The HW 50S breakbarrel from Weihrauch.

Part 1

Part 2

Part 3

Part 4

Part 5

Part 6

Part 7

Part 8

Part 9

Part 10

Part 11

Part 12

This report covers:

- Stock screws first

- The rear stock screw

- Never fails

- Bottom line

- Scope

- Stop pin

- Finish

- Test it

- Are we finished?

- Time

- Summary

Today I take whatever time it takes to mount the 3-12X32 Bug Buster scope on the HW 50S rifle, using the Burris XTR Signature rings. I also address the stock screws that loosened during yesterday’s accuracy test. Plus I will show you a weak spot on the Rekord trigger. Are you ready? Let’s go.

Stock screws first

First I will address the stock screws. There are only three and they are straightforward except for one that I’ll discuss.

I used a threadlocker on all the stock screws today but it wasn’t Locktite. The stuff I used is called Vibra-Tite and it’s a gel rather than a fluid. It’s from ND Industries. I think a reader recommended it to me and when I bought it I was surprised to find that it costs about three times what a similar amount of Locktite costs. I think this is the first time I’ve used it.

I accidentally deleted the photo of the Vibra-Tite on the screw threads, but suffice to say it is a gel instead of a liquid and I applied it all around the screws.

The rear stock screw

The single forearm stock screw and the front trigger guard screw are both quite large and strong. And the threads they go into are also very strong. A lot of torque can be applied to both of them. But the rear stock screw is different.

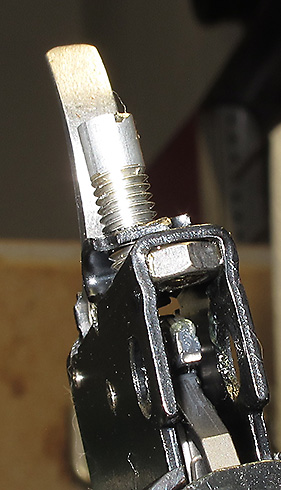

This screw passes through the rear hole in the trigger guard. It threads into a steel nut inside the Rekord trigger. And this screw is very prone to strip out if tightened too much.

The rear stock screw is stripped.

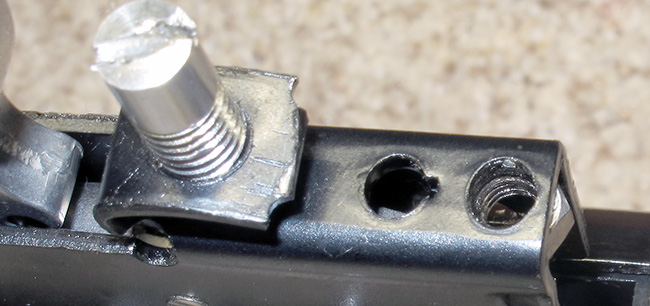

That nut inside the sheetmetal trigger housing is where the rear trigger guard screw goes.

The top (or bottom) view of the Rekord, showing the nut where the rear triggerguard screw attaches.

Before you start criticizing Weihrauch for this design, it’s actually an improvement. A couple decades ago they simply punched that rear hole in the sheet metal Rekord box and threaded the punched-out hole. When the trigger guard screw was over-tightened on that setup it stripped out the threads in the housing, ruining it. The nut is replaceable, though I cannot find any airgun parts dealer who stocks it. Yes it is probably a standard metric nut but BB has a life and no time to look into details like that. At least not all the time! I wanna just buy a PART!

Never fails

I wonder if Weihrauch considers this nut to be a non-failure point? I remember years ago working on a telecommunications system redesign for the surface Navy because their Control Data hard disk motors were failing and there were no replacements. Control Data told the Navy that those motors never failed so they never stocked replacements. And, perhaps in air-conditioned office spaces where most of these hard disks were found they never did fail. But on shipboard they did fail, and of course they did so at a time when the equipment was old, outdated and no longer available. So we had to redesign the system they were in to operate with new hard disks. This isn’t thumb-drive stuff, guys. It’s hundreds or thousands of lines of code plus lots of hardware alterations and changes to make it work. And on ships, you can’t just cut holes in the floors and walls to run cable!

The Weihrauch rear trigger guard screw is so much of a problem that a guy in the UK has come up with a solution. He calls it the Weihrauch Record Trigger Captive Nut and Rear trigger guard screw.

Weihrauch Record Trigger Captive Nut and Rear trigger guard screw. From eBay, this can fix the problem of Weihrauch not selling the captive nut.

But BB — isn’t this pretty much what Weihrauch puts in the trigger? Yes, except nobody will sell you the captive nut.

Bottom line

In the end the correct thing to do is always the same. Don’t over-tighten the rear trigger guard screw if your rifle has a Rekord trigger!

That should fix the stock screw problem. Now on to the scope.

Scope

From Part 12 we learned that the first shot from the scoped HW 50S hit the target 3-1/4-inches (82.55mm) below the aim point when I shot the target from 12 feet away. No amount of scope adjustment could correct that much drop. I did adjust the scope up and to the right a lot, just to get close to where I was shooting from 10 meters. Let’s see why that was.

The Burris XTR Signature rings have bushings inside them that allow some angular movement of the scope within the rings. I showed you those rings and inserts in Part 12. But how were they set up for the HW 50S? Take a look.

When I disassembled the rear scope ring these two bushings came out. The one on the left was inside the top ring cap and the one on the right was in the bottom scope ring. When I installed the scope this time I switched them, so the one on the left was in the bottom ring. That lifts the rear of the scope, giving it a downward angle that makes the rifle shoot higher.

As you see the rear scope ring was the problem. The front ring has two thin bushings that are identical.

Reader Derrick asked me if the Burris rings have scope stops built in. I didn’t answer him yesterday because I wanted to show you today. Both rings have provisions for scope stops, but only the ring you put at the rear needs one. I didn’t put a scope stop in the rear ring yesterday and that proved to be a mistake. The rifle shot so smooth I thought I could get away with just tightening the ring clamp screws. When the rings slipped on the rifle I did stop the rearward movement by tightening the clamps on the ring bases even more, but that’s not the right way to do it. Today I installed a scope stop pin.

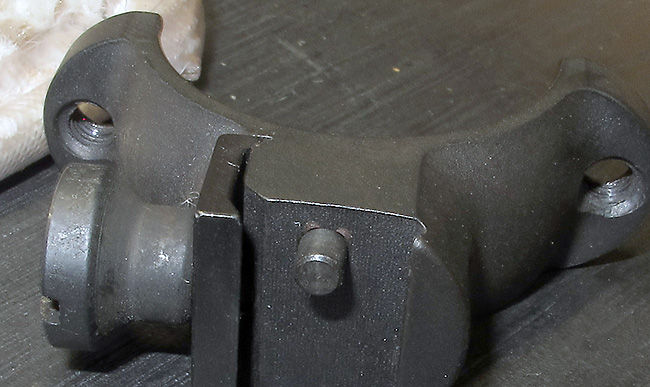

Yes, the Burris rings have provisions for a scope stop pin, but I did not install one yesterday.

Stop pin

The scope stop pin is not threaded. It’s a plain steel pin that just pushes into the hole in the bottom of one of the ring bases. I put the stop pin in the rear stop pin hole on the rifle’s spring tube so I could position the scope as far to the rear as possible, since this Bug Buster doesn’t have much eye relief.

The Burris scope stop pin is a plain steel pin that looks like this.

Test it

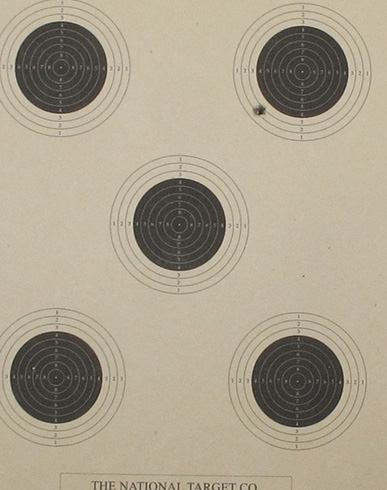

After correcting the rings and remounting the scope there was but one thing remaining — a test. It isn’t a complete accuracy test — just a test to confirm that the work has corrected the problem.

Standing 12 feet from the target and holding steady on a door jamb I aimed at the center of the center bullseye and fired a shot, using the same Air Arms Falcon pellet as yesterday. This time, instead of hitting 3-1/4-inches below the center bullseye aim point, the pellet hit 1-1/2inches above and one inch to the right. Yesterday I adjusted the scope up many turns of the elevation knob and also quite far to the right. Both moves loosen the erector tube return spring, making scope shift more possible. Now I need to adjust the scope down and to the left. Both will tighten the tension on the same spring.

After all the work is done one shot demonstrates that things are where they need to be.

Are we finished?

The test shot shows us the scope is now positioned correctly. All that elevation can be dialed out again, plus the right adjustment. When that’s done there will be some tension back on the erector tube return spring. But is everything as it should be?

That we don’t know yet. What is needed is another 10-meter accuracy test done as close to the same as the one in Part 12. I’m running short of RWS Meisterkugeln Rifle pellets so I may not be able to shoot a test target with those again, but I do have the other three, so that’s possible.

What that test will demonstrate is whether the “fixes” we applied today are relatively permanent or if there are still issues. You will also see the differences in the group sizes, if any, between yesterday’s test that was shot with loose stock screws and a loose erector tube return spring and now, when everything should be tight. That needs to be done before I back up to 25 yards.

Time

The work you have seen here took me right at two hours to accomplish. Normally I won’t take that much time just to mount a scope because the four to six hours of writing and photo work plus editing makes for a long day. But I got to write about what I did today, so the setup was the report.

Summary

Now the HW 50S is set up properly — I hope. I can’t wait to see the results!

B.B.

How about shooting 5 shot groups with the Meisterkugeln?

The rear trigger nut is a common metric size. Every Ace hardware should stock it. Why wait days+ for somebody to ship it to you? Would it make sense to epoxy that trigger nut in place. I find the hardest part is starting the threading on the loosely captured nut.(no pun intended).

-Y

Yogi,

I think I have 4 pellets left.

I probably have another can somewhere, if I only can find it.

BB

BB,

Do not bother with the wadcutters as their group will fall apart the further you go anyway. They were not that good to begin with.

BB,

I’ll be curious to see how that Vibra-Tite works for you. I’ve always been using Blue Loctite; but if you think this stuff works better, I’ll buy some…even if it is 3 times the price. 😉

Blessings to you,

dave

You only use a drop or two. Having i dry out once you open the bottle is a bigger issue.

The best part is that you do not need to apply it everytime, like you do with Loctite. If you still see it in the threads, you are good to go…

-Y

Cool; good to know; thanks. 🙂

Dave,

I’m curious, too. I have no idea because Vibra-Tite is not supposed to harden.

BB

Sounds great. I see screw threads with a dab of blue on them all the time. I have not investigated to see if it was “soft” still, but I will have to check this out next time.

Where I work, I can get all the free Lok-Tite I want. A lifetime supply for most of us is not much. If this works better, a tube of Vibra-Tite is not that much of an investment for most of us. This may need to be added to “the list”. 😉

Wow, that’s pretty interesting. 🙂

Too bad they did not combine the nut and housing for increased threading area.

A nice machine screw with an all-metal self-locking nut would work great there. No need to over tighten with one of those to keep it snug. They never come loose on their own.

Bob M,

We use those nuts at work. They are more expensive. For a “non-failure point”, that would be a waste of money. 😉

RR

That may be true, but according to BB the rear stock mount screw is a high failure point.

Bob M,

This is indeed true, but as BB pointed out, Weihrauch apparently considers this to be a “non-failure point”. The Weihrauch engineering and design team also consider the new Minelli stock to be quite usable with the open sights. I have not had this screw failure or experience with the new stock. Until proven otherwise, I will consider BB to be a more reliable source. 😉

I like the fully adjustable Sportsmatch rings. I have a set

/product/sportsmatch-30mm-rings-fully-adjustable-high-11mm-dovetail?a=4353

I do like the idea of the Burris rings. I am going to have to give them a try. I can see a possible advantage to them over the Sportsmatch as in ruggedness, but I think the Sportsmatch are more adjustable and most definitely easier to adjust.

I like the Sportsmatch rings, too, but they CAN’T be that expensive to manufacture. $150??? Really?? The Chinese make some knock-off you can buy on eBay, but I don’t know if they’re any good.

Motorman

Eastern MO

PS. My wife has family in Swords Creek. Anywhere near you?

Those SportsMatch Adjustable Rings are only recommended for PCP’s.

The company told me that the recoil of a springer would shift them out of alignment.

-Y

Yogi,

I have never used mine on sproingers. I can see where that could be a very real possibility. I do know that Hawke used to recommend that their one-inch diameter scopes not be used on sproingers, but have since changed their recommendation.

Motorman,

When you use slave labor, it becomes easy to manufacture something cheaply.

Many also forget that you do not want a 1st gen Draonfly, Stormrider, Avenger, etc. To be fair, you do not want a 1st gen anything, no matter where it is made. Most, but not all, learn from their mistakes.

I have no idea where Swords Creek is. I live “near” Roanoke, VA.

B.B. – were the stop pins included with the Bug Buster? FM understands the need for them, but since at least the scopes and rings at hand in Casa FM came without, do you source the pins separately? Fawlty types all over the world need enlightenment so as to pin down this knowledge gap.

Thank you for showing the underside of the scope rings with the stop pin. I’ve added that feature to a few sets of rings over the years. There’s not always much to work with sometimes necessitating a separate scope stop.

I’m still holding out for what you’ll use for a muzzle brake.

Derrick,

I’m not so sure I will mount a muzzle brake. Yes, it does “finish” the barrel and provide a good handhold, but we shall see.

BB

A muzzle brake is not needed for cocking ease on this Weihrauch. You could always put the front globe sight back on if it pleases the eye better.

Deck

I understand your comment about having a life and just wanting to order a screw and nut, but being able to ID and source common fasteners is a huge benefit whether you’re working on a Weihrauch or a Honda.

Derrick,

Yeah, I know. Lazy BB just has to pull that nut and go to the hardware store where “they” have a station to figure it all out for me — thread size and twist rate plus overall size.

Lazy BB — bad BB!

BB

BB

I never find trips to the hardware store to be work,, a distraction, yes. I tend to wander the aisles admiring the various widgets and gizmos until my wife drags me out. Not something for the busy sort.

Myself, on the other hand, am not. In fact, I spent all of last week doing nothing,, and I find I’m not finished, yet. I do love being retired.

Ed

*** I spent all of last week doing nothing, and I find I’m not finished, yet. ***

Ed,

That made me smile!

I do love being retired as well but have found that with the projects collecting at an alarming rate I am busier than ever!

Hank

Retirement just means you don’t get paid.

The family figures that I have all that time on my hands to help out.

I was less tired going to work 5 of 7.

It is just the way it is.

B.B.,

Persecution Delusion?

The HEAT can easily bring on this delusion!

https://en.m.wikipedia.org/wiki/Persecutory_delusion

The other thing i have found to bring on this malady in Air Gunners is shooting break barrel (metal) spring piston airguns ;^)

shootski

PS: Most Dark Siders never suffer from this condition.

BB

I too look forward to seeing the results of your work today. Later when you are ready for 25 yards I predict you will get 10 shot groups with a preferred pellet measuring between 1/4” and 3/4”. You may need to try more pellet types to find the best. I would try JSB Express and AA Express 7.87 grains. Also the 10.3 grain by JSB and AA.

Deck

I’m surprised that those readers who are machinists by trade or by hobby hadn’t yet commented on the repair of a stripped nut or hole. My solution is either drill out the nut and re-tap it (many stores sell a kit containing proper drill size and tap) to the next size up or, I think both JB Weld and Locktite sell epoxy kits that you can use to fill the stripped hole/nut and re-insert the OEM screw/bolt but with a releasing agent on it. I’ve used both with success to fix my ham-fisted mistakes.

Fred formerly of the Demokratik Peeples Republik of NJ now happily in GA

Fred DPRoNJ,

I’m surprised no one has suggested a HELI-COIL®

https://en.m.wikipedia.org/wiki/Threaded_insert

That company was my first Stock Market investment sixty years ago when our Home Room teacher gave us impromptu instruction on how the Bulls and Bears on Wall Street run.

shootski

Boy Howdy! I forgot about helicoil. Have used them on spark plug holes and bolt holes on various motorcycle over the years. But for a 4 or 3mm bolt might be a bit overkill. But that’s another good idea for stripped bolt repairs.

Fred etc, etc

I expect you could find a drill bit in your shop the right size for the scope shop. Just cut off a short portion of the shank. It also looks like it would be easy to drill about any scope mount for a stop pin if the mount didn’t come with one.

David Enoch

B.B.

If Bugbuster scopes are popular, why doesn’t some company make a one piece scope mount just for it?

They could bundle it with the scope and charge extra!

Also, an alternate way to mount a BugBuster would be to use a dovetail to picatinni adaptor and then use regular picatinni/Weaver single rings.

-Y

Yogi,

I wouldn’t buy a one-piece mount for anything, unless it was the only way.

BB

BB

Wow, that was an unexpected bold statement. Does it include single point mount adapter scope rails? like on an AK or M14 with side mounts ?

I have seen a lot of single point mounts used on AR-15’s. What gives here? A blog topic perhaps?

And what about all those one-piece dovetail mounts with many screws on the rail to keep it from moving?

Why?

Maybe that could be the subject for a blog?

-Y