by Tom Gaylord

Writing as B.B. Pelletier

Crosman 600 CO2 pellet pistol.

This report covers:

- Update on the Brice scope mount base for the Daisy Red Ryder

- A true semiautomatic

- .22 caliber

- Power and gas use

- Ultimate ergonomics

- Gas caps

- Sights

- Safety

- Modification

- This pistol

- Could Crosman do it today?

Update on the Brice scope mount base for the Daisy Red Ryder

I was going to mount an optical sight on my Red Ryder and test it for today’s report. Unfortunately I discovered that the base does not work on my old model 111-40 Red Ryder.

The problem is the rear sight. The mount requires the rear sight elevator to be removed to fit the base, but a 11-40 rear sight doesn’t have an elevator. The sight is tack-welded to the gun and doesn’t come off.

The rear sight on my vintage 111-40 Red Ryder is tack-welded in place. The Brice mount will not fit over it. The raised portion to the right of the sight is the mainspring anchor.

The Brice scope mount base has a notch for the rear sight with the elevator removed, but it’s for the modern version of the gun.

I’m getting a new model Red Ryder from Bill Brice to test the mount base for you, so this report will be written. It will just take a little longer.

Today I thought I would take advantage of the opportunity to start the report on the Crosman 600 pellet pistol I got at last week’s Texas Airgun Show. Let’s get to it.

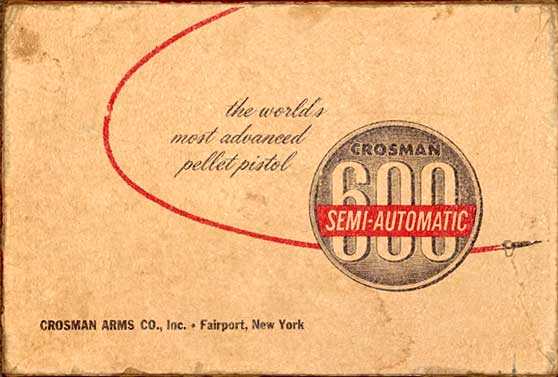

Crosman 600 pistols were made from 1960 to 1970. I mentioned that this 600 came in a rocket box. Let’s take a look at that first.

That tiny rocket on the box lid is what makes this a rocket box 600. It is one of the final versions of the gun.

A true semiautomatic

The Crosman 600 CO2 pistol is a true 10-shot semiautomatic. I say true because it actually operates semiautomatically, using the CO2 gas to power the action. A lot of air pistols today say they are semiautomatics when in fact they are just double action revolvers in disguise. That shows up in their long heavy trigger pulls. The Crosman 600 trigger pull is long, but it’s also very light. When you feel it for the first time you fall in love with the gun.

Instead of a blowback slide cocking a hammer, the 600 employs an odd cammed feed arm that swings to the left to align with a 10-shot inline magazine. A pellet is pushed by spring pressure into the chamber on the end of the feed arm, and it sits there until the trigger is pulled. When the gun fires the arm swings to the right to line up with the breech and the gas blows the pellet into the barrel and out of the gun. This all happens in the blink of an eye and is hard to detect.

Here the pellet feed arm (arrow) is swung to the left side, to align with the inline magazine. A pellet is pushed into the feed arm chamber and waits for the shot. When the gun fires, the arm swings to the right, aligning with the barrel and the pellet gets blown forward by the gas.

There is no simulated recoil. A 600 is a very smooth-shooting air pistol.

.22 caliber

A 600s are .22 caliber. There is a model 677 Plink-O-Matic pistol that shoots BBs, but it never sold well and is very scarce today. It absolutely cannot be converted to shoot pellets because of how the inline magazine operates. This pistol has a magazine and not a clip, and it is so integral to the frame that it offers no easy path for modification.

Because of how the mechanism works, the 600 is sensitive to the length of pellets it uses. I have found RWS Hobby pellets work well on many guns, as do RWS Meisterkugeln pellets. The old vintage Eley Wasps also fed in all of the 600s I have owned. And Crosman Premiers work well, too. But pointed pellets probably won’t work as well because the nose of one pellet can get caught in the tail of the pellet in front of it in that inline magazine, and when the swinging feed arm tries to move to the barrel it can jam.

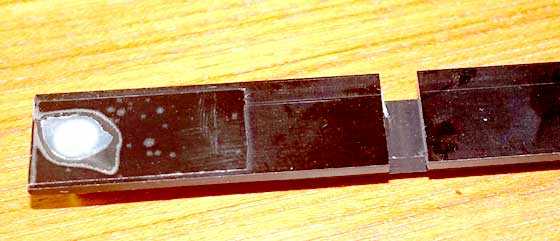

The empty inline magazine is seen at the top, with the follower all the way forward. At the bottom of the action is the cocking slide.

Power and gas use

A 600 is not a high-velocity air pistol. Expect velocities in the high 300s and low 400s for a stock pistol. I have owned a couple what were souped up to the low 500s, but that did involve a longer barrel than the 5-inch one that comes stock with the pistol.

The 600 is a notorious gas hog. I hope to get 25 good shots from a 12-gram CO2 cylinder. A tuned gun can stretch that higher, but many tuned guns also have small bulk tanks attached, so its a moot point.

Ultimate ergonomics

The Crosman 600 is the airgun equivalent of the Luger firearm — utterly ergonomic. The poster-child of how a pistol should look and feel. Pointing a 600 is like pointing your finger. And many 600s had the barrels to back it up!

Like most airgun makers Crosman rifles barrels by pulling a button through seamless tubing. In high-volume guns like the 600 there is no time to ream the bore first, but the rifling button irons in a certain amount of uniformity.

Most of the time this works well and you get surprising accuracy from a budget airgun. But if there are hard patches or voids in the tubing, the barrel can come out bad. So it’s always a crap-shoot, whether a certain 600 will be accurate. I would call accurate the ability to put 10 pellets into one-inch at 10 meters.

Gas caps

There are three different types of Crosman 600 gas caps. The oldest one is a button-piercing cap. You install the cartridge, then press in on the rounded button to pierce the cartridge. The second type is a lever cap. It works like the button type, only a lever makes piercing easier. The third type is the last type Crosman used. The cap itself contains the piercing pin and pierces when the cap is screwed down. On some guns you must tart to unscrew this cap to let the CO2 gas begin flowing.Once it does, the o-ring locks the cap tightly in place.

This end cap screws on to pierce the CO2 cartridge.

This lever cap is on a Mark I pistol, but it looks the same on a 600. The lever forces the cartridge into the piercing pin.

Sights

The front sight is a square post that is perfect for shooting both targets and for plinking. The rear sight has a square notch that adjusts in both directions. You can’rt ask for a better set of sport pistol sights than you get with the 600.

Safety

The safety is a simple trigger-block type located at the front of the left grip panel. It slides up to set and down to fire. It is very important to bear in mind that the 600 is always cocked and ready to fire when there is a CO2 cartridge installed. So this safety is important!

The safety is difficult to see, but it’s at the point of the arrow. Slide it up to block the trigger.

Modification

You can always install an aftermarket barrel in the 600, and people are doing that. It is popular to install a 7-inch Lothar Walther barrel in the gun and boost the accuracy to a surprising level. You also boost the velocity, just by giving the gas a longer time to push on the pellet.

This pistol

The pistol wasn’t charged when I got it, and with a 600 that can cause problems. I never leave mine empty. The seals need to be under pressure to keep the airborne dirt out and the gun should be dry-fired from time-to-time to keep the mechanism working. But I knew all of this, and the seller, who is reader Jonah, told me he had shot it as recently as a couple months ago. So I figured it would work.

I installed the first CO2 cartridge after dropping 10 drops of Cropsman Pellgunoil into the gun before inserting the cartridge. The seals were most likely dry (they were) and needed to be oiled to work. I also put a drop of Pellgunoil on the tip of the cartridge before installing it. Then I cocked the pistol and fired. Nothing. I expected that. I cocked and fired the gun about 25 times with no response, then I tried to unscrew the cap where the CO2 cartridge goes. If the gas it inside the cap should be on tight, but it wasn’t. As it unscrewed, gas started hissing and I tightened the cap once more.

Now the gun fired, but weakly. It didn’t cock the mechanism for a second shot, so I cocked and fired manually for about 20 shots. Gradually the shots became more powerful, but after each there was gas leaking out of the barrel. The gun still was not cocking with each shot. By that time the first CO2 cartridge was empty, so I removed it and went to Plan B. Plan B is to pour transmission stop leak into the gun before piercing the next cartridge. I didn’t count the number of drops but ket’s call it 50 to be safe. You cannot over-oil these guns as the excess is blown out the barrel on every shot.

This time the gun fired and cocked again. So I shot it several times, then set it aside for several minutes before firing again. I wanted those seals to be under pressure to seat properly, now that they were oiled again. I shot that gu over the course of the nesxt 8 hours and it functioned perfectly. When the gas ran out I installed a third cartridge — this one oiled with a drop of Pellgunoil on the tip in the conventional way. The gun was shot several times that day and again this morning, as I am writing this report.

The pistol now sounds like it’s back to factory spec. We will see when I do the velocity test in Part 2. The point of me telling you all of this is the Crosman 600 is touchy about how it wants to be treated. It is a fine air pistol that is rugged and reliable as long as you keep it charged all the time and oiled with Pellgunoil on each new cartridge. It puts me in mind of a Harley KR flathead racing motorcycle that takes a special procedure to break in after a rebuild, but is dead reliable, if you just run the poo out of it once it is broken in. In other words, this pistol is finicky because it needs to be shot a lot!

Could Crosman do it today?

People who shoot the 600 wonder why Crosman isn’t making this pistol today. The complex mechanism is one reason, though CNC machinery makes complex manufacture so much easier. But a simpler action would probably be needed. And Crosman made it in their Nightstalker carbine. I talked to Crosman engineer Ed Schultz about this for several years before he left the company. He agreed it would be a good seller, even with the harder trigger pull (required by their lawyer). But as far as I know, nothing has happened yet.

The Crosman Nightstalker carbine, now out of production, would make a good candidate for a modern 600 pistol.

B.B.,

Very nice. It will be interesting to see what this will do on paper. Interesting too on the different types of piercing caps. I love the unique action and magazine too.

What is that “rod” that is in the box? (top photo)

Also, on the safety, how is that red-ish dot part of the grip? Is it a sticker, or molded into the grip panel?

Thanks, Chris

Chris,

That “rod” is a real rod. It’s for clearing jammed pellets from the barrel.

Reddish dot? Sorry, but I am red-green colorblind. I don’t see it.

B.B.

just curious . Mine has the same piercing cap, bought it on Gunbroker a few years back. It came to me in a Crosman zippered pistol case , with straps to hold the pistol in place, Crosman logo, and the push rod. How common were these ,and what period of production were they?

Michael,

The case is a later item from the late ’60s, I believe.

B.B.

Chris,

It looks to be molded into the grip.

I believe the “red” indicates the fire position for the safety.

RR and Dave,

Yea, I figured it was red for fire position. I was just thinking that it would be hard to get a perfectly round dot like that into a molded product. Maybe not.

Good point, Chris; the more I look at B.B.’s final pic, the more curious I become about that red dot 🙂

RR,

From the bottom photo, the top of the dot would indicate it being raised,… (residue from wiping). But,…. the bottom half looks very flush and even molded into the grip plastic. Mmmmm?

BB,

I myself am not into CO2, most especially the new action pistols, but this 600 sounds like a CO2 pistol I would not mind having. I really like the fact that it needs to be shot on a regular basis and can be pretty accurate. One inch at eleven yards is pretty respectable if you ask me. This thing could make quick work of a pack of feral soda cans.

RR,

I think every airgunner needs one of these.

B.B.

I think this is my favorite semiauto, especially in 22. I shoot pistols lefty and was able to track down a set of original left hand grips. Don’t like thumbrests , so I made a pr of flat grips from the lt and rt hand pair. Put a set of wood grips on second pistol. The first one is a rocket box version like yours. How long can you leave the pistol cocked with co2 if you don’t use the whole cartridge? Not that you get that many shots anyway. It seems that if you leave co2 and a lubed cartridge in the pistols the seals don’t leak. I have some of the older SA 45 revolvers that have held co2 with out leaking for a couple of years. Found a Hahn bb pistol that I forgot about and put away several yrs ago with co2 and hasn’t leaked

B.B.

I have a Crosman 600 that I bought over 50 years ago that has been sitting unused in my closet for about 40 years. Your reviews inspired me to fire it up, so a bought some Pellgunoil and applied it as noted in your blog. After a few CO2 cylinders it was working fine. I was surprised since all the O-rings and seals were original from the 1960’s. Last week when I went to install a new CO2 cylinder I was unable to screw in the end cap. I seemed like the O-ring had expanded to the point of not permitting the threads on the end cap to engage. I figured that after 50 some years the O-ring needed replacing anyway so I went to Lowes and bought a package of O-rings sized 9/16″I.D.x 3/4″ O.D.x 3/32″. After installing a new O-ring the gun was again working fine. I left the gun charged for a week or so and then did some shooting until the CO2 cylinder was discharged. When I unscrewed the end cap to install a new cylinder the new O-ring literally fell off into my hand. It was intact but had expanded to about twice its original size. It looked like the offspring of the Michelin Man. I set it aside and by the next morning it had shrunk back to its original size. What gives? Are O-rings designed for faucets not suitable for airguns? If so then why is it that the 50 year old O.E.M. O-ring also expanded? Any thought you have would be appreciated.

BB,

You did not go into any details about the handle on the side below the magazine. Is this how you would cock it? Is it single action or double action? Does the charging handle blow back or just the striker?

You seem to be saying that the cam holding the pellet does not move until the trigger releases the striker and then it snaps into line with the barrel and fires, then returns to accept another pellet as the striker returns to the cocked position ready for the next shot. Is this how it operates?

RR,

I called it the cocking slide. I thought that was description enough. The gun is single action and cocks with each firing. It doesn’t move upon firing.

Yes, the feed are is on a long cam and does exactly what you said.

B.B.

BB,

Ah, I found it in the photo caption. It did not stick in my head when I read through previously.

I would indeed like to have one of these. A well made version of this pistol should sell quite well today.

The only issue I think it could have is getting it past marketing. They are going to insist that it look more like a real firearm. Then the accounting department is going to insist on a redesign so that it will cost less to manufacture. Then they will have it made by Wang Po Industries who will then find various ways to cut cost to increase their profit margin. When the container of 10,000 of them arrive here, the company will realize what they now have is something no respectable airgunner would ever want to own, so they sell them en masse to a certain big box store who will promptly display them with a price tag that seems ridiculously low until we get it home and try to shoot it. After quickly becoming bored and / or frustrated with the futility of such, it is unceremoniously deposited in the local landfill where it belongs. 🙁

Perhaps I will just go to Hickory, NC and see if I can find one. 😉

B.B.

Thank you for another interesting piece. It has inspired me to break open a Daisy Powerline 1200 that a friend, John A., loaned to me a couple of weeks ago. John speaks very highly of the gun’s performance and it will be fun getting into it. It is different enough from the current crop of semi-auto BB pistols that I’m going to have to ask him some questions before I use it, such as, “do you have to unscrew the grip to install a cartridge”? Sure looks like it

And I’ll bet the the seals need oiling.

Thanks, again, for everything you do.

Walt

BB,

I had to laugh at your last paragraph – I was thinking that as I read the blog.

Revised and re-printed copies of technical books are readily available. I have often wondered why companies didn’t do limited production runs of their best most popular products – think they would make a killing!

My friend had a 600 and it was a blast to shoot with – I am not fond of Co2 rifles/pistols but if a “new” 600 was available I would order one right now. Ditto for a new 101.

Hank

Hank

Have you got to spend any time with your Tx?

B.B.

Can you see the spot ?

http://i189.photobucket.com/albums/z244/twotalon/spot/DSCN0241_zpstgplywhw.jpg

twotalon

TT,

I see the malware! Please don’t send people to places like that!

B.B.

B.B.

Photobucket is infested ?

tt

TT,

I opened 3 false windows before I stopped. I just got a hit from malware. That site is infested.

B.B.

B.B.

I guess that site has to go .

tt

TT,

I clicked on the link and it led to Photobucket. Stay on the page long enough and all sorts of annoying Pop-ups start appearing eventually replacing the page.

Yeah, there are annoying pop ups . So far Norton has not red flagged anything .

Guess I better find another site . Pop ups are annoying .

Maybe I should just give up on the whole thing .

tt

TT

That’s why I started taking what I call picture video’s of a gun or such. Then I upload it on YouTube. Then after its uploaded just post the link.

What I like about YouTube is you can keep the video on the private setting. That way it can only be viewed if I provide the link. And you can delete your video on YouTube if you don’t want it to work if someone clicks on it. It will say video has been removed.

To me a little easier to use and the links are clean.

B.B.

I have seen some pretty nice examples of these guns for sale (likely by people who do note want to shoot them as often as they require =>); if I should get one, who is a good person to do any re-seal or tune-up or repair that it might need? Thanks.

take care & God bless,

dave

Dave,

I suppose there are many who reseal the 600, but Rick Willnecker is the one who makes the seals theyb all use. He would be my recommendation.

B.B.

Cool; thanks for the quick reply. I should have known the answer without asking, since you already wrote an answer back in 2005 🙂

/blog/2005/7/co2-and-pneumatic-guns-where-to-get-them-fixed/

Hi BB,

I like the lever type gas gaps best of the three designs. It is easiest to work and seems most fool proof. I guess some people might not like the lever poking out of the cap. My current 600 has a longer barrel and muzzle brake. They are fun guns. I wish I had one of those aluminum rotating high capacity magazines they used to sell, just for the cool factor. That was in interesting mechanism.

David Enoch

Anyone have suggestions for easy cocking spring air gun with a good trigger? If I had the money for a Beeman R7, this conversation would be moot. I’m thinking about refurbished Tech Force M8 but I’ve heard both good and bad. I understand it has a very good trigger, though. I just want a plinker with a great trigger for not a lot of money. I bet everybody else does too 🙂

Brent,

One option would be to get a Wally’s mega blaster (springer) and do a spring chop on it. Not sure what to recommend on the trigger though, or model. You can always clean and lube the trigger while you have it apart. Instead of having 3″ of preload compression, you could chop it to a 1/8″ preload. Just an idea.

Chris U

You apparently have shot one yet. Try a break barrel and see what their about. Why do you think I like the fixed barrel underlever air guns.

And then once you get a nice German or English break barrel and one of the Wally world break barrels and compare them you will be surprised how much different one air gun is to the other.

Remember you started out with good springers. Got to say it again. Yes the guns you have got you spoiled and you don’t even know it. And you know I got to do a little rub it in. 😉

But be happy you got em. They are nice guns. 🙂

GF1,

You are right,… I have not tried one yet. Speaking of spoiled,….. I dusted off the TX and LGU today and saw what they were doing at 30 and 40 for hold over and under. Then,… had to do the M-rod for a few.

I was thinking LGU for squirrel. Heavy straight out, but not bad at all when tipped up 45 degrees for a tree shot. By the way, the LGU outdid the TX at 30 and 40.

I just thought that a spring chop would be a way to go for Brent.

Chris U

Them Wally world guns tend to beat you up when you shoot em. They vibrate. Their hard to cock. Have noisy shot cycles. And I’m not talking about the report the barrel makes when the pellet leaves it. The springs twang. The piston slap and thud when they stop. The barrels don’t lock up constantly. And triggers are ridiculous. Then talk about accuracy.

By time you fix and tune all that stuff you’ll have more money in it than a nice German or English gun. If I could say it different I would. But most of them Wally world guns are money traps.

GF1,

Well,….. that sounds as if that is a,.. “been there,.. done that”,…. (on your end)?

Yep,…better to save and buy 1 something that you will happy with,.. instead of 3 somethings that you wish you had never bought.

Chris U

I paid the piper if you know what I mean. My whole idea was to try as many guns as I guess I could afford and learn about how the poor air guns were as well as the good ones.

Nothing comes cheap and experience is everything.

Brent

I had a .177 M8. They are nice guns for the price. The triggers are nice. They cock easy.

But they are no kind of way a Weirauch, Diana, Walther or Feinwerkbau.

They have a fair shot cycle. Accuracy is fair. No 50 yard can kill’n with the one I had. Probably 25 yards is a good distance for the gun. I tryed many different pellets in it. All pretty well with the same results. No pellet stood out really.

Oh and I had to drill and tap a hole for a scope stop. It will mess that back plastic end cap up if you don’t do the set screw for the scope ring to stop on.

If it was me I would save up the extra money and get a Weirauch HW30. You would have a more precision made and shooting air gun verses the M8 plus should last forever. And Weirauch tends to make replacement parts for years as well as the other German air guns. Hope that helps.

Brent,

There is a certain airgun dealer in the Southwest US that is selling wood stocked Walther Terrus for well under $200. As BB has stated in his blog of such, it is an excellent air rifle at an excellent price and should fill the bill quite nicely.

This same dealer is also selling the Webley / Hatsan Tomahawk for just under $100. This is a magnum sproinger and very likely each will have certain minor quality issues, but if you can work on sproingers you can turn it into a really nice one without too much effort. I know this because I have one of them. 😉

Chris and Gunfun1 will try to steer you toward an underlever instead of a break barrel. Although they will inded be more accurate, the problems with those are they are more expensive and they weigh more. These are great for “serious” shooting, but if you are just wanting to thin out the pack of feral soda cans running around your yard, they are almost too much to deal with. Gunfun1 has picked up a couple of plinkers recently himself.

I would suggest that by the end of the day you contact that certain airgun dealer in the Southwest US and order a Terrus. You will be quite pleased.

RR,

I have nothing against break barrels. In fact, I was looking for something (lighter) for off hand and the woods. You are right, the underlevers are too heavy for either. I looked up some of the rifles mentioned with regards to weight. TX 9.3#, Tomahawk 8.0, Terrus 7.5 (either stock), M8 6.5, HW30 5.5, Maximus 5.0.

Chris,

That is why I recommended the Terrus to Brent. It is lighter and easier to shoot than an uber magnum sproinger and BB gave it a glowing review. Also the price that you can get one right now for is awesome! The only reason I did not get one is the Tomahawk is under $100 and I was wanting a break barrel uber magnum sproinger to try out.

If you are thinking of a break barrel, I would strongly suggest you go check out that deal I was telling Brent about. They are not going to last long at that price.

Brent,

GF1 surprised me with his recommending the HW30, which is the R7. The same dealer that I spoke of has this at a reasonable price also.

Either the Terrus or the HW30 would be superb for what you say you are looking for and you will not be disappointed by either. You will be risking dissatisfaction to buy anything less expensive than these. At the price of the Terrus, you would be quite hard pressed to find anything near as good in quality.

RR

I had a .177 Weirauch HW50s. It was a nice gun. I have been seriously thinking about a HW30. They are a little less powerful than a HW50s. But that should be a good thing. Less cocking effort and maybe even a better shot cycle. I do see myself with one I. The future.

GF1,

I recall your HW50. You even offered it to me. I would have taken it except I was looking for a break barrel in .22.

The HW30/R7 would be a superb plinking rifle that you would find quite enjoyable to shoot. Do keep in mind though that the stock is sized for someone of a smaller stature. It might be something your daughters would enjoy shooting, or a grandson. 😉

RR

I probably did offer it to you. That’s been a little while back.

And I wonder if the HW30 uses the same stock as a HW50s. The 50 seemed small and light to me also. Haven’t owned a 30 so can’t compare.

But you mention smaller guns. The Daisy 74’s are light and small too. Makes for some easy shooting. Me and the daughter’s plink with them all day and don’t get tired out. And the shorter length of pull doesn’t bother me either. Sometimes a smaller lighter gun is nice to shoot.

GF1,

The HW30 is a little over one pound lighter and is almost two inches shorter with the same barrel length as the HW50. It is also about as powerful as a 10 meter air rifle. It was designed to be a youth air rifle, light, short pull, easy to cock with a gentle firing cycle.

I know you guys have really been enjoying those 74’s, but I do not think they would be my cup of tea. I picked up the Daisy 99 for that slot in my “collection” and I recently picked up a Daisy Buck for my grandson so we can hunt feral soda cans together.

A little update for you. I shot the Webley Tomahawk some Saturday afternoon. Before I started tiring out I shot a 10 shot, 1 inch group at 25 yards using H&N Field Targets. I think that once it gets broken in good and quits dieseling and I get used to it, this is going to be a great “sow’s ear”. I think this is going to turn out to be a nice looking, nice shooting uber magnum sproinger.

RR

Sounds like the Tomahawk is turning out to be a nice gun.

And yes the 74’s are fun guns. And cheap to shoot. It still amazes how many shots from a 12 gram co2 cartridge. They are getting seriously 300 shots and more per cartridge. If you did just casual plinking a cartridge would last a full day of shooting. And bb’s are cheap. PA even honors the buy 3 get one free. On my last order with the 2nd Daisy 74 we got 4 containers of 4000 Daisy zinc coated bb’s. They were $8 for 4000. So with the $40 price tag of the 74 and cheap cost of bb’s and so many shots per cartridge the 74 is a bargain. And I’m sure any kid that got one would be very happy to own it. You really should try one. Oh and if your worried about bb’s laying around a magnet on string makes quick work of picking them up.

And about the HW30. Smaller and lighter than a HW50s. Well I think I like that. And yep I think that lower power would actually make a nice little bench rest gun even out to 50 yards. You remember the FWB 300’s I got from you. They both did great out to 50 yards even though they are known as a 10m gun.

But head’n out to shoot. Really nice out and dead calm. For the moment anyway. 🙂

RR

Just my 2 scents: The 74 is really unique. You might want to get one now in case Daisy’s new owners drop them. Put it away when your grandson grows out of the Buck.

Fido3030

Fido,

I am trying real hard not to have a closet full of air rifles, though it is not easy.

Once he outgrows the Buck, he can shoot my 99 for a bit. Then he can move on to the Edge and the 1906 BSA. When he starts craving power there is the Talon SS, Diana 46 and the Webley/Hatsan. There is also a strong possibility of a big bore in the foreseeable future.

I think I can keep him busy slinging lead for a while. After that he is on his own.

Brent,

Save up a little. You will be happier. I think the Diana 240 is worth a look. My Dianas are older but still I imagine that new 240 would be worth the money, even though it’s 2x as much as the tech force. It is advertised with a t05 trigger. I have found my unit to be very useable. The fiber optics are probably good enough for cans. I guess it all depends on what you want to spend scoping the m8.

I picked the hw30 over the the rest I was considering, m8 included. I have not regretted my choice. It all depends on what you want. Let us know what you pick. 🙂

This pistol design puts me in mind of a whole class of pistols with a similar look including the Ruger Mk. III. Sadly, they are no longer available in California along with a bunch of other things, but one can still fantasize. I read somewhere that this famous and highly successful design is based on the Japanese Nambu pistol of WWII. I thought Nambus were junk; the general opinion of Japanese small arms of that time is pretty low. Besides, given the similarity, I would suppose that the Nambu is a copy of the earlier Luger. However, my source clearly identified the Nambu as the inspiration. Curious.

BarryinIN, I can’t conceive of how people could use a 180lb. bow either, the same as I cannot understand how the farthest targets at the old archery range of Finnsbury Field were a quarter mile away, or how some longbow archer fired an arrow 4 inches into an oak door at Abergavenny Castle in Wales. I don’t think that anyone even believed that bows had this much weight prior to the discovery of the Mary Rose shipwreck. How they recovered the bows is another puzzle. I would think that seawater would be about the worst environment for bows and that there is no way they could survive for hundreds of years in that environment. As it turns out, there were a bunch of other interesting discoveries. One was of the remains of a sailor who was afflicted by rickets. This was some kind of disease of malnutrition, common at the time, that weakened the bones and left this individual with severely bowed legs. However, his upper body was built like an Olympic gymnast. (How they determined that only from the skeleton I am not clear on but apparently it has to do with examining the thickness and robustness of the bones and the areas of muscle attachment.) The archery mystery may be partly explained by the fact that people from that time were just a heck of a lot stronger than now. It has been observed that if you just remove all the modern labor saving conveniences, pre-modern people had to do much more physical work, and the sailing ships of the time were particularly strenuous. They’ve been compared to 24 hour gymnasiums. Exams of the bodies of original archers show enormous, Popeye size left forearms, which I can relate to with the crushing pressure on my left arm with even a 60 pound bow.

But to complicate the question still further, you can see YouTube videos of people shooting 180lb bows today without much apparent effort. I don’t get it. I’m not that weak. Or maybe they are lying about their bow weight.

Anyway, my plan is to snatch the bait from the trap which is my approach to a lot of things. I may study Jack Dempsey and whale away on the punching bag, but ain’t no way I am stepping into the ring with anyone. For archery, I might work up to a 120lb bow with my new technique and see if I can get some sense of what the old archers accomplished. Reviews of the bow say that it is actually a lot of fun to shoot.

Matt61

Looking forward to the Red Ryder scope mount post. Mounting a scope on a Red Ryder seems pointless but I can’t resist the temptation. The big problem now (as mine is a fairly new one so the mount should fit fine) would seem to be finding a scope that looks right when mounted. Long tube with a small diameter would be perfect but may be hard to find. Anyone have any suggestions?

Nowhere,

I had an Daisy 880 that came with an ultra-cheap scope. The parallax seemed to be set for something like 50 yards. Bad! I read where you could turn the front lens and I tried it and it worked great. I was doing 24′ indoors no problem. Try an ultra cheapy scope with the adapter. If I had the adapter, I would have already done it on my 75th Red Ryder. The 499 will smoke the Ryder all day long though…… 😉

Nowhere

I tryed a scope just yesterday on one of my Daisy model 74’s.

The best I can say is I hated it. First thing is I could see very well every bb fly to the can I was shooting at. It made me feel like the bb was going all over the place. Well and it was. It wasn’t hitting in that precise place I was aiming like my accurate pellet guns do.

Not putting the 74 down. I luv it open sight shooting. When I shoot the can rapid fire shooting all I want to do is see a hit. I don’t care where. I just want to hit the can every shot as fast as I can.

Now if I was doing some indoor target shooting at 5 or 10 meters then the scope might be good on the 74. But I’ll tell you it does what it suppose to. It magnifies the shot and where it goes.

So probably just not the right thing for the way I shoot the 74. But it will be interesting to see how BB does with the scope mount on his gun. And definitely something like a UTG Bugbuster scope will needed for those up close distances to focus in that close. That’s what I had on the 74.

Nowhere,

I do, but that is part of my report, so I’d like to wait for it.

B.B.

BB,

There’s a new book available on Amazon: The Toolmaker’s Airgun by Paul Betts. Have you heard of the author? Gun on cover looks Gary Barnes-y. BTW, just took advantage of a sale at Gander Mountain & bought a crosman 2100 (inspired by your test from years ago)! Got a T/C encore barrel too!

Regards,

Nathan

Nathan,

Thanks. I just bought it. You’re right about the gun looking Barnes-ish.

B.B.

Nathan,

Thanks for the heads up about that book. It looks like it might be a real good read. I am going to have to get that one.

BB & regular commenters,

Saw that Baker Airguns has a Hy-Score 806 (so a Diana 22?). It seems to be in rough shape. Would you consider this a good buy? I’ve settled on a vintage airgun for my next buy, possibly a crosman 140 but I could still go for a springer.

Thanks,

Nathan

Nathan,

My Blue Book says you are right about the Diana model no.

A good buy? Really it depends of whether you want the gun. A 22 is a youth gun, but they are also very smooth to shoot. I have a 23, but not a 22.

Your call,

B.B.

Nathan– I have a Diana 22. It has a rifled barrel. It is in 90% condition. I found out why when I began to shoot it. It had a heavy trigger pull. It probably was not shot very much for most of its existence. Thanks to BB,s suggestion, a dab of moly grease fixed the problem. I have 4 Slavia 618,s, (3 with a scope), a slavia 21, a Diana-Milbro 27, a Haenal #1 (rebuilt inside), and a Bronco . The Diana 22 shoots as well (and often better) than those guns. However, the condition of the Diana 22 is important. If it has a good bore, if you can rebuild it( or are willing to send it to someone who can), then buy it. If I had to part with the above guns, I would keep my Diana 22. Ed PS is the gun a smoothbore (most common) or is it rifled (rare, according to BB)? Keep us up to date, if you decide to buy it.

Nathan–I looked at the baker website. Only the stock seems to look “rough”.They claim that it shoots, but do not say if the barrel is rifled or smoothbore. BB has done a report on a Diana 23 smoothbore. You should read it before you make your decision. Ed

Nathan– I just reread the Diana 23 report. BB does not say if it is rifled or smoothbore. However, the report is worth reading. —–Ed

Way off subject, but in old post , you said to just post in new blog. I have 2 B3-3?(no markings, not even caliber). The way I understand it is that most chines guns are copies of some other design. My question is what gun are these copied from? And thanks for all of the good info.

Nomadgd,

Welcome to the blog.

As far as I know, the B3 is unique. It copies nothing.

B.B.

Nathan— The smoothbore Diana that BB tested was a Diana 25. His test is dated January 11, 2013.——-Ed

BB—I enjoyed revisiting your Diana 23, 25 and “pogo stick repeater” articles. Is there any chance that you will do an update on the “pogostick”? ——Ed

Zimbabweed,

If I recall correctly the “pogo stick repeater” was forwarded to Vince who after studying and tinkering with it pronounced it unworkable.

Ed,

Yes, and Vince took it apart to try and re-create the Diana rifle is was based on, but he gave up on that project.

B.B.

BB

Since Labor day is tomorrow I have a labor related question.

How is the Marauder based pumper going that Dennis is maybe working on. Notice I say labor related. If he’s working on it I’m sure he has a lot to do. Pump mechanism and valve.

Haven’t heard anything and thought I would ask. Interested in that project though. Hope it could be happening.

GF1,

Dennis isn’t working on a Marauder-based multi-pump pneumatic. That was just something that was mentioned.

B.B.

BB

I kind of thought that. Was hopping he would of gave it a try though.

At least now I know it ain’t happening. And thanks for the answer.

Darn phone.

How about hoping. Not hopping.

Siraniko—BB— thanks—–Ed

Thanks everybody for your suggestions. If I had the money, I would lean towards the Diana 240. The Walther Terrus is a little too heavy already at 7 and a half pounds, probably would be 9 by the time you added a scope to it. The Diana 240 would weigh about 6 and a half pounds with the scope, which I think is a perfect weight for shootin off hand and from a two-point position seated, which is my favorite position is shoot a gun from.

Brent

No problem and let us know what you get.

Regarding this bit: “He agreed it would be a good seller, even with the harder trigger pull (required by their lawyer”

They should fire that lawyer and hire one who will defend the company properly. They have good instructions, and even markings on the gun sometimes. It’s time to start holding folks responsible for handling guns properly, rather than castrating the guns for everyone.