by Tom Gaylord

Writing as B.B. Pelletier

Michael’s Winchester 427 is a Diana model 27 by another name. The rifle pictured is my Hy Score 807/Diana 27

This report covers:

- SHOT Show

- Today and Monday

- New parts

- Scragging?

- Lubricating the mainspring

- Rust removal

- Lubrication

- Putting the piston into the spring tube

- Pull the trigger!

- Attach the barrel

- Break

Many of you have been reading this series in which I tune reader Michael’s Winchester 427 that is actually a Diana 27. This is not an air rifle for beginners to learn on! The mechanism is too complex for first-timers for a number of reasons that should become clear today.

SHOT Show

I have to tell you — this is a very lengthy report. I won’t get it all done today, so Monday I will finish up. And on Monday I will be in Las Vegas at the SHOT Show. I won’t see your comments as frequently as usual while I’m there next week, plus after I walk out of the show every day I have to go back to my room, write the next day’s blog and have it ready to publish by 9 p.m. which is midnight on the east coast where the WordPress server publishes the blog. So please don’t ask me any lengthy questions. I am not going to have dinner with anyone this year, so I can do my work without being whipsawed!

Today and Monday

Today and Monday could be called, “Putting her back together,” because that is what I am going to do. In Part 4 you read and saw how I cleaned the major parts. They were rusty, but by soaking them in Ballistol for many days the rust loosened and came off quite nicely, revealing a gun that really has not been shot or used that much. I have certainly seen others that were a lot more worn.

Several readers asked me to show how I lubricate the gun parts as they go back together, and that is a big part of what I will do today and Monday. I will also pass along some tricks of the trade that will help you in the assembly process. Let’s get started.

New parts

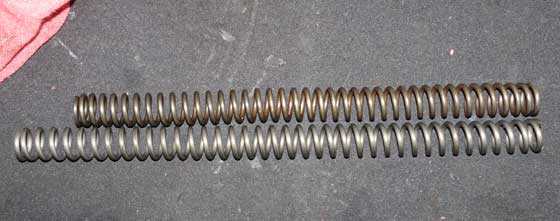

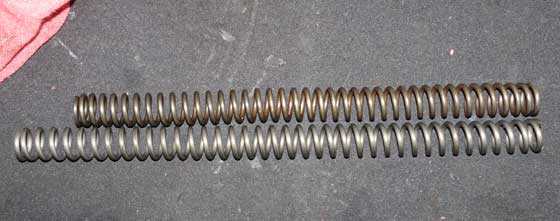

I have already told you that I’m installing a new piston and piston seal assembly. You can see both of those in Part 4. Michael also sent me a new mainspring that he obtained from Chambers in the UK. It is not yet scragged (shortened by compression), so it will be harder to install than the old spring would be. The old spring is in good condition and would be fine in this rifle, too. But Michael bought the new one and that’s the one going in.

The new mainspring (bottom) is longer now because it has never been scragged. After being inside the rifle a few days it will become about as long as the old spring.

Scragging?

Should I have scragged the spring before installing it? It would have made installation much easier. To learn more about scragging, read this report.

Lubricating the mainspring

Many of you wonder how much lube to put on a mainspring. Some also wonder what lube to use, but a regular readers knows I recommend Tune in a Tube (TIAT) grease that’s available here at Pyramyd AIR. If you are an overseas reader or if you want a lifetime supply of the stuff it is Almagard 3752 grease. I have written a lot about how well it works — now let’s see how much we should use.

Here you see the lubed spring on the right and the dry spring on the left. This is lubing “sparingly”, which is all the Diana 27 spring needs.

The Diana 27 is neither powerful nor is it notorious for vibration, so the spring doesn’t need that much grease. And Tune in a Tube is probably different than any grease that most of you are used to. It’s extremely tacky and doesn’t vibrate off. It doesn’t take very much to quiet any vibration, so use it sparingly. Because of its nature, you’ll use more than you intend, so apply it lightly and spread it around.

You will note that I did not lube the inside of the mainspring coils. But I did lube the spring guide and the piston rod with TIAT. They will transfer their grease to the inside of the spring coils as the rifle is cocked and fired. If I was using white Lithium grease I would have lubed the inside of the spring coils.

I lubed half of the spring, then stuffed it into the piston that was already inside the rifle (I haven’t discussed that yet). That held it so I could lube the other half and not get too much grease on me.

Rust removal

I mentioned using Ballistol to remove rust from the parts. The other thing I used was steel wool. I used OOOO wool on the inside of the spring tube and I used a stainless steel pot scrubber on the other parts. The parts were coated with Ballistol when I rubbed them. I will show just one so you get the idea.

The spring guide was rusty before the cleaning. It’s not bad, but look at what can be done.

After cleaning the guide with Ballistol and a stainless steel pot scrubber, look how clean it is.

Lubrication

All the other parts were cleaned in this same way. That gave them clean surfaces for the lubrication. Like I said — TIAT on the spring guide and piston rod, as well as the mainspring.

The inside of the spring tube was coated with a thin coat of Moly grease. Now, molybdenum disulfide is not grease. It’s a dry compound that bonds with steel to form a low friction surface. The grease is the vehicle that the particles are mixed in that allows the moly to be applied more easily. To apply it to the inside of the spring tube I use a thin wooden dowel that’s wrapped with a bit of paper towel at the end. I can then swab the moly on the inside of the spring tube like using a giant cotton swab.

Coat the paper towel with some moly and then spread it all around the inside of the spring tube.

I used to also coat the piston with moly front and back until I realized that the piston seal prevents the front of the piston from touching the interior spring tube walls. That’s part of its job. Now I only coat the flared rear section with moly. It conceivably touches the inside of the spring tube from time to time, because small scratches in the blued finish on the inside of the tube show it. Read Part 4 to see what I’m talking about.

Putting the piston into the spring tube

This is where the assembly begins. The new piston with its new leather seal has to go inside the spring tube first. I have soaked that leather seal in light oil for several days, so the leather is soft and pliable. The insert inside the seal (see Part 4) keeps it from collapsing in on itself.

The seal appears to be larger than the spring tube because it is full of oil, but it is also very pliable like a loaf of soft bread. I insert three-quarters of the seal into the end of the tube, then use a flat-tipped screwdriver to press in the other quarter as I gently push in on the piston. This is a careful technique like putting on an expensive pair of new leather shoes with a shoehorn. You don’t want to damage or distort anything and if you work carefully you won’t need to.

Pull the trigger!

As you press the piston into the tube it soon comes in contact with two hooks on the end of the trigger. I will explain what those hooks do in a bit. Pull the trigger back to move the hooks out of the way and keep pressing the piston into the tube. Watch each open window in the spring tube, to make sure the leather seal doesn’t hang up on any sharp edge that will shear off some leather. Use the screwdriver to press the seal back into the tube at these points. At some point the piston will go all the way into the tube where there is no more worry. Use the mainspring to press it in when you can’t push it with your hand.

Attach the barrel

Once the piston is in the tube, attach the barrel and cocking linkage. The end of the cocking link is flared and the front of the cocking slot has an enlarged hole through which the flared end of the linkage must pass. The flare keeps the cocking link inside the spring tube as the rifle is being used. Coat the flare top and bottom with moly grease that will transfer to the piston and the inside of the spring tube where there is already some moly.

Once the link is attached put moly on both sides of both base block (the section that holds the barrel and the pivot bolt) where the washers go and slide the base block into the spring tube fork. On some guns the washers will walk out of position, but the Diana 27 washers fit in machined recesses on either side of the base block. The washers are different, so each one only fits one side of the base block. The moly grease will hold them in position during this operation.

The last thing is to put some moly on the pivot bolt and screw it tight. The Diana 27 has a place for a locking screw to hold the pivot bolt in place, but Michael’s gun did not have one when I got it. As long as he watches the tightness of that bolt there shouldn’t be a problem.

Break

I will end this report here because the next part involves putting the trigger together and is very long. You have already seen several things that might be called tricks of the trade. On Monday there will be many more! Have a great weekend and I’ll see you next week.

B.B.

Remember, “what happened in Vegas, stays in Vegas…..”

If the edges of the windows in the spring tube are so sharp that you worry about cutting your leather seal, why didn’t you file/sand them smooth?

Have fun,

Yogi

Yogi,

Even if the holes and slots were free of burrs the leather would extrude out through each hole as the seal came to it and hang up the piston. Forcing the piston in without poking the leather back into the tube would shear a chunk out of the leather. Synthetic seals are more like steel piston rings and will more or less maintain the circular shape of the spring tube if the hole or slot isn’t too wide, but an oil-softened leather seal will be pliable enough to poke out of any hole it comes to.

Half

Yogi,

I usually do that, but this Diana is so well made that it isn’t a problem. Still, because the seal bulges, you have to take care.

B.B.

BB,

Thanks to you and this blog and its many experienced readers/commenters, Because of it, I recently developed the confidence I needed to tear into my RWS model 52 to replace its broken spring with a Pro Guide kit from Air Verturi. I have to say that the Pyramyd AIR website almost scared me away with their warning that the kit was for, ” professional installation only”, but after reading every report of yours that had to do with Diana/RWS tear downs and Model 48/52 reviews and in spite of my fear of the T01 trigger and its mysterious trio of steel balls I felt equipped to do the job. Well, that’s not entirely true, what I was actually sure of was that I wouldn’t be able to get the gun into a mess that a plea for help to you and your readers wouldn’t be able to undo. 🙂

I bought a Sun Optics spring compressor and went to work. Glad you and the other guys were there in the background because the instructions that came with the kit are ..uh….incomplete. I am also absolutely thrilled that I didn’t have to fool with dis or re assembling that trigger group! For anyone that might do this repair/mod, a short length of the pointy end of a bamboo skewer is perfect for moving that safety spring out of the way for the reinsertion of the two pins that go in the rear of the gun to retain the trigger group. You’ll see what I mean, if you ever get there. 🙂

Seriously, these tear down and rebuild reports go a long way towards taking the mystery out of airgun workings. So please keep doing them and thanks. I’m sure that the tricks you reveal on Micheal’s gun will give someone else just the nudge they need to put an old Diana 27 back in working order.

Half

P.S. under “Lubricating The Mainspring” second sentence,….but AS regular readers…..

Halfstep,

Glad you were able to open up your rifle and repair it. Thank you for that tidbit that bamboo skewers are enough to retain the trigger group. I was over thinking about it and was wondering if I had to use cut off sections of a 4 inch nail. Now all I’ll have to do is get round to making a spring compressor.

Siraniko

Siraniko,

Just remember to put the rearmost pin in first. My new spring didn’t have a terrible amount of preload on it but I don’t think I could have gotten the pins in while pushing in on the assembly by hand, so I do recommend a compressor, it just won’t have to be built like a tank, so don’t let overthinking that part keep you from it. Do you have a broken gun or do you just want to improve yours?

Half

Halfstep,

Piston seal deteriorated. Still scrounging for parts for the spring compressor. Hopefully that’s all it needs.

Siraniko

BB,

When working on my 1906 BSA I had the same issue with the leather seal being swollen with oil to the point it did not fit the tube. My solution was to take a strip of pliable plastic and wrap it around the seal after it was installed on the piston. I then put a hose clamp over the plastic strip and gently tightened the clamp until the seal was smaller in diameter than the tube. After letting it sit for a minute, I quickly removed the clamp and plastic and carefully slid the piston in the compression tube before the seal expanded to fit the tube.

If anyone out there in TV land has not guessed by now, the purpose of the plastic is to keep the hose clamp from cutting the leather seal, most especially where the gear tooth holes are.

Like I tell Kathy all the time, “One of those tricks I learned in the Congo.” 😉

B.B.,

Glad all is going well. Have fun at the show. As always,… we will be looking forwards to the day’s recap.

No dinners? I can see that. It does not do a body good to get worn out. Still, I would think that some that you have had previously and depending on who they were with,… would be some of your most memorable moments at past shows.

Then again,.. people (go) to see The Godfather,… not the other way around. 😉

Good Day to one and all,……….. Chris

B.B.,

I really like the part about the “giant cotton swab.”

That could be useful on everything from airguns to motorcycles; thanks.

Safe travels to you,

dave

B.B.,

Thank you once again for doing this. I am glad it is providing the blog with so much excellent content.

For my own future reference I saved a copy of your photo of the new mainspring with TIAT grease on one end and the other not yet lubed. That photo is gold! It will be my guide when I dive into my “learning”

air rifle (a late model, beat to death BSA Meteor)and then others to lube their springs to decrease vibration.

Thanks to you, this classic air rifle of mine is being brought back to life. Your observation that it probably has been fired very little makes this restoration all the more important, I think. An air gun such as this deserves to be shot and enjoyed. It would have been a travesty for it to have become just a parts air gun without first having been well-enjoyed for many years.

Michael

Michael,

I just placed an order with Chambers for the locking screw for the pivot bolt. And, as long as I was there I bought a synthetic breech seal, because the Winchester 427 came with one.

The rear sight is still on my to do list. I may not be able to fix it — we’ll see. But I will install a temporary rear sight for the accuracy test.

I will tell you now without spilling the beans on Monday’s blog that your rifle is in fine shape now. It shoots better than mine! I will explain on Monday.

B.B.

Michael,

This thing is gonna be sweeeeet!

Once B.B. has it all done and gets it back to you,

you might want to post your own mini-review and let us all know what you think.

I believe that would get a lot of interest from the folks who read this blog. =>

Have a great weekend,

dave

Dave,

I can’t wait to get my hands on it and shoot it. I put only a couple pellets over my chrony after I received it. B.B. is correct whenever he writes that everyone should have a chronograph. It really is an important diagnostic tool to determine if something is amiss inside an airgun. Performing far below what it should have been doing is what told me it must not have been right, no matter how nice it looked for an air rifle that age.

Michael

“B.B. is correct whenever he writes that everyone should have a chronograph.”

Amen to that! B.B. is the one who talked me into buying mine. =>

Michael,

Testing a new pellet over my chrony is exactly how I discovered I had a broken spring in my Model 52. If you own many airguns, I don’t think you should be without one, or at least have a buddy that has one. Heck, I don’t guess he even has to be a buddy, just someone you can tolerate for the 15 minutes it takes to check a gun out. 🙂

Half

Michael,

Go for it! The best way is to jump in with both feet and do it. Most of these oldies are relatively simple and well constructed enough to withstand minor abuse during use and restoration. Once you are done you have the double pride of owning a fine old airgun and having restored it yourself.

RR,

My old BSA Meteor is in woeful shape, but it will be a good example for me to cut my teeth on. If I mess up a thing or two, it is really only about an $8 air rifle anyway. I need to install a new trigger return spring and new breech seal, and take look at the spring and piston.

Unlike this Winchester 427 / Diana 27, the BSA has a worn and chipped stock, rust all over its outside, and is really a mess. It will be good for me to learn with before I work on any nice air gun.

Michael

Michael,

There you go. If you should mess it up, no big loss. If you get it cleaned up and working it will become the pride of your collection. My 1906 BSA was not working when I got it. Now it hangs over my fireplace and I so enjoy taking it down every once in a while and kill a few feral soda cans with it.

RR, is this the same as the 1906 BSA you have?

http://www.oldbike.eu/museum/1906-2/1906-bsa-lincoln-jeffries-air-rifle/

Dave,

Almost. They had two configurations of stocks. This one is the target or competition style. Mine has the straight style.

Cool! I like that straight style even better; you’ve got a real sweet rifle there! =>

Dave,

It is real sweet! I too prefer the straight stock. What does not show up well in the photos because of the dark finish on it is the stock is a nice tiger striped walnut. I have been debating long and hard about whether to strip it and refinish it. I think it has been done once before because the checkering seems to be almost gone. It has probably been worn down from usage.

“… the stock is a nice tiger striped walnut.”

I tried to enhance the pic for you to bring out the beauty of the wood…gorgeous!

Dave,

The walnut table it is sitting on doesn’t look too bad either, does it?

Yes, that table it’s sitting on is a real beauty as well! =>

RidgeRunner,

Whether or not you decide to refinish the stock….rechasing the checkering is not hard if you have the patience and tools. I know you have the patience. Do you have the tools?

Kevin,

The tools are easily obtainable. the trade mark will be a little more difficult, but not out of the question. It is being given serious consideration.

Dave,

That is our dining table. It is about 10 feet long. It was made from a local tree by a local craftsman. The top is about 3 inches thick. The legs and framing are 4″x4″. All of it heart walnut. It is all two men can do to pick it up and move it a short distance. Fortunately the two top planks can be unbolted and taken off if need be.

Kathy jokes that I bought the house for the table.

RR, that is totally awesome!

That’s not just a table; like the stocks Hank (Vana2) makes,

it’s a work of art! =>

Dave,

Thanks. It does go well in our log home.

=>

RidgeRunner,

That is one beautiful air rifle! I am a sucker for that straight, western-style line on the lower edge of the buttstock. That’s one of the things that at first glance attracted me to the Air Venturi Bronco. I also have a C-1. It kicks tyoo much to be very fun to shoot (B.B. declared that model the one that is responsible for the artillery hold: /blog/2009/05/the-beeman-c1-part-1-the-rifle-that-created-the-artillery-hold/ )

Michael

Michael,

LOL! Now you are starting to realize why I am hooked on these old gals.

You can tame that C1 down some and turn it into a real smooth shooter. It depends on what you want to do with it.

RR,

If anyone would know how to strip and refinish while at the same time highlighting the tiger stripes,…… I can only think of one name.

Chris (nice on the 2nd pic.)

Chris,

Let me guess. Hank?

RR,

Of course. At least run it by him. It may be on par with painting restoration which is highly specialized and slow. Maybe years of patina build up? There may be more that can be done over and above just stripping and finishing (in order to bring out the tiger stripping).

Chris

Chris,

I am certain there is. I do have to be cautious about removing any wood as I would not want to remove any of the checkering that remains. Besides the checkering, there is also the company logo and stock length.

This is likely another one of those round tuits.

Chris

I do hope that’s going to be a report from Hank too.

How to finish the wood.

GF1,

I think you just signed Hank up for two more blog entries.

Mike

Mike,

If you look at the end of Part 4, he did say 2 more installments. 5 = checkering, embellishment’s, etc.. 6 = finishing.

Chris

Mike

Job wouldn’t be complete with out finishing it.

I hope Hank has something planned with stock finishing

Let us Dream a little bit with Giles.

https://www.youtube.com/watch?v=qetKADz_FOs

RR,

Impressive. That is the most I have watched on the gun thus far.

Giles,….. I love that guy to death! Well,… not actually “love”,… or “to death”,… but you get the idea. 😉

He is getting quite spiffy with his videos I must say!!!! Butlers, limo drivers, bench side food service. Tea and crumpets anyone? He is getting really good at shooting and editing, not to mention VERY creative and entertaining content.

And,…. talk about being photogenic! 😉 Among the many, he is right at the top.

Chris

Chris,

I have always enjoyed his reviews, but this one is about the best so far, warm bath and all.

RR,

I (MUST) confess,…. I watched only 95% of it. I DID miss the last “warm bath” parts. As they say,… the Brits are known for their rather dry and cheek-ish humor. We could use a bit of that.

Chris

Chris,

Indeed. 😉

R.R.,

Really enjoyed Giles on this one! Just watched it this morning! Been busy with a new PB.

The FX Dreamline is Dreamline for shooters who are just getting into THE DARK SIDE!

The 250cc air tube makes it very much hand pump friendly…even if you are challenged by pumping to 3,000psi you can pump to some pressure above the regulator and just put up with fewer shots. Giles is another reviewer who is honest and factual in his reporting and we all know they are few and far between even in airguns.

I had been torn between the SIG P210 Target and the P320 X FIVE Full-size for months. I knew I had promised myself a reward for waiting to 70 to draw my Social Security Retirement and just needed to decide which one was going to be that reward. I have been back East for a few weeks and had been visiting the gun department at the herbs Marine Corps Exchange and drooling over the PBs ;^). Yesterday the staff were unpacking a new shipment and had three (3) X FIVE with a price tag that I just couldn’t resist! They also had the same deal as the SIG Page with the ROMEO 01 (NO BASE) for less than half the normal MSRP! Got one and now need to wait for the baseplate to get back in stock.

If you want a top of the line small reflex (red dot of 3 moa) this deal is a steal!

shootski

Shootski,

This thing should be most hand pump friendly. You should also be able to top up a few times with one of the buddy bottles. The price tag may make more than a few newbies choke though.

I have had my eye on one of the Sig Romeo sights for some time. They are really nice from what I have heard. I think I would rather get my hands on an Echo1. 😉

Something else that has tempted me for many years has been the Edgun Lelya. I have desired one since the very first time I found out about them. The latest version of the Lelya has my attention like never before. The one reason I have not added one to my “collection” has been the price tag. These little babies have a price tag to rival almost any top shelfer.

Now, another Russian company has come out with a small bullpup that rivals the Lelya and is a little more “affordable”.

/product/ataman-bp17-soft-touch-22-air-rifle-black?m=4714

You are still going to need a thick wallet, but not quite as thick.

I noticed the same thing about the piston, but still smear grease over the whole thing to keep it from rusting…

G’day BB

Tune in a tube…I wonder if that would quiten the spring in a semi auto shotgun. I will order some and try.

Cheers Bob

Hi Bob,

I believe it would. Let us know.

B.B.

Bob from OZ,

Could be the Cat’s MEOW!

I would, however, start out with a very, very, very light application; following the Less Is More school of thought. TIAT as B.B. has pointed out is very viscous and may hinder the autoloading capability by slowing the action too much.

Hope it works for you!

shootski

There is an awful lot of Dreaming going on right now.

https://www.youtube.com/watch?v=VH5LoEKtol0

Anybody want to buy an HM1000X?

I’ve been looking at single stroke pneumatics, both on old blog posts here and out on the net. It’s the usual sort of thing, I’m wondering why there aren’t more powerful examples I can buy easily!

I’ve seen the Freedom 700, and the Parker Hale Dragon. Even looking at the pump-assist Benjamin Marauder as it’s got an interesting linkage

I’m getting the idea that for what I want, I will have to build myself. So I guess what I’m wondering is if anyone has seen any one-offs or custom builds that go beyond what is normal?

On a somewhat dimly related subject, I’m also thinking about building a spring-powered cork gun which can be armed & fired like a spring gun, or maybe I want it to be a fire piston also? But the cork gun idea is to have something that be reset & fired again very quickly, something like a multi-shot springer

As a trigger fired fire-piston, I was thinking it might be interesting to see if that could work for firing a blackpowder rifle

Ok, so maybe too many ideas at once! That’s just the triple espresso talking…

Clicky,

Well,.. I see that you have made your way to the current blog! 😉 Very good.

That is quite the list of ideas that you have. From what I gather, you must have pretty good mechanical skills/knowledge and some sort of machine shop tools at your disposal? I do admire the drive and enthusiasm.

“trigger fired fire-piston”,……. HUH????? Please elaborate.

Have a brew, shot or mixed drink to off-set the triple expresso! 😉

Chris

Anyone ever seen a high powered SSP big (.25,.30) bore?,……….. or anything even close?

Fire pistons are an interesting way to light a campfire. And they have a lot in common with spring piston pellet rifles. I have a small aluminum fire piston which I bought off of ebay. But it really would have been better if I had made the thing, it’s really just too simple! It is a very small diameter piston with an excessively long stroke, very much like a PCP hand pump. The main difference is the outer tube of a fire piston is a plain cylinder with the end closed off solid. A fire piston has a hole or notch on it’s face to hold tinder, in normal use you are supposed to withdraw the piston quickly and blow on the tinder to keep it going, then touch that ember to your main tinder, which could be char cloth with twigs on top. I’m thinking about putting black powder in that location, screened for a fine particle size, or triple F. To use a fire piston, you must compress it very quickly all the way until it hits bottom. It will heat the air inside the tube hot enough to light the tinder. In my case, I think a spring powered piston would be the best way to go. If this lights off blackpowder, then it will drive the piston back to it’s cocked position, and simultaneously exhaust the gases out a side port and into the pan of a muzzle loader. Just for initial testing, it will just simply exhaust into open air so as to act as a noise making device. If that works, then I want to use a low-cost .22 pellet rifle barrel for further testing and see if the exhaust alone is enough to drive a pellet out of the barrel

I have a 6″ metal lathe and various hand tools. I’ve used milling machines, used to have one. I weld with oxy-acetylene and TIG rod, usually preferring to use my 000 tip for fabbing carburetor linkages or other little things instead of doing 1/4″ welds. I think the smaller stuff is more fun. I’m thinking I ought to get a 0000 tip very soon

I spend a lot of time reading old patents, or trying to beat google at their own game, in relation to anything with moving parts

I used to have a R1, and of course had the trigger completely apart several times. Had it working better than new, once I understood it well enough

I’ve never really had any formal training, I just grew up taking everything apart. And eventually, putting things back together again

A fascinating collection of patents to read has to do with light gas guns. Preferably the smaller benchtop variety. I think there’s a few things in there that might benefit a spring piston rifle. These devices are used to propel physical objects to well above supersonic velocities, in order to better understand kinetic physics, and evaluating various materials for impact resistance. That’s why I want to build a better cork gun, in order to create high-energy shock waves that might be used to drive a pellet down a barrel. They typically use a burst disk in order to create a higher energy pressure spike, but I think it might be ok to scale back a little bit on expected velocities. The world record for getting things to move fast with a light gas gun is measured in kilometers per second

Clicky,

Wow! Impressive. Now that you have found the link to the daily blog,… I assure you that you (will) be a most welcome addition to the comment section. Innovation and problem solving are a skill set shared by many that frequent here. I have done some (sometimes laughable) experimenting of my own in the past. 🙂

In 3rd grade,.. I took my new 20″ bicycle completely apart. My parent’s, while quite impressed,… also let me put it back together,.. which I did. So,… I can relate on tearing things apart JUST to see how they work.

Your explanation of a fire-piston makes perfect sense and as you say,… in perfect parallel to a springer detonating. I did not know that such a simple fire starting device existed.

Chris

Clicky

But why.

You don’t like air?

I’m not sure I can answer that easily. Maybe because it’s a curse I must endure? Or because it just looks interesting? Or just because of all the times I was told ‘don’t fix it if it aint broke’? Sometimes I think it’s simply because I haven’t seen anyone else make something work, but my tinkering senses are telling me there’s something there. Or maybe I’m just crazy

Kinda like 20 years ago when I was reading a book on how to design race kart frames, the author said that ratcheting differentials, that is – the sort of rear axle differential which allows one wheel to freewheel in corners like a 10-speed axle does when you stop pedalling, could never be a good idea for serious racing because they wouldn’t allow engine braking into corners. So I put the book down and inside an hour had drawn out a ratchet type locking differential which will only freewheel up to a left/right ratio that is what you find in turns, but will immediately switch directions and work the same exact in the opposite rotation depending on if the engine is accellerating or slowing in relation to what the rear axle is doing. No gears inside the diff, only a friction device and a bunch of spring loaded ratchets. Diff would be only 2″ wide and could easily be mistaken for an over-sized sprocket hub

But I never built the thing as I didn’t really get into racing go karts, and too many other things that got my attention over the years

Clicky

That sounds like the posi units some cars have.

And yep know what you mean about tinkering.

Maybe in the way it feels while driving, but I have looked into the design of various locking differentials back in my 4-wheeling days and none use ratchets. The torque-loads on a passenger car are pretty extreme, so a ratchet system would have to be very large to survive long. For example, I had a car with a welded-up diff. I looked the welds over before installing that. The spider gears had three passes from a 1/8″ rod. But it only lasted about 15 months before the welds failed. My 2nd attempt used a Ford 8″ axle with a 9″ mini-spool. That setup never failed. It was my daily driver and I drove it to work about 60 miles each way. By the way, that was on a Pinto station wagon, with a 2.5 V-6 & 4-speed out of a Mustang. Had a homemade 6″ suspension lift and 4.63:1 gears, 14″ Super Swampers on the back with 14″ standard truck tires on the front

Clicky

Here’s what I’m talking about.

https://www.speedwaymotors.com/Richmond-Gear-92-0690-3100-Powertrax-Ford-9-Inch-Locking-Differential,38393.html

And yes I use to build drag cars. And had a few 4 wheel drive trucks in my time.

That’s a familiar design. I call that a dog clutch. You can see the locking plate for one side in that image. My ratchet design is more like this: https://dirtmountainbike.com/features/work-freehub-body.html, but my design looks like what you would see inside a socket wrench, so try to imagine a pair of such wrenches side by side, with a thin plate in between them to control both sides direction at the same time

I know that design pretty well, I don’t consider it a ratchet type, preferring instead to call that a ‘dog-tooth plate clutch’

What my design uses for ratchets will look more like this: https://dirtmountainbike.com/features/work-freehub-body.html

I also was interested in using a roller sprag style, as that would be quieter

In my design, imagine a pair of socket wrenches side by side. Both have a reversible direction. There would be a thin plate in between the pair, that plate will control which direction is selected for both sides at the same time. This control plate is operated by a simple friction clutch and some interaction between both output flanges vs the outer casing

Clicky

Wonder why nobody has made one yet like your talking about.

Should’ve known it might take an hour or two before seeing a post get up here!

Think I’m hitting the thread limits. Got no reply button for you GF1. A ratchet diff is probably like a high-power SSP. No market. Doesn’t matter if it works, if not enough people will buy it

The torque limits for a ratchet setup will limit the application to race karts & riding lawnmowers. Maybe with the right industrial marketing, it might get somewhere as a contractors option for professional grass cutting or some such thing. I think rototillers are fine with solid axles, so not likely any application there

I really couldn’t say for sure about race karts, but I think they like to stick with bullet-proof vs anything complicated

Clicky,

An interesting piston design and cocking design is the Whiscombe air rifle. An under lever that has opposed pistons that fire towards one another, thus cancelling recoil. I am not sure that it fits your idea of a single stroke pneumatic (SSP) making more power, but since you are looking at making your own leverage/linkage, I thought that it might be of some interest.

On the topic of making something from the ground up, we had/have? a reader named Duskwight? that was building an opposing piston rifle from the ground up. He has not posted in quite some time though.

B.B. has one and has done multiple reports, but I was unable to find one just now that explained the mechanism and showed some good pictures of the workings.

Chris

Chris,

Here are 11 of them.

/blog/2017/05/pellet-velocity-versus-accuracy-test-part-11-2/

B.B.

B.B.,

Thank you. That is the one. I did find 3 that dealt with adjusting the muzzle weight. The search box is certainly spell sensitive. Whiscombe vs Wiscombe etc. I should have remembered that was the one that you did the accuracy vs pellet velocity testing with.

With us old codgers having periodic memory lapses all of the time, your job is safe for a long time to come with all of the reinstruction, reclarification and redirection that you do for us. 😉

Chris

I just want to see how that Whiscomb releases both pistons at the same time. Getting them to come together at the right point inside the compression tube will define some other very important design details inside that gun. I really like the opposed piston idea as used in aircraft diesel engines. It solves the power to weight ratio problem, increases reliability a bit and

An opposed piston design will work just fine with what I am thinking of adopting from the light gas gun designs I’ve been looking at

I don’t think I would bother doing opposed pistons for a SSP, but that doesn’t mean I wont consider that approach just for fun

Clicky,

Well, I can assure you that you have piqued the interest of those here. Keep us posted. Did you see the link BB posted to 11 past articles on the Whiscombe? Something ought to be in there.

/blog/2017/05/pellet-velocity-versus-accuracy-test-part-11-2/

Note the series numbers/links (11,10, 9, 8 etc.) at the top of the article and you can click your way back to the first one.

Chris

I just finished reading that entire series. I remember seeing that post the first time it came out, but somehow I don’t remember anything about the Whiscomb having opposed pistons. Been a while, but I’m thinking I might’ve wrote it off as too expensive and never looked into how it worked

So now I just need to find a teardown or something so I can see how it works. If only I was B B’s shop helper, the stuff he gets that I’d love to tear into!

Clicky,

Whoao! Can I have some of that espresso? Let’s talk about the SSP subject while my morning coffee kicks in.

There is a limiting factor of just how much air can you compress? I have a Baikal 46M pistol. With the length of the lever and the linkage it is very easy to operate, however it only develops a few foot pounds. I used to have a FWB 601 rifle. It also was very easy to operate, but once again it was not very powerful.

Just before Webley went belly up and was bought out, they were developing a single stroke pneumatic spring piston hybrid called the Paradigm. The prototype developed just under 12 foot pounds and it was just about all the dude could do to cock it. If you search online you can see video reviews of the prototype and diagrams of it’s guts.

I personally think it is awesome cool and would really like to have it, but it is not very practical. A multi-pump hybrid such as the Independence or the Freedom is far more practical. Something that would be nice would be a slim, lightweight hybrid version of the Maximus or Fortitude operating at 2000 PSI. Easy to pump, easy to carry, low operating pressure.

RR,

I agree on the Maximus/Fortitude idea. A handle like the 880 has would look nice. But,.. I bet it would add 2# plus to the weight by tucking a 3 stage pump into the front. Then, it is no longer slim or light weight. 🙁

There is always a compromise and/or a trade off to ruin the “party”! 😉

I remember seeing a video of a fellow that made a .22 SSP with a butterfly pump (type) mech. attached, but could not find it in a search. As I recall, it was quite long, heavy and bulky,… but he did it. At least I think it was a SSP. A break barrel would make no sense. Pretty sure it was a .22.

Chris

Chris,

I too recall that video. It had dual levers, one on each side and looked something like a Mattelomatic. It was an older gentleman and he was looking for financial backers to take it from a proof of concept / prototype stage to production.

To my way of thinking I would rather carry a small buddy bottle in a pack and have a light air rifle when hunting than have a built in pump system, even a multi-pump. When hunting just how many shots are you really going to need. Most states have bag limits on small game. When at the “range” I can have a hand pump, tank or compressor handy.

Like Pelletpopper and I were discussing about the Dreamline, it has a huge magazine that sticks way up, forcing you to use high mounts. But it can also use the smaller FX magazines, allowing the scope to be mounted lower. Works for me. I will just have to change out the magazine more often.

RR,

Yea,… when I was looking at the higher end stuff,… that FX super capacity flying saucer was an immediate turn off. What?,… you are going to “force” me to mount my scope high? If nothing else, it helps to keep the center of gravity lower,… less fall to the side effect. I would bet that you get the big one and the smaller one is an option.

The Fortitude would make a really sweet looking MPP. Arm like an 880. Air conserving. 1-2 pumps to keep it topped off between shots. And, it’s a repeater. Do not, DO NOT drop the Schnabel!

Chris

Chris,

LOL! The Maximus and the Fortitude are nice looking. And for the price they are awesome! They would also not be too expensive to upgrade into some real nice air rifles.

AAAAAAHHHHHHH!!!!!! Too many choices!

Chris,

Oop, wait a minute! I would not mind having a Maximus but scratch the Fortitude. It only gets a 3 star rating on the PA site. I can do better with my hard earned change.

It looks like I will not be getting an air rifle from TCFKAC again this year. I only own one and it was made back in the Forties’.

That would be the Freedom 700, before it’s piston was shortened and a check valve added so it could become a multi-pump. It reached higher power as a multi

But that design didn’t have enough cocking effort, but the cocking motion was just awkward enough that increasing the effort level would have been a bad idea

That guy stated that he only had 200 people who were seriously interested in buying his gun, so he decided that wasn’t enough of a market to convince an established manufacturer to produce his design

I haven’t found anything on how his valve body works, no telling what might be inside that. But it looks like he accomplished the goal I was originally interested in. He was getting up to 20ft/lbs. So I’m hoping he did that without doing anything too interesting in between the pump piston and the breech

Clicky,

Well,… I see that you are far into your pursuit. As you may, or may not have surmised, there is a (really) smart bunch that hangs here. Stick around, toss out some ideas and concepts and I am sure that you will have some good incoming input to work with. (Ok,… continue, to work with) 😉

Chris

Clicky,

You may have already seen this https://www.youtube.com/channel/UCaYRVbQUAEEEDwJlNOX_UNw/airgun-videos he also has an email contact “For business inquiries” on the about tab he might be open to talking directly about his creation.

Mike

Yeah, I saw that. But I was too busy chasing tech trivia to consider that

I did think for a bare moment that he might be better off running a kickstarter and link up some forums like this one

I’ll give it a shot. especially as his design is pretty much what I was asking for to start with

Clicky,

It does look like a workable design but still making it light and easy to pump is a deal breaker. Perhaps something more along the line of a 3 or 4 stage pump could get enough air compressed into a combination reservoir/valve to have enough power for .22 or even .25 cal.

Mike

What he showed on youtube are prototypes that I’m sure could be re-worked into smoother actions. Being as that is, it didn’t look all that difficult when he showed how to cock his rifle while standing outdoors. He was placing the butt on top of one boot toe in order to keep the butt from getting dirty, then compressing the arms down. It appeared that didn’t put any undue stress on his foot

The double-arm approach will keep any sideways loads from being an issue for the pump linkages, but that doesn’t mean his guns will never work without those double arms. Something like the Webley Venom Paradigm’s single under lever ought to work just as well on the Freedom 700

And that’s not even getting into more complicated linkage designs like the variable ratio setups I’ve been pondering

I’ve already been thinking about multi-stage pumps. But I think that will add more weight than a single stage with more advanced linkages would have

On another note, I have also been thinking about how to introduce the concept of a burst disk into a traditional spring piston design. This comes from Light Gas Guns, the larger of which fire projectiles in excess of Mach 20

But even the smallest of the LGG rigs must use a burst disk in order to operate at the higher velocities they were designed for. The engineering principle which dictates that all LGG’s must use a burst disk, is that it’s a very bad thing to allow your projectile to begin accelerating before peak pressure can reach it. The burst disk acts as a valve which momentarily delays the rapidly building pressure front, until it reaches a high enough level that the disk ruptures. These disks normally have a carefully engineered cross engraved in their center so that they will open only at the very center of the bore, and do so in a manner which is repeatable & consistent. They also peel open without fragmenting

Another very important detail is that the transfer port is full-bore and is acting more like an impedance-matching funnel. The ports are usually very long with a taper that stays under a boundary limit. I’m not certain yet, but I have the impression it appears that the ports are all somewhere near 22° overall taper, or 11° from the centerline. This is an important boundary limit that I have seen from my research into building hydraulic eductors. A friend of mine has several gold claims, and he’s had me build some ‘venturies’ for his dredges. 11° is the optimum angle for the water jets as they enter the venturi main tube. The US Navy did extensive research on this, in designing dewatering systems. Though I’m still not sure why a hydraulic shape is related to pneumatic design. It could be at the extreme energy levels seen inside a LGG, the gas must be treated as a fluid of moving molecules with a notable inertia & turbulence

A very small LGG is powered by a blank 12-gauge shell, which drives a piston down the compression tube. This tube is usually filled with hydrogen or other high-performance gas mix, as standard air can’t move fast enough through the transfer port

Anyways, what I’m pondering is how to replace a burst disk with a valve that can be reused, yet still manages the airflow in the same way. My so-called ‘cork gun’ musings

The idea being that the piston of a spring gun will strike the valve just as it nears the end of it’s stroke, thus releasing a much higher energy level to the pellet than it would normally experience

I also think it might be worth playing around with purging existing spring guns with nitrogen. Among other things, it could help eliminate dieseling if there’s no oxygen in front of the piston

Clicky,

Lots of interesting thoughts and musings, I hope it comes to an actual working airgun. I think the PCP is the best airgun now and in the past as it is not really a new idea.

I hope your ideas can come to be and also hope to see what you can come up with in the world of single stroke pumpers.

Mike

Thanks. Just keep in mind I tend to stray off onto other things. For the moment I’m thinking air rifles mostly because a friend has an armload that need repair. All wooden stock classics. Just finished doing a Benjamin 137, I saw a really nice kit that had a conversion to a flat-top piston with a viton o-ring. So I decided to whip out a test piston using a buna-n o-ring and some scrap aluminum. It worked so well, I just slapped it together & sent it back. But not before verifying that I could hit a beer can at 30 yards with every shot. weird thing, it shot to the right on 8 pumps. But fine on any other number. I was using some Walmart Crosman Premier Pointed I had just picked up for the occaison

At some point, he knows someone who wants to get rid of about 15 air guns for around $1000, so he’s trying to stay inside the loop on that deal & I’m going to be the one who overhauls any that need work

I was just reminded of an important detail I had forgotten about existing air rifles. They all have a small amount of delay designed in like the burst disk I was going on about. The fact that a pellet should fit the breech tightly will among other things give it a delay effect that is important. But It’s not enough delay for going beyond the current state of the art

Kinda thinking maybe I should just build a spring gun that uses burst disks, just for a reference design?

And, my idea for a spring piston that strikes a delay valve is really a lot like a SSP that has been designed to fire automatically as soon as the pump is closed. That’s why I’m a bit disappointed that there aren’t a ton of high-power SSP’s already! That does not bode well for what I was thinking…

Thanks for bringing up that Webley Venom Paradigm. It has at least one good idea I will adopt

I’ve found this: http://www.get-designs.uk/Blog/Paradigm-Development-part-3, which appears to be the source of the design. From there I might see if there’s been a patent or anything else. But from the looks of it’s transfer port, I doubt it uses the sort of shockwave generator I am thinking about

In this Paradigm, the pump piston is able to slide back on the pump rod, with a very high-force spring. When in the compressed position, the piston is compressing the spring pack. When fired, the piston is driven forwards by the spring pack, keeping the compression chamber pressure from dropping very much until well after the pellet has begun moving

Besides the very large bore & stroke, making this a higher power SSP, that springy piston was the magic bit. All the rest of it is pretty straightforward. Though the trigger might be worth looking into just to see what’s up with that sub-section of the design package

The triple slot just upstream of the exhaust valve is also a good idea, but I’m more partial to some designs that the airforce uses on their jet fighters, for smoothing out the flow going into inlet ports

Clicky,

So, the Paradigm just may be available. Hmmm…

By practical limit I mean how strong are you AND the compression assembly. As I noted, the Paradigm is a hybrid SSP and spring piston. It takes a considerable effort to cock and only produces about 12 FPE.

I wouldn’t call that a true hybrid, as what the additional spring accomplishes is a little bit different. Most notably the spring effect will not raise the temperature of the compressed air while it is inside the compression chamber. It acts merely to maintain pressure while firing. Or, another way to look at it. The spring will not raise the pressure during the firing cycle

The R1 I used to have, I installed a hop-up spring kit along with swapping from .177 to a .25 barrel. The cocking effort went up a lot compared to a very old spring, but was still manageable. I think it might have been 40lbs. I didn’t mind, I would just pause a moment after just breaking the barrel open, before completing the cocking stroke. I tuned the damping to just take out any vibrations, and I think that added a tiny bit of drag to the cocking effort, so it might have required a lot of that black tar to get it to smooth out

Anyways, I wouldn’t want a SSP that took more effort than that R1, as it did tire me out when just straight target shooting for an hour. However, I think that still leaves a lot of room to increase power beyond production models

If the owner of GET Design could round-up 150 pre-paid orders, I think it would be golden. He just wants to finish off the 150 stocks he has. His manufacturer stated they would run a 50-unit minimum batch order. So maybe in three rounds, if needed?

Clicky,

I must be mistaken about the way the action works. It was my understanding that upon firing the spring released, adding a little more to the pressure of the chamber. I guess I will have to dig into it a bit more.

You almost had it right. The spring does release on firing, but only because the air in the compression chamber is leaving, so the spring is merely following it on it’s way out through the transfer port

In a way, the spring does ‘add pressure’ in comparison to unsprung that is. But it doesn’t raise the pressure any higher than where it is just before firing

The Freedom 700 was tested with a similar system, and their spring pack stopped springing after a few shots. So that was abandoned. I’m not sure as yet, but I think it was being operated at high pressures

I would also recommend to anyone who wishes to try that out, to consider designing the system to have the piston compressed against a stop block so as to have a consistent volume on every pump stroke. And maybe set the stop at 90% compression

Best place to start digging is here: http://www.get-designs.uk/Blog/Paradigm-Development-part-1

I just keep thinking – ‘practical limit to compressing air? Isn’t that when all the molecules are touching each other like the spring in a break barrel?’ – oh, wait, you did say ‘practical’…

Clicky,

Now that you have made your way to the current blogs, check out the RSS Comments at the top right. It saves a TON of time on catching up on comments.

Example: Go to bed at 10 pm (note the last comment). Wake up, click on RSS Comments and ALL of the comments made while you are asleep will be there. Also note: This will be comments from ANY blog, even if it is 15 years old. That is how I saw your comments.

Note also,….. some here have tried this and it will not work, Others have downloaded something new and got it to work. Others have had no luck.

Try it. If it works, you will never have to search/scroll a blog again. Oh, you should get replies in your E-mail inbox as well.

Chris

Thanks, I’ll give that a try. I’m always fooling around with software issues, might be another long night if that feed acts up!

Clicky,

I do as Chris has demonstrated, just a bit different. First, I open the current day’s blog and read, along with all the comments posted. Secondly, I open the RSS Comments feed and scroll all the way to the bottom. The heading on the comments that I have read will be “red” and the new comments that I have not yet read have a “blue” heading. Then I start scrolling up to the first “blue” heading and click on it. That opens a new tab in my Firefox browser. I read the comment and then close the tab which takes me back to the original tab. I scroll up to the next “blue” heading and click on it, and so on, until I reach the top and all the headings are “red”.

Recently, Firefox removed the RSS reader. There is an extension to replace it which works even better than the one FF removed. Download at: https://addons.mozilla.org/en-US/firefox/addon/rsspreview/

Geo

I’m using Waterfox 56, on 64-bit Win7. The RSS feature is still a default option and worked perfectly for me on the first try

My email notifications seem to work just for replies to my own posts, while the RSS catches all the rest. It defaults to a dropdown menu on the bookmark bar, which has the option to open into a new tab showing a full list. I think this is the typical setup everyone should know from previous versions of FF

I might try the improved version though, thanks for the tip!

Clicky, wow! I’m surprised Win7 is still usable. I dumped MS back in ’08 (sort of). I am using an older ASUS laptop with 64-bit Win7 original OS. I loaded Ubuntu 08.04 back then for free and never looked back. I can’t remember the last time I wanted to boot up with Win7 for something but I know it was several years ago. Anyway, I found QuiteRSS as another free download and it works brilliantly! Just mentioning this for anyone tired of bowing down to the MS/Apple monopolies.

Geo791, thanks for the link. I may try it out to see if it has any more features than QuiteRSS, but I doubt it.

Oh, I wouldn’t recommend anyone totally dumping their OS to try Ubuntu because there is a learning curve. I’m still working on pictures/photos. But, for baby steps, an older laptop with something like Win7 on it would make a fun project.

Larry from Algona

LarryMo,

I am running Windows 7 32-bit on a 12 year old desktop and it runs just fine and does everything I need it to do. The RSS reader I linked to is lean with no obvious features. It works just like the one FF had before dumping it with version 64. I don’t use the RSS reader for anything other than reading comments from this blog.

My old system will not run Windows 10 and 7 will become unsupported soon. So I will be doing a new computer desktop build. I don’t like using a laptop for most things. My eyes like the big 23″ screen on my desktop 🙂

Geo

Geo791

I didn’t mean to imply that you HAD to use a laptop – old laptops can get new life with Ubuntu when MS keeps crashing on them. I started with a desktop and a big screen but wanted more space on my work area. I’ve got my laptop set up for dual-boot but almost never boot to MS. I was looking in my storage cabinet and it reminded me of the hours it would take me to do regular backups of the MS system and I felt SO content knowing I didn’t have to do that anymore. If I need to rebuild my OS all I have to do is reload it. I back up the folders that I use monthly by merging all the changes onto my backup thumb drive. It just took me 15 min. to do that. (2.2 GB)

LMo

My other computer is an ex-XP machine with a Pentium-4, got Ubuntu Mate running on that one

There’s a few softwares I like using that are not available on Linux platforms. And on the Win7 machine, I run the browser inside a sandbox at all times. I export my bookmarks in order to have those for the next browser session, plus being able to import those to other platforms. The sandbox is a pain at times, but it keeps knocking malwares off my machine every day

I’ve totally uninstalled Adobe Flash, and everything else Adobe has, plus dumped Java, and never bothered installing Silverlight. I don’t run any printer applications, as I’ve decided no printer is worth my time if it requires another layer of corporate oversights in order to function

I was a very early adopter of the ‘wait & see’ camp, when Win8 1st came out. Still waiting…

Clicky,

Well, I guess you know then that linux developers around the world are constantly working on upgrades to the Ubuntu platform(s) and freeware apps it can run. I go thru the available software list periodically looking for new freeware I can use. It’s how I discovered QuiteRSS.

LMo

But then there’s a reason why FF removed the RSS feature: https://www.darkreading.com/attacks-breaches/rss-syndicates-malware-too/d/d-id/1128619

Has anyone else noticed that the smiling and winking emojis are not showing up as they once did?

Halfstep

They have been that way for awhile again. That happened some time back.

Guess nobody brought it to IT’s attention this time. Maybe they will look into it now that you brought it up.

Half,

Mine are showing up as before. I do 2-3 spaces before and after when doing one. It will eliminate the spaces after it post. Maybe it is something funky like the RSS feed that some peoples browsers will not support? Beyond that,… I haven’t a clue.

Chris

Chris,

I’ll give that a try. 🙂

Half

Didn’t work.

Half,

Yours looks yellow and black, like normal, on my laptop.

Chris

Chris,

All I got was a small outline of a square. I’ve seen them on web pages before where they act as sort of a placeholder for a graphic that didn’t download. Thank’s for letting me know.

Half

Well, this looks like it will be “The Year of the Multi-Shot Sproinger” at the Shot Show.

Gamo is bringing out two new versions of its Swarm with a horizontal magazine assembly. I do hope they interchange with the old rifles.

It looks like TCFKAC will finally be bringing out their Mag-Fire. As usual, I am not impressed.

Umarex is getting in on the deal with their Synergis. Now this one just might interest me if you can hit anything with it.

There is no telling what other companies will unveil a multi-shot sproinger this year. I would not be a bit surprised if Wang Po Industries brought something out, although they may wait for IWA.