BSA Meteor Mark I: Part 3

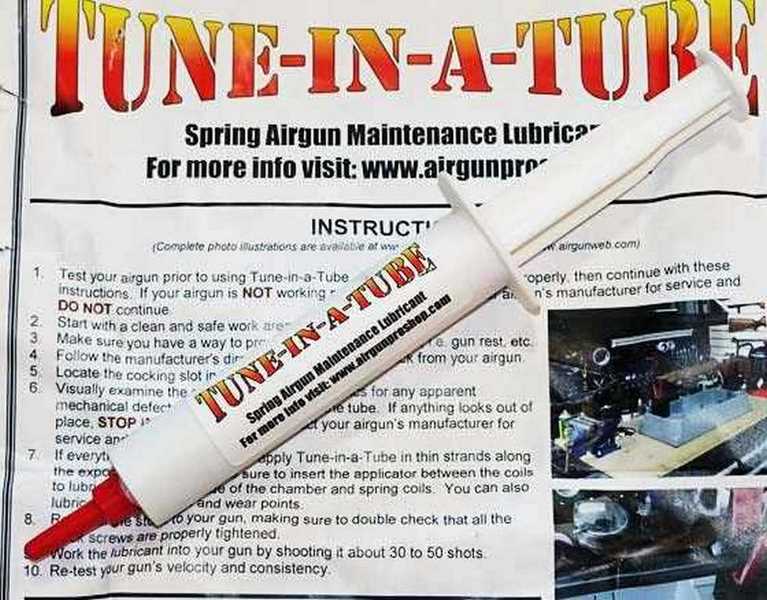

by Tom Gaylord Writing as B.B. Pelletier BSA Meteor Mark I. Part 1 Part 2 A history of airguns This report covers: Tune in a Tube Baseline the Meteor A second tune? Disassembly The compressor What did I find? The rest of the powerplant Offset transfer port The pivot point What’s next? Ho ho, hi … Read more