by Tom Gaylord

Writing as B.B. Pelletier

The Beeman R8 looks like a baby R1.

Part 1

Part 2

Part 3

Part 4

Part 5

Part 6

This report covers:

- New mainspring

- The compression chamber honing

- The Rail Lock Compressor

- Cleaning

- Piston seal

- Installed the new seal and mainspring

- Back in the stock

- Cocking effort

- RWS Hobbys

- RWS Superdomes

- JSB Exact RS

- Firing behavior

- Conclusions so far

The new mainspring and piston seal Pyramyd AIR sent for my R8 arrived and I installed them last Thursday. This will document how that installation went and look at the velocity results, plus the powerplant smoothness.

New mainspring

The new mainspring is made from better wire than the stock Weihrauch spring. Gene Salvino has reports of guns with up to 9,000 shots with this spring that have lost little velocity, if any, since installation.

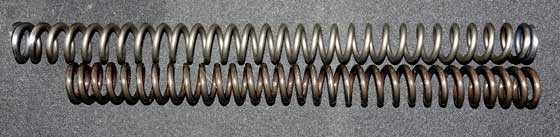

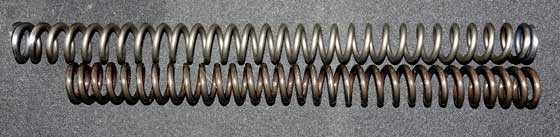

I knew there would be a lot of interest in this mainspring, so I examined it carefully and also photographed it next to the existing spring. The new spring wire is silver colored, where the Weihrauch spring wire is a darker color. The new spring appears to be about one inch longer than the original, but I don’t think it has been scragged.

Scragging means leaving the spring fully compressed for a length of time (4-8 hours) to shorten it to its operational length. This will happen while it is inside the gun, so except for the fact that it is longer and needs to be compressed more to install, there is no problem. However, I did show you years ago how to scrag a mainspring if you need to.

New spring on top. Both springs are the same size, except for the length of the new spring.

Both springs have 30.25 coils of wire that is 0.120-inches in diameter. And both are ground flat on both ends. So they have the same compressed length. The new spring will eventually become shorter just from being under compression inside the rifle. I examined the new spring under 10X magnification and it appears to have been shot-blasted by very fine media. The Weihrauch spring under the same magnification appears smooth.

The compression chamber honing

This was a difficult picture to take, but I was able to get a photo of the start of the compression chamber. You can see the honing that runs around the inside of the chamber, perpendicular to the axis of the piston’s travel.

The arrow points to the start of the compression chamber. The crosshatch honing from the factory transitions to circular honing in the chamber where the arrow points.

Lighting that photo was extremely difficult, but you do get to see at least a small part of the circular honing I have talked about. That pattern is not correct, and we will see what effect it has on velocity, if any.

The Rail Lock Compressor

With the longer new mainspring I had to adjust the Air Venturi Rail Lock Mainspring Compressor out an extra inch, and it barely fit. Also, it had to push the mainspring in that extra distance to get the end cap to meet the threads in the spring tube. It was harder to do, plus the white Nylon tip did walk around the end cap as I compressed the spring.

When the end cap was finally up to the threads I thought it would be difficult to get the threads started, and in truth it was harder than before. But I used a rubber hammer to move the end cap slightly until the threads seemed aligned and they did start. It took me maybe five minutes of fiddling to get the threads started this time, but I think the same would be true for any mainspring compressor. Maybe if the white tip at the end of the threaded rod turned freely it would have gone easier, but that would be my only observation.

Cleaning

I spent a lot of time cleaning all the grease from the action. When I was finished surfaces were dry and ready for the new parts. I probably spent a half hour just cleaning the gun.

When I removed the old piston seal there was old grease underneath. I dried the end of the piston and thoroughly cleaned the inside of its body with paper towels and cotton swabs.

I cleaned the inside of the spring tube and compression chamber again with paper towels on the end of a long dowel. This area was already pretty clean, except some of the grease I had applied in my previous tune had gotten onto the surfaces. When I was finished, the inside of the tube was dry.

Piston seal

The old piston seal was very soft and pliable. There is a small imperfection at one spot on the outer edge that the new seal doesn’t have, but I don’t think it caused any problems.

Installed the new seal and mainspring

I know I said I was just going to install the new seal and see how the rifle performed first, but after seeing how the new mainspring compared to the old one, I couldn’t resist installing it. I greased the new seal and back end of the piston with white lithium grease. I also greased the new mainspring and the old spring guide with the same grease. I kept the amount of grease low, but all metal surfaces were coated. Lithium grease is thin, so I expect no velocity loss from what was done.

I checked the fit of the new mainspring on the spring guide. One end of the spring was tight on the guide, so that was the end I used. The new mainspring fits the inside of the piston ever-so-slightly tighter than the factory spring, which should help reduce vibration.

Back in the stock

The entire job took 2 hours, which included time to take pictures and to clean the parts. Then I put the barreled action back in the stock. Now it was time to test.

Cocking effort

With the new spring the rifle now cocks with 30 lbs. of effort. It certainly feels heavier to cock than before, which was measured at 25 lbs.

RWS Hobbys

Okay, here we go with the velocity test. First up are RWS Hobbys, which are light and should be fast. The R8 was rated at 735 f.p.s. when it was new.

Before tuning…….First tune………Second tune……..Today

Vel…….Spread….Vel…….Spread…Vel….Spread….Vel…….Spread

523……..27……..402……….64…….416……47…….741……..18

The velocity with Hobbys averaged 741 f.p.s. The spread went from a low of 732 to a high of 750 f.p.s. At the average velocity this pellet generated 8.54 foot pounds of energy at the muzzle. This R8 has obviously returned to factory performance with the installation of the new Beeman mainspring and piston seal.

RWS Superdomes

At 8.3 grains, the RWS Superdome pellet is on the heavy side for the R8. Let’s see how it did.

Before tuning…….First tune………Second tune……..Today

Vel…….Spread….Vel…….Spread…Vel….Spread….Vel…….Spread

503……..32……..445……….13…….NA……NA……680……..18

Superdomes averaged 680 f.p.s. in the R8. The low was 671 and the high was 689 f.p.s., for a spread of 18 f.p.s. At the average velocity this pellet generated 8.52 foot-pounds at the muzzle.

JSB Exact RS

The last pellet I tested was the 7.33-grain JSB Exact RS. This should be idea for the R8’s power.

Before tuning…….First tune………Second tune……..Today

Vel…….Spread….Vel…….Spread…Vel….Spread….Vel…….Spread

645……..29……..582……….18…….NA……NA……666……..31

RS pellets averaged 666 f.p.s. They ranged from a low of 654 to a high of 685 f.p.s. At the average velocity they produced 7.22 foot-pounds of energy at the muzzle.

Firing behavior

The R8 shoots smoothly. A tiny but noticeable bit of vibration has crept into each shot. It is not bothersome and I actually have to feel for it to know it’s there. I can tell the rifle isn’t as smooth as before, but it’s 100/200 f.p.s. faster which I will take.

I think as this tune settles in the cocking effort will lighten just a bit. I doubt the slight vibration will ever go away. I could give it a shot of Tune in a Tube, but it isn’t unpleasant enough to warrant that, in my opinion.

Conclusions so far

My concerns about the compression chamber honing appear to have been groundless. That’s very comforting, because it means I can stop chasing that gremlin.

I could go farther and give this rifle a top grade tune with piston button bearings, a custom fitted spring guide and a piston liner to remove all vibration, but that doesn’t seem suited to the R8. Instead I will keep it as it now is and shoot it whenever I want a nice lightweight accurate pellet rifle.

I’ll probably do one more accuracy test — just so I can shoot the rifle again. Maybe I’ll back up to 25 yards, but I think I’ll still use the iron sights.

B.B.,

Your photo of the cross hatching in the compression chamber is glorious! Incredibly difficult shot. I believe that Mac would be impressed.

Please know that although I can’t post much these days I read everything you write. I’ve especially enjoyed this series on your new/old R8 because it’s my favorite springer sporter.

Kevin,

It means a lot, just knowing you are reading! 🙂

B.B.

B.B.,

After I read your comment on the difficulty of getting that photo, I had my wife look at it. She was impressed (which doesn’t come easy — she’s had numerous one-woman shows and has been a serious art photographer for over 40 years). She wanted to know if you lit from inside the tube and if so, what you used. Also, she asked if you availed yourself of any Photoshop tools for contrast enhancement. Lookin’ sharp! (Pun intended.)

Michael

Michael,

I lit the tube from the inside using a Pelican 1920 flashlight. I made one mistake. If I’d used my newer 1920 it has a lower 20-lumen level, where the one I used only has the maximum 100-lumen rating. I had to back the light outside the tube to decrease it enough to even get what I got.

I did do a little enhancement with Photoshop, using the Levels tool that allows closer balance of light and contrast. But the photo is still way too hot.

Please tell your wife thanks for the compliment.

B.B.

B.B.,

I’ll pass that on when she gets back from shopping.

She told me for lighting the insides of small things she has long used (heck, I bought it for her :^) a gooseneck flashlight with a “white” incandescent bulb, but when the switch goes, she’ll research LED replacements. Her worry is that with super-bright LEDs so popular now it might be difficult to find an element that is appropriate for her needs. There are medical use goosenecks with fine control over brightness, but they are insanely expensive.

I wonder if any of the mechanics here can chime in on what they use for when lower intensity is desired because the material is reflective?

Michael

Michael,

I have a bore light that has both a laser and a gooseneck low-intensity white light. It’s a Chinese thing that was given away at SHOT years ago. It uses button batteries which I detest (hard to find) but it would have been better for this photo. I forgot I had it until you mentioned the gooseneck.

Look here:

https://www.amazon.com/Remington-Bore-Light-attachments-batteries/dp/B0015NA32Q/ref=sr_1_1/146-3508775-8125713?ie=UTF8&qid=1495473783&sr=8-1&keywords=bore+light

B.B.

B.B.

B.B.,

It’s ACP! Will it work with moon clips? ;^) Thanks for the tip. I’ve bookmarked it and will share it with my wife upon her return.

Here’s a tip for you. Regarding button batteries, I am the designated family watch-battery-replacer as I have an assortment of watch opening and repair tools. (I am deeply into wristwatches.) A few years ago I bought (ebay, from China, etc.) a large blister card with an assortment of common button batteries models, five or so of each. They are dirt cheap, as in maybe $10 or so with free shipping for 25 or 30 brandless batteries. The first three I used paid for the whole thing by themselves.

And FWIW, if name-brand is the only option, I have it from three different audiologists/hearing aid experts that Rayovac are by far the best button batteries.

Michael

Michael,

After finding the Remington, I bought a Winchester light that looks better:

https://www.amazon.com/DAC-363219-Flex-Bore-Light/dp/B004DW5NC6/ref=sr_1_2?ie=UTF8&qid=1495479547&sr=8-2&keywords=bore+light

B./B.

I’ll e-mail the links to my wife (weird, I know, but we do that all the time) so she can look at both plus a lot of the others when she gets online. Ideally it would have adjustable intensity and a white light. The length of the gooseneck is not as important as other factors.

Thanks!

Michael

I have a similar device, and I love it. It is fun to inspect the bores although I have not yet figured out what to do with the laser.

Matt61

B.B.

Love the R8! Sounds like a real sweetheart.

Other than paper towels and elbow grease, did you use any solvents to clean the reciever/compression tube?

Thanks,

Yogi

Yogi,

I’ve used them in the past, but not this time.

B.B.

Oh no! Don’t start another solvent tome! The one I was partly to blame for ended up being like a Russian novel!

Michael

Michael

Better that way of more information than no information. You know what I mean.

Listen to you- “Maybe I’ll back up to 25 yards, but I think I’ll still use the iron sights.”(!!!) Ain’t having both eyes hitting on all eight glorious?

Cobalt327,

Yeah! I’m kind of bragging on it! 😉

B.B.

BB

Do that open sight 25 yard shooting.

I do believe I refound something about open sights that I didn’t think about when I was younger.

I get my front and back sight lined up correctly with my off eye closed. I’m actually be pretty focused on the sights at that point.

I then get the sights on the target again with the one eye closed. Then I slowly on my off eye till things go out of focus. I then start closing my off eye. Kind of squinting with the off eye till everything comes back in focus. I make my hold on the target and shoot.

I actually got pretty good yesterday with my new HW30s.

This sentence should say (open) my off eye.

Not this.

“Then I slowly (on) my off eye till things go out of focus.”

Congratulations. 2 hrs. is pretty darn good. Glad the ol’ girl is back up to par.

Chris USA

IIRC, you shoot indoors sometimes. I happened across a thread where a fellow had scaled down the already-scaled-down 25m Appleseed targets for use at 10m. I made a few copies from the pdf file he provided and I’m going to try them out when the weather permits. You, and anyone else who shoots at 10m/yards, may get a kick out of shooting them. BTW, the Appleseed ‘Rifleman’ score is 210 points or more. The simulated 400m targets are scored double.

G’luck!

Forgot the link- https://www.thehighroad.org/index.php?threads/aqt-target-scaled-for-10-meters.821243/#post-10557658

Cobalt,

I do not have a printer, but thank you for thinking of me. I use neon colored ring binder reinforcement stickers that I use at 24′. I put a small washer inside one of the 0 inserts and the combo works great. There is actually a bit of daylight on the outside of the sticker. It is almost too easy as long as you can keep it on center.

By the way, we have a new convert on the 499 magnum tune. Benji Don from the weekend blog I do believe without looking. He said that he will be doing it when he gets some down time. I pointed him your way over at THR.

Thanks for this! I shoot most often at 10m in my basement. This target will make for a nice change.

Jim M.

BB, why do springs shorten inside guns? Is it due to pre-load?

Riki,

Mainsprings are made of steel that is arranged in a structure like strands of spaghetti. Over time those strands slip against each other. The more the spring is compressed at rest the faster they slip, until they are all comfortable again. That is the scragged spring length. That then lasts for decades or thousands of shots.

B.B,

Thank you BB. Do other springs break into pieces inside guns because the steel used in their construction is more brittle?

Riki,

Yes. Diana mainsprings in guns made for the American market have that problem.

B.B.

BWAH! Why do we get the crummy ones?

Michael

Riki,

Good to hear from you. I think of your shooting and studies often.

BB,

I am glad to hear you were able to bring her back up to snuff.

Awesome photo of the cross hatching. That pattern is not as bad as you had led us to believe. No gremlin there.

RidgeRunner’s Home For Wayward Air Rifles still has an available space for a nice break barrel. Just saying.

RR,

I guess it looks worse than it is. I just wasn’t expecting to see it there and I got unnerved.

B.B.

B.B.,

I am relieved the unconventional honing was not the problem. If it had been the culprit, might that have doomed this fine specimen into being a parts gun?

Michael

Michael,

Boy, do I agree. I was starting to research plating options and oversized piston seals!

B.B.

B.B.,

So with Hobby pellets, she actually meets the factory specs; that’s pretty cool. =>

Nice pic of the cross hatching, and interesting that it had no effect.

Great report; keep up the good work!

take care & God bless,

dave

B.B.

Way off topic, but I, like I suspect numerous others of us in this “experienced” age group, may need cataract surgery at some point soon. It sounds like you have obtained very good results. Would you mind sharing some of your observations and key learnings? I would be interested in things like:

* How closely can you see clearly without needing reading glasses? Can you clearly see the car gauges while driving? How about for computer work? Can you get a good sight picture for both rifle and pistol?

* What was the progression and timing of sight improvement after surgery?

* Were you able to achieve 20/20 with the new lens?

* Do you have clear near vision with reading glasses?

* How is your night vision?

* Knowing what you do now, would you have had it done earlier?

* Did you consider inter-ocular lenses which are supposed to provide good near and far vision?

* Any other learnings or important questions we should be sure to ask our doctor?

I know you are not a doctor, but I’ve recently gone through cancer treatment and learned as much or more from discussions with my fellow patients than I did from the busy doctors. Thank you for whatever you are comfortable with sharing.

NewAirgunner62,

I can sometimes see clearly enough to read 12-point type without reading glasses. I need reading glasses to see the computer screen. The car gauges are tricky. They have red needles against a black background and being red-green col,orblind, they have never been easy to see. It isn’t the focus — it’s the color.

In my most recent eye exam last week my right eye measured 20/25 and my left eye measured 20/20. Both eyes took about two weeks to settle down to where they would be.

I selected reading glasses of 2.5 diopters as my reading glasses before the last eye exam. My eyes were then verified as 2.5 diopters for reading by the doctor.

The one thing I must tell you is that I was awake during both surgeries. I wouldn’t have though that possible before the first surgery. I was given a sedative that calmed me way down, but I walked out of the surgery room after it was over. The sedative collapsed the time the surgery took to seem like 10 minutes, though I think it was closer to 30 minutes.

I did not go for the dual-focus lenses because I felt (and still feel) that reading glasses were no problem. At nearly 70 years of age, I really don’t need to be in fighting trim anymore. It’s okay for me to fumble for my glasses when I need to read. Also, some types of dual-focus lenses don’t work for all people and you don’t know until the operation is done. Why spend a thousand dollars of my own money for something that might not work?

My night vision is as good as it was before the cataracts started growing. The cataracts made oncoming headlights blind me.

I can see the sights as good as I need to after the surgery. I am satisfied. If I needed to see the sights better I would use a lower-level reader like 1.5 diopters that would still leave the target visible.

B.B.

It’s great that you have achieved such favorable results. Thank you very much for sharing!

BB,

Speaking on behalf of all of those who eyes will never “fire on all eight” again, I would encourage you to do a scoped accuracy test at 25 yards as well. That said, I recognize that you may not wish to further lengthen this series, but the R8 strikes me as a classic worthy of it.

Best wishes,

Lance

Lance,

I think my eyes are back to as good as they were. But a scoped test might be fun — another chance to shoot this rifle.

B.B.

B.B.,

Given how puzzling and, perhaps, frustrating this one turned out to be, I concur with Lance. Have some real fun with it now that you’ve nursed it back to health!

Besides, how many healthy R8s are out there to share with us? :^)

Michael

Michael,

You asked a great question. I’ve always wondered how many R8’s were sold in the USA. Doesn’t seem like many since they’re scarce as hens teeth. Don’t know if this is because of low production numbers or if it’s because the owners never want to sell them.

Here’s an example. This R8 came up for sale last night at 11:03 PM and sold in 50 minutes WITHOUT ANY PICTURES OF THE GUN OR ANY INFORMATION ABOUT THE HEALTH OF THE GUN (chrony numbers):

http://www.network54.com/Forum/79574/thread/1495422223/last-1495425190/–%3E+Expand+Thread

Maybe the lesson here is that you need to stay up late on Sunday night to have a chance to buy an R8?

Kevin,

Wow! And it wasn’t cheap (although maybe for an R8 that IS).

And he sold it so he could buy a PCP?

Michael

Depending which Beeman vintage scope it had……that R8 may have been a ridiculous deal.Some of mine cost me 2 to 3 hundred……and DID not include an R8!!

I have the great fortune of possessing one of very few Beeman HW50’s before they became the “R8″…….with a PW adv. tune and setback target trigger.Shooting it is a joy unlike any PCP you could buy for the money.I wouldn’t even know how to value it…..since it was an AWESOME gift from a great person.

B.B.,

You mentioned a hint of vibration. Did you apply even a skosh of lube on the new spring, or is it bone dry?

Michael

Michael,

The new spring is coated with a thin coat of lithium grease.

B.B.

BB

I have a feeling that the crosshatching is already polished in from the old seal.

It’s probably at a point where the lines are visible but can’t really be felt. If you take your finger nail and run it across the crosshatching I bet you can’t even feel the lines.

When you have fresh crosshatching done to a cylinder you can definitely feel the lines or grooves as we call them.

So yes even though there is some weird lines in your cylinder they have been polished enough to work with your good new seal.

And speaking of seals. You did say that you seen a wore spot on the old seal this time around. You won’t believe how easy it is for air to blow by a seal with even the smallest scratch or line in the he area that seats to the cylinder wall.

Anyway glad it’s working. And just maybe the spring is really what got your power back. You know there is a way to tell don’t you. But you have to take it back apart and put the old seal back on with the new spring. And heck then you can indeed see if the spring settled in.

Different powerplants are on my mind. As I mentioned before, the M1 Garand mystery is solved although I accidentally posted the report to last Thursday instead of the weekend. Anyway, after digesting the results, it seems like the answer to the mystery in a nutshell is that more gas likes bigger volumes in the gas tube to work properly. This is pretty intuitive. More gas goes with a bigger charge of powder which is also intuitive. But how burn rate affects things is complicated, and it is jumping between burn rates that really messed me up. From my reading, it appears that, other things being equal, a slower powder has less force that is sustained longer. So there are two opposed factors which contributed to the confusion. It seems roughly analogous to airguns where a springer gives a single swat to the pellet, as described by the blog, where a pcp gives more of a steady push. For firearms, the slow powder is supposed to be preferred for heavier projectiles and longer barrels. That would explain why the slower-burning IMR 4064 has become popular for the M1 with its relatively long barrel over the original faster-burning IMR 4895.

The gas volume part of the M1 also seems suggestively similar to the swept volume that is the key to spring gun power. But there may even be an additional complication for the firearm in that not only is the volume important but the rate at which it is filled by different burn rates might also play a role. No wonder it took a genius like John Garand, 20 years to perfect this rifle! Unraveling his system for improvement has brought a whole range of issues into play. But now that I understand the system, it is kind of gratifying. It’s like I have my rifle back again with new capabilities. But it’s too bad that I will now have to pull over 300 cartridges which I loaded with the wrong charge. 🙁

Matt61

Please put the best scope you have on ALL rifles equipped to take it!, how else are we supposed to make a judgement on accuracy otherwise!, I understand that at this power it may not be an owners first choice of sighting but using it with opens will almost certainly relegate the fine shooting R8 to the standard of a ropey old Hatsan or Ruger that you happily put optics on.

It’s the only part of your testing you don’t have a level playing field on, there’s an arbitrary decision made to hobble some guns,

I think this R8 will find another 50fps in time, try the H&N FTT, it’s the pellet all Weihrauch are developed with (and indeed the pellet rebranded as Weihrauch pellets)

I know at least one UK tuner who lightly crosshatches all but the last inch or two of the compression chamber

Dom….are you the one a while back that asked about BSFs without the Freimark? If so I checked through mine and found one.It is a BSF B55 that came from a retired dealer.Lucky me it was NIB so probably from right at the end(of BSF).

Frank B

Aah, it’s YOU that’s got it!

Seriously though, non friemarked BSF’s seem incredibly rare, to the point I suspect that they just made them all the same way, stamped them all the same, then, at least in the most part (though obviously not always as I thought!) decided where they were going afterwards, I’d imagine it’s not illegal to sell to higher powered foreign markets with a friemark in place as it’s only a recognised legal marking domestically.

Well Dom all credit goes to you for me looking and noticing it’s absence.If it makes it worth an extra thousand I will be duty bound to split it with you! LOL

Scopes.

That’s where I seem to shoot my best. But it sure is interesting to see what can be achieved with open sights and even dot sights.

People really should try some of their known accurate air guns with open and dot sights. I think they just might be surprised by the results.

And see what happens at different distances with open and dot sights. You will be surprised I think. You don’t need to use hold over as drastically as you do with a scope for different distances.

BB and Fellow Airgunners

I’m so glad you were able to bring this gorgeous R8 back to original specifications. One pellet that surprised me was the JSB Exact RS 7.33gr pellets. It gained a mere 20fps from “before tuning”. I’ve always used the Exact RS pellets for maximum velocity in my low-mid range velocity airguns with great success. I was wondering if you, or anyone commenting would have an explanation for what I consider poor performance of these pellets.

Fantastic picture showing the honing in the compression chamber. I love these blogs that start out routine, but end up taxing our combined knowledge of the “simple” airgun.

Ciao

Titus

Titus,

I was surprised by the JSB RS performance, as well. I can’t explain it.

B.B.

B.B

I posted this in response to twotalon’s suggestions yesterday and wondered what your thoughts are also. The JSB Exact 15.89 pellets are fitting loosely in the breach of my RWS34 P .22. If I don’t seat the pellet deep into the breach until it engages the rifling, the pellet will fall out if I de-cock the rifle.

twotalon,

Yes, the RWS 34P combo came with a Hawke 3-9x50AO IR scope with an RWS one piece lock down mount. I removed the scope today and will do some work on it to make sure it is centered optically in it’s range. Then I will attempt some groups with the open sights.

Okay, I inserted a JSB 15.89 gr pellet into the breach and then used my cleaning rod to push it on through. For the first 6″ or so, the pellet pushed fairly easily. Then there was very little resistance until it reached within about 1″ to 2″ from the muzzle. Then there was a moderate amount of resistance towards the end of the muzzle, almost like the barrel was choked. Then I viewed the pellet with my jeweler’s eyepiece and there were no perceivable marks on the head from the rifling. The skirt had some slight marks and the skirt was crushed down to the same O.D. as the head.

I thought the resistance felt strange going from slight resistance, to no resistance, and then back to moderate resistance. It’s like the bore is barrel shaped (no pun intended) meaning it’s larger in the center than on either end. I would say it was on the loose side but not bumpy or rough.

Next I did a pellet analysis. I use my 1″ micrometer and jeweler’s eyepiece to carefully measure the head and skirt on (20) JSB 15.89 gr pellets. These are the one’s that are fitting loosely in the breach.

The pellets were very consistent.

The heads measured 5.49mm to 5.50mm on a (20) pc sample. The skirts measured 5.69mm to 5.72mm on the same sample. Seems like the head size is a little small to me.

I measures a sample of CPHP pellets 14.3 gr.

Heads measured 5.50mm to 5.54mm with one pc at 5.38mm (that’s probably a flyer)

Skirts measured 5.61mm to 5.64 mm on (10) pc sample

I measured some left over RWS Superdomes I had enough for a (10) pc sample

Head measured 5.51mm on all (10) pcs, very consistant

Skirt measured 5.73mm to 5.74mm on (10) pcs

I also noticed that the RWS and the JSB pellets were of a much higher quality. They were more consistent and roundness was better than the Crosman Premier HPs which have a noticeable parting line from the molding process. I had some dome pellets and they are the same crude looking pellet. I was a quality inspector for forty years at a hydraulic pump division so I know quality.

After I removed the scope from the rifle I cleaned the barrel again with JB bore paste and a brass brush as per Tom Gaylord’s instructions. I was advised to clean the barrel again after having shot the CPHP pellets through it and then reseason with the JSB pellets. That’s all I had time to accomplish today. Welcome your thoughts on my findings. You have at least lead me down a different path than most of the other posters.

Geo791,

Tomorrow’s blog may be of some help. I will read your post later today and try to incorporate some of it.

Thanks,

B.B.

geo

Your scope mount should have droop compensation built in to fit the 34 . As long as your 34 is about average for droop, it should be O.K. , but we still need to watch that .

The loose pellet fit is the major worry right now . It will cause power plant problems ….inconsistent shot cycle . If I was to guess at this point, it would be harsh, and would have a distinctly forward recoil feeling .

Try the biggest pellets you have for fit. They may not be the right ones, even if they do fit, but let’s see what turns up .

tt

The RWS lock-down mount does have droop compensation. I measured it tonight and front end marked with an arrow is .8mm thinner than the measurement at the back end. I ran the adjustments for windage and elevation back and forth to their max travel and then back them up half way to center the optics to mid-range and insuring that there is enough spring tension on the adjustments.

I took the RWS out back with out the scope and shot some groups with open sights. I had to move my target back from 25 yards to 10 yards because the front sight was larger than the 1/2″ bullseye. I had to make the bullseye 1″ in order to see it then. Open sights definitely not going to work for me!

I did not want to shot any dirty Crosman pellets so I shot some of the JSB 15.89gr. I have just cleaned the barrel with JB Bore paste so I didn’t thing the groups would be very good. But at just 10 yards, my shots looked like a shotgun pattern….just horrible. I shot about 25 shots and it started to sprinkle so I quit. Two of the shots sounded like there was no pellet even loaded. These JSBs are definitely too small for my bore. I bought this tin of JSB pellets on ebay from a retailer in Poland. They were listed as being 5.52mm but I found them to be 5.49mm. Could there possibly be an issue with them coming from overseas? European size could be smaller?

I won’t shoot any more from that tin because I think they could harming the piston by not having enough resistance in the rifling. I don’t currently have any pellets other than the CPHP pellets. The head sizes on those varied a lot but were slightly larger than the JSBs.

I measured the breech with a small hole gage and mic tonight. The breech ID is 5.54mm. I also mearured the muzzle end but was only able to reach in about an inch. It measured 5.46mm. Not sure what the specs are for the bore size. I think the center portion of the barrel is 5.54+ just by the feel of the pellets passing through the bore.

geo

Very large bore, and some small pellets . Not good .

Go ahead and try the crosmans for fit, but they will probably be small too for the barrel.

tt

Matt61—Dont waste your time pulling and reloading those 300 rounds. Get 30-06 bolt action rifle and shoot them in it I am sure that you would enjoy owning a 1903 ( or A3 ) rifle as a companion to your M1. If you want to spend less money, there are several economy model sport bolt action rifles available. I would not recommend going to a gun show, unless you take an experienced person with you. Re-size but do not reload a few empty cases with the same die setting that you use for your M1. Make sure that they will chamber In the bolt rifle before you buy it, or you will have to pull the bullets and resize the cases to fit. ——Ed