Crosman MAR 177: Part 3

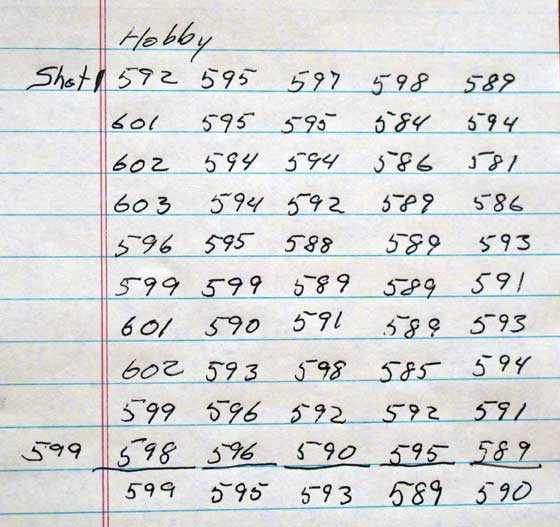

by Tom GaylordWriting as B.B. Pelletier The MAR177 from Crosman. Part 1Part 2 History of airguns This report covers: Baseline with Hobbys Today’s test What is the average? Second page of numbers What does “estimate 601” on page 2 mean? But — what is the average velocity? Photos Pressure gauge and fill pressure Big lesson … Read more