by Tom Gaylord

Writing as B.B. Pelletier

My new Beeman C1 is a .177.

This report covers:

- Take this gun

- History

- Artillery hold

- A compromise

- Smoother with use

- Use a mainspring compressor!

- The test rifle

- Description

- The breech

- Barrel pivot

- This C1 has

- The plan

- Goal

Sometimes you buy airguns because you long for them. Other times you buy them on the recommendation of others. And every so often a good deal just pops up and you feel you really need to take it. Such is the case with this .177-caliber Beeman C1 that I bought at the 2019 Texas Airgun Show.

Take this gun

A man walked up to my table holding a Beeman C1 that was scoped with a Beeman SS1 scope. The price he asked was so reasonable that I didn’t hesitate buying it, and, before long, reader David Enoch walked over and asked to buy the scope. I sold it to him, and I was left with just the rifle for a very reasonable price.

History

The C1 is a Webley rifle that was also sold by Beeman. It was made from 1981 to 1996. In the .177 caliber I am testing it was said to shoot pellets up to 830 f.p.s. with a cocking effort of 35 lbs. I will test all of that for you, of course.

The production of the U.S. rifles (apparently Webly sold the C1 in the UK, as well) began with serial number 800,000, according to the Blue Book. My test rifle is serial 801,309, which makes it a very early gun. Webley added a safety to the rifle in 1983 and my test rifle doesn’t have one, so it was made before then — probably in the first year of production. The first C1 that I purchased new back in the late 1980s had a safety, so it was a gun made after 1983.

My Beeman C1 is an early one.

Artillery hold

The C1 is the rifle on which I developed the artillery hold. One of my airgun catalogs, probably from Air Rifle Headquarters, said to hold a spring gun tight to cancel the recoil. I tried that for a long time and could never get the C1 to group very well. It could maybe put 5 shots into one inch at 10 meters.

One day I decided to see how really inaccurate it would be if it wasn’t held tight at all. So I laid it on the open palm of my off hand and didn’t bring the butt into my shoulder hard. The rifle was free to flop around as much as it wanted. And, to my utter surprise, the rifle put 5 pellets into 0.3-inches at 10 meters!

Naturally I tried this over and over to see if it really worked, and it did. I was so thrilled that I wrote Dr. Beeman a letter, telling him of my discovery. I thought I might write it up for his catalog. He never answered me, so the idea almost died, except 10 years later when The Airgun Letter started I wrote about it there. I also gave it it’s name while writing the 9 articles that became the basis for the Beeman R1 book. I don’t think I ever wrote a specific article for the newsletter about the artillery hold, but I do think I explained several times how it worked and my readers caught on. And it all came from shooting that first C1.

A compromise

My first C1 was a compromise — something I know many of you can relate to. I really wanted an R1, but at the time we didn’t have the money to stretch that far, so I bought the C1 as the closest I could get. The difference was $189 for the C1 and $249 for the R1, as I recall. That little difference made my decision for me.

When it was new, my first C1 was quite stiff and hard to cock. The trigger was also very stiff. To say I was disappointed by the shooting performance was an understatement! After hearing all the good things about precision adult air rifles and having already owned an FWB 124, this C1 was a boat anchor in comparison. But it was all I had, so I stuck with it.

Smoother with use

After about 2,000 rounds had passed through the rifle, I began noticing that the cocking was getting smoother. At first I thought it was my imagination, but then I started noticing that the firing behavior was smoother, as well. After 3,000 rounds the trigger started getting very light and, if not exactly crisp, at least predictable. It seemed the more I shot the nicer the rifle’s action and trigger became.

About that time I disassembled the rifle to see what I could do to improve it. What I was thinking, I’ll never know, because I hadn’t a clue how to tune a spring gun. The Beeman R1 book was still many years in the future. Black tar hadn’t been discovered by airgunners yet. It existed as open gear lubricant, but it was not known to the airgun community, so we used Beeman’s Mainspring Dampening Compound instead. It did pretty much the same thing, though it wasn’t as viscous, and you had to use a lot more of it.

Fortunately, I also didn’t own a chronograph yet, either, so I had no idea how fast my rifle was shooting. I trusted the Beeman catalog implicitly.

Use a mainspring compressor!

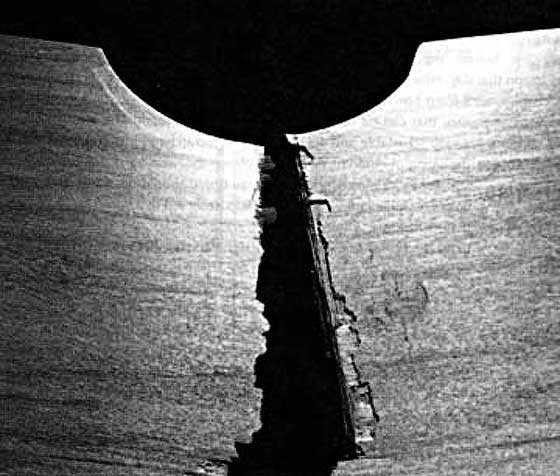

While either disassembling or assembling my C1 a curious thing happened and I got the first photo to go into the R1 book. The rifle’s heavy solid steel end cap got away from me, sailed across the room and broke a desk drawer divider in two! Had my arm been there instead, I’m thinking it might have been broken — bruised for certain. I instantly understood the need for a mainspring compressor!

The C1 end cap hit this desk divider to the right of the crack (see the dent in the wood) and busted it in two.

The test rifle

The test rifle is a .177 caliber, as mentioned. It does have open sights, but the rear sight has been broken and poorly glued together with epoxy.

The rear sight has a central screw for elevation and I can see nothing for windage. You can see that the excess epoxy makes it unclear if there even is any windage adjustment. You certainly are’t going to do any!

The front sight is bent to the left, probably from a fall. That makes the open sights useless on this rifle. Yes, they can be fixed, but since I don’t plan to use them, I’m not going to bother!

The front sight is a single unit held on by a screw. This one is bent to the left from a fall.

After the front sight was off I test-fired the rifle at a backstop on my desk three feet away. I was surprised to see the pellet striking the backstop three inches above the natural hold. The barrel is severely bent upward right at the baseblock! This air rifle was fired with the barrel open! There is no anti-beartrap, so it’s possible to fire with the barrel broken open.

That would present a problem for many shooters, but you may recall that a few years ago I showed how to straighten a bent barrel. I am probably the right guy to work on this rifle.

Description

The rifle under test is a tad less than 38 inches long, and the barrel accounts for 13-3/8-inches of that. This rifle weighs 6 lbs. 10 oz.

The western-style stock is hardwood that’s probably beech. The pull is 13-1/2-inches. The buttpad is a soft grippy rubber pad. There is no checkering and the stock is very full. The stock on this rifle was the inspiration for the Air Venturi Bronco stock.

The C1 stock was the inspiration for the Bronco stock.

The single-stage trigger is light. I think it’s a bit too light for this rifle. Someone may have been inside, though I do remember that C1 triggers get very light over time. And the rifle cocks easier than 35 lbs. So it may have just been shot a lot.

The spring is quite buzzy, so the rifle needs to be taken apart and overhauled. The piston seal is PTFE, which is a generic name for Teflon. I’ll show it to you when I can. Tune in a Tube will perform miracles on this rifle! At some point either Webley or Beeman realized how buzzy the powerplant was and later on in the production run they installed a spring guide that was also a mainspring dampener. But I think I can quiet the action much more than that with just TIAT.

The steel is deeply blued all over with speckles of rust in many places. I think this may be someone’s first spring gun. They may have tried working on it and didn’t quite get it right or it may have just been neglected. I’ll know more when I get inside. Fortunately, like an older Harley Davidson, the C1 has a lot of extra material to work with, and I think I can turn this sow’s ear into a very nice purse.

The breech

The breech on a C1 is different enough that it’s worth examining. The outside of the barrel has a large deep groove that rests against a crosspin in the action forks. A spring-loaded chisel detent pushes the barrel down against this pin. Theoretically this would have been a way to prevent barrel droop in a similar way to the ASP20’s keystone breech.

Looking down on the C1 breech we see the grooved breech that rests against the steel crosspin.

Barrel pivot

The C1 barrel pivots on a plain pin. The barrel can get loose and there is no easy way to tighten it. My last C1 barrel wobbled from side to side a lot, which causes poor accuracy. This one is tighter, but there is a little wobble. So — what can I do?

This C1 has

Poor open sights

Bent barrel

Trigger that’s too light? (remains to be seen)

Buzzy powerplant

Rust speckles over all the steel

Wobbly pivot pin

The plan

This test will go differently than they usually do. I will test the velocity next, but I can’t test the accuracy because the barrel is bent up so much that the rifle will shoot 12 to 18 inches high at 10 meters. A scope mount can’t compensate for that. So I will tear the rifle down after the velocity test and straighten the barrel. Since I have to fully disassemble the rifle to get the barrel out, I will also examine and tune the powerplant at that time. I may have to order parts for the rifle after seeing what’s inside. The rifle cocks easily now, so the mainspring could be original and needing replacement. Then I’ll assemble the rifle and start the accuracy test.

Goal

My goal is to turn this little springer into an air rifle that’s so fine people can’t stop shooting it! It’s been abused, and it’s time for pampering! This series may take longer than normal, but it should have a happy ending.

B.B.

That C1 has issues that only a dedicated airgunner like yourself would want to tackle. That rear sight alone would have me running for the hills.lol

Waiting to see if you can turn a sow’s eye into a silk purse?

-Y

Yogi,

One problem at a time. It only seems daunting when you look at all of them together.

B.B.

B.B.,

Maybe the bent barrel would have pointed right on target with its vintage scope? Then again it would only work at a particular distance.

Maybe you could compress the forks in a vise then hit the vise with a hammer?

I see this forthcoming series as another guide to rescuing project airguns. Looking forward to the rest of the articles.

Siraniko

Siraniko

Siraniko,

You are getting too smart. Time to start you own blog. 🙂

B.B.

B.B.,

Just my rememberer working overtime. Heheh!

Can’t think of something that I can write about that you haven’t written of before. As someone once said: “Confound these ancestors they’ve already taken the best ideas!” 🙂

Siraniko

BB,

I get all excited when you work on something like this. Learning some of the “tricks of the trade” without having to actually experience them is such a relief sometimes. There is also the joy of learning something new.

I have always enjoyed taking things apart to see how they work. I have a partially assembled 101 in front of me right now. I have had to take two steps forward and one step back a couple of times now and it looks like I will have to take a backward step again this evening.

RR,

“two steps forward and one step back a couple of times” – know this dance very well!! Been doing it a lot recently LOL!

The new .22 Maximus barrel that I got to replace the old 101 barrel ended up being put on my .177 Maximus as part of the Maximus regulator/trigger upgrade project so the 101 will inherit the .177 barrel (guess I will have to start calling it a “100” now).

The Maximus mod turned out well – added a light 4×32 scope on medium height rings and it is shooting nice groups at 28 yards (Zero range). I set up the regulator to get 750 fps with JSB 15.89s; the average ES is 6.5.

Hank

Vana2

Are you trying for a solid 50 meters EMR Hank; or going for 60m or more?

shootski

Shootski,

I plan on doing some shooting (with all my rifles) to see how far I can hold a 1 inch group – I suspect that with the PCPs that will put me into the beyond 50 meter range. I usually constrain my shooting/practicing to the rifles’ Point Blank Range where no compensation is required.

The 28 yard ZR comes from the ChairGun program – on my .22 Maximus, for a 3/4 inch Kill Zone, and 750 fps a 28 yards ZR will yield a PBR from 11.0 to 31.2 yards. For comparison, on my .22 HW100 the numbers are 951 fps, ZR 36.7, PBR 16.0 to 40.2.

It’s been extremely hot and unsettled for the past month so I’ve been shooting a bit in the early morning and hiding in the workshop during the day – hope it is better where you are!

Hank

Vana2,

PBR is certainly a good way to zero. Do you find that ChairGun is close enough? I use a number of different balistic calculators and programs but find nothing beats shooting the weapon-pellet-slug combinations to know the actual shooter-weapon system results. I know you are an advocate of a full workup too.

We (wife and I) were out in Utah for about three months this past May into July. It was down right COLD in May and then got slightly warmer, but very wet, in June. July was dry and hotter but very comfortable. We got to ski and kayak most of the days. We even skied on the 4th of July in the morning and then did a Sunset paddle on the Great Salt Lake. The density of the lake provided a great lesson in the physics of water type effect on boats, paddles and paddlers. We learned a great deal more about paddling/wave dynamics. We are back East now and it is HUMID and WET; we are miserable. The long range forecast looks like August is going to be cooler and dryer here!

Hope you see some nice weather soon!

shootski

Shootski,

I haven’t found an obvious reason to not believe Chairgun so it must be fairly close – close enough to be a starting point for actual on the range testing anyway.

I’ve popped a number of grackles with the HW100 at 60-65 yards using a rangefinder and the “hold-over/under” cheat-card I printed so that works. I only take those shots in dead-calm conditions and a solid rest though.

Lots of renovations this year so I have been close to home. It’s been unusually hot this summer so I haven’t done as much fishing as I normally do and haven’t gotten the kayak out yet – need to fix that!

Hank

Hank,

Not remembering how it goes back together, I am working my way through the pile of parts trying to make it look like an air rifle. I have managed to do pretty well except now the pump pivot/guide head is trying to bind in the tube so I need to take it back apart and see what I can do with it. Maybe one day it will shoot.

You are tempting me with the Maximus.

RR,

I really like my Maximus. It points well, shoots well and is light to carry around. It’s not as stable to hold as a heavier rifle but it’s a great little plinker.

Because I carry it around while I am working outside (never know when those feral soda-cans will attack) I am shooting it a lot – being close by, find it very convenient for pesting – much to the grackles chagrin LOL!

Happier now that it is .22 – the .177 pellets are fussy to load where the .22 ones drop nicely into place.

The stock trigger is easy to fix – a couple of 5/8 inch long 4-40 screws, some lithium grease and a bit of work with the springs yields a half-decent trigger. There are some good YouTube videos on how to do the mod.

Hank

Hank,

The Maximus is an updated Discovery. These have been around long enough for TCFKAC to work all of the bugs out. I have also very seriously considered a Fortitude, but I have to give TCFKAC time to fix whatever issues it has. It is a real shame that they still have not figured out a sproinger trigger.

RR,

…”the pump pivot/guide head is trying to bind in the tube” – seen that oil/dirt/grease can get packed into the groove that the tube seats into so you might want to check that area.

Hank

Hank,

This thing is clean, at least at the moment. I am referring to the round piece pinned to the pump mechanism that the plunger screws into. When you pull the plunger all of the way back and push on the pump handle, this piece is pushed against the tube and is binding. I will have to remove the tube and polish the inside some and likely this piece also. Follow that with a little TIAT and it should work then.

(apparently Webly sold the C1 in the UK, as well)

B.B.

I am looking forward to your reports on the C1 overhaul – love this kind of blog!

Happy Monday!

Hank

BB,

How about putting a lighter spring in this rifle? Maybe something like 650 or 700 fps with CPLs.

I put the SS1 on a pre-safety R7. That got me to thinking about an R7 powered C1. I think that would be sweet.

David Enoch

David,

I’ll give that some thought.

B.B.

DavidEnoch,

I’m really interested in why without actual data on this air rifle you would want to down spring it?

If it actually shoots above 800fps with good or better accuracy why would you want 650-700fps in what, in my view, seems purpose built to be a hunting arm?

shootski

Shootski,

I have owned several C1s along the way. I always liked the stock as it fits the way I shoot off-hand. I don’t really care for their triggers and as I get older, I enjoy lower powered airguns more than more powerful ones. It’s not that bad, probably about 40# cocking effort, but but I think it would be a sweet shooting gun at about 650-700 fps.

Oh, one more weird thing about the C1 is that the breech is normally oversized. On a lot of C1, the pellet will fall out if you raise the open barrel much past level. You have to be careful to not drop a pellet and dry fire the gun.

David Enoch

David,

Understood.

Thank you for the C1 background information.

I like that style of stock best for an iron sight too!

shootski

BB

Much fun is in store for us. Have at it!

Deck

BB

This promises to be another great series, full of mysteries, discoveries and lessons learned. Exciting!

By the way, what you said earlier “One problem at a time. It only seems daunting when you look at all of them (together.)” is a wonderful piece of advice and applicable to all kind of things.

Henry

BB,

“This C1 has

Poor open sights

Bent barrel

Trigger that’s too light? (remains to be seen)

Buzzy powerplant

Rust speckles over all the steel

Wobbly pivot pin”

Are you suuure this was a good deal?? 😉

Half

Half,

Yep! If someone gave you a dirty sack of gold would you complain about the dirt?

This is a 1948 Harley panhead that needs a tuneup, some frame welding, a lot of brightwork re-nickeled and new clutch and the saddle recovered. What’s not to like? 😉

B.B.

B.B.,

So you won’t go so far as a four banger inline Indian!!!!

shootski

shootski,

Never had one. Had the ’48.

B.B.

B.B.,

That ‘splains it! I don’t know how much dirt is on this sight but you might need a nugget or two of parts in your work on the C1. So if you don’t know this outfit a link:

http://www.proteksupplies.co.uk/webley-rifles-parts.html

shootski

shootski,

I didn’t know this outfit and they have the entire rear sight. But it’s more than I now have in the rifle.

Chambers has the mainspring and other parts I need, including a piston seal if it comes to that. I will get by somehow.

B.B.

B.B.,

It looks like it might be windage adjustable if my quick look was the same one. I guess it depends on if the rifle proves accurate and you want a better rear sight. No need to throw all too much money at sights for an inaccurate rifle!

shootski

BB—-My San Rafael C1 has the safety, fully adjustable rear sight and is a .177 caliber. When I got it, the action moved forwards ( about 1/16″) when it was cocked, and backwards when fired. The action screw was slightly bent. I glass bedded the action to lock it in place. This C1 was harder to cock than any other of my airrifles ( until I got the Diana Mauser). The trigger pull is also heavy. I have been hoping that you would review the C1 for a long time.——–Ed

BB,

I really like how the lock up for the breech is different. That alone makes the C1 collector worthy. It seems Webley was always trying to find a different, better way to do things. They collapsed just as they achieved their pinnacle, the Paradigm.

B.B.,

This has the makings of an excellent report I will be tuned into this one intently. I have always wanted one of the Beeman rifles, maybe I will finally get one.

For anyone that has one or both, is the difference between the R7 and HW50s worth the $50? I know the HW50s is advertised a little faster but that isn’t a huge deal for me, I want the most accurate fun to shoot springer that I can get and maybe do a little pesting with.

Brody

I can recommend the HW50s in .22 caliber. Mine likes Field Target Trophy 5.54 mm pellets but others do well. It is not overly hold sensitive. Quality is typical Weihrauch. Expect 1/4″ to 3/4″ ten shot groups at 25 yards. I don’t know how it does at longer ranges since 25 yards is my maximum space.

Someone will have both and maybe chime in about aesthetic comparisons.

Deck

Deck,

Thanks for that assessment; I’ve been eying the HW50S for some time as an addition to the HW30S (which I love…great quality!). Your input is much appreciated. =>

take care,

dave

Dave

I have the HW30s also which has similar quality and accuracy. The HW50s is not hard to cock in my opinion but there is quite a difference when compared to the former. Just so you know.

Deck

Deck, do you mean difference as in range and power? Thanks.

Dave

The 50 is harder to cock than the 30. I think I remember one reader commenting that the cocking effort was a little much for the velocity gained. Again, I don’t mind it and I shoot both a lot.

Deck

Cool; thank you for that information. =>

B.B., this (C1 carbine) is a gun I always wanted…but never got one…perhaps this series of reports will push me over the edge to dig up a good used one…I just think they look so cool. =>