likely be as smooth as you made my Diana 27/Winchester 427. If mine is “The Gaylord 27,” perhaps yours, once it is just as smooth, should christened “The Krytox Killer?” I do imagine that Krytox is excellent at many applications. At the price it commands, it would have to in order for so many folks to purchase it.

Michael

Michael,

I think that piston metal will rust no matter what. And see — I knew there were things I forgot to do! 😉

B.B.

B.B.,

Ah, don’t we all forget something. :^)

Well then. I suppose you will just have to open it up again. Hey, you know already that you will apply TIAT to the usual places, but you could take a little time to ponder what would be an ideal rust-delayer, one that would probably play nice with the TIAT. I would be very interested to know what you end up using and why. We all know that “rust never sleeps,” so it would be good for many applications.

Michael

Michael,

I think Ballistol might work.

B.B.

B.B.,

That’s what Read-Response checklists are for!

Maybe you can get one of the cats reading!

They need to work for their vittles!!!!

Enjoyed your report. Considering the horrors of that BLACK Spring Tar used by some; KRYTOX just seemed low on viscosity to get the dampening job done.

shootski

I was told that it’s more about how you hold your tongue and which side of your mouth it protrudes from. I haven’t tuned any airguns, but these lessons make me feel like I should. Guess I’ll have to start looking for something old and rusty.

Edlee,

I am old, And my wife says I’m rusty if I don’t get off the sofa and get something done every once in a while!

Michael

B.B.,

Given the occasion, I thought I would share that yesterday was sunny (finally! some linking weather) but a bit chilly, so I did not stay out long and had to space out my shooting sessions. I took The Gaylord 27 out and shot it about fifty times total. The cocking was smooth and light at the start, but it did lightened even more by the end. My guess is it now cocks at about 16-17 pounds.

I forgot to try something I will try today if I have the time. Before I put my Diana peep sight on my Diana 50/Winchester 450, I want to see if it will visually clear the open sight on The Gaylord. That would make easy for me to determine which helps me shoot more accurately.

Michael

BB, BB, BB, of course the Krydox wasn’t going to produce the same results.

You forgot to drill the hole in your barrel for the rear sight like Michael’s gun. Oh and most importantly fix the hole the same way as you did Michael’s gun.

How could this even be a comparison.

What was you thinking. 😉

GF1,

Silly me! 🙁

B.B.

BB

🙂

And on the serious side. Now to see the difference with the tune in a tube compared to the lithium grease you had in your gun.

And you talked about the color change of the lithium grease. I’m thinking that was from the moisture in the gun after heating and cooling and making moisture. That surface rust you see inside your gun.

I don’t think the moisture can be stopped. But maybe the tune in a tube will help prevent it more than the lithium grease. Maybe???

GF,

For what is worth, at work we had very good luck with LPS 3. I’ve always used the spray cans to lightly coat what had to be protected. it dries to fairly tack-free waxy texture.

I don’t know how well it does long term, say 20 years, but on shorter time frames it was very effective in nasty industrial environments.

Henry

Henry

I use lithium grease when I tune spring guns.

I think I will try TIAT on a springer sooner or later. To me it’s awful tacky though from what I’m getting from what people say. I think learning to use the right amount of it will be the trick. We’ll see.

GF1,

The right amount is the trick with TIAT. It’s less than many people think. I showed the amount in Part 5 of Michael’s tune.

/blog/2019/01/tuning-michaels-winchester-427-part-5/

The gun was taken apart and assembled two times after that and no more TIAT was put on the spring.

B.B.

BB

Yep I had that in my my mind about TIAT for some time. Now I need to get me a springer to try it in. Maybe even a magnum springer like one of the Diana 460’s or even the Diana K98 Mauser.

And thought about this and forgot to ask. Is the spring in Michael’s gun new or the original. And how about yours? Could that be why Michael’s gun is smoother

GF1,

Michael’s rifle has a brand new spring. Mine is old. Mine should be smoother.

B.B.

BB

You would think that. But maybe the process and steel is different now days compared to back then.

When you try the TIAT in your gun we should know some of that answer.

Back in the day I used Waxoyl on an MG Midget. Mine was a pretty crude application, paint brush and a pump-up sprayer. Worked good on the Midget. That was about 40 years ago.

Googling, I see that the product is still going strong but is described as a thick liquid. I recall a lower viscosity, about the level of a 10W oil or less. I don’t recall thinning it but I was able to spray hard-to-reach areas with a garden sprayer.

Anyway thought that something like this might be useful on the hidden but non-wearing ares of a fine spring gun. If one could purchase it in less than industrial quantities.

Just a thought…

Dan

Tom ,

I am glad You did this test. I am sure the Krytox is a better lubricant , but too thin to prevent vibration. Before We found out about the TIAT I just used Lithium grease from NAPA . I found it to be the best all around lube as it didn’t slow down the low and mid powered guns as bad and had enough tackifiers to dampen vibrations. TIAT is the only way to go when working on anything from HW50 size and up !!

Gene,

Like I said in the report, you told me about TIAT many years before I actually tried it. So I had to try Krytox. And I agree, it’s probably a superior lubricant. If I even tune another gun like the Diana 45 I did a few years ago, where I buttoned the piston and made a super-tight spring guide, I might try Krytox in that.

B.B.

Tom ,

I agree, the Krytox would be good in a gun with a tight spring to guide fit . With a tight guide even Lithium grease will bind it up . After I found out about TIAT It took me awhile to switch out . What TIAT does to a production grade gun is amazing . I have tried/experimented with different greases and even Gear oils . Grease is the best barrier lubricant by far . In a real tight gun any Non-Fluid oil is also good. I have tried some LSA in guns, it is too thin to prevent buzzing but is good for pistons in gas ram guns .

Gene,

LSA! How many years has it beed since I carried a bottle of that in the camouflage band on my helmet? Heck, I didn’t even wear the PASGT “Fritz” helmet — I wore the M1.

B.B.