by Tom Gaylord

Writing as B.B. Pelletier

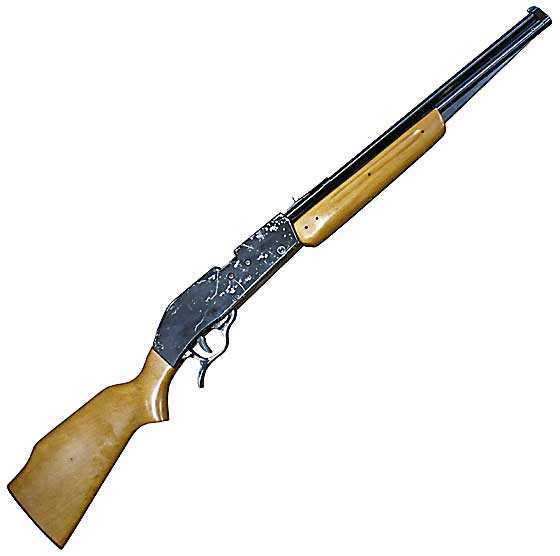

My S&W model 77A rifle. The black paint is flaking off the aluminum receiver, but the steel and wood parts are both in good condition.

This report covers:

- How healthy is it?

- GunFun1

- S&W 77A trigger pull

- Pump stroke

- Pump is loud

- Velocity

- Crosman Premier

- Repeatability

- RWS Hobby

- H&N Baracuda with 5.50mm head

- Final test

- Pump effort

- Summary

Today we look at the power of my new/old S&W 77A multi-pump pneumatic air rifle. Many of you said you liked how this rifle’s action operates. It cocks via the triggerguard swinging down and that gives a satisfying feel and sound to the operation.

How healthy is it?

I got this rifle in a trade at this year’s Texas Airgun Show from one of our readers, Pgray who goes by the name of Pat. Here is what he told us:

“Before trading with Tom I had that rifle for about three years. Picked it up at Seth’s airgun show in Arkansas. The paint was in the same shape then as now. I like to think I take good care of my guns. Even though it came up in the rotation for shooting and I really liked the design and build quality. It never became a favorite. That’s why it ended up as trade bait at the show. No accounting for taste and all that. Maybe it’s the long throw of the pump arm.”

It seems pretty healthy from just firing it into duct seal and seeing the penetration, but today I will put it over the chronograph so we all know. According to the Blue Book of Airguns the velocity should be around 600 f.p.s. It’s a .22 caliber, so that would put it roughly in the same power category as a Benjamin 392. We shall soon see.

GunFun1

Reader GunFun1 asked several questions that merit more than a simple answer, and I would like to begin there. Here is what he asked:

“I’m guessing it’s a steel barrel right. It looks like it might be soldered though.

But it’s a cool gun. I like how it cocks. And is it a 2-stage trigger or is it like some pumpers that build trigger pressure the more it’s pumped up?”

The first question has a simple answer. The barrel is straightforward rifled steel. I’m not sure I know what a soldered barrel is, but it seemed to me that he meant a thin “soda straw” barrel liner inside an outer tube. This isn’t that. This barrel is solid and attracts a magnet.

I don’t know if this shows it too well, but the 77A barrel is solid steel. The muzzle cap is aluminum.

The second question is worthy of discussion. As far as I know, only one kind of pneumatic valve affects the trigger by making it harder to pull as the number of pumps (and the pressure inside the reservoir) increases. I have called that valve the “blow off” valve in my writing, but whatever you call it, it’s the kind that’s in the Crosman model 140 and 1400 multi-pumps, as well as the 130 pistol.

You never cock those rifles because they don’t have a hammer. Their triggers block the exhaust valve from blowing open, and as a result the trigger pull gets harder as the pressure inside the reservoir that presses on the exhaust valve increases. As the gun is pumped it is automatically “cocked” through the blocking function of the trigger.

Crosman used this valve in the 1950s and beyond to overcome the problem of valve lock. Some owners were over-pumping their guns, thinking that made them more powerful, when it actually did the reverse. It made the valves unable to remain open long enough to exhaust all the air inside and ultimately it ruined the gun.

These are not common pneumatic valves, but there are other airguns that have them. The Sharp line of multi-pumps uses this kind of valve, which is why I found the trigger so surprising on the Sharp Ace Target I tested for you. The trigger pull did increase as the pumps went up (see that in Part 2) but even at the maximum 10 pumps the trigger pull was just under 10 ounces!

S&W 77A trigger pull

Since the 77A is cocked via the triggerguard, we know that it has a hammer that has to be cocked. Therefore its valve is a common knock-open one and the trigger pull never increases as the gun is pumped. I tested the rifle on two pumps and the single-stage trigger broke at 5 lbs. 12 oz. On 10 pumps it broke at 5 lbs. 10 oz. It’s definitely a hammer-fired pneumatic with a conventional trigger.

Pump stroke

Pat mentioned the huge pump stroke this rifle has and I agree. Let’s look at that now.

The pump swing of the S&W 77A is long and the pump lever is also long. It makes for a huge stroke.

Pump is loud

The pump handle clacks loudly with every stroke. There is no sound-deadening material under the wooden pump arm to quiet it. But S&W put a spring-loaded lock in the end of the receiver to lock the pump lever in place when it’s stored. Unlike many multi-pumps the handle on this one should never drop down.

A spring-loaded pump lever lock (arrow) in the end of the receiver locks the pump handle up when it is stored.

Velocity

Okay, let’s look at the velocity of my test rifle. Since it is a multi-pump it will be tested in a different way. With apologies to Smith & Wesson who no longer market pellets under their brand name, I will start the test with the 14.3-grain Crosman Premier pellet.

Crosman Premier

Pumps……..Velocity

2…………….236

3…………….318

4…………….376

5…………….409

6…………….469

7…………….503

8…………….532

9…………….542

10……………539

11……………547

12……………545

S&W recommended a maximum of 10 pumps. I went a little beyond because some people on forums are reporting pumping their guns many more times — as many as 30! But looking at the curve in this string you can see that for this pellet the maximum number of pumps that accomplishes anything is 9, not 10. Yes, more pumps does make it shoot faster, but the increase is minimal. Why subject your airgun to stress for such paltry results?

Repeatability

Does the gun continue to shoot as we have seen here? For that I pumped it again and chronographed these results.

Pumps……..Velocity

4…………….308

6…………….466

9…………….532

I noticed in this test that I was pumping a little faster at the start of each shot, so I did the test again and slowed down to a very deliberate pace. Here is what I got.

Pumps……..Velocity

4…………….370

6…………….475

9…………….537

And here are the first test, the second test and the third test laid next to each other.

Pumps……..Velocity1…Velocity 2…Velocity 3

4…………….376……….308……….370

6…………….469……….466……….475

9…………….542……….532……….537

RWS Hobby

The rifle is fairly repeatable. Let’s now see how it does with a lightweight pellet — the RWS Hobby.

Pumps……..Velocity

4…………….417

6…………….511

9…………….576

10……………592

11……………604

12……………620

13……………629

14……………631

That is as far as I’m going to push this old rifle. I have no desire to break it, but I did want to see what it would do above 10 pumps. There was no air left in the gun after even 14 pumps, so the valve is exhausting all the air. And the gain in velocity is significant. Nevertheless, the gain from additional pump strokes isn’t worth the effort and strain on the gun, in my opinion.

H&N Baracuda with 5.50mm head

The final pellet I tested was the H&N Baracuda with a 5.50mm head Here is what they did.

Pumps……..Velocity

4…………….298

6…………….384

9…………….471

10……………479

11……………495

12……………500

13……………503

14……………522

Once again the velocity continued to increase after 10 pumps, and once again the gains were significant. I still stopped because of the risk.

Final test

The last velocity test I conducted was to return to the Crosman Premier pellet and try it at 9 pumps and the 13 pumps.

Pumps……..Velocity

9…………….538

13……………594

The velocity on 9 pump strokes is remarkably similar to all other tests. Here they all are together.

Pumps………Vel…..Test 2…Test 3…Test 4

9……………542……532…..537…….538

But on 13 pumps the velocity went up to 594 f.p.s., where it had sort of stuck around 540-545 in the first test. Why the difference?

I think what may have happened is the seals inside the powerplant heated up and became more efficient from all the pumping as I conducted this test. If that is true, I think if they were rested for 24 hours the velocity would go back to where it was in the beginning.

HOWEVER — I did lubricate the pump piston head with ATF Sealant before starting today’s test. I wasn’t going to tell you about it unless it made a difference. At this time I can’t say that it did. But, if the rifle still shoots ultra-fast on 13 pumps tomorrow (in the vicinity of 594 f.p.s. with Premiers), then the ATF Sealant is the reason — not exercising the seals by pumping.

It could also be a combination of both things, in which case we would perhaps see a 13-pump velocity of 575 f.p.s. or so in that test because the pump mechanism will not be warmed up. That test will be interesting! You’ll see the results on Monday.

Pump effort

Here is what it takes to pump the rifle.

Pumps……..Effort in lbs.

1………………9

2………………9

3…………….13

4…………….16

5…………….16

6…………….15

7…………….16

8…………….16

9…………….17

10…………..16

11…………..18

12…………..17

13…………..17

14…………..17

Each pump stroke was slow and deliberate. Pumping faster would have spiked the effort considerably.

I measured the force on my bathroom scale where I measure the cocking effort of spring guns. Don’t ask me why the effort numbers went up and down — I just recorded what I saw.

This is far less than a Benjamin 392 or Sheridan Blue Streak, whose 8th pump would be about 35 lbs.

Summary

I think my S&W 77A is probably performing as it should right now. I may refinish the outer metal but not refresh the powerplant in the future. But before I do anything we want to see how accurate it is. I will use both the factory sights and that UTG Reflex Micro dot sight. I am also thinking I will try it with a scope after that. So, stay tuned — there is more coming.

Very cool.

I think GF1’s comment about a soldered barrel is like the way the Benjamin barrels are soldered to the tube. But I may be wrong.

The pump swing reminds me of the IZH 46m.

I had read in some forums of people pumping them 20 times, that seemed ludicrous, but your test shows it is entirely possible.

Do you think the pumping effort being so much less than the Benjamin is due to the longer arm, swept volume, or combination there of?

Ian

That’s like half of the 46 swing! But I wish more pneumatics took full advantage.

Ian,

I didn’t think of that because I said there is a plastic spacer between the barrel and pump tube in the first report.

B.B.

BB

As usual I missed that in the first report about the barrel.

And ok with the cocking. What I was thinking is that the cocking lever just moved the bolt to load a pellet. Then it could have the type of valve that builds trigger pressure with more pumps.

That’s why I asked about the trigger.

hi BB, i am from india i want to send you some images of my air gun made in india can you please help me in tuning them for smoothness. my email address is rajnandini279@gmail.com

Mahesh,

I recommend you remove the mainspring and coat it with Almaguard 3752 grease. In America it’s called “Tune in a Tube.” and it will quiet your airguns.

As far as images go, you can post them to this blog.

B.B.

Mahesh,

You might not be able to find Almagard 3752 in India but here is a list containing greases with properties similar to it: https://norfolkbearings.com/products/timken/TIMKEN-GREASE-INTERCHANGE.pdf

Look under the column Timken Premium All Purpose Industrial LC-2 Grease you might be able to find a grease that is locally available to you.

Siraniko

45Bravo

That is what I was thinking about the barrel.

BB,

You are most definitely going to want to refinish this, especially if you are wanting to hang on to it and are not concerned with upsetting the “collectors” about doing such. She does seem to be doing quite well.

Gunfun1,

I’m guessing from the few photos that the barrel is held similar to the Crosman 1400 where the barrel is attached to the receiver and the tip is held by the muzzle cap. A plastic spacer fills in the gap between the barrel and the pump tube.

Siraniko

Siraniko

Yep that’s what BB said above. He said he mentioned that in part 1.

BB,

A few thoughts before testing the FX Dreamlite again.

FX should know what they are doing with .177. They have much experience with this caliber and even produce some fine field target rifles.

If this was in my possession I would disassemble the modules and inspect them, giving special attention to the barrel liner, barrel, shroud and moderator. I would give the liner a good cleaning and then reassemble the air rifle insuring everything was properly fitted and tighten in place, however I would leave off the shroud and moderator.

I would at this point test the accuracy. After this I would install the shroud and again test the accuracy. Next would come the moderator and another accuracy test. It would not be the first time these have caused problems.

Of course they could have just dropped the ball as so many others have when rushing a new model to market to meet demands. I am starting to learn that I should wait a few years before buying a new airgun to see how many “generations” it goes through before the company finally fixes all of the problems.

RR,

I forget now where I saw it (HAM?),… but a fellow was shooting a Red Wolf without the shroud in a competition. Not sure if he stayed with that set up,… but initial testing must have had some positive indicators for him to try it. No doubt louder though.

Chris

Chris,

When you are out on the range, it is usually not an issue. Maybe not “backyard friendly” though.

RR,

It may well be possible that shrouded, noise reducing guns are not the best for accuracy,… but have become the new norm due to public demand for a quieter, high power shooter.

Chris

Chris

What?

I have and had many shrouded guns. They have worked great.

So you think people step their expectations down to have quiet.

I hope not. And I hope people don’t think that.

Kind of surprised hearing that from you.

GF1,

I may be wrong,… but I think that the super high end stuff is not shrouded. I guess it all comes down to repeatability from shot to shot.

Chris

Chris

Yep I believe your wrong.

Do some searching and let us know what you find.

GF1,

Well,… it would not be the first time. 😉

Chris

I just watched the Rocky Mountain Airgun Challenge competition. All the best pro shooters were there competing and everyone of them had moderators on their rifles. Also, it appeared that they were all shooting FX Impacts and modded Impacts.

Geo

Geo,

I do sincerely admire on how you keep up on what is out there. Thank you for the continued links and updates on what you find. As I am sure you know,… the shrouded barrel can “absorb” some air blast (helping) with noise. A moderator (silencer) can further add to add to noise reduction. 2 systems really. Depending on maker,… “results may vary”. 😉

Chris

Geo791,

That, RMAC, was an interesting evolution. I was really interested in making it to that shoot untill I saw the The RULES for the competition. The specified technical requirements almost ensured that certain brand(s) was about all one could shoot. I certainly understand that a sponsor(s) might be permitted to have the major input on what is permitted. What I’m not so certain of is if setting up a competition in that manner is good for the Airgun sport in the long term.

My wife and I paddled our new EPIC DOUBLE on the Great Salt Lake instead. We visited with the Seagulls, Cranes, White Pelicans and lots of other birds passing through on the Flyway head to the Northern part of our planet.

shootski

Shootski,

I mentioned those very issues to AOA when RMAC was first starting up. Sponsorships have indeed guided rule changes, etc. in many shooting competitions. These are showcases to some extent.

Field target almost totally died away because it became so expensive to even think of competing. What started out as a fun thing for a bunch of airgun hunters to do together soon turned into something that if you did not have a $5K air rifle, $3K scope and all of these fancy outfits, seats, harnesses, etc. you did not need to even bother shooting.

Fortunately for them, they noticed it in time and created the hunter class.

A friend of mine used to shoot archery. Same thing. When sponsors show up and money is involved, the true fun goes away. Some rules are needed for safety, but let us not overdo it.

RR

Not only air guns.

Drag racing, motocross, rc airplanes and so on.

If I’m not having fun any more then I need to stop. That’s the way I see it.

GF1,

Perzactly. I understand their need to showcase their products, but…

RR

Right.

Shootski,

Sorry, this old mind muddled geezer confused his events. Of course it really is the same thing with Extreme Benchrest and many other high sponsorship competitions.

In truth, you probably had more fun on the lake than you would have at RMAC. I am pretty certain Mrs. Shootski did. The last few weekends Mrs. RidgeRunner and I have been working together on remodeling the loft. We have really enjoyed the time together. That is one of the reasons I married her. 😉

As far as an airgunning event to attend, you should look into the GTA Fun Shoot. Every year the GTA (Gateway To Airguns) forum sponsors a Fun Shoot where members get together and shoot, eat, talk and generally have a good time. It is typically a weekend event in the middle of May, but some usually show up a couple of days ahead and start setting up, shooting, etc. Previously it was held in northern Kentucky, but the last two times it was in Arkansas.

They usually have door prizes and giveaways of donated airgun related items. There are usually a few friendly competitions where they might even have a trophy for the winner. Any and all airguns are welcome, from 10 meter to big bore, Wally World special to custom.

You do not even need to bring an airgun of your own. Most everyone will bring an extensive collection and are happy to put one in your hands to try some. You can spend the entire time shooting other peoples airguns. The times I have gone several people wanted to try out my 1906 BSA.

On occasion there have been vendors there and there are usually a few tables if you want to display and sell/trade something, but it is most just a time for airgunners from all over the country to get together and enjoy each others’ camaraderie.

Shootski,

See how muddled I am, I replied to myself. What was the number for that nursing home?

Shootski,

Sorry, this old mind muddled geezer confused his events. Of course it really is the same thing with Extreme Benchrest and many other high sponsorship competitions.

In truth, you probably had more fun on the lake than you would have at RMAC. I am pretty certain Mrs. Shootski did. The last few weekends Mrs. RidgeRunner and I have been working together on remodeling the loft. We have really enjoyed the time together. That is one of the reasons I married her.

As far as an airgunning event to attend, you should look into the GTA Fun Shoot. Every year the GTA (Gateway To Airguns) forum sponsors a Fun Shoot where members get together and shoot, eat, talk and generally have a good time. It is typically a weekend event in the middle of May, but some usually show up a couple of days ahead and start setting up, shooting, etc. Previously it was held in northern Kentucky, but the last two times it was in Arkansas.

They usually have door prizes and giveaways of donated airgun related items. There are usually a few friendly competitions where they might even have a trophy for the winner. Any and all airguns are welcome, from 10 meter to big bore, Wally World special to custom.

You do not even need to bring an airgun of your own. Most everyone will bring an extensive collection and are happy to put one in your hands to try some. You can spend the entire time shooting other peoples airguns. The times I have gone several people wanted to try out my 1906 BSA.

On occasion there have been vendors there and there are usually a few tables if you want to display and sell/trade something, but it is most just a time for airgunners from all over the country to get together and enjoy each others’ camaraderie.

Chris,

I know GF1 and Geo have already pointed out how pretty much all of the top enders are shrouded and/or moderated. My HM1000X is. So is your Red Wolf.

A properly designed, constructed and installed silencer can improve accuracy by stripping away and diverting the air blast behind the pellet quickly after it leaves the muzzle.

My concern with the Dreamlite that BB is testing is that if things are out of alignment, the pellet can clip a baffle which will cause it to not fly true.

Another possibility is the outer and/or inner barrel may be loose. That will throw shots all over the place.

Of course, it could be FX needs to work on production and quality control a bit more and quit acting like TCFKAC and others. Get it right and then give it to us.

RR,

Yes, I agree that something must be out of alignment. It certainly could have happened during shipping. If you remember, when B.B. reviewed the Gamo Urban it shot poor groups that were not typical of the rifle. Then upon further investigation, he found that one of the baffles had some excess material and the pellets were clipping it. He removed the moderator and the excess material from the baffle. Then the rifle grouped pretty well. But it took time away from the review process to correct the problem. I would liked to have seen more beyond the repair, with more shooting and testing of pellets. The review didn’t represent the Urban in a very favorable light.

Also, remember when B.B. shipped my Diana 34P back to me after his review. He had installed a BKL adjustable mount on it and had it all setup for droop. The rifle was packed in a

nice Plano case but when I received the rifle back, the mount had been knocked completely out of position. I actually posted a picture of it at the time. There was no damage on the box or the case but something happened to move that mount like it did. So anything is possible.

Geo

Geo,

Ah yes, Oops…I mean UPS. Of course I am sure all of the other carriers handle their packages with the utmost care. 😉

RR,

Yet another reason to allow moderators,… that are removeable,… that can be taken apart. I will add,…. make them with a proprietary “air gun thread” that can not be used on firearms. Define that in law and then let it go forwards. How can “we” be so far behind the Euro crowd on that issue? Then again,… they do fuss over about anything over 12 something or other too,……… I do suppose that “we” win out on that point. 😉

Like I even have to say it,…. the “bad” guys are going to get their hands on whatever,… however,… no matter what,… anyways.

Chris

Chris,

Well, after this last nut using a silencer, that is not going to happen. As far as threading goes, if you have enough competency to build a silencer you likely have enough competency to thread a barrel.

RR

Yep and why couldn’t it happen.

Now you see why I do so much shooting and paying attention to what a gun does.

There’s just to many things that can happen. And you know that’s kind of scary for those new shooters. How would they know unless they got common sense to look for problems.

GF1,

Well of course it would have to be a problem with the gun. It could not possibly be their lack of skill or experience with an airgun. 😉

An issue like that could indeed throw a newbie off. Even an old hand may need to stop and think.

RR

Yep.

B.B.,

Great start to this review. I’m really glad you got this rifle. I saw it at the show, was surprised at the S & W name being on it, and meant to come ask you about it, but got sidetracked with something else.

It really looks to me like 9 pumps is the “sweet spot” for this, in terms of decent power without over-stressing the rifle.

I agree with RidgeRunner — I would re-finish this thing so it looks good.

Jim

B.B.,

I really like the spring loaded pump lever lock…a nice feature. Yes, if it was my rifle, I, too, would touch up the receiver. She’s a sweet ol’ gal; she deserves a bit of cosmetics. => I look forward to her accuracy tests.

Take care & God bless,

dave

We all know where this is going.

Next he will pick up a S&W 80g for testing to complete the S&W airgun line.

At least I think that completes the vintage S&W line.

Except for a few 79g pistols that were marked 80G by mistake, and made it into circulation.

Ian.

45Bravo

Does the blue book of air guns have that info?

If not maybe you should be contributing to it.

Everytime I hear this stuff it reminds me of the muscle cars that got made that nobody knew existed. I had many plain Jane cars back in the day that was better equipped than its muscle car counterpart.

I wonder how much air gun info is out there that we don’t even know exists yet. I like this stuff. Maybe even more so than a report on one given gun.

GF1,

Get ya a Blue Book and find out. In case you are wondering,… which it would appear that you are,… yes,.. it is in there.

Chris

Chris

I knew someone would bring that up.

Your missing the point.

Back when I was growing up and later on when people was talking and writing about muscle cars I knew what they didn’t know. Then sure enough a car would pop up like I was talking about.

What I’m saying is I bet there is guns slipping under the radar so to speak. Guns that were made and someone owned. The others don’t even realize it. Then they tell about it. And they are not listed in the air gun blue book.

And true if I had a blue book I would know if 45Bravo does have info that isn’t in the blue book. But you do have a blue book. So since you spent the time to comment. Can you spend some time to look and see if his info is there already. If not shouldn’t it be?

GF1,

11th edition,… pg. 618 – 621. Pistols and rifles listed. 9 pistols and 2 rifles,… both as 45 Bravo noted.

Really dude,…you only have of a 10% idea of what is out there and what has been. In fact,.. I would guess closer to 5%,.. or less.

Bravo might be mistaken though as it list the 78G that was mis-stamped, not the 79.

Chris

Chris

No big deal to me. I’m sure others might be interested.

I was just giving props to Bravo for knowing something that others might not.

I guess that’s why BB runs the blog. He does report what he knows. And says when he don’t know something. I just hope he keeps notes to pass on the correct info. So it will get mentioned sooner or later. If something is right or wrong. Kind of like the pistol the other day. Sooner or later the info gets out there.

And let’s see where this goes.

I have never even picked up or thumbed through a blue book of airguns.

I have seen them, but just never wanted to pay the admission price so to speak.

I have seen 2 pistols for sale that were mismarked, and handled one.

And yes I am probably mistaken on the caliber.

So, you say the book has listed that only 9 mis marked pistols were made?

I should have jumped on them when I had a chance, as they sold at a very reasonable price compared what i have seen in the price changes that have happened over the last few months.

Oh, if anyone is interested, there is a 78g on gunbroker, that is up to only $92 at this time, and has 4 hours until the end.

Non adjustable trigger, but still in good shape.

I am going to venture a guess it will go for about $140-$160.

And no i am not bidding.

It will be interesting to see where it ends,

Bravo,

9 pistols are listed and 2 rifles of S & W brand. (not 9 mis-stamped pistols) The 78 notes the mis-stamped, not the 79.

If you swap and trade and sell at all,…. it is the “Bible”. Get you one if you do not yet have one. It ain’t gospel,…. but it will at least give you a good idea of what is out there and a good start point of reference.

Chris

I will add,.. as I said to GF1,… if you have not gone through one,… you might well have just a 10% idea of what is out there and what has been. Really,.. it is an amazing piece of work.

Chris

The point is that maybe everything that has come about is not listed in the blue book.

It’s a good reference source no doubt. But I think there is more that’s not listed and always will be no matter how well some one thinks they know about air guns.

I seen a new Chevy SS/Malibu body style the other day at the local gas station that I never knew existed. Needless to say I was very happy I talked to the owner of that car. The exhaust in it sounded better than some of the muscle cars of the day. Yes it was a new LS3 v8. 425 naturally aspirated horsepower. And supposedly there is a 600 horsepower supercharged version. But it’s not written in the books. You see what I mean.

Now again we see why BB mentioned the other day that the next edition of the blue book is on hold.

GF1,

Cars aside,…. don’t tell me about what is and is not. Get a Blue Book and (then) tell me. I think that you would be jaw dropping amazed of what (IS) in there,… let alone of what “hypothetical” stuff that is not in there.

B.B.,….. I am very sure could add much more to my comment. I can assure you though,… you have not seen 1/10th of what is out there/has been.

Chris

Chris

Your missing the point again.

It’s not what’s in there. It’s what is not.

since I don’t have one on hand.

What are the 9 pistols listed?

Are they all vintage ones, made by Smith and wesson,

or the more modern ones made in conjunction with Umarex?

I know the 78 and 79,

the 77 rifle we are learning about here, and the 80G BB repeater.

And I have owned a couple of the 586 co2 revolvers over the years.

Ian

Bravo,

78G, 79G, M&P 40, M&P 45, M&P R8, 327 TRRB, Mod. 586B4/586B6/586B8, 686N4/686N6/686N8.

My bad,…. 8 listed.

Chris

ok, thanks for taking the time to look them up.

I have owned all of them except for some of the revolvers.

Only owned the 586B4 and 586B6 of that line.

Chris

So where did all this go.

You was trying to make a point then stopped.

I’m really wanting to say there are people out there that can contribute to the air gun blue book but don’t. For who knows what reason.

I bet you as we continue in our time there will be guns that show up that aren’t listed.

That’s always the mystery. Finding those guns that nobody knew existed.

As I said above. Not only air guns.

I know I should get one, but just never have.

For years, I was one of the silent masses, I have always shot airguns since i was a kid, and powder burners, and black powder, and everything i could get my hands on.

I am a self confessed addict of anything with a trigger.

The first blog of Tom’s I ever read was:

/blog/2005/04/rock-roll-with-an-airsoft-submachinegun/

I had picked one up, and was researching it online.

As my interest changed with the winds, i would read the blog daily, then not for months.

My primary interest was firearms, but airguns in the yard.

Anytime you can get some trigger time with any type of gun is good, as you are always working the same exercise, sight picture, trigger pull and follow through.

I didn’t get seriously into airguns as my main interest until 2008 or so, and became a full time airgunner in 2013 when the ammo crunch came following the Sandy Hook tragedy.

Since then, I have been a full time airgunner, and started joining forums, and this blog.

Sharing with others, and learning along the way.

I have swapped and traded many over the years, and even 1 from you Chris USA.

A 24 inch .177 Crosman 2400 with an AR15 stock adapter.

I will pick up the new edition when it comes out.

But for some reason, it just has never been on my radar at the time i had the money.

Ian

Bravo,

1 from me? A TX200 or LGU would be it. They are the only 2 I have sold.

At any rate,… get a Blue Book and you will be kicking yourself for not getting one many years sooner. Trust me,… it is that good.

Last I heard,… B.B. is like one of the top dudes on the staff. 😉

Chris

you are right, just checked my email history.

It was from a GTA member back in 2015, and he had a similar name . but Not Chris USA.

Getting old sucks..

Bravo,

It has been a pleasure. I can relate on the “old” stuff. 😉 Have a good evening.

Out’a here,…….. Chris

I had found a manual for this rifle online. It may be on my computer at work or it was posted at one forums online. Point being 20 pumps was listed as the maximum. I don’t blame you for not going that far as old as this rifle is. I don’t want to be pushed to the max at my age, parts are hard to come by for us older models.

One note, it does have a Mac 1 pump cup. The original was very weak and I replaced it. The original cup was like the old Crosman 100 series rifles with the pressed on brass retainer. I had used Mac’s pump cup on a couple of Crosman rifles so already had it in hand. It worked fine and was all this rifle needs to start working. Unlike every 100 series rifle I ever found.

One of the reasons to make it to a airgun show is to see guns like this and see first hand how well they are made. Sometimes at the show I feel like I’m the docent at an air gun museum. But it’s all good because one the fun aspects of this hobby, besides the great people, is talking about airguns .

Really enjoying the series, but that is not unusual,

Pat

Hey, BB

I have the same gun (77A) and a copy of the owner’s manual. The manual says “Never Pump your gun more than 20 times”.

Took that to be the max.

With 20, this one clocks Superdomes @ 670, Hobbies @ 715. Hadn’t clocked it @ 10 yet.

Skillet,

Thank you! That was what I wanted to hear. I will do something with that information!

B.B.

How do I private message B.B. Pelletier?

John Carlisle

John,

Because you asked first send it to blogger@pyramyd air.com. I delete those not expected without reading them.

B.B.

B.B.,

I noticed that you left a space between pyramyd and air.com. It would be very unusual for there to be any spaces in an email address. Just thought you should know. I pick up on things like that 😉

Geo

Geo,

I suspect he did it to dodge the bots, that pick up every email address posted.

Or perhaps just an error as he posts that email for guest blogs.

Mike

Mike,

No, it was a mistake. But he got through anyway.

B.B.