HW 35 Luxus: Part 5

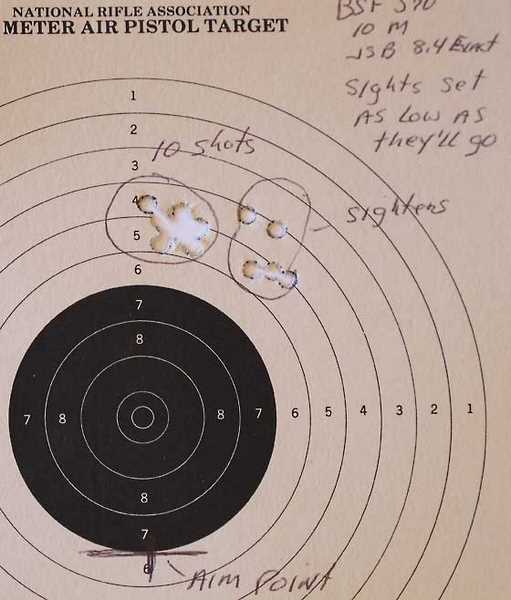

by Tom Gaylord Writing as B.B. Pelletier Part 1 Part 2 Part 3 Part 4 HW35 Luxus. This report covers: Barrel droop First pellet Next pellets Bottom line Before I begin, I must tell you that my wife, Edith, passed away yesterday, Sunday, July 26 at 10 a.m., Central. She was under sedation and unaware … Read more