by Tom Gaylord, a.k.a. B.B. Pelletier

Part 1

Part 2

Part 3

Part 4

Part 5

Part 6

Part 7

My rifle is actually a BSA Super Meteor.

Today, you’ll see how I fixed the bad muzzle crown on the BSA Super Meteor, and then we’ll see if that had any effect on the rifle’s accuracy. You might want to read Part 7, again, just to remind yourself of what I faced.

The BSA project has been just that — a project from the start. All I wanted to do was test another vintage spring-piston air rifle for you and report the results, but this particular air rifle has challenged me at every turn. From the time I bought it at the Roanoke airgun show last September, it’s been nothing but a prolonged learning scenario. I won’t bore you by recapping all that’s happened; but if you want to find out, read Parts 1 through 7.

At the end of Part 7, I showed you a nasty muzzle crown, which I surmised was the reason that all the pellets were leaving the barrel with a yaw to their axis. They weren’t tumbling, because every one of them struck the target paper in exactly the same orientation. They were yawing, or traveling forward while pointing off to one side. Because the barrel is rifled, they were spinning on their long axis, but that axis didn’t happen to coincide with their flight path.

The BSA Meteor crown has some serious nicks in it. The dark spot at 10 o’clock is the deepest. Compressed air could escape through this channel before any other part of the pellet leaves the bore, and the jet of air could push the pellet over on its side.

The solution was to crown the bore; but as you can see in the picture, the Meteor’s muzzle is counterbored by more than an inch. In other words, it isn’t where it appears to be from the side. It’s deep inside the barrel, where the theory says it shouldn’t get damaged as easily. Only this one was — perhaps from over-zealous cleaning through the muzzle. Who knows? The point is that it had to be fixed.

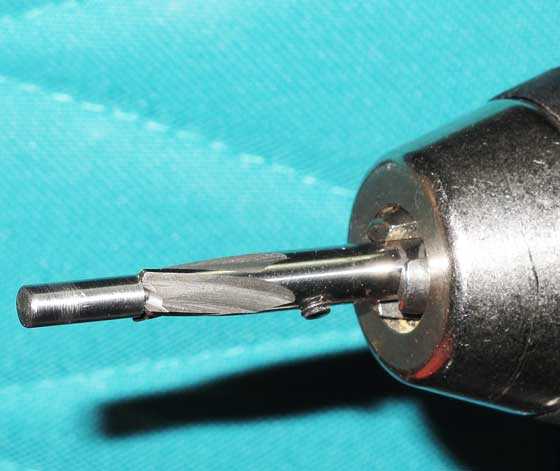

My shooting buddy Otho suggested a piloted counterbore to face off the crown true and square to the axis of the bore. And he volunteered to make the pilot, so I slugged the bore for him and found it was a diameter of 0.176 inches. That seemed odd to him because it’s larger than the bore of a .17-caliber rimfire bullet that’s about 0.172-inches. But that’s the difference between .17 caliber and .177 caliber — which is important for airgunners and firearms shooters to know. The pilot he made measures 0.1745 inches and fits the Meteor’s muzzle comfortably.

Otho made the pilot for this counterbore.

The counterbore chucked up perfectly in my portable electric drill. I allowed extra length for the bore to go down into the barrel and touch the muzzle without the drill chuck touching the barrel.

The counterbore is chucked in the drill and set to run true. It sticks out far enough to cut the crown without the drill chuck touching the barrel.

Plugging the barrel

Before starting the work, I pushed 3 fat pellets into the breech and then pushed them with a cleaning rod to within 2 inches of the true muzzle. These will keep the metal chips from dropping down the bore.

I oiled the counterbore and pilot with a good grade of light machine oil before inserting it into the muzzle of the gun. The drill was set on a slow speed, but I can also control the speed by how hard I squeeze the trigger. I wanted a slow steady turn without putting much pressure on the drill. The counterbore is sharp enough to cut the soft barrel metal without a lot of encouragement.

The drill is set to run slow, and I’m also slowing it more with the trigger. You don’t need speed for a cut like this.

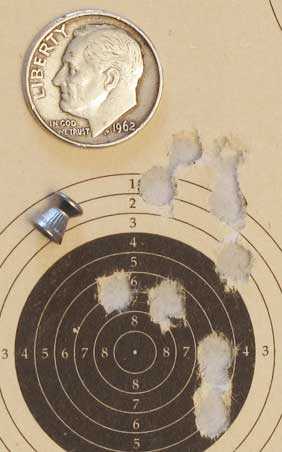

After about 10 seconds of cutting, I removed the counterbore and cleaned the new crown with a cotton swab. There was a band of bright metal around the muzzle where the counterbore had cut. Upon close examination, I could still see gouges in the bright band. The gouges were deeper than the first cut.

The new crown is bright after the first cut, but there are still gouges that need to come out.

I cleaned the counterbore with a swab and oiled it again. Then, I made a second cut on the crown. This time, I felt the drill pulse as the cutter removed the uneven metal. It became smooth, and I knew the cut was finished. When I cleaned and inspected the new crown this time, it appeared smooth and even. The job was done.

I apologize for the blurriness of this picture. Focusing on the crown is very difficult when I’m also trying to light it from the same axis as the lens is pointing. The lens is about one inch from the end of the barrel, and this was the best picture I got. There are still some faint marks on the crown. After examination with a loupe, I didn’t think they would be a problem.

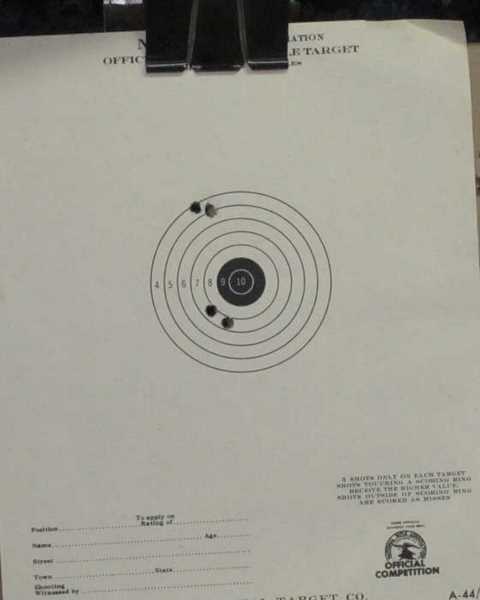

At this point, I felt the crown was as clean as I could get it. And there was a simple way to see if this had made a difference. I drove the pellets in the bore out the muzzle and a few steel chips came with them. Next, I shot two RWS Hobby pellets offhand from 12 feet. If the crown was good, they would cut the paper perfectly instead of hitting sideways. And that’s what happened.

So, I backed up to 8 yards and shot 2 more shots from an improvised rest. These 2 pellets landed very close to each other and also showed no signs of tipping. I felt the job was done.

The two lower shots were from 12 feet. They confirmed the pellets were hitting the paper straight-on. The two upper shots were from an improvised rest at about 8 yards. They told me the crown is probably working.

Now for the test!

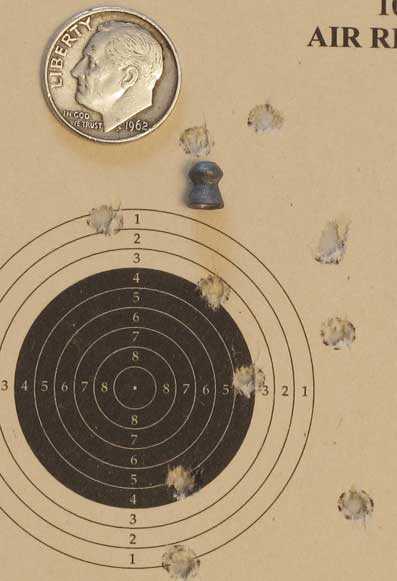

The test is a rerun of the Part 7 accuracy test. I used every pellet from the last accuracy test and shot at the same 10 meters.

Pellets:

Eley Wasp

Crosman Premier lite

Air Arms Falcon

RWS Hobby

Ten Eley Wasps went into 2.256 inches at 10 meters.

Ten Premier lites went into 1.522 inches.

Ten Air Arms Falcons went into 1.941 inches.

Ten RWS Hobbys went into 1.361 inches.

Conclusions

If you compare these targets to those in Part 7, one thing jumps out at you. None of these pellets tipped when they went through the paper. So, crowning seems to have solved that problem!

But the accuracy seems no better. The Hobbys did group better in this test, but the Falcons grouped worse. With groups this large at 10 meters, I’m not willing to say anything has improved. I’ve had cheap Chinese air rifles group better than this.

I have one trick left up my sleeve. I’ve noticed that the Meteor rear sight seems hinky and difficult to adjust, and I suspect it jumps around as I shoot. It’s not loose to the touch, but I don’t trust it to hold zero.

I’ll do one more test of this rifle with either a dot sight or with the See All Open Sight if I can get it mounted to the Meteor. If that doesn’t work, I’ll probably abandon this air rifle as a bad investment.

LOL! Bad investment? You have increased your knowledge and ours, you have produced eight days of reports with more to come and I will bet big money you have had fun doing all this. I do not see it as a bad investment.

I end up fixing up a lot of old 70’s British air rifles, and found that RWS Superdomes seem to be the most accurate as well as Hobby’s. My groups appeared to improve when the pellet was deep seated, this is just a general rule of thumb for these rifles as i’m sure you have found for yourself.

I have never had any issue with the open sights myself, because by the time i get hold of them some previous owner has lost them so i end up using a 4×32 scope instead.

TTFN

Best wishes, Wing Commander Sir Nigel Tetlington-Smythe

Sir Nigel,

Okay, I will add Superdomes to the list. And deep-seating, too!

Gonna have to use some kind of optical sight next time, so we shall see.

Thanks,

B.B.

Nice little reamer Otho spun down for you. And you even used a loupe to inspect your work. Nice. And I wonder if somebody will ask what a loupe is.

And I just have to think that you wont stop until you get the gun were you want it. But I guess I could be wrong. Maybe you will be done with the gun.

Yes respect is due. One thing, I know the barrel lockup seemed solid, but is it really? Might that be contributing to this? Also, if the battered crown was indeed the result of overzealous cleaning might the rifling not have some minor nicks too?

Oliver,

Oh, the barrel on this rifle is 40 miles of rough road! It is not pretty, despite my cleaning it with JB Bore Paste.

As for the breech, it seems tight by every test I know how to do.

Nevertheless, I will make another attempt to get it going.

B.B.

You certainly have struggled with this rifle. However, that gives you the opportunity to share more repair methods. Before you give up on it, consider brushing the bore. Look at all the dirt rings and spots on the target holes – it’s probably got years of yuck in the bore.

Three thoughts;

1) I agree with RidgeRunner: he investment looks to have paid off VERY well in experience you gave US!

2) Regarding Feinwerk’s comment: a) do we assume you’ve already looked/cleaned the barrel before, & b) could pellets be treated for “fire-lap treatment” to moderately clean it out, if needed?

3) HOW in the heck DID you manage to pour so much light into the recessed crown, with the camera lens so close? My skills at looking into muzzles & photoing same aren’t anywhere NEAR yours!

—respectfully, Barrika

Barrika,

You, sir, are a photographer! I use a Pellican 1920 pencil-sized flashlight that I can get close to the lens of my Canon G11 point-and-shoot. What you see here is about the limit of what I can do with this setup.

B.B.

Why did you need a pilot on your counterboring tool ? Was the rifling at the new muzzle damaged or enlarged by the pilot? I have a Mosin-Nagant m 91, dated 1898, that has been counterbored. Despite the worst trigger I have ever seen on a M-N a nd 77 year old eyes, it will group inside 3″ (100 yds, off a sandbag). I don’t think that the Russians and the Finns used piloted counterbores (I could be wrong). Many counterbored M-N rifles group as well as the unbored ones. Blogs re counterboring use drills without pilots to do the job. Ed

Ed,

I used the close-fitting pilot because I was cutting the new crown deep inside a hole and I didn’t want to cutter to grab or wander off straight and true.

B.B.

He needed the pilot because he was doing this with a hand held drill. You right about not needing the the pilot to crown the barrel–when it’s chucked in a lathe with a steady rest it’ll stay centered.

I’m going to second the quality of the pictures in todays article. Simply amazing.

I’m really struggling to find something nice to say about that late model Meteor. Let me give it some more thought.

kevin

Yes, that sure is a nice-looking new crown. But the pictures left no doubt about those large group sizes either. Not much of a return for all the hard work.

Matt61

Note to self. Don’t buy any 70’s vintage Meteors!

Mike

BB, If this rifle does not group with a red dot sight ( or see all sight), Why not cut off the end of the barrel , down to just past the pilot depth, and recrown the barrel ? I would do this as a last ditch effort to see if I could get this rifle to shoot good groups. This would remove any influence that the reboreing and the pilot may have had on the pellets. Ed

Ed,

That was my thought, too. But Otho though it would be best to keep the barrel as original as possible. Well, if it doesn’t shoot with a dot sight, maybe I will whack it off!

B.B.

Run! BB has an electric drill and he’s using it! 😉

Nice job on the counter-bore! After fixing the sight, maybe look into changing the harmonics a little to see if that tightens up your groups any. Try a barrel weight or something. That has helped me in the past.

/Dave

/Dave,

It won’t hurt to try.

Thanks,

B.B.

BB,

That piloted counterbore is exactly what I was thinking would work.

This is my suggestion, and it may be off-base. I would, however, go one step further and attempt to de-burr the crown, if necessary, even though the recess is not going to make it easy. It does shoot like some Chinese rifles which have crowns with burrs on them but otherwise look good; even many clunks will shoot that well or better at 20-25 (not 10 yards), though, so there is still something really wrong. The “standard internet test” to check is to put a q-tip in the muzzle and pull it out, to see if any fibers are caught (obviously, you have to repeat the test several times for good coverage. Even tiny little burs you can’t see from the [counter-]boring process hanging on the lands, or (my opinion esp.) in the grooves can ruin accuracy. If there is a hint of a burr, you need to do something about it. Otho probably knows a good way or has fancier tools, but you can always use the procedure Fred (I think) outlined in a guest blog. While you are at it, you can do the breech also in a similar way, in case pellets are being marred upon loading. Also, I would probably (later) try going to a more aggressive polishing compound in the bore and just count on using larger pellets (aka Superdomes)…

Don’t give up now — it would be a shame to have come this far and not get full functionality out of it! On the other hand, this series is why many of us are shy about used rifles :)! Do you like the way it is shooting otherwise (excluding accuracy, which I realize is a preposterous exclusion, but can usually be addressed)?

PS. Your crown job obvious helped and you didn’t damage anything (unless you drilled into one of Edith’s couches)! Otho is a good influence on you.

BG_Farmer,

Otho suggested the same thing (deburring the new crown).

I’m not giving up. I guess there are a lot of things yet to try.

B.B.

One doesn’t hear much about rebarreling airguns as you do with firearms. Is it not worth it?

CowBoyStar Dad, that was a police unit wasn’t it that did the shooting after the exercise? That kind of surprises me. It sounds more like a military scenario when you are in the field. I’ve heard that police sniping is much more focused on precision. Where military snipers must hold 1MOA, police snipers hold .5 MOA. Their scenario is much closer shots in hostage situations where they have to put a criminal away so that they cannot even activate their trigger reflex. I guess it doesn’t hurt to be able to hit shots under stress, but that sounds different from their primary mission.

gunfun1, for the biathlon, I guess you train by skiing like mad and spending a lot of time on the shooting range. But you’re right that the only way to really train for this event is to do both together. I can see how both of these abilities individually would be very desirable, but doing them together in the biathlon must feel terrible. They are so opposite. And I don’t think it’s good for your body either to come to a dead stop to shoot and start up again. I’m not even sure how you would manage your sight picture. Your wobble area would be way off the target. Do you press ahead? Or do you find a hold on target between heartbeats and then time the release then when your sights jump back on target?

And is that the unsupported prone they are shooting in? That would make things tougher.

Matt61

Matt61,

I love the Biathlon event. For some reason, I think back to the Soviet invasion of Finland and how Finland held off the entire Soviet Army. I can see Biathlon developing from that! Anyway, off- topic – last Fathers’ Day, my wife, trying to be nice, bought me a serious RC helicopter. She had seen me playing with one of the cheapie 3 channel copters and thought this would be a nice present. As I said in the past, the remote control, a DEVO 7, looks like something off of the Lunar Lander. It took me 10 seconds to crash the thing. It’s rebuilt now with 4 new rotors, a new tail boom and a new main drive gear. Cost new was $150. Anyone who is a RC addict here, I’ll sell it for $75 including shipping. The model is a Walkera LM 180 and if you contact me off-list at cyclealleyriders@gmail.com, I’ll send photos of it sitting on the ground! If I try to fly this again, I’m sure it will crash so no photos there. If you go to youtube and search, you can see a video of it in flight. Oh, it also has a video camera attached to it. A warning to anyone with no RC experience – these things are not for the weak of heart or someone that doesn’t like to tinker (read rebuild after the crash).

Fred DPRoNJ

Next time instead of posting your email adress like that, write down like this:

cyclealleyriders “at” gmail “dot” com or somethingt like that, it will keep it from being picked up by bots that surf the net in search of email adresses. You may see an increase in the amount of spam you get even if google as a pretty good spam filter.

J-F

Never thought of that. Great advice. Thanks!

Matt

I would bet they put in a lot of hours a week training. And It has got to be hard to control your shot in the conditions they shoot under. I would have a hard time controling just the breathing part. Then maintain stamina. I bet they are exhausted after a run of the course..

Matt

I would bet they are exhausted after they run through the course.

My phone is killing me.

B.B.,

Sent you an idea for the air pump($100 PCP) via e-mail. Have a look see and let me know what you think.

Pete

Pete,

I saw it this morning. Will respond later.

B.B.

This means I’ll have to dust of some of my meteors and prove the can shoot.

Dag,

Please do that. I am not trying to crucify the model here. I would prefer it much better if this rifle was accurate.

B.B.

B.B.

It’s unfortunate this rifle is not more accurate than it is. My first thought at the mention of chopping the barrel was that you’ll never get your money back through a resale if you do that. But then I realized that when you tell a potential buyer about this gun’s accuracy you’ll never get a good price for it anyway. So, I guess you can do whatever you want to it and take your chances on resale value. Unless you can improve this rifle it’s probably a parts gun now anyway.

However, as long as you enjoy it keep working on it. If anyone can solve this problem I’m sure you and Otho can. This has been an interesting journey.

G&G

G&G,

I have rebarreled spring air rifles before. I hope it doesn’t come to that, but if so I can do it.

B.B.

B.B.

I forgot to ask. Do you plan on testing the new Marauder? I’m curious if accuracy has been affected by the changes. Also, none of the advertising mentions it, but it is my understanding that the new stock is more streamlined and nearly a pound has been removed from the rifle’s weight. Do you know if that is true?

G&G

G&G,

There’s already a 4-part blog on the new Marauder. Here’s part 4, with parts 1-3 listed at the top of the blog:

/blog/2014/01/benjamin-marauder-22-repeater-with-synthetic-stock-part-4/

Edith

G&G,

I will be doing Part 5 soon.

B.B.

Edith and B.B.

I did not realize the synthetic stock Marauder incorporated all of the changes that the new wood stock Marauder has i.e. de-pinger, increased shot count, revamped breech block. Nor did I realize the synthetic stock was identical to the new wood stock (except for material of course). Nothing I have read really indicated that. Since the new wood stock Marauder was introduced at the SHOT Show I simply assumed it was new altogether. MY bad.

Thanks for the correction.

G&G

G&G,

Yes, I made it a point to use bold red print to indicate the changes from the old Marauder to the new on the product pages. I don’t know why you overlooked it, but some people at Pyramyd AIR also overlooked it and thought nothing had been written about the updated guns 🙂

Here are the changes from the old fixed-comb Marauder:

Upgrades from the original version of the gun: Factory-installed depinger changes the sharp “ping” to a dull thud. Improved valve (increases the number of shots: .177/.22=32 shots, .25=16 shots). Trigger moved back for better hand position. Reversible bolt for left- or right-handed shooters. Simplified the breech design for assembly, service and to provide a more stable platform for larger scopes.

Edith

Edith,

I can explain why it was overlooked. Or course the changes to the new wood stock Marauder are obvious. However, it has been a long time since I looked at the Product Page for the synthetic stock. I simply did not remember seeing these changes on the synthetic stock product page. Were they there originally or added more recently?

Thanks.

G&G

G&G,

They were there originally…the day the gun went live. I recently added some text to both Marauders to enhance comprehension, but all the basic upgrades were listed in bold red text since day one.

Edith

Edith

To be honest, I’m not sure I ever read the product page for the synthetic stock Marauder. I was never interested in buying it. But one way or the other I did not remember the description. As I said earlier, MY bad for assuming anything. Thanks for your patience.

G&G

Guys,

quick question – Twotalon and BB should know this. I bought a Talontune angle adapter mainly so I could have a pressure gage on my non-spinloc tank and also to allow me to have a lower scope mount. The question I have is there an easy and quick way to de-pressurize my tank or do I have to just keep dry firing it to empty it?

Fred DPRoNJ

Fred…

Drop two dimes in your fill adapter, then start screwing the tank into it until air starts leaking out.

Keep the air leak slow. The times that I have dumped tanks, the leak kept getting faster as it went, so had to back off on the adapter a few times to keep it slow.

twotalon

TT,

I knew you would have the answer. Thanks. I’ll be home tomorrow due to snow (working from home) and will put your advice to work.

Fred DPRoNJ

Fred

I forgot to mention that you might want to keep a pair of channel locks handy. The fill adapter gets very hard to back off when the air leak gets to going fast.

twotalon

Fred

I have been thinking about getting one for my Talon SS. I sure miss having a gage.

I thought about converting it to the new spin lock tank. But that adapter your talking about will kill two birds with one stone if you know what I mean. I will have a gage and I can adjust the bottle/butt stock to get a more comfortable feel if I’m remembering correctly about how it works.

I would like to know how it works out for you after you get it mounted and set ok.

You got it! There is a video on the Talon Tunes website (and I’m sure there are ones on Youtube) that demonstrate how to install the part and how to re-align it so it fits properly or is in time.

Fred DPRoNJ

Fred

I’m going to check out the videos. I looked at them awhile back. I forget how they work. And still I will be interested in your results. So make sure you post something if you will.

What a shame, these rifles are ten a penny over here in the UK, and are much beloved of clubs and cadet groups as junior trainers, mainly because of their accuracy and dependability!!!!! !

I have a Mk6 in my collection that was given to me and owned a few in my youth, they shoot rather better in. 22 in my experience

My mk6 shoots at 9.2 ft/lbs in. 22 (normally around 8 in. 177 and 9 in. 22) so very healthy despite never having been opened up…..it gets an average of 8fps variation though this shrinks a bit if I weigh off and grade the pellets. Its a shame that such a mainstay of British airgunning is proving a bit of a dog for you. On the other hand your article has made me blow the dust off the old thing and put a few pellets through, I might even treat it to some maintenance

incidentally, with a scope, at 20m you should get groups of about 3/4 of an inch, maybe a bit less from a decent rest, and I’m no Annie Oakley, don’t be shy of losing the thick spacer rings in the piston head, the rifle shoots just as smoothly and a bit of extra help getting the pellet clear of the spring guns barrel flip early always helps!

BB

Look at your 7th picture down. Now that you re-crowned the barrel it seems to me that something stands out more. There is still something wrong at the 10:00 position and also at the 8:00 position with the new re-crown. If you look close.

And sorry that could be miss interpreted the way I stated that. You did a wonderful job on the re-crown and obviously the pellets are flying straighter. But may be there is something wrong with the barrel. Maybe those 2 positions are gouges in the barrel made by somebody or something. If so that could be why there is still problems with the way the gun is shooting.

Did you do your shine the bright light trick down the barrel and see what things actually looked like after you re-crowned and cleaned the barrel? I’m sure you probably did. But just another thought.

GF1,

Like I said, the photos are not perfect. But the crown is good.

Yes, I used a bright light and the loupe to check the new crown.

B.B.

BB

I mean farther down in the barrel. Not at the point when the pellet leaves the barrel but down in the barrel more.

Maybe a pellet got stuck at some point in time in the barrel. Then whatever somebody used to try to get the pellet un-stuck gouged the side of the barrel rifling and tore up a land or something. That will make the pellet do some funny stuff.

And I wouldn’t know anything about this kind of stuff happening. Well actually I do. I messed up a Gamo Whisper by getting a stuck pellet out. DON’T use a coat hanger to get a stuck pellet out. I now have a wood dowel rod for the different calibers incase that happens. The wood wont tear the barrel up. And then worst scenario is you have to go in through the receiver end and clean the barrel by pushing the stuff out the muzzle end after you get the pellet out.

Oh and that Gamo Whisper would never group the same anymore. I still got the gun. I have it setting by my work bench. It just sets there quietly and reminds me to think before I attempt to do something. So maybe there is a reason for everything that happens.

And is it hard to change a barrel on that gun or other break barrel guns? I don’t usually mess with break barrel guns. So I was curious about how hard that is to do.

GF1,

You are seeing a piece of lint in the barrel.

B.B.

BB

Yep I see the lint. And your pictures are very clear. But I mean 3 or 4 inches deeper into the barrel. Not right there by the crown. What I usually do is go over to a window on a bright sunny day and hold the barrel up to the light. I can see the whole distance of the barrel that way.

Like the barrel on the Gamo whisper. I messed up about 2″ of one of the lands about 4″ from the muzzle end when the coat hanger slid of to the side of the pellet. If I hold it up to the sunny window I can see the missing land plane as day. That’s what I thought could be wrong with your barrel.

GF1,

I don’t know what you are seeing, but there are 3 pellets in tandem, just 2 inches from that crown. I used them to block the barrel.

B.B.

Now you got it. I cant see it. Is there something wrong deeper in the barrel. Like half way down the barrel.

wow, this rascal has plagued you a lot aye b.b.? might be the rear sight like you said, it would be my next place of inspection too

B.B. and other guys,,

There is more GOOD info on this site than the law allows. THANK YOU!! THANK YOU! THANK YOU!!!

Thanks to ALL you folks for you input. It really helps us newbes in the air gun/pellet arena. NOT to be

confusigated w/ the air-soft B.S. all over the internet!!!

keep up the good work, the RAMBLER

Rambler,

Welcome to the blog.

B.B.